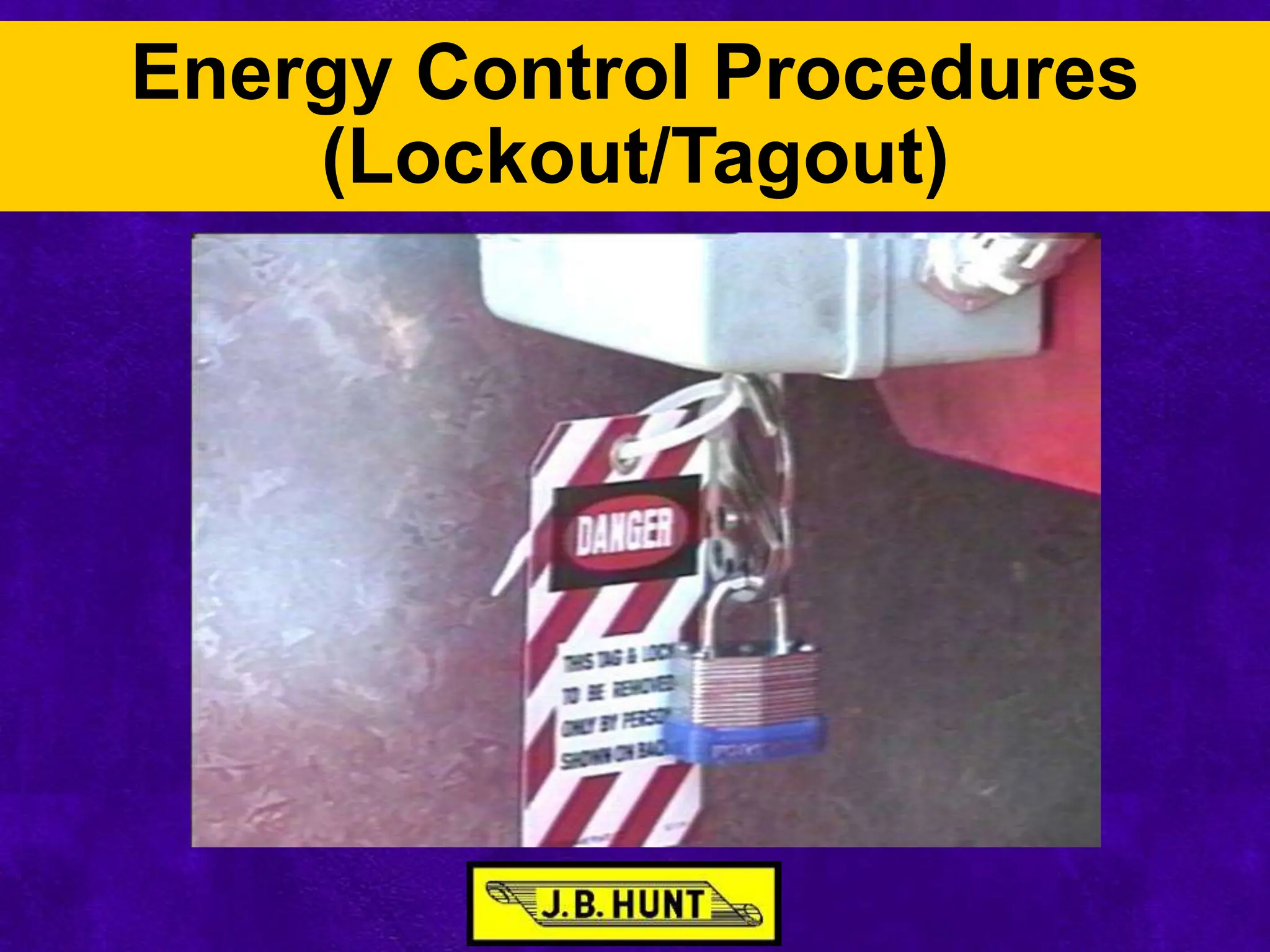

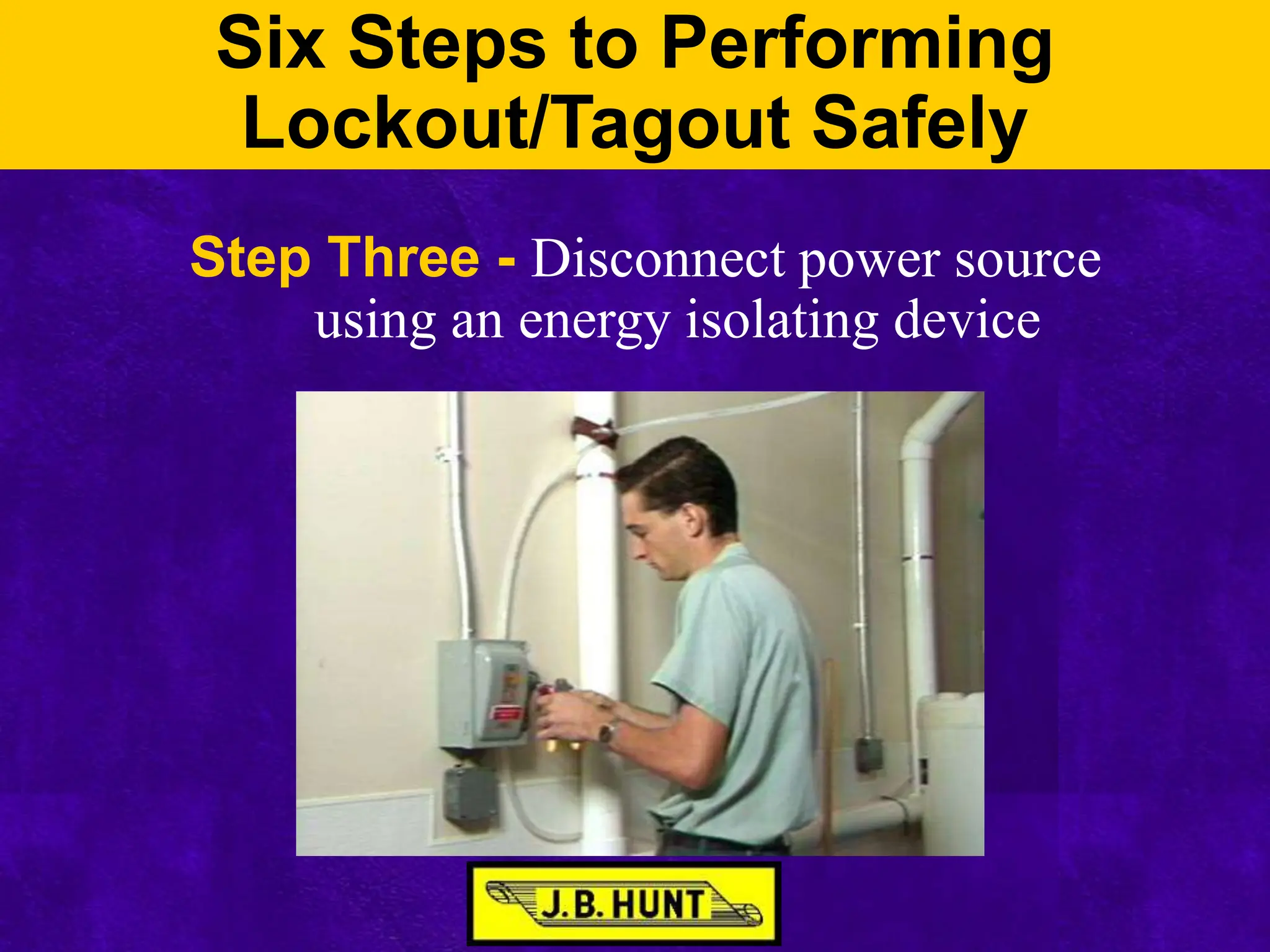

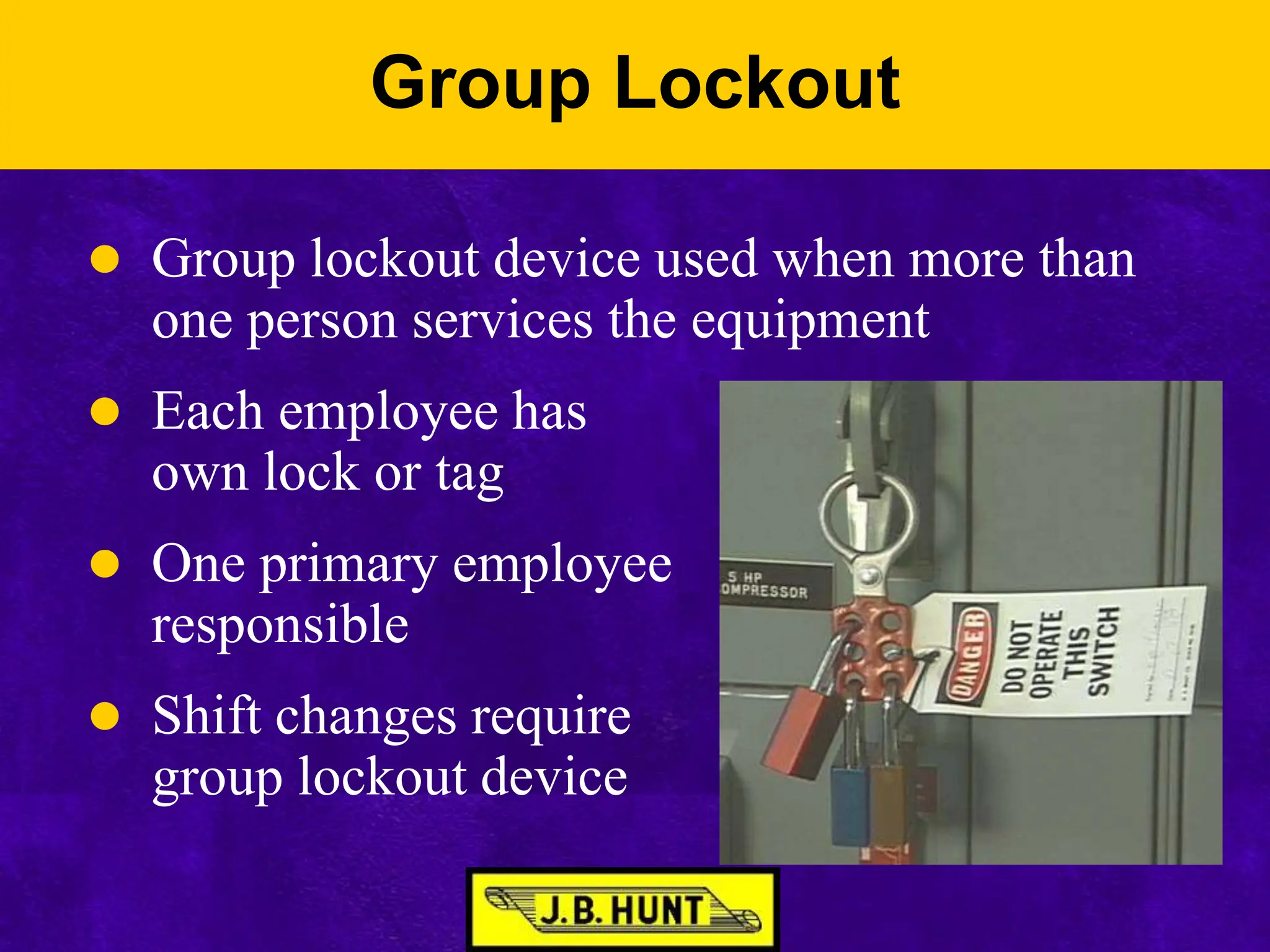

The document outlines the lockout/tagout (LOTO) procedure, which ensures safe equipment shutdown and maintenance by preventing unexpected machine startups. It details the roles of authorized and affected employees, the six steps for safely performing LOTO, and emphasizes the importance of compliance to avoid serious injuries or fatalities. Additionally, it highlights the limitations of tags as warning devices and the protocols for group lockout and tag removal.