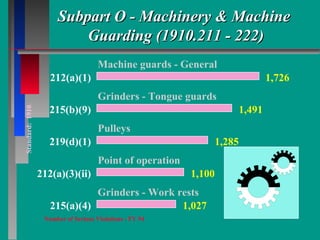

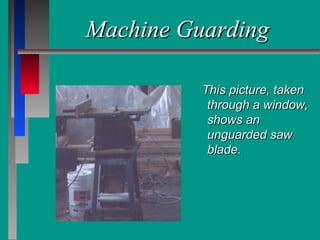

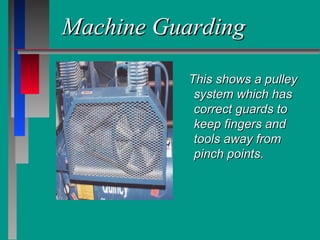

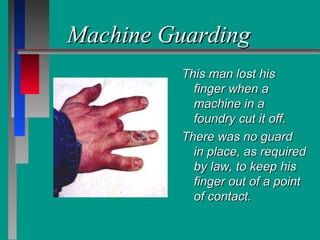

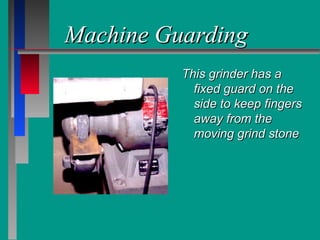

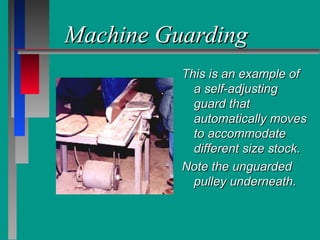

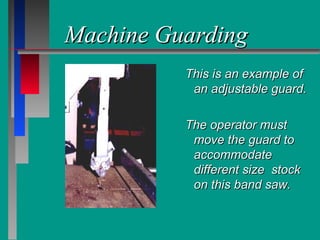

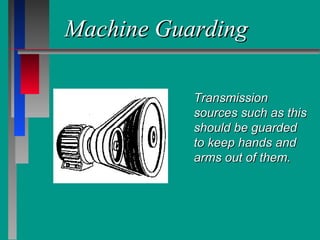

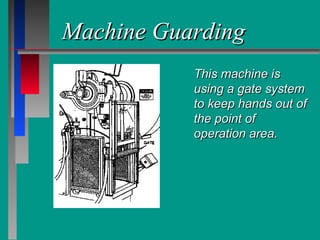

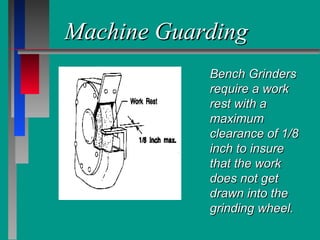

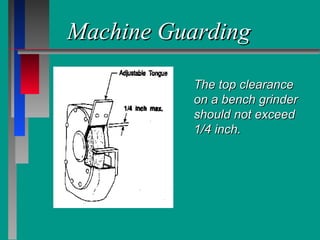

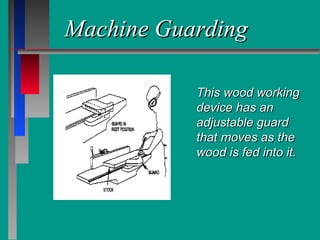

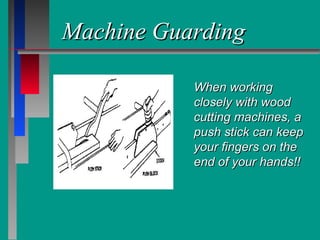

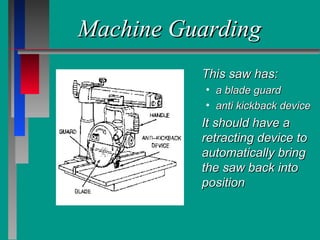

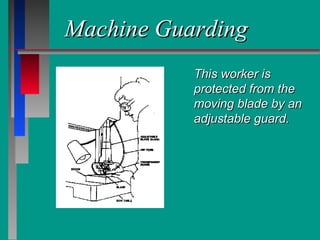

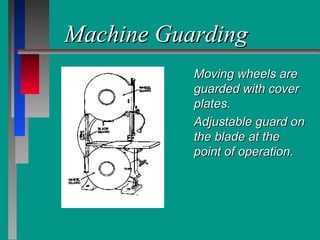

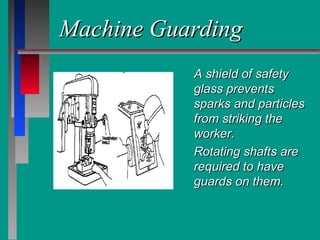

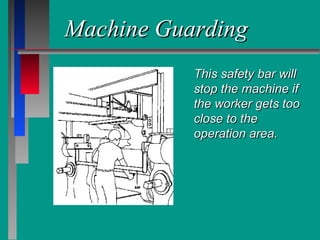

This document discusses machine guarding requirements and guidelines. It provides information on various types of machine guards, including fixed guards, interlocked guards, adjustable guards, and self-adjusting guards. It emphasizes that all hazards on machinery, including moving parts like belts, pulleys, gears and shafts, should be properly guarded. Employers must provide training to operators on machine hazards and safeguards. Standards require guards on abrasive wheels, and that work rests and tongue guards be used properly.