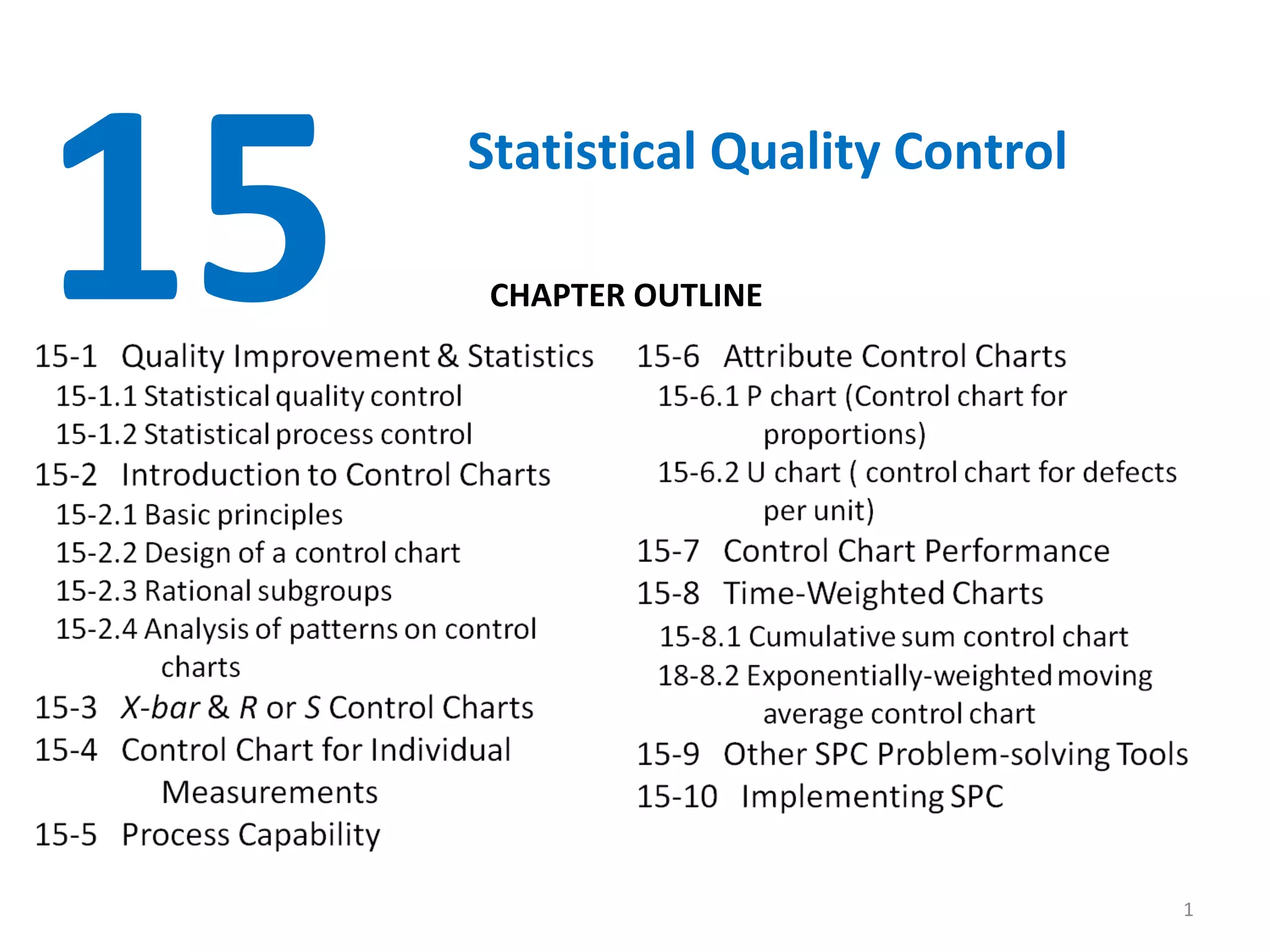

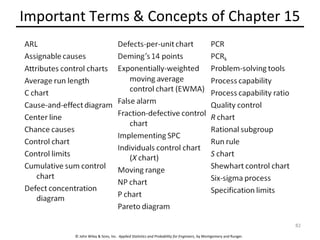

This chapter discusses statistical quality control and control charts. It covers the following key points:

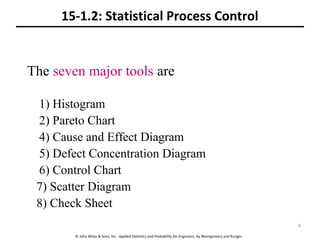

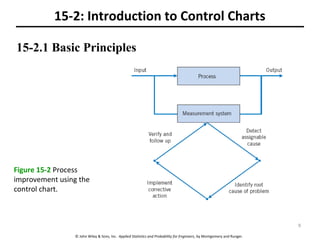

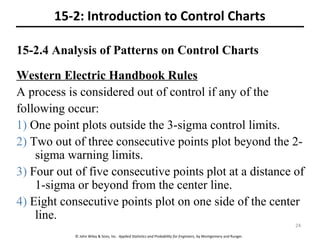

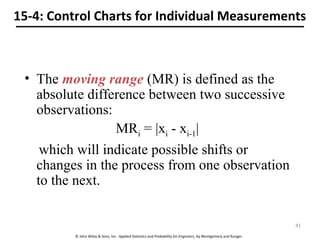

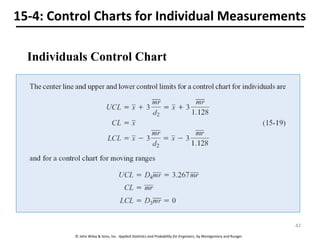

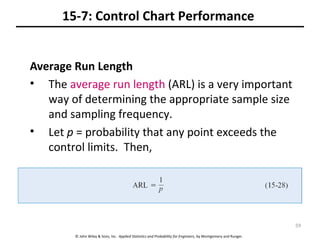

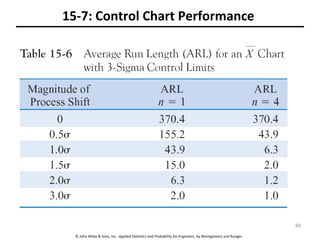

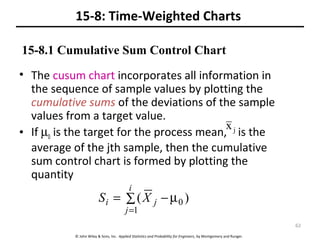

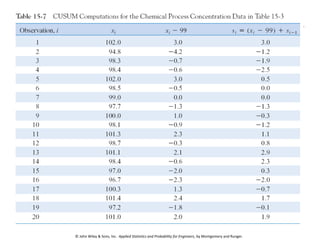

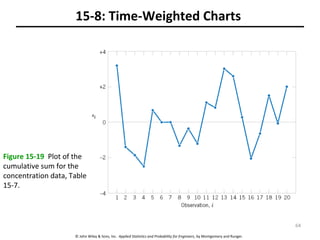

1. Statistical process control uses tools like control charts to reduce variability and identify assignable causes of variation.

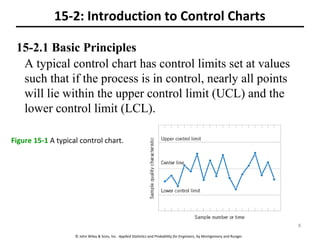

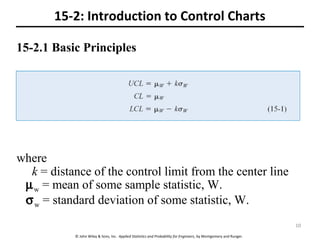

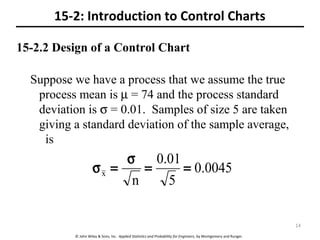

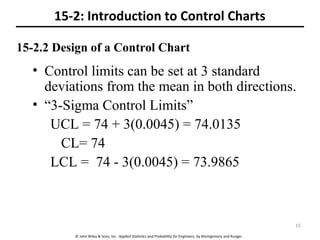

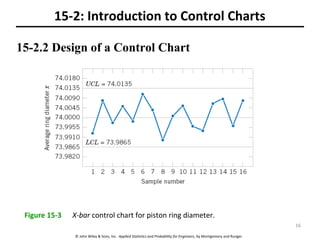

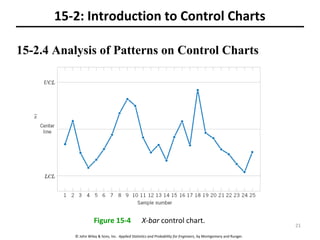

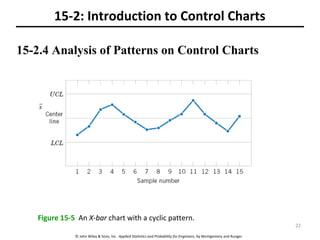

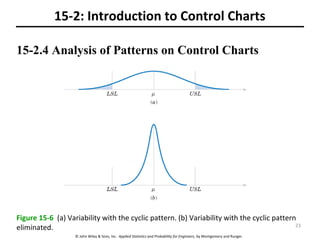

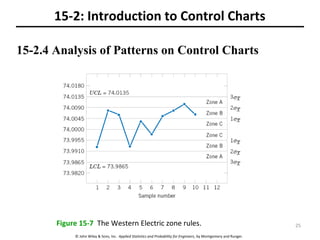

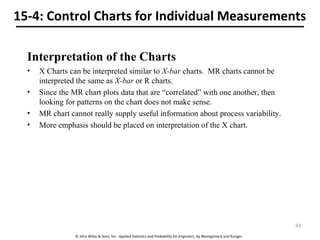

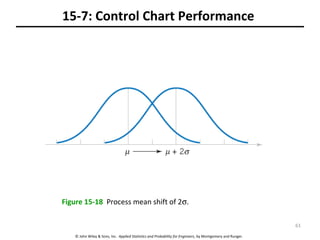

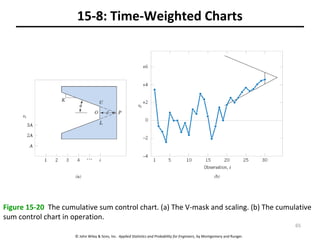

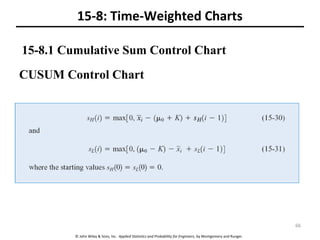

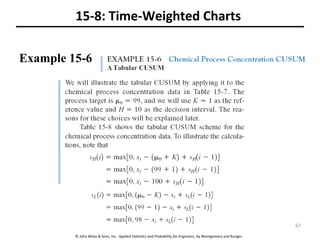

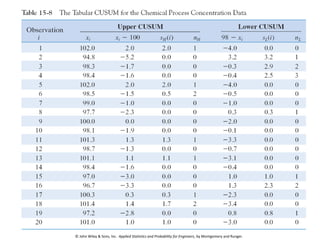

2. Control charts monitor a process over time and detect when the process moves out of the state of statistical control.

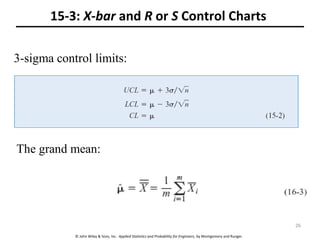

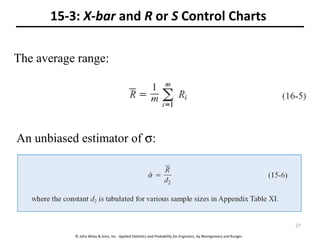

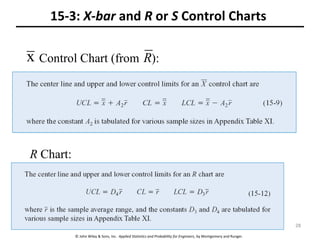

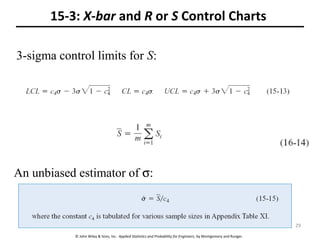

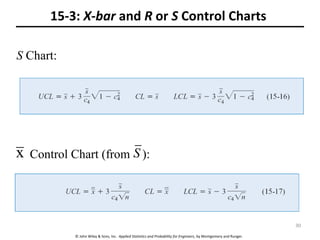

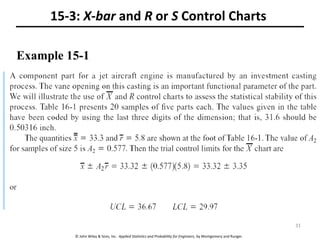

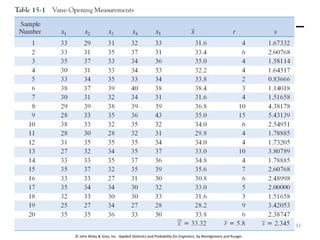

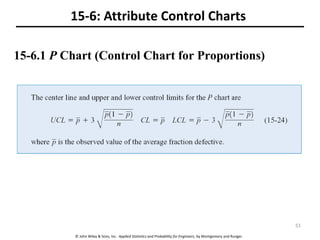

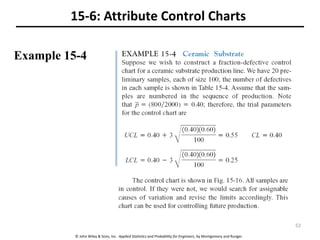

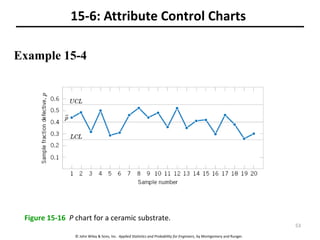

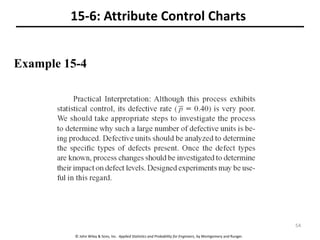

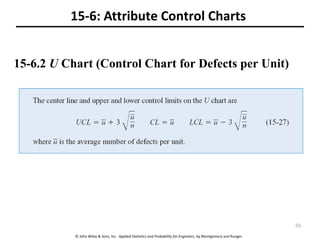

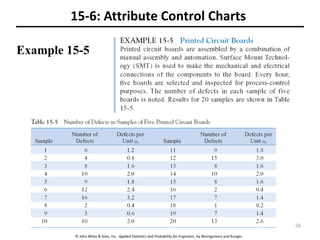

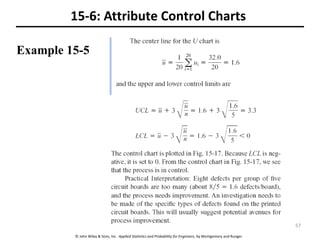

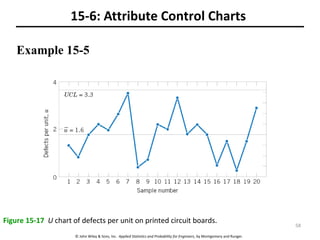

3. There are variables and attributes control charts. Variables charts like X-bar and R charts are for continuous data, while attributes charts like P and U charts are for discrete data.

4. Rational subgrouping aims to maximize differences between subgroups while minimizing within-subgroup differences to better detect assignable causes.