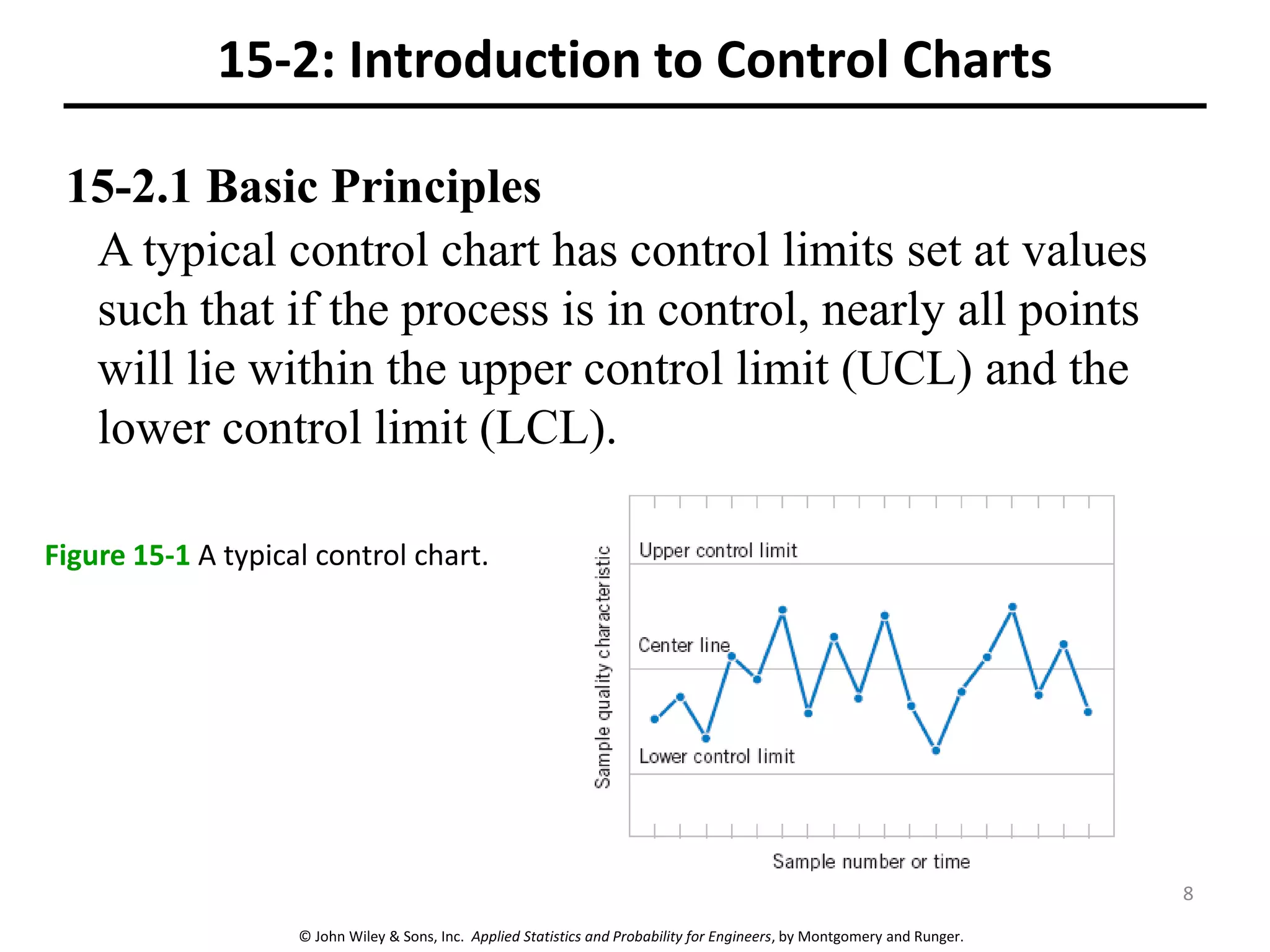

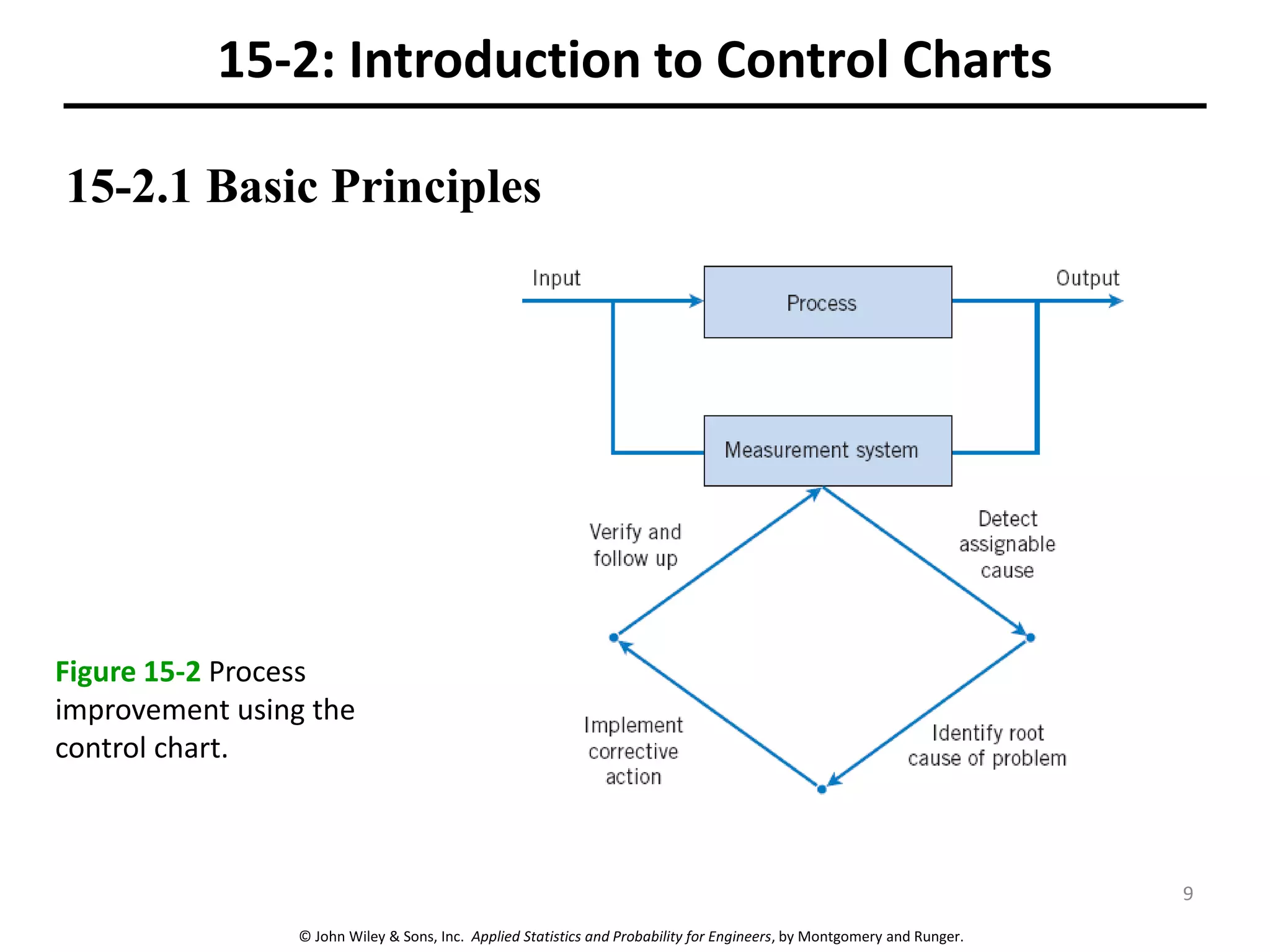

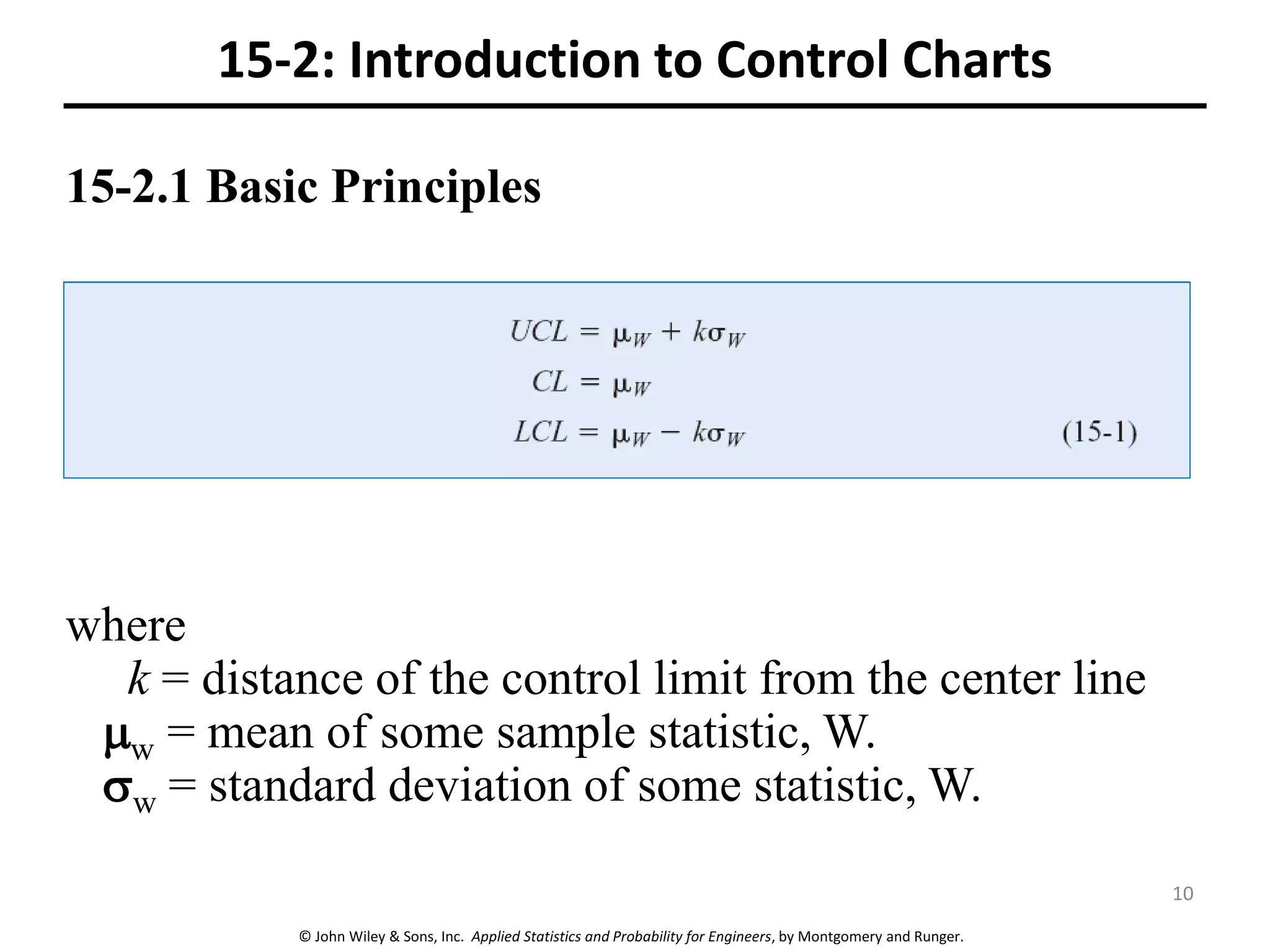

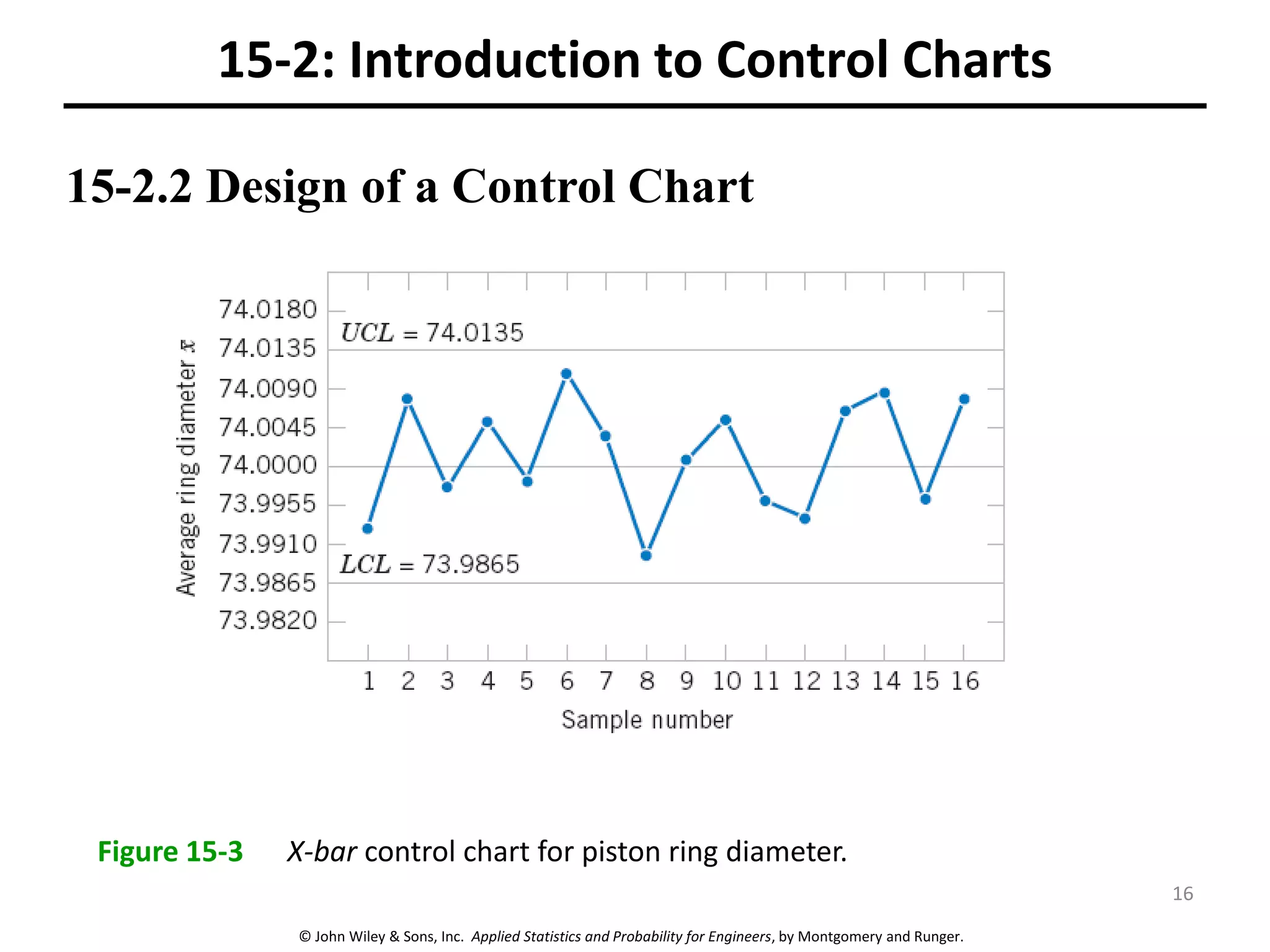

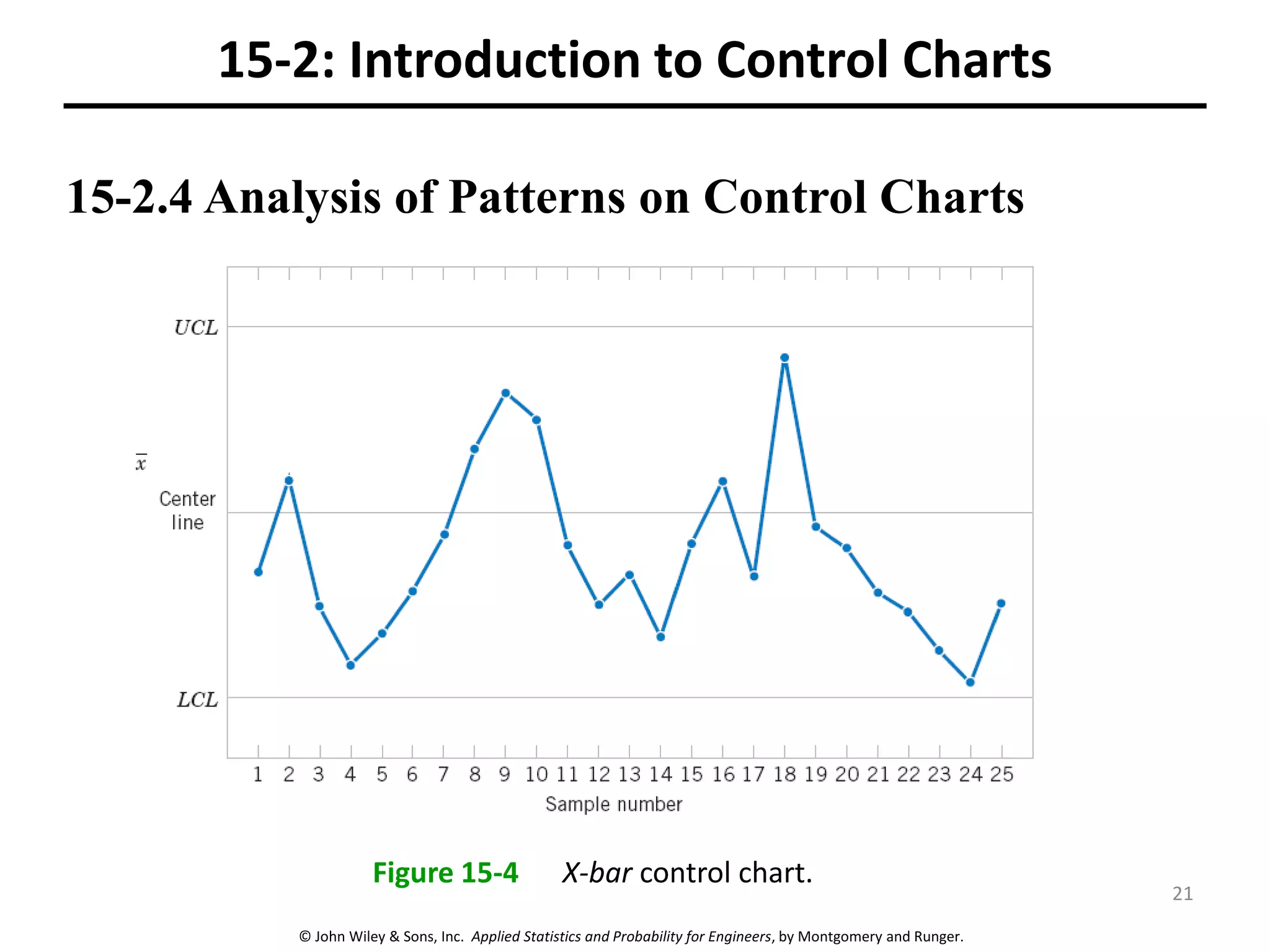

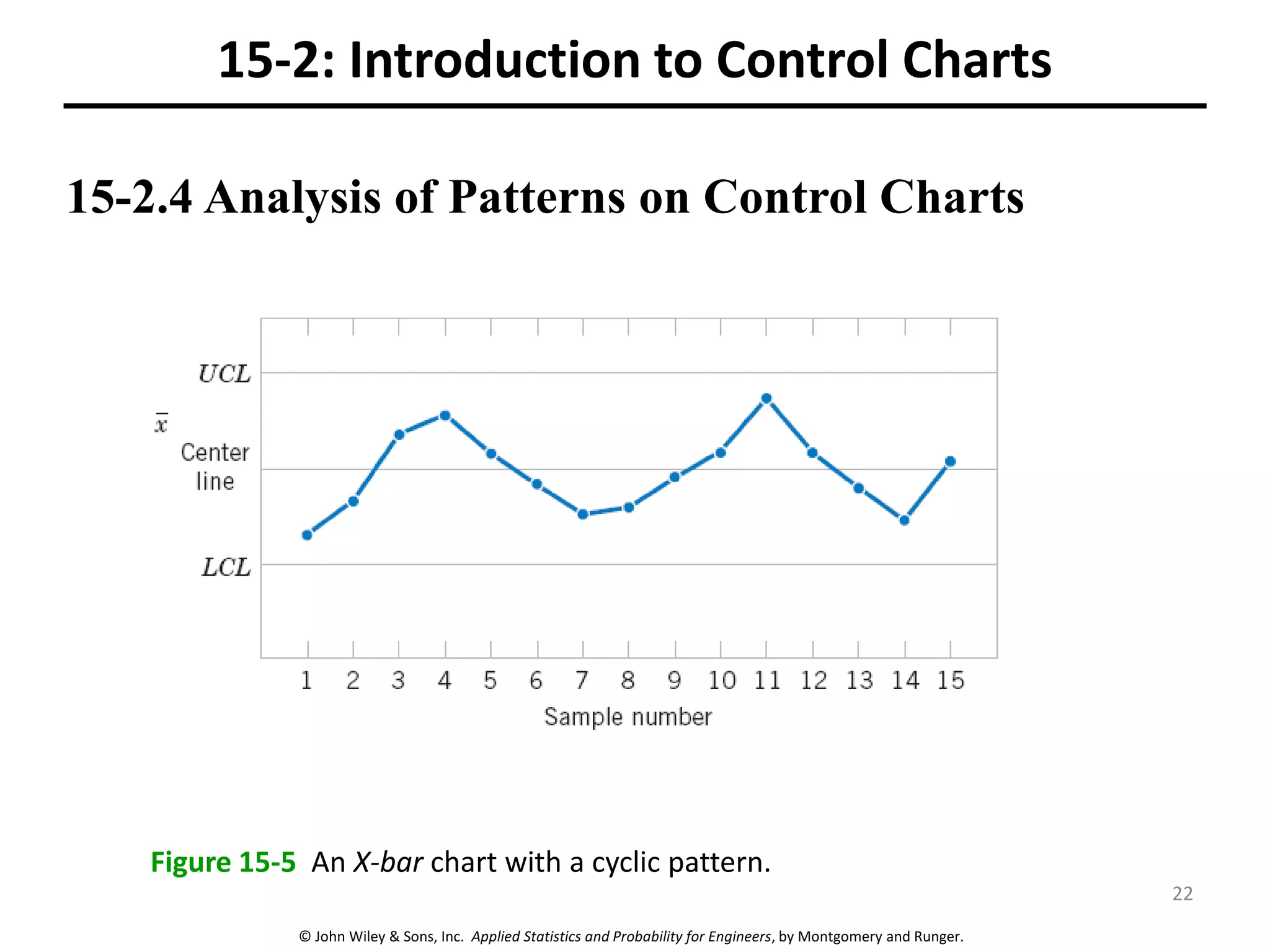

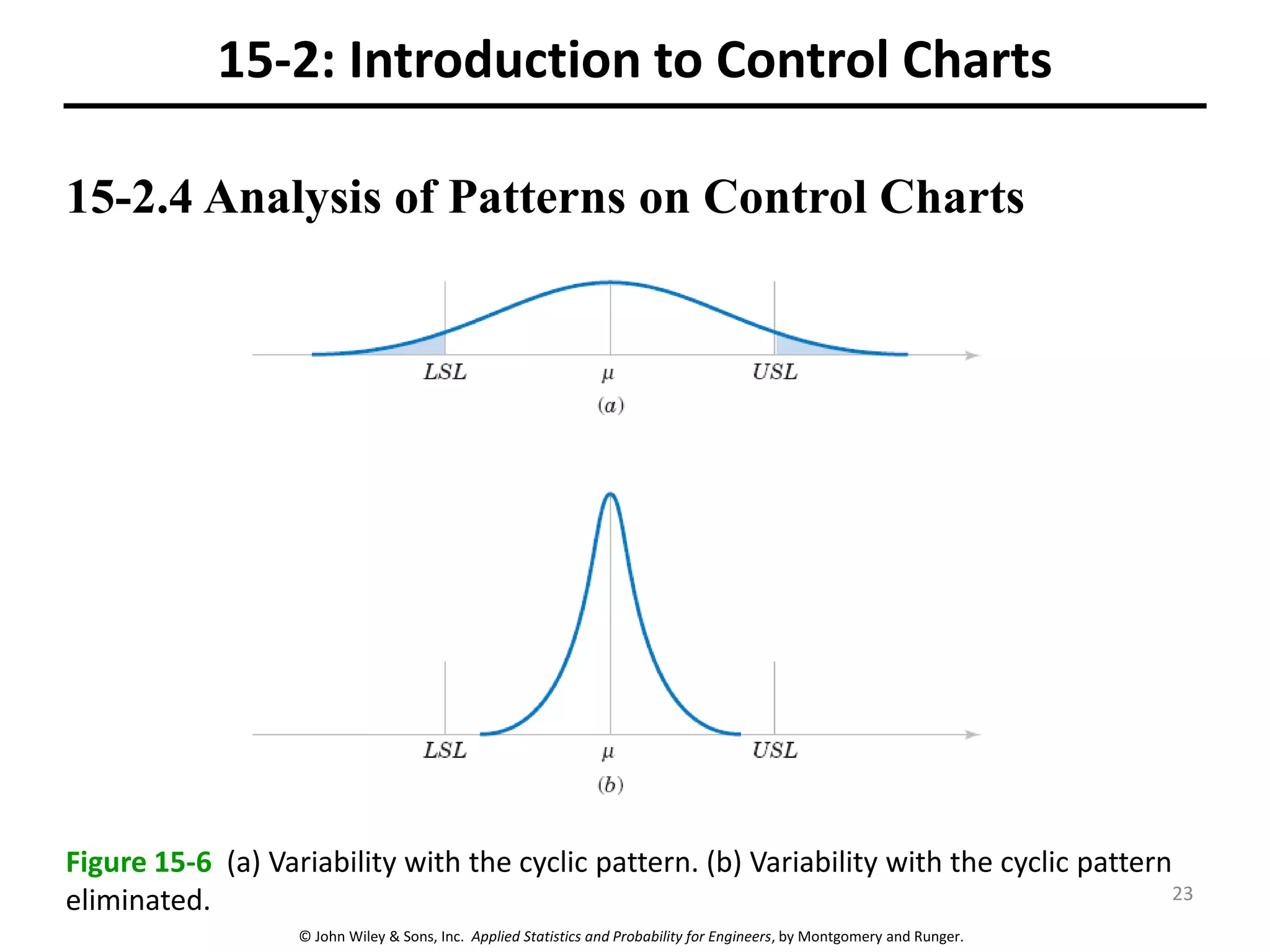

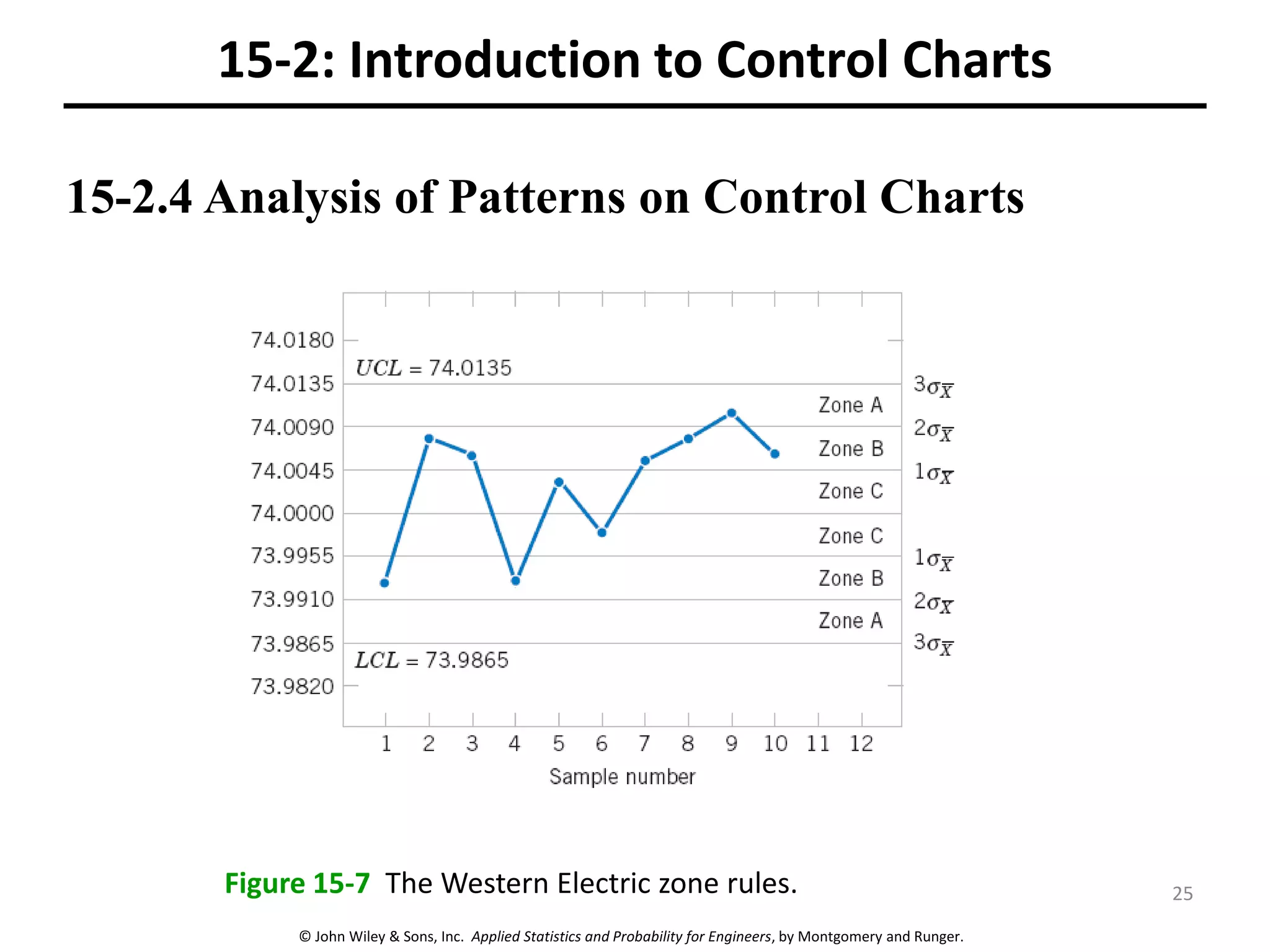

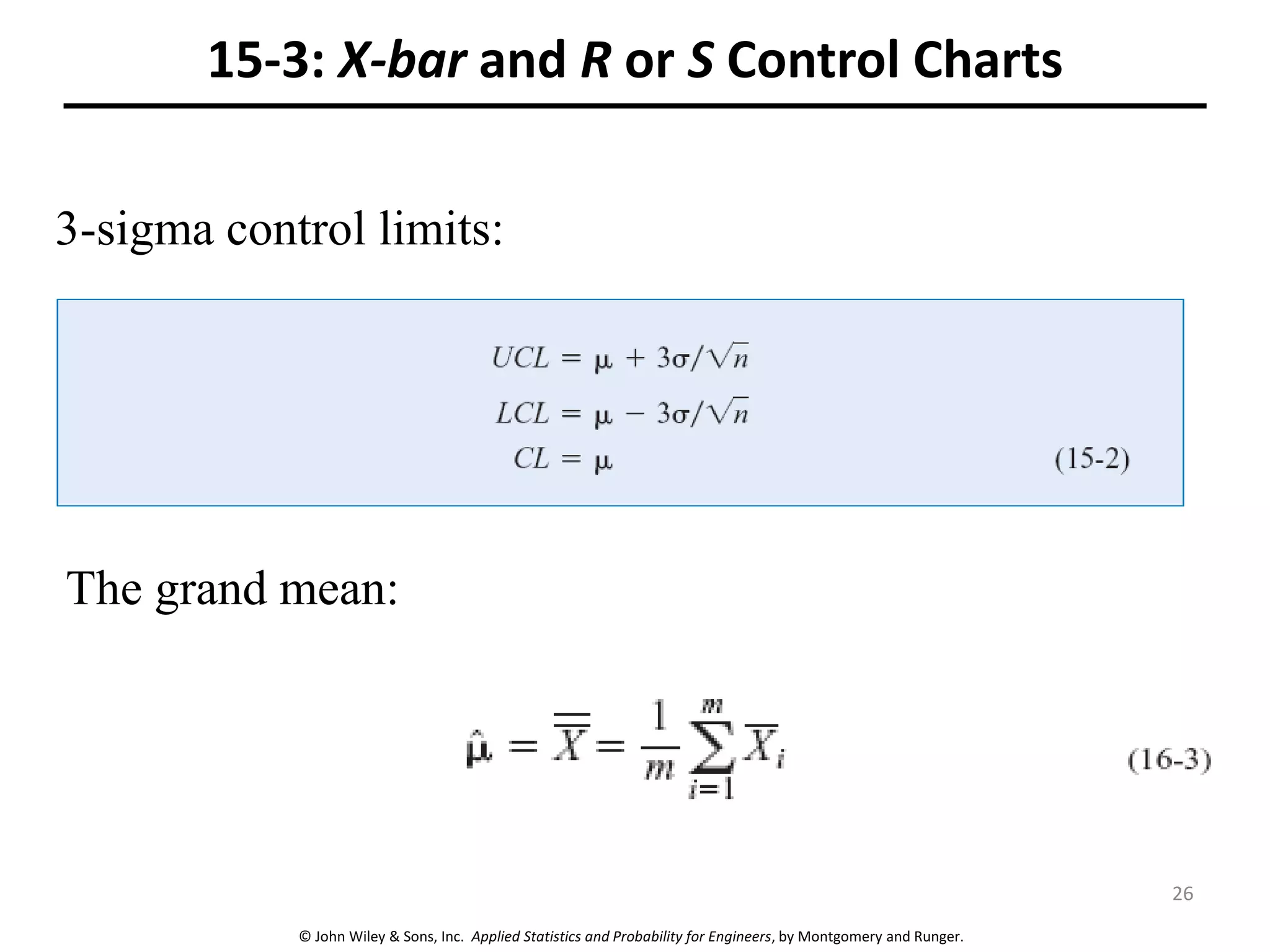

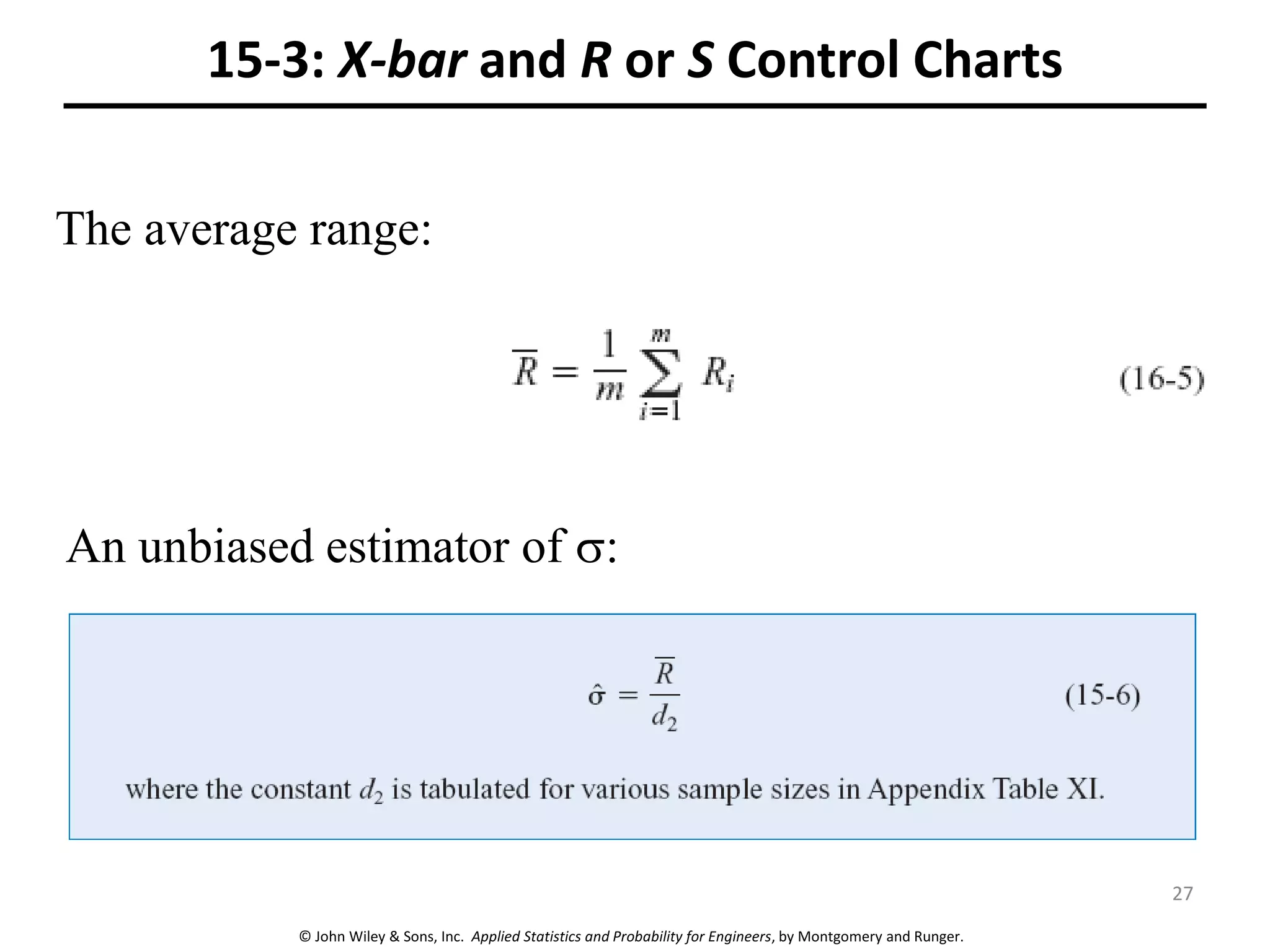

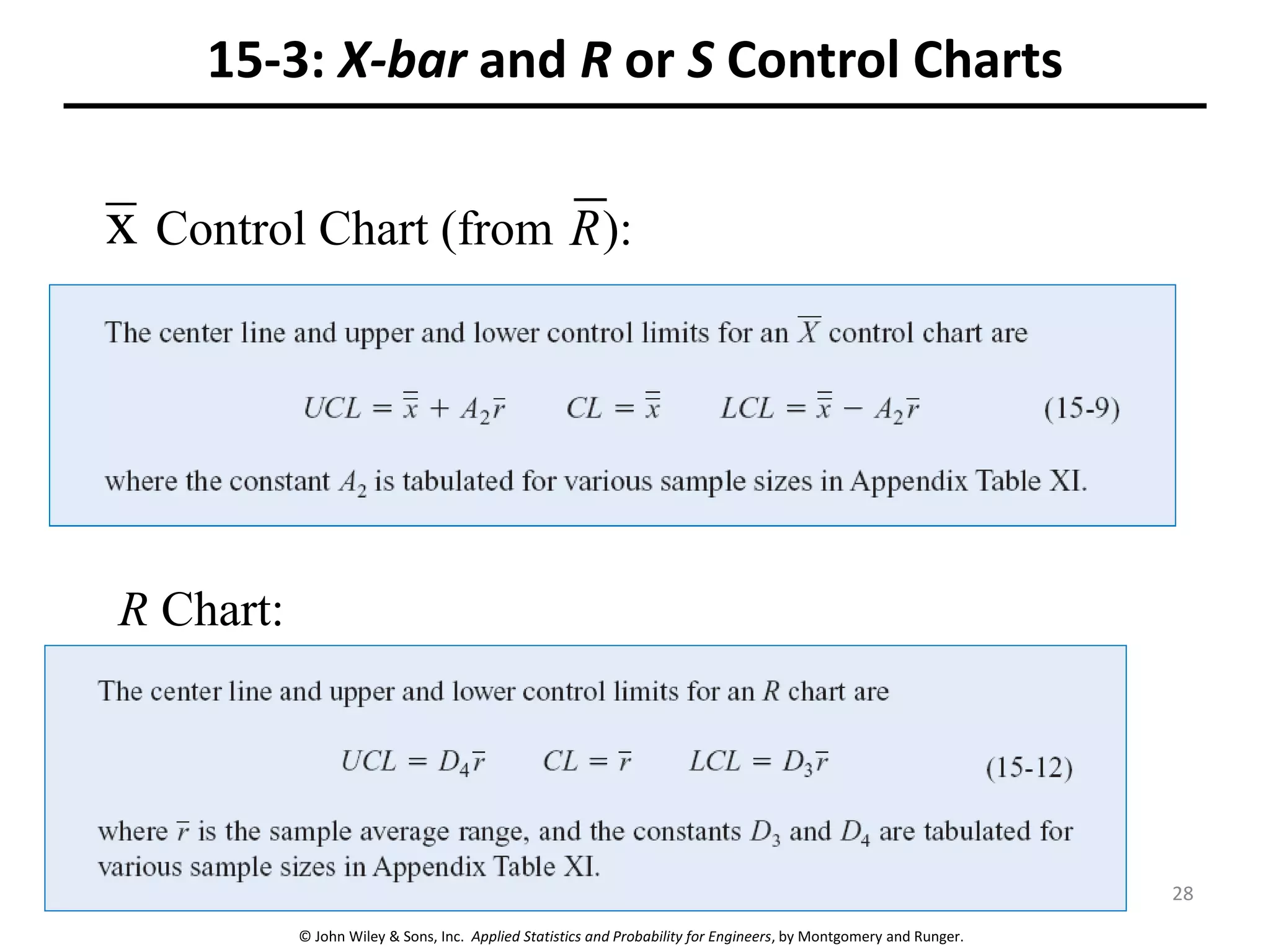

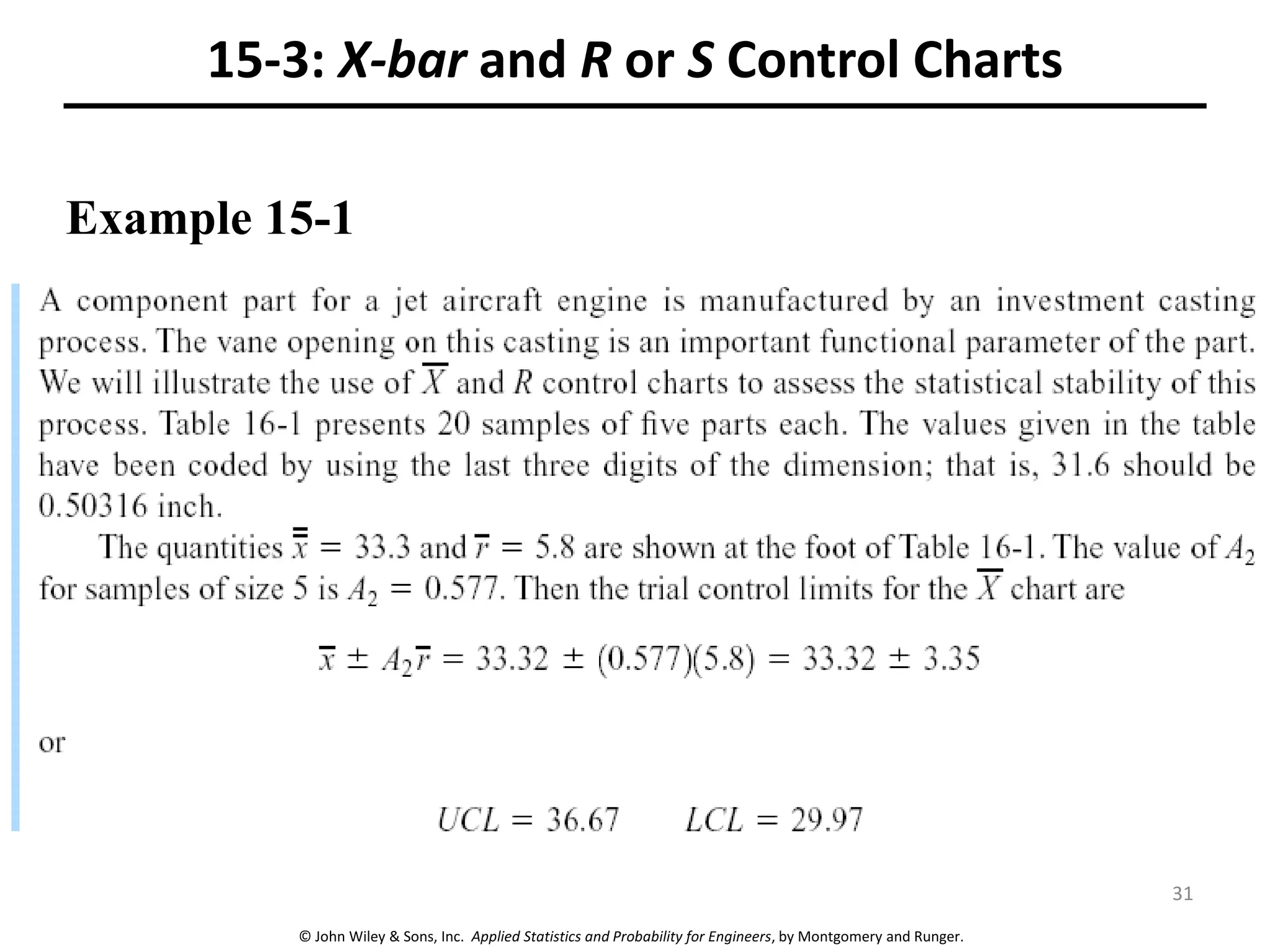

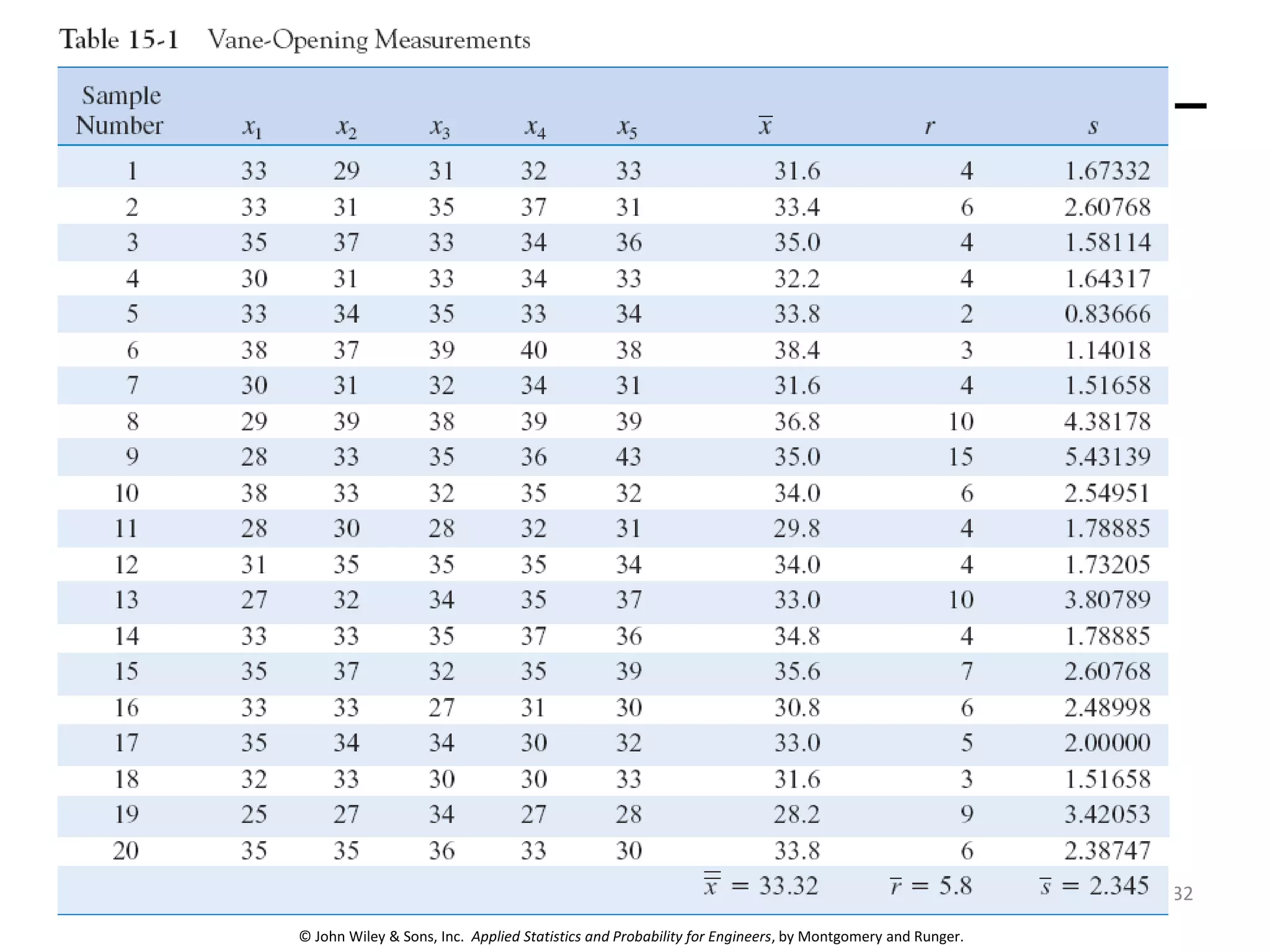

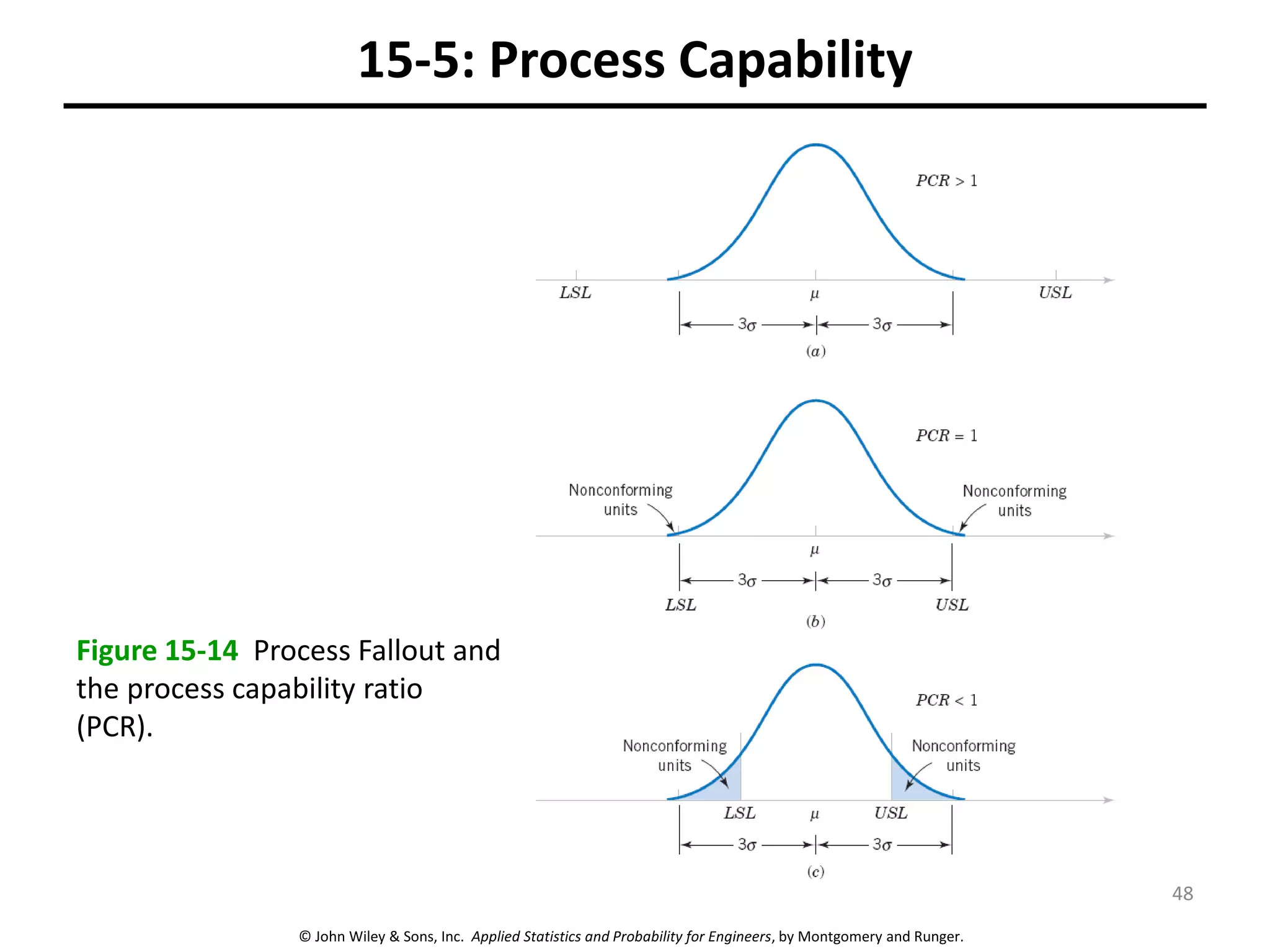

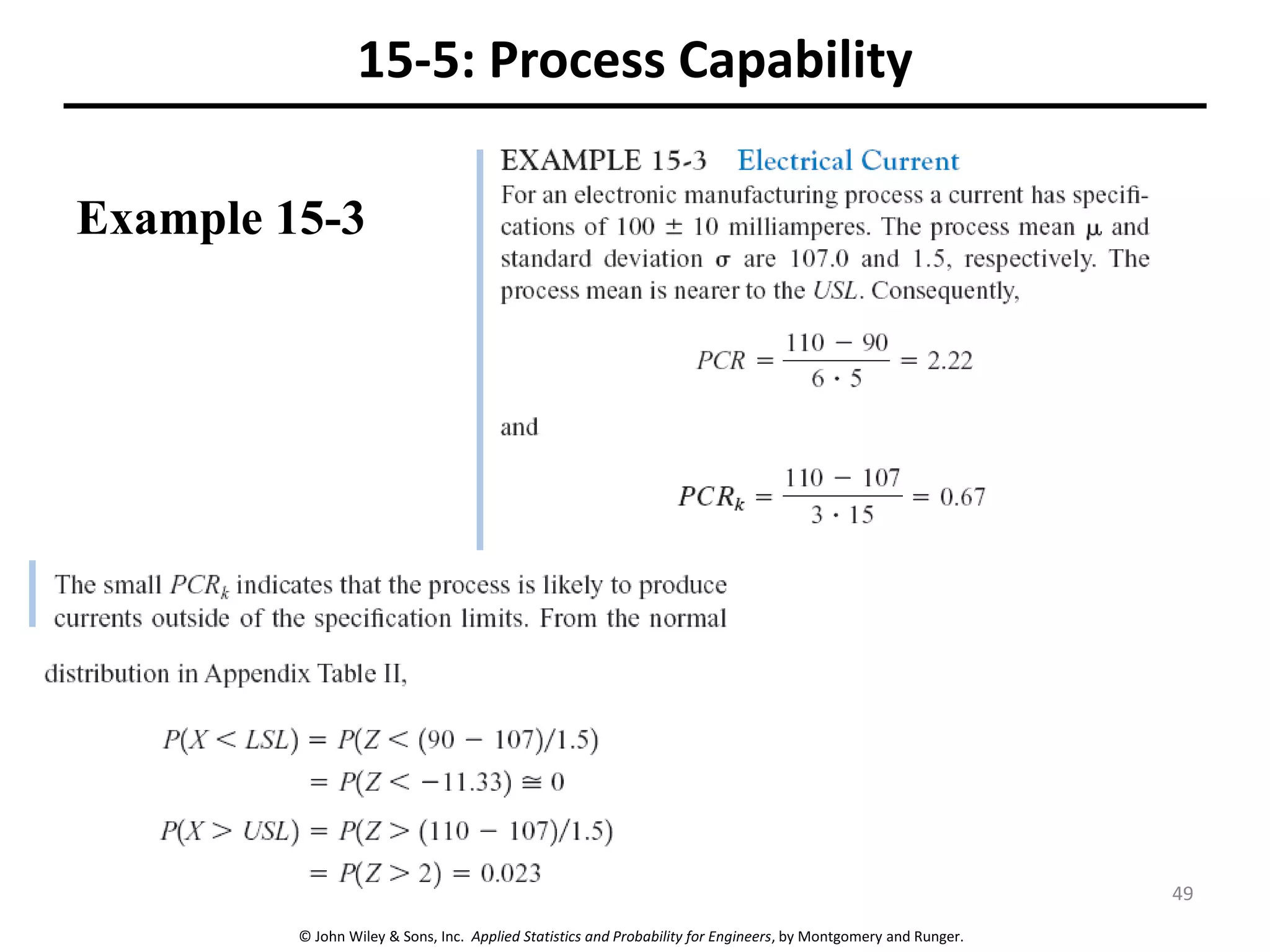

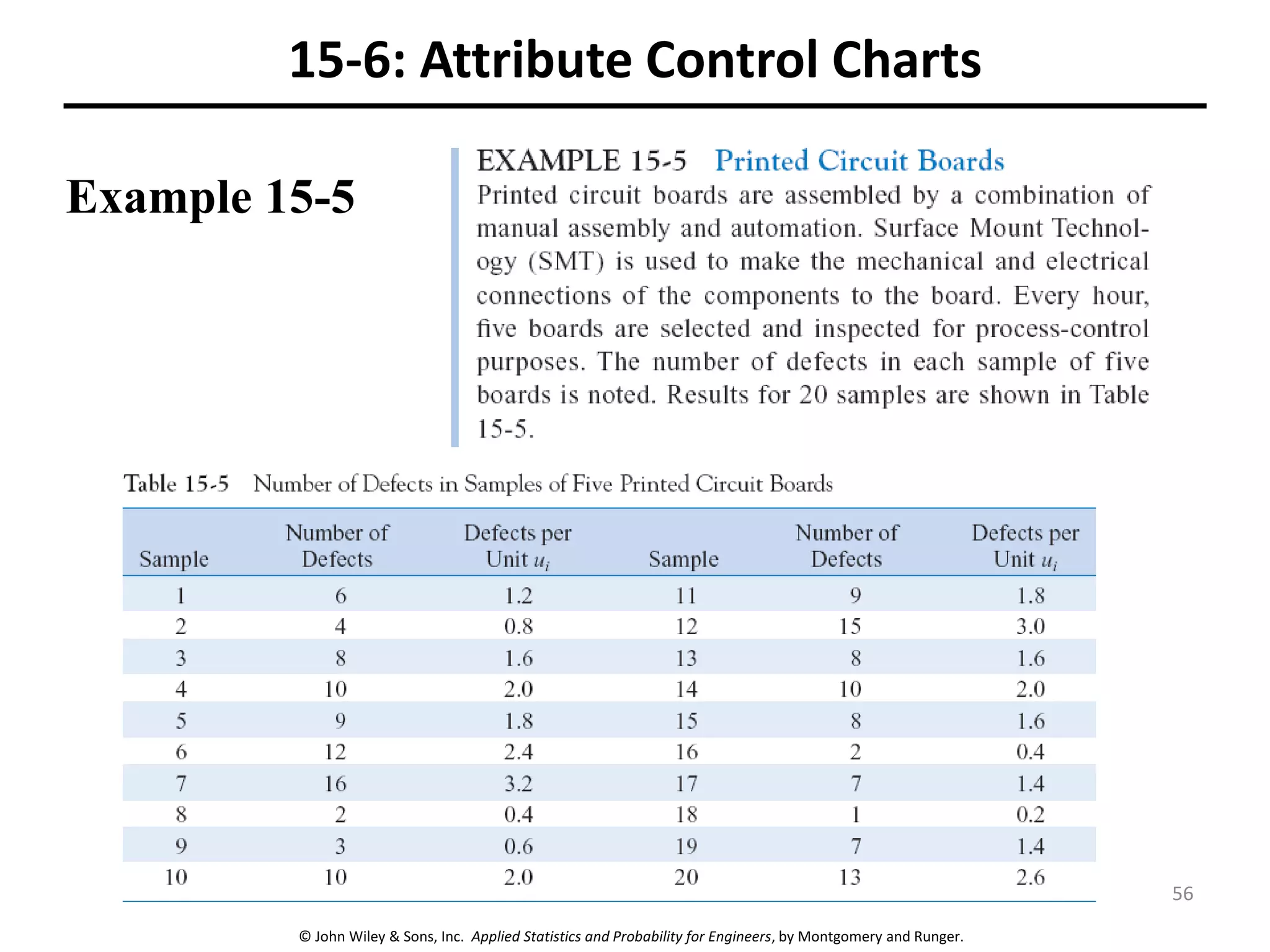

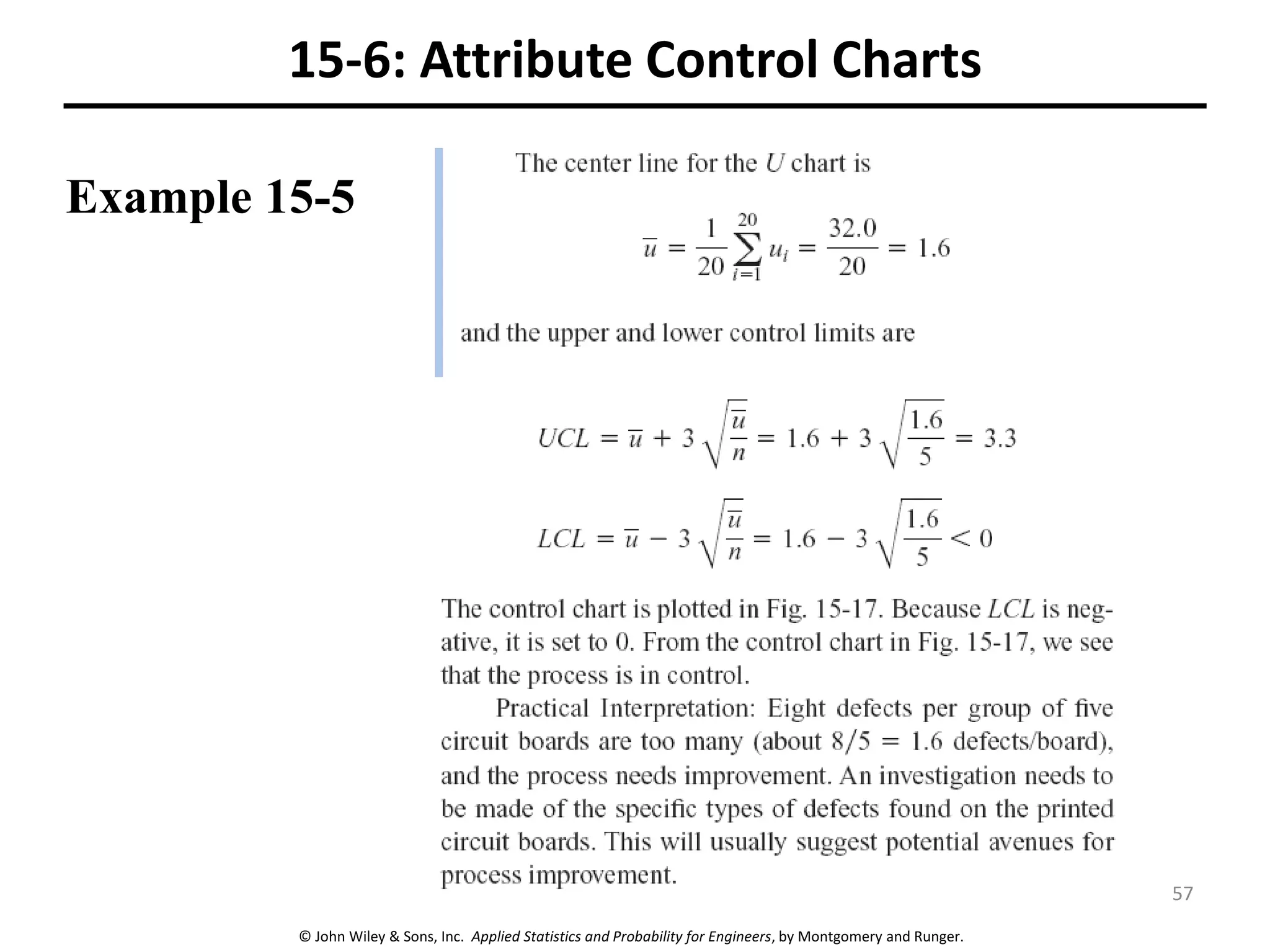

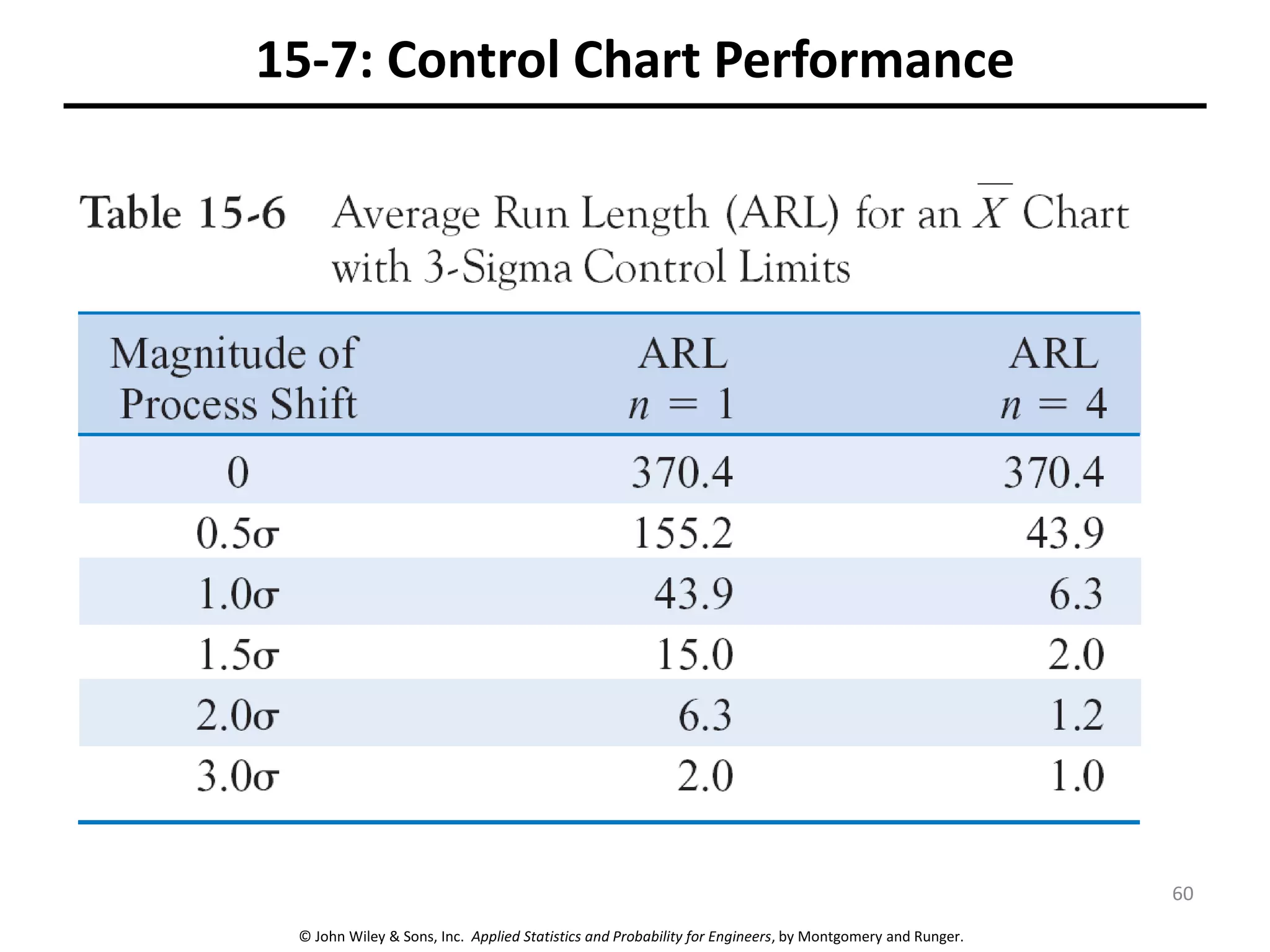

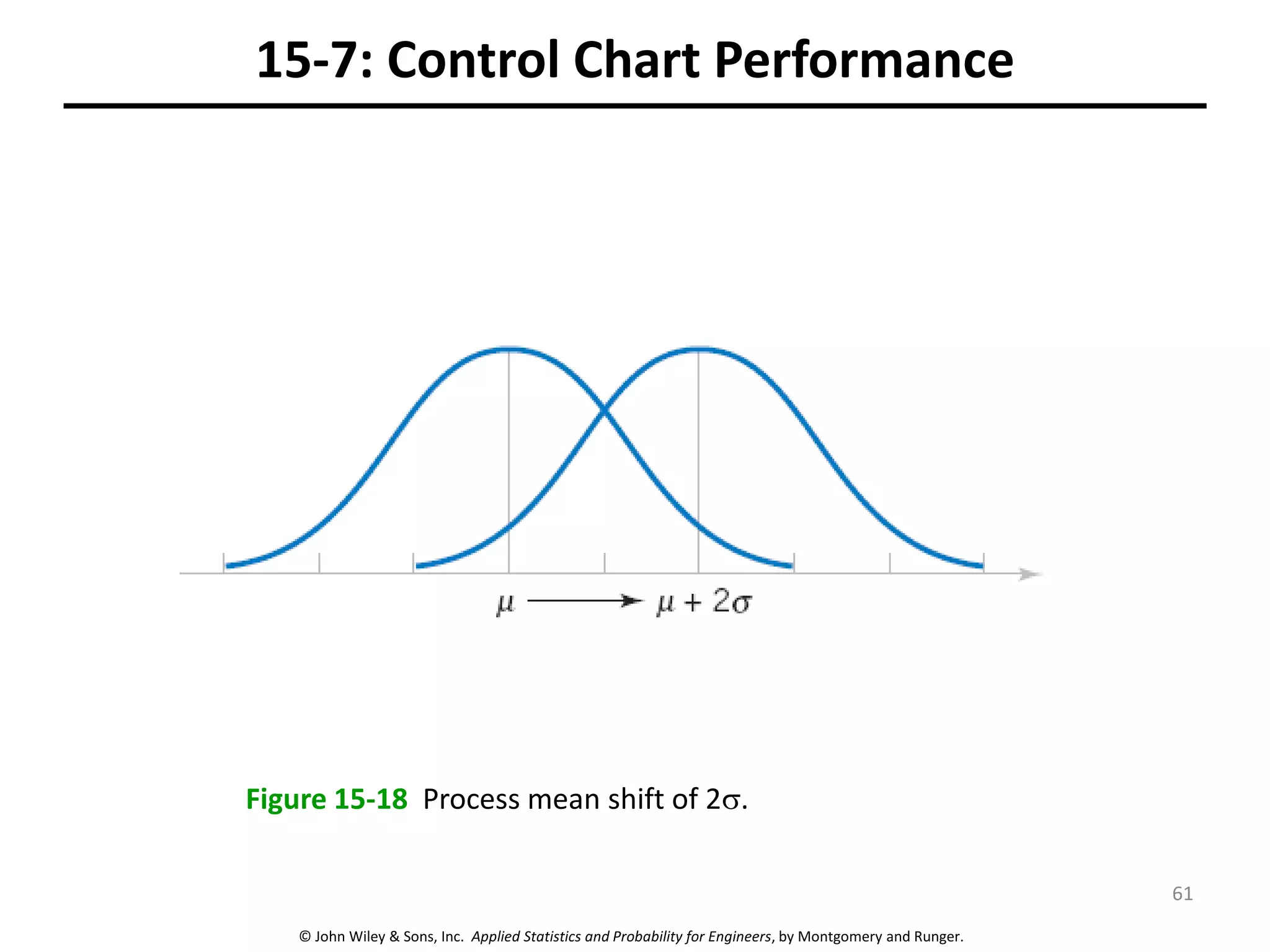

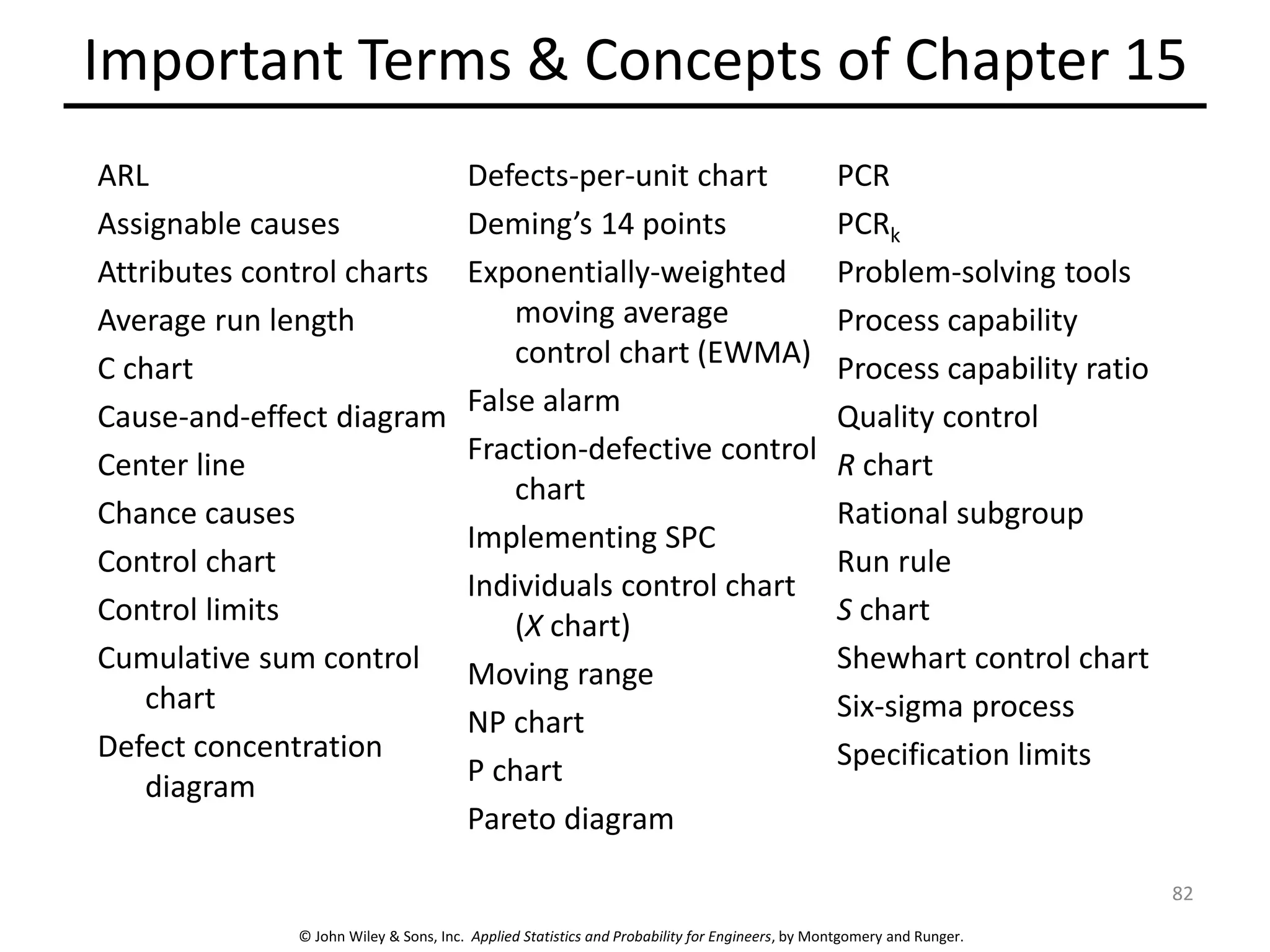

This chapter outline describes statistical quality control tools including control charts. Control charts are used to detect assignable causes of variation and improve processes. The chapter will cover both variables and attributes control charts, including X-bar and R charts to monitor process means and variability. It will also discuss rational subgrouping, pattern analysis, process capability analysis and calculation of control chart performance metrics. The goal is understanding how to construct and interpret different control charts and use statistical process control tools to improve quality.