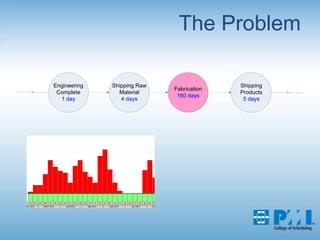

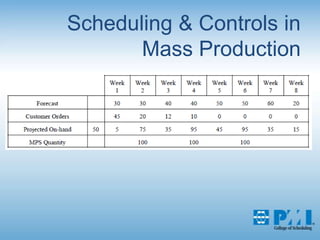

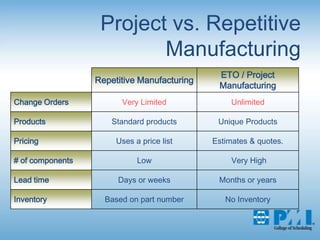

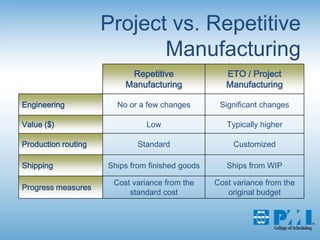

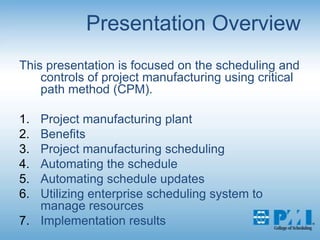

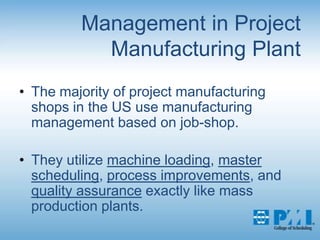

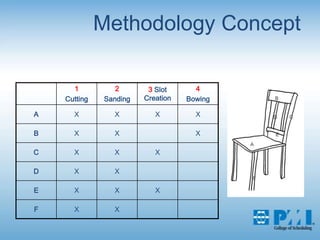

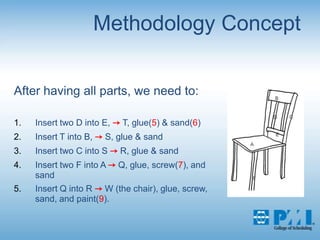

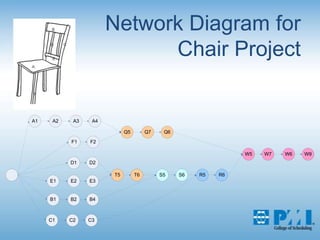

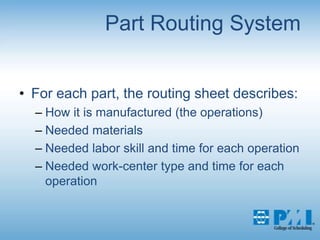

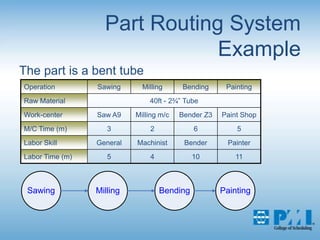

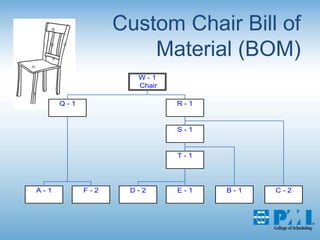

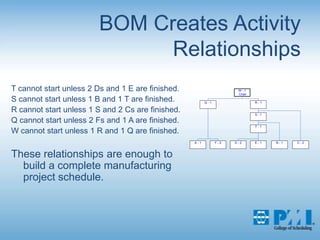

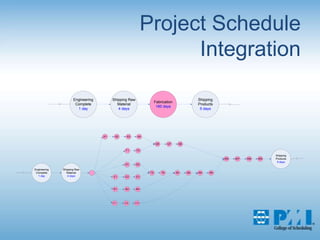

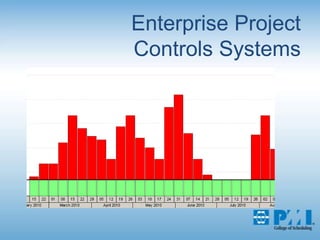

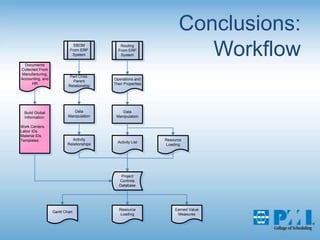

This document discusses scheduling and controls for project manufacturing. It begins by contrasting mass production, job shop manufacturing, and proposing project manufacturing as a third method. Project manufacturing schedules unique engineered products using critical path methodology (CPM). The document outlines automating schedule creation from routing and BOM data, integrating project schedules, resolving resource conflicts in an enterprise system, and concludes the approach provides benefits like improved project integration and controls for project manufacturing plants.