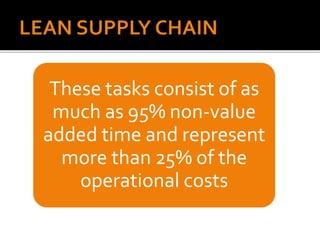

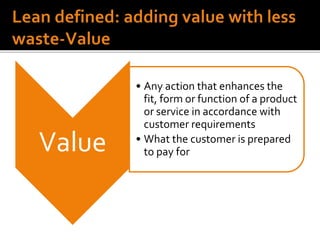

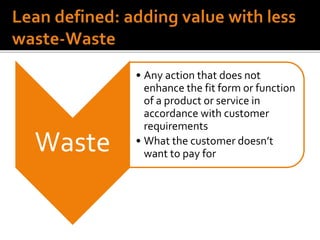

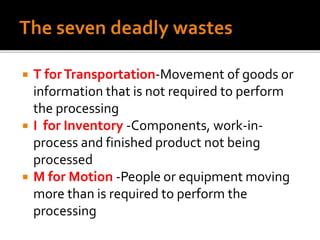

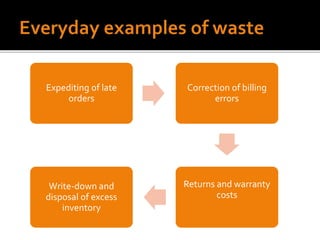

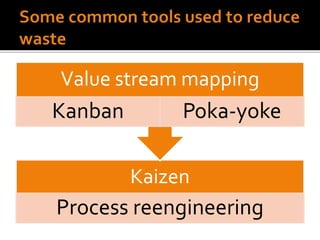

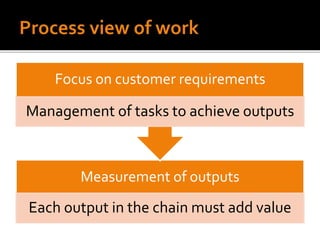

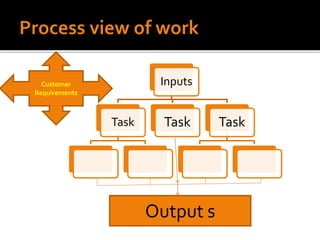

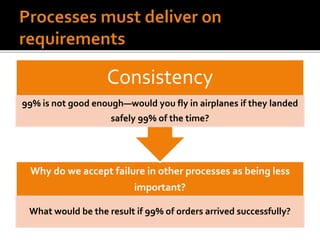

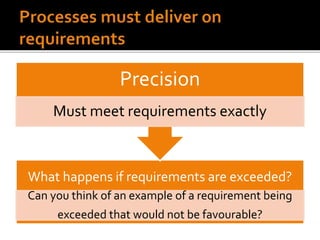

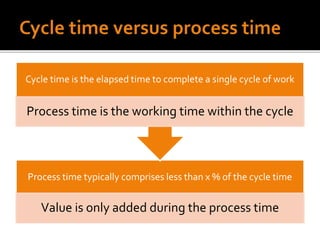

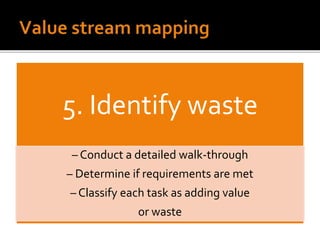

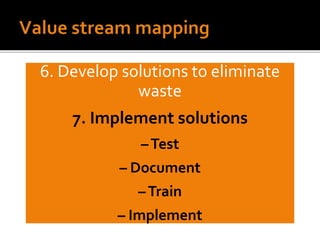

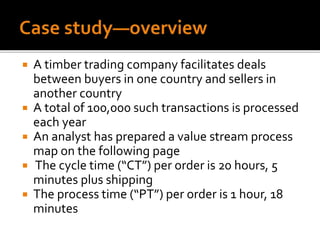

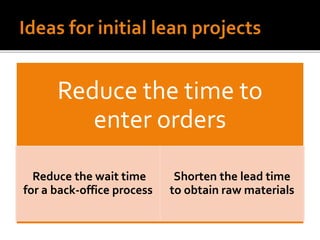

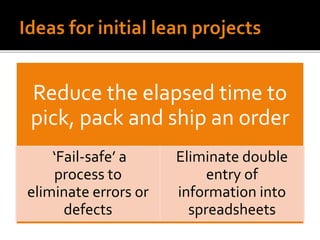

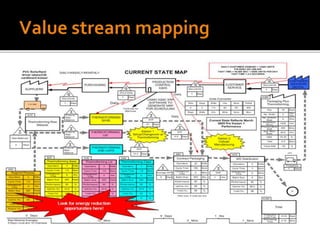

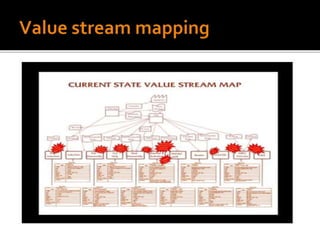

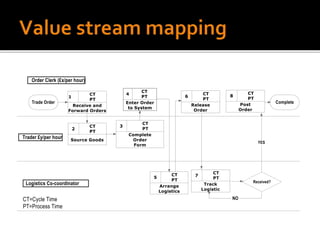

The document discusses the Lean supply chain philosophy which aims to eliminate waste from processes. It notes that non-manufacturing tasks in the supply chain represent 50-80% of lead time but 95% of that time adds no value. Implementing Lean principles like value stream mapping can help identify waste like excess inventory, motion, transportation and help companies meet customer requirements more efficiently. Process mapping and focusing on continuous improvement are key to reducing cycle times and costs through the elimination of non-value added activities across the entire supply chain.