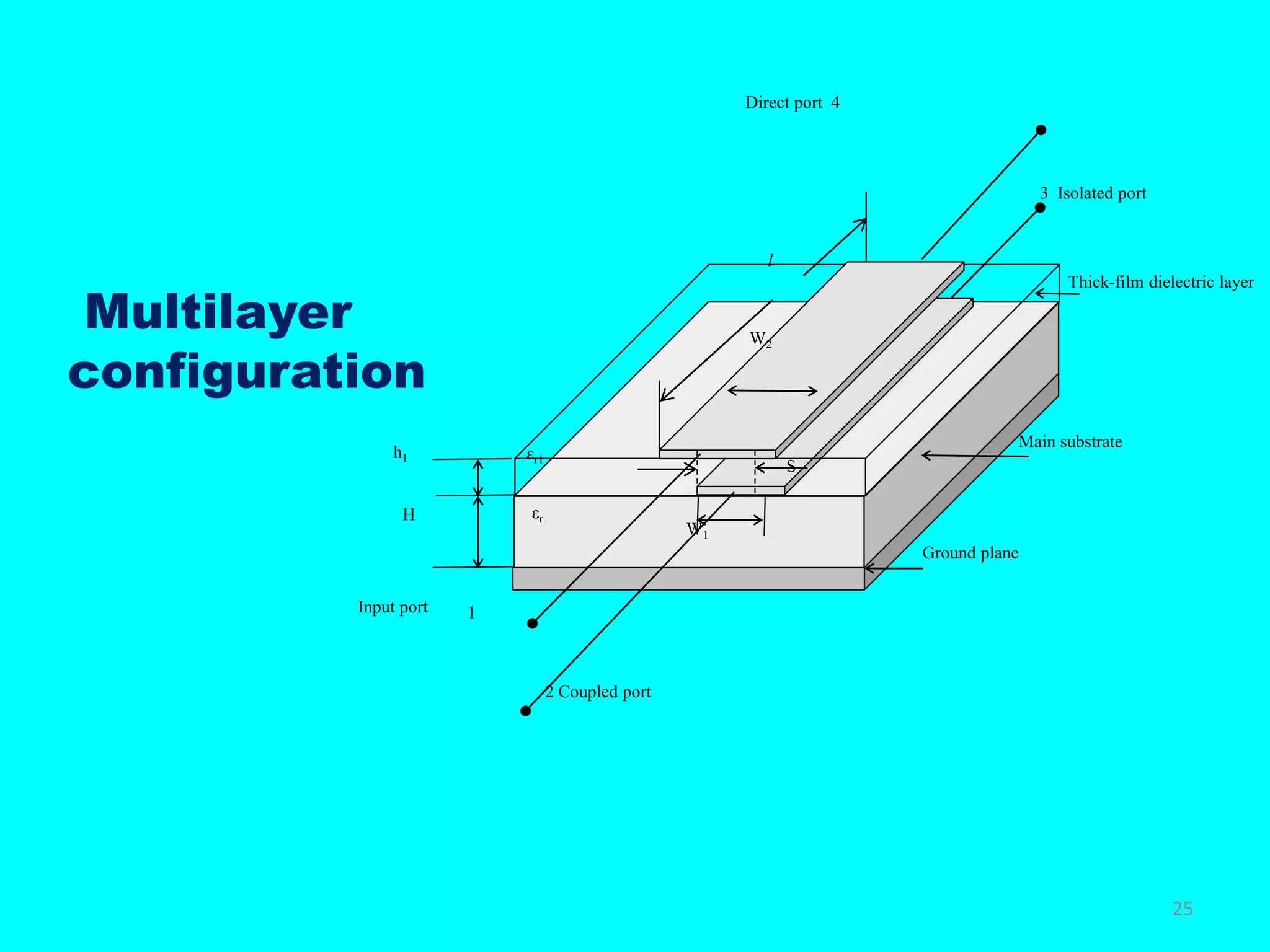

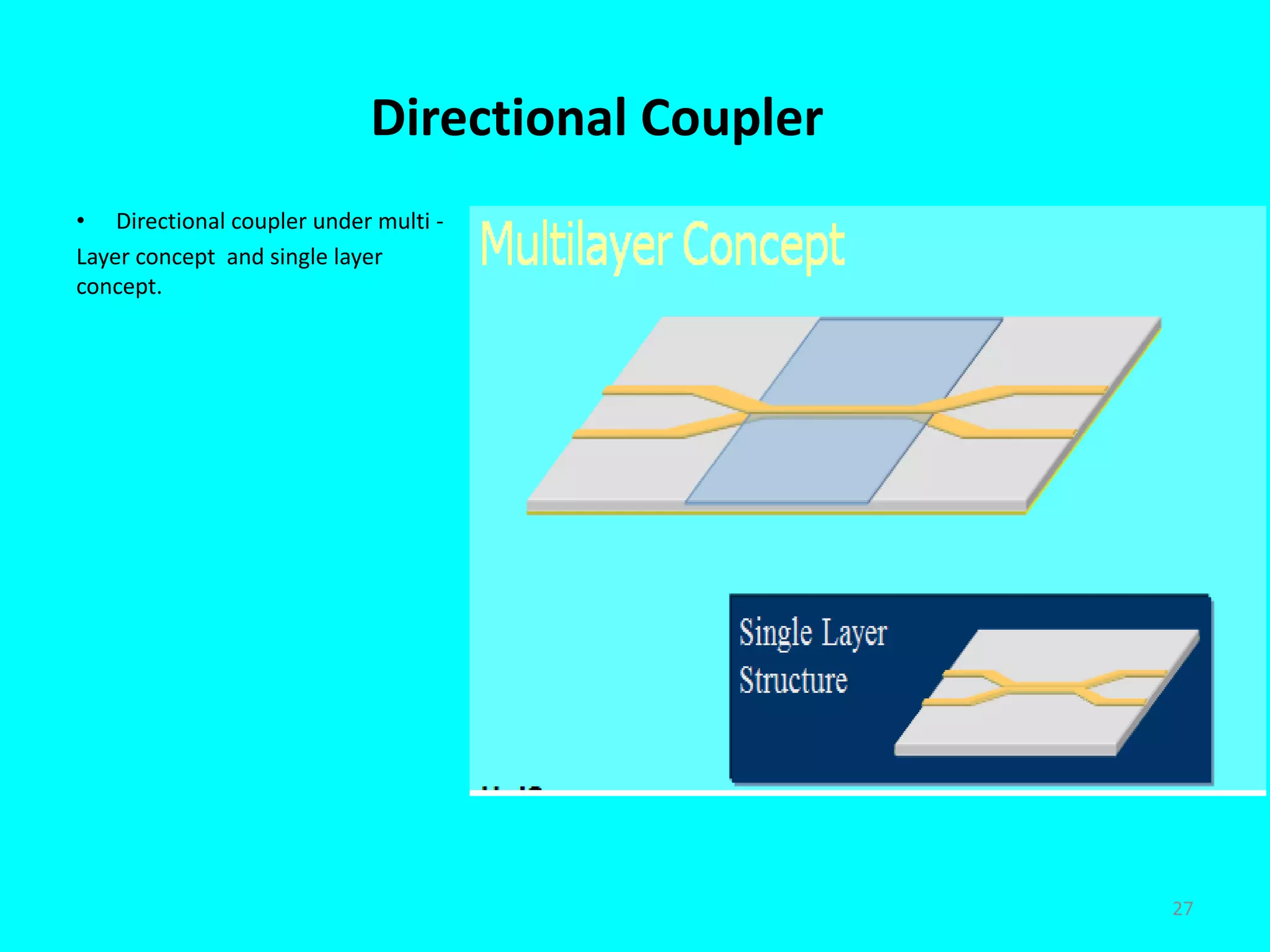

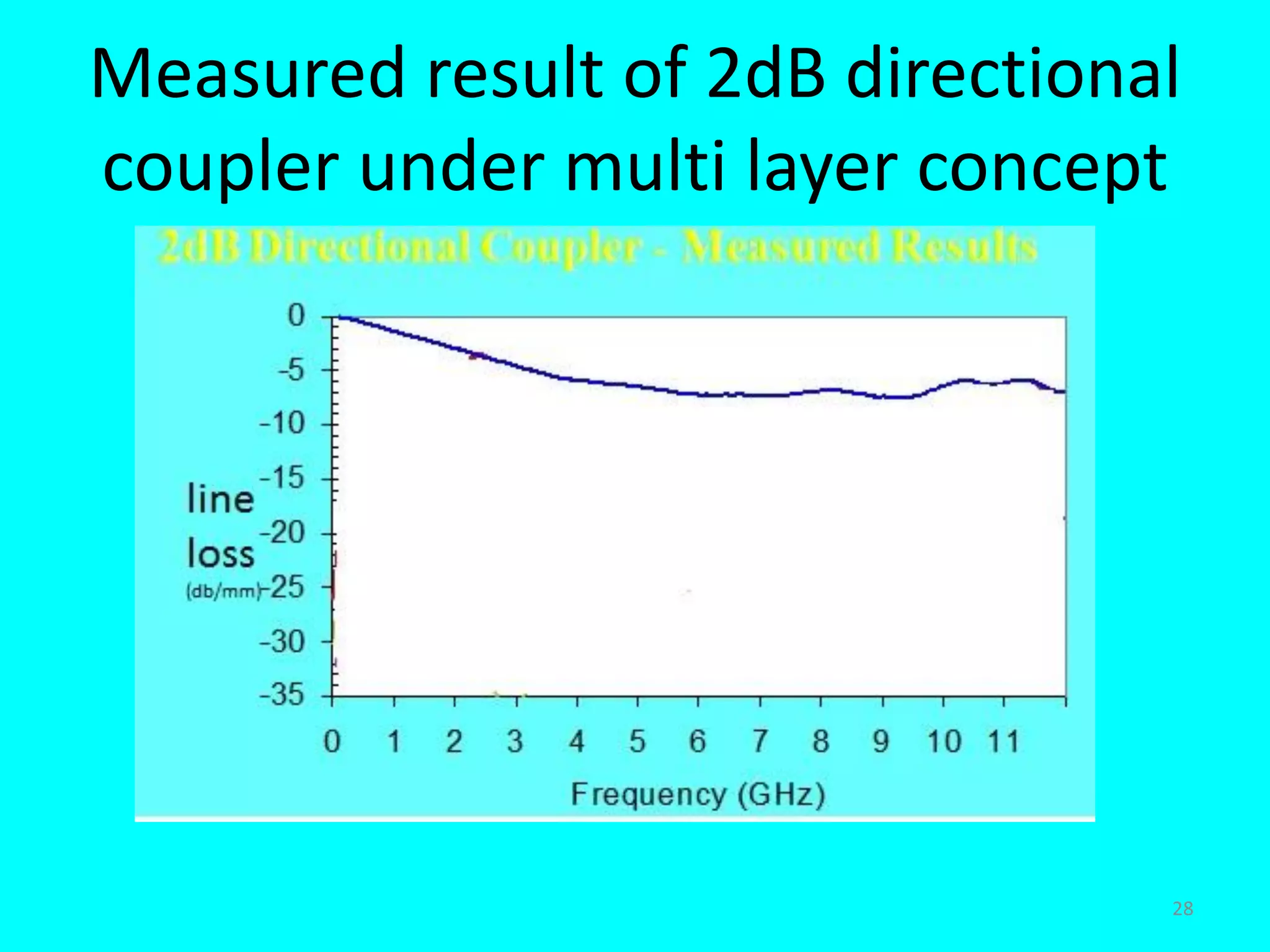

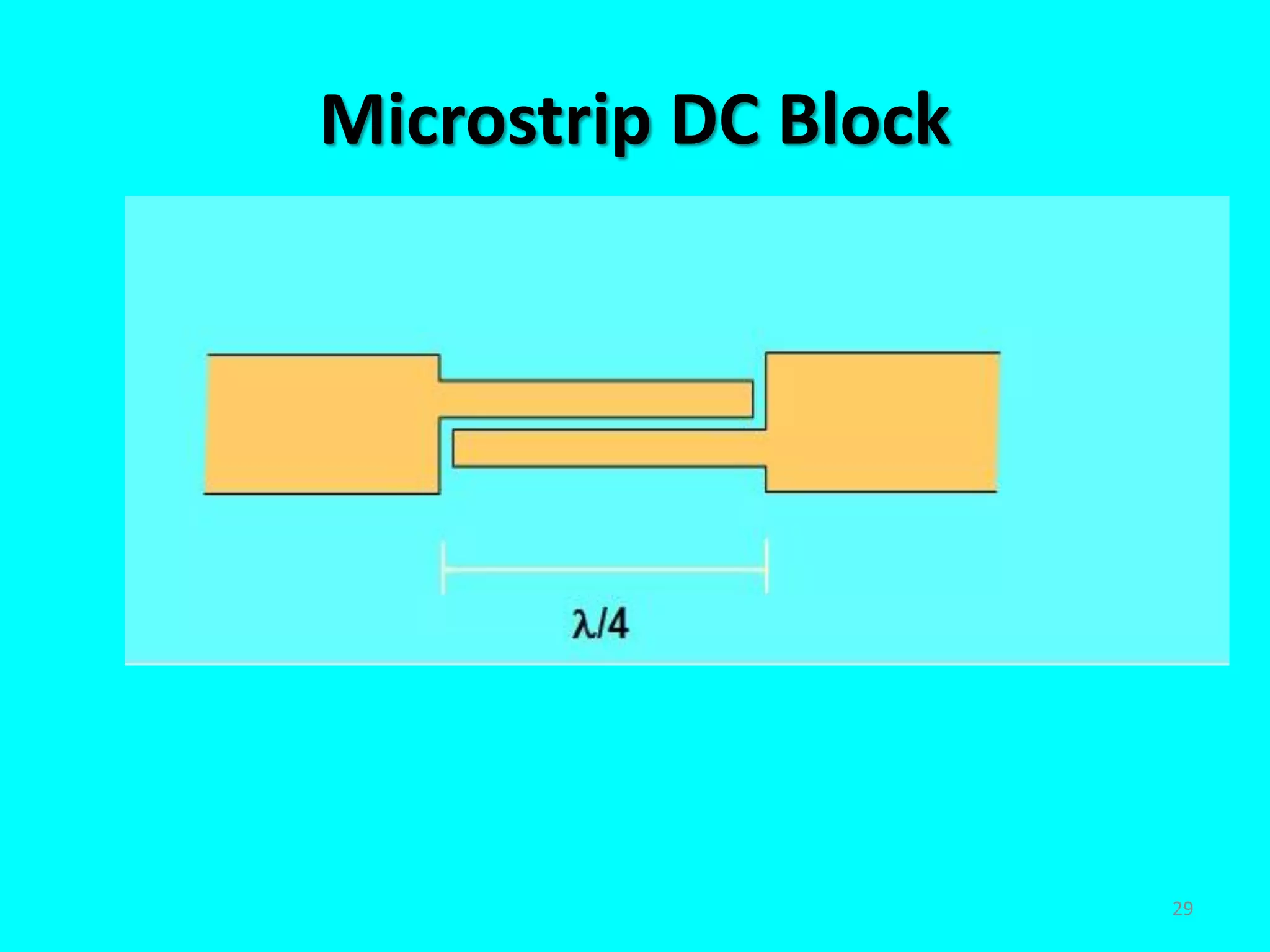

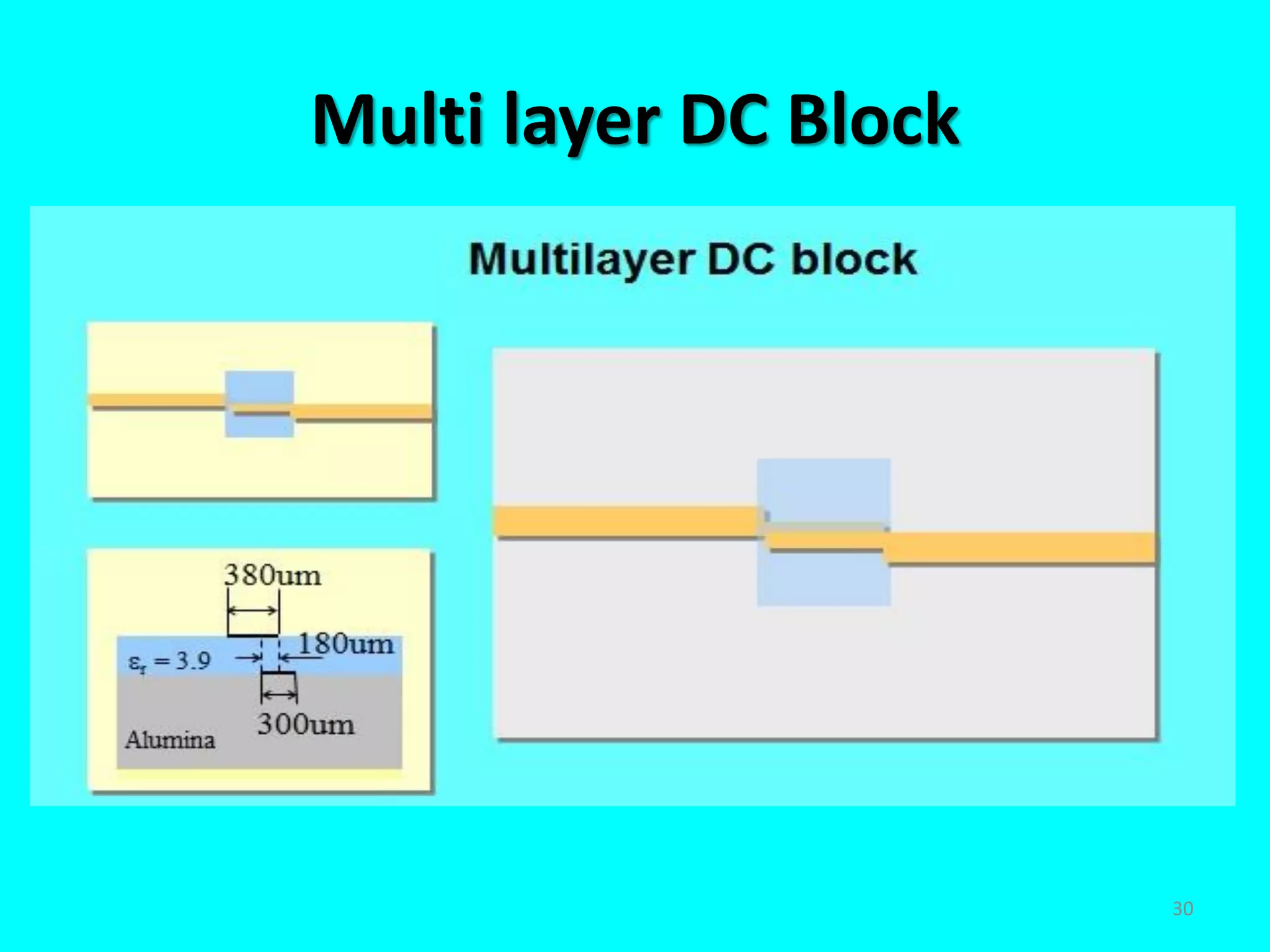

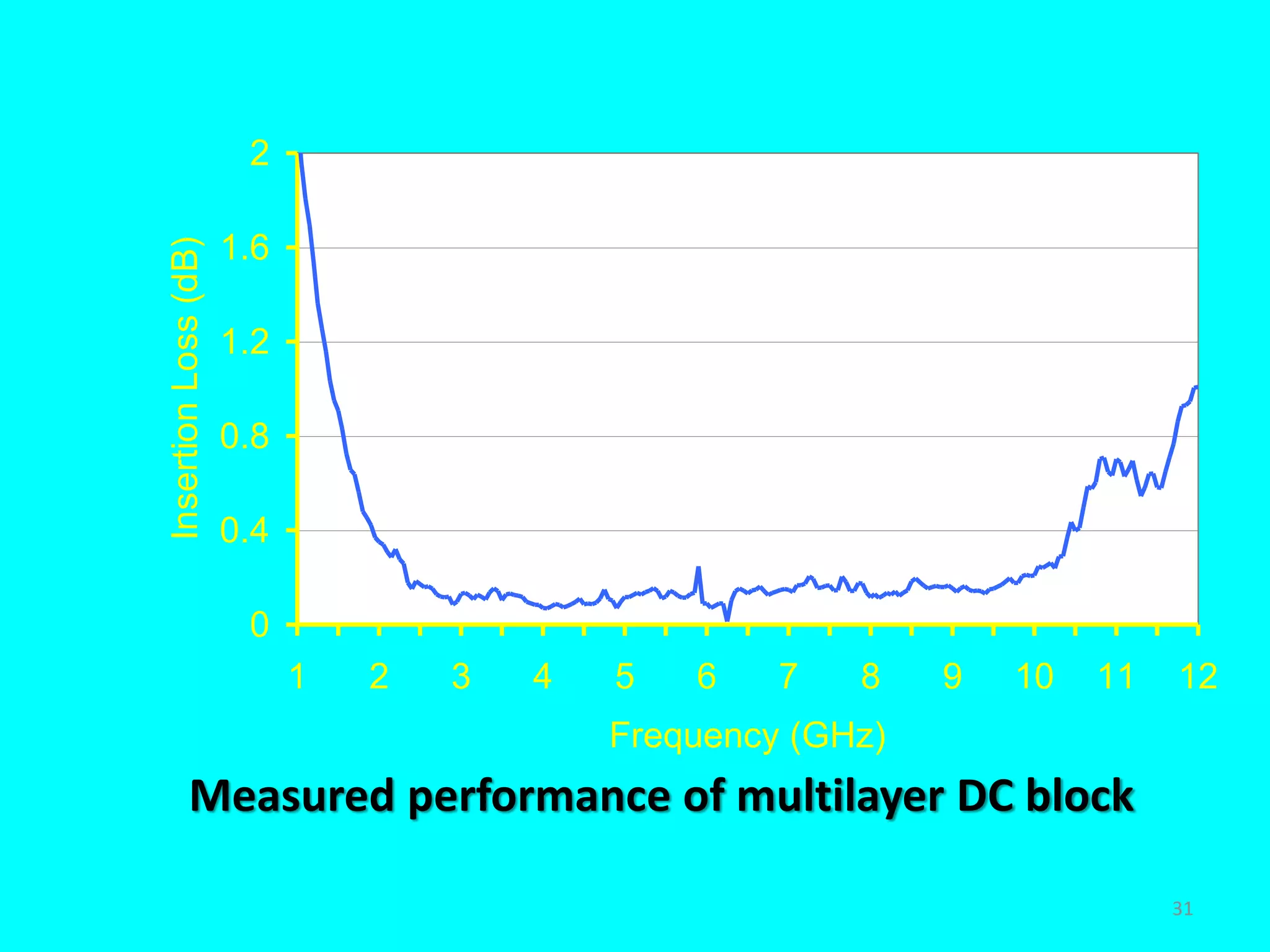

Thick-film multilayer microwave circuits offer advantages over single-layer circuits for wireless applications. Multilayer circuits allow for strong broadside coupling between conductors on different layers, eliminating the need for fine gaps. This makes them well-suited for thick-film printing technology. Examples discussed include directional couplers and DC blocks fabricated using a multilayer approach that demonstrated improved performance compared to single-layer designs. Thick-film technology is particularly applicable for implementing multilayer microwave circuits due to enabling higher density integration and close coupling between conductors.

![Losses in Thick-Film Technology

• Skin effect: at RF and microwave frequencies current tends to

flow only in the surface of a conductor.

• Skin depth (): depth of penetration at which the magnitude

of the current has decreased to 1/e of the surface value.

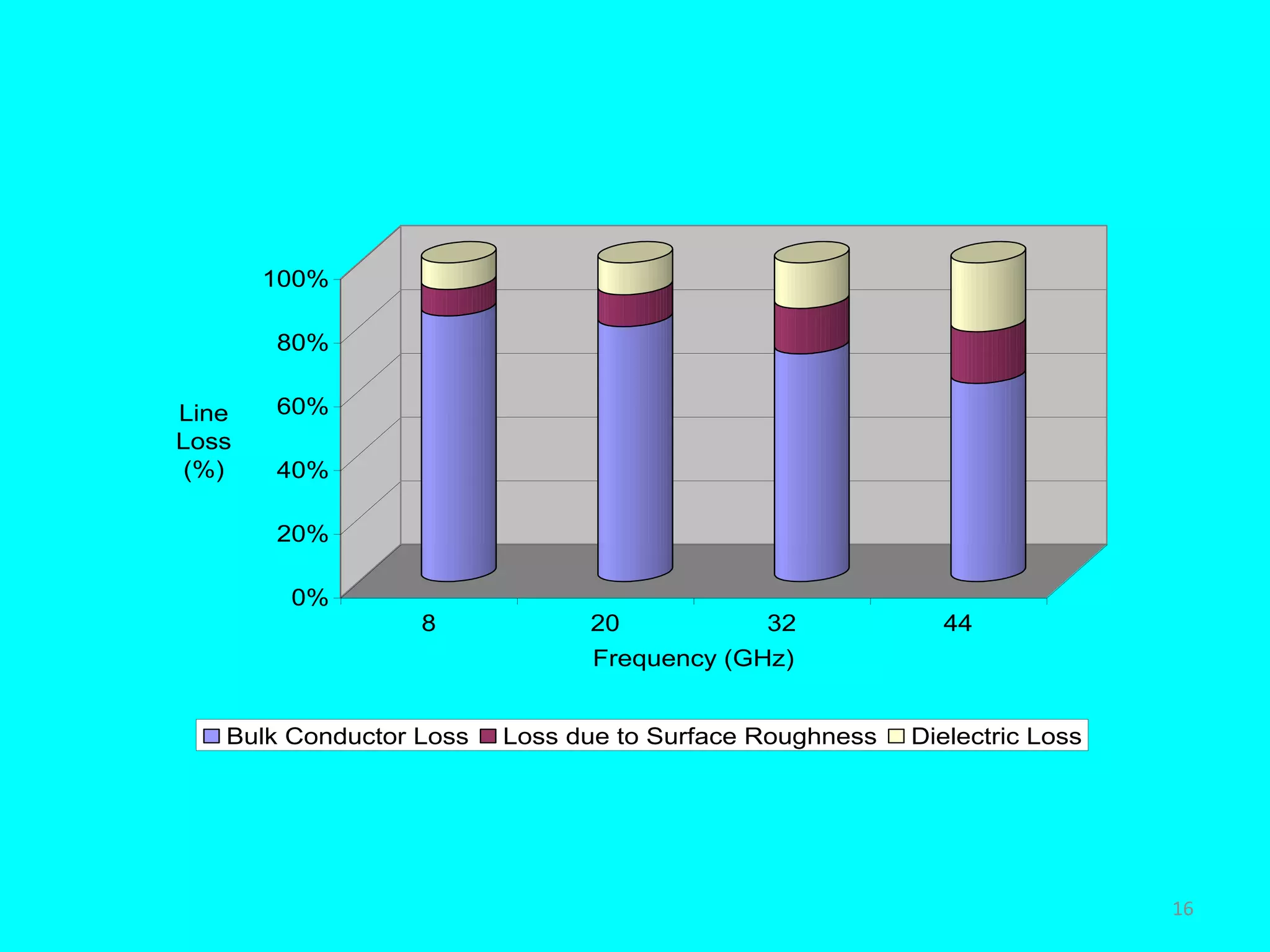

• Effect due to loss tangent on line : - this effect is shown in

figure [1] on next slide.

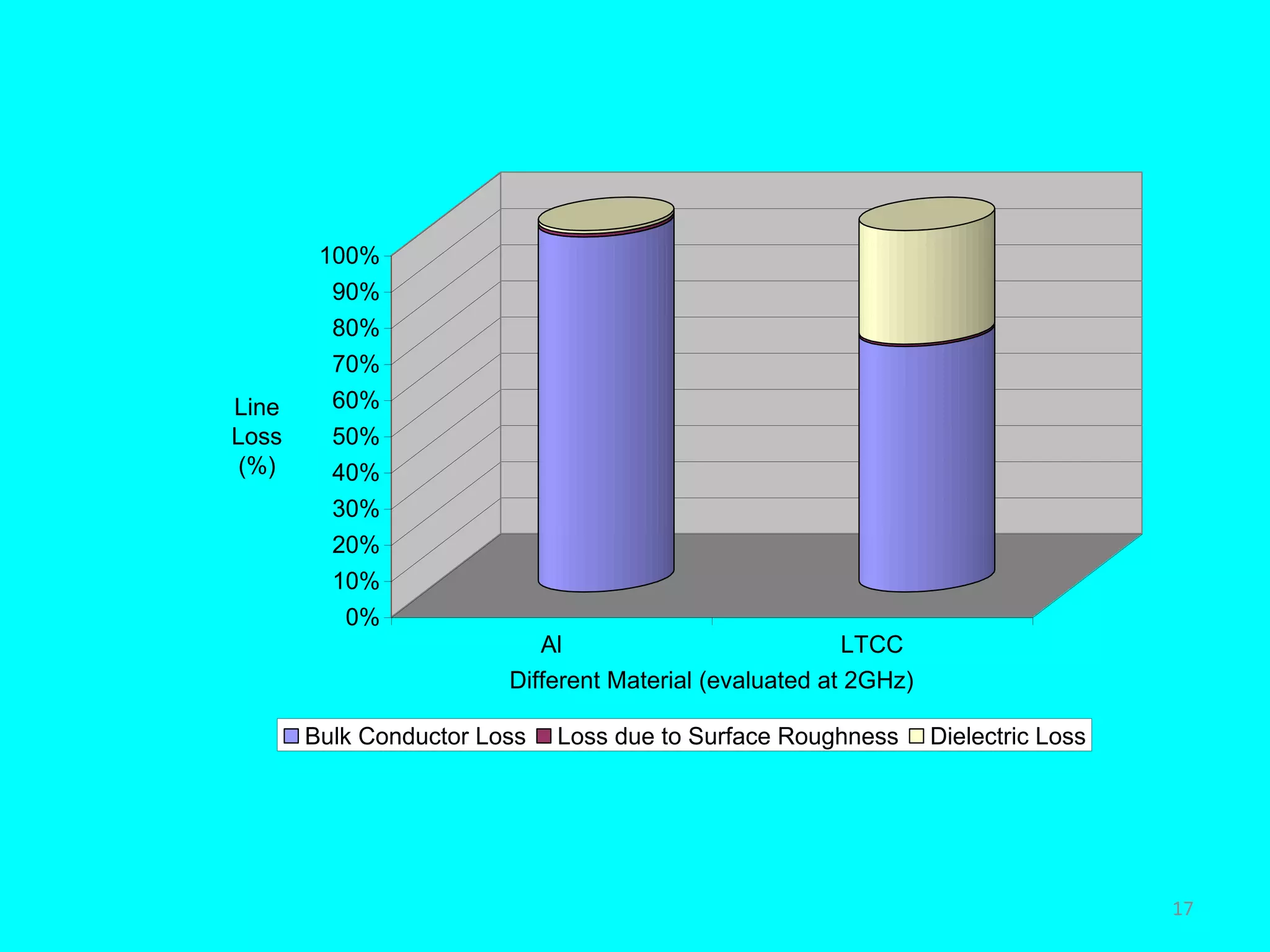

• Effect due to surface roughness:-the roughness on surface

creates a loss,shown in figure [2]

f

1

13](https://image.slidesharecdn.com/thick-filmmultilayermicrowavecircuitsforwirelessapplications-150604084630-lva1-app6891/75/Thick-film-multilayer-microwave-circuits-for-wireless-applications-13-2048.jpg)

![Figure [1]-Effect of loss tangent on line

14](https://image.slidesharecdn.com/thick-filmmultilayermicrowavecircuitsforwirelessapplications-150604084630-lva1-app6891/75/Thick-film-multilayer-microwave-circuits-for-wireless-applications-14-2048.jpg)

![0

0.005

0.01

0.015

0.02

0.025

0.03

0.035

0.04

0.045

0 10 20 30 40 50

Frequency (GHz)

Lineloss(dB/mm)

RGH=0.5

RGH=0.2

RGH=0.1

RGH=0

Figure [2]-Effect of surface roughness

15](https://image.slidesharecdn.com/thick-filmmultilayermicrowavecircuitsforwirelessapplications-150604084630-lva1-app6891/75/Thick-film-multilayer-microwave-circuits-for-wireless-applications-15-2048.jpg)