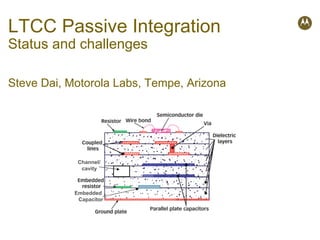

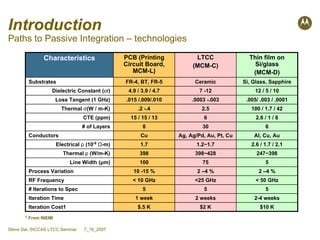

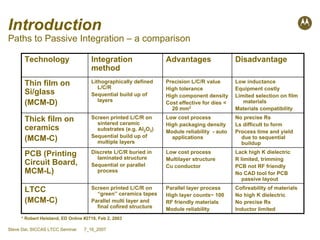

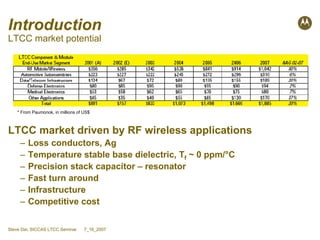

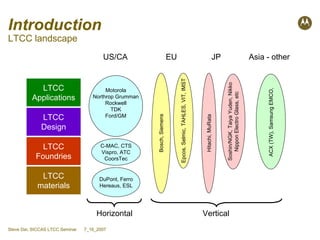

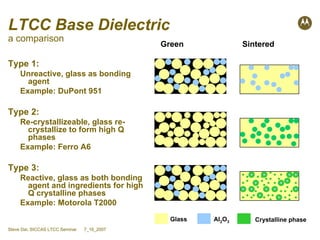

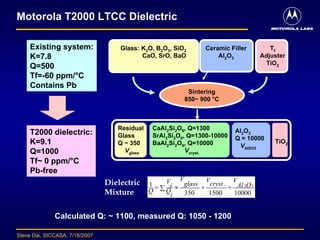

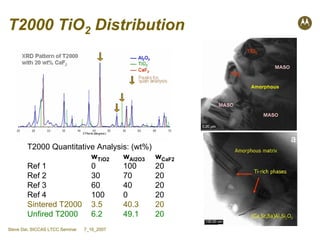

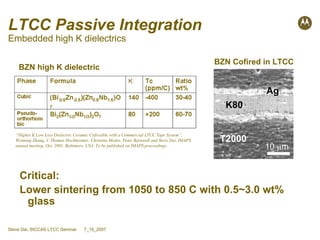

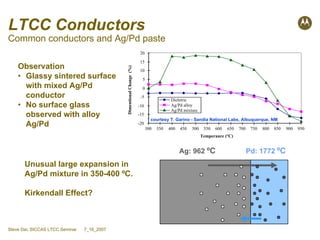

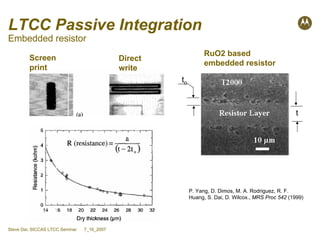

The document discusses LTCC (low temperature co-fired ceramics) passive integration, including challenges. It provides an overview of LTCC materials and processes, comparing LTCC to other integration technologies. Key advantages of LTCC include its parallel layer process, ability to achieve high layer counts up to 100 layers, compatibility with RF-friendly materials, and potential for high component density and module reliability. However, challenges for LTCC include limitations on forming precise resistors and inductors. The document also reviews common LTCC dielectric materials and provides details on Motorola's high-Q T2000 LTCC dielectric composition.