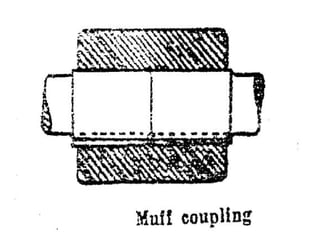

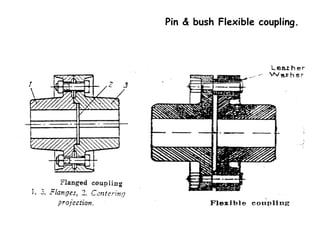

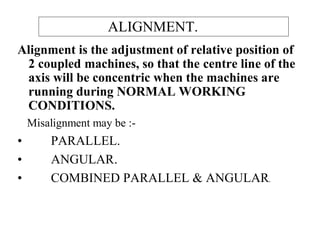

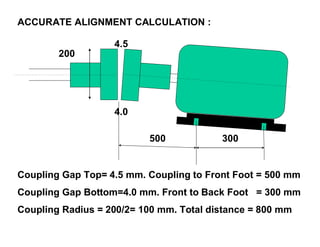

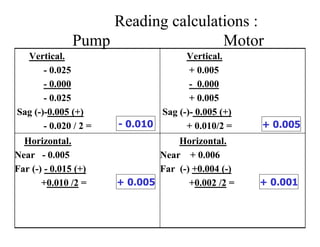

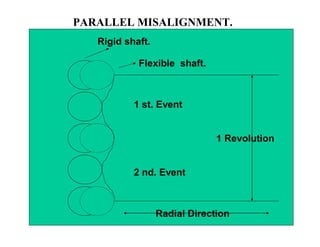

This document discusses shaft couplings and alignment. It describes different types of shaft couplings like flange, sleeve, muff couplings. It discusses the requirements of good shaft couplings and problems that can occur in couplings. The document also covers alignment of shafts, methods to detect and correct misalignment like soft foot. It describes different alignment methods including dial gauge, reverse indicator and laser alignment. It discusses the effects of misalignment on vibration and characteristics to identify different types of misalignments.