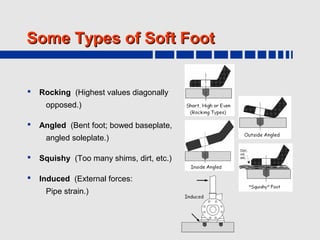

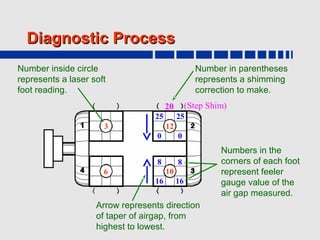

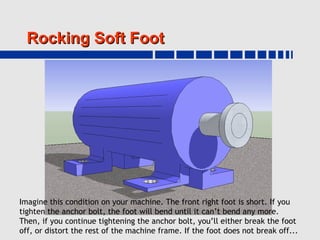

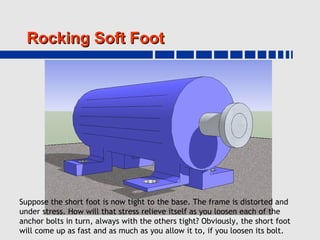

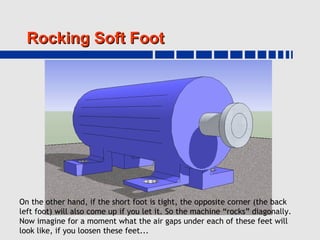

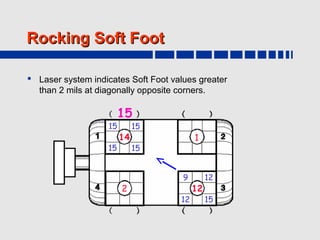

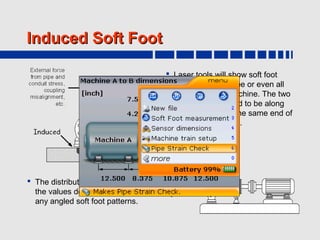

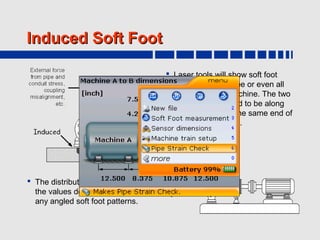

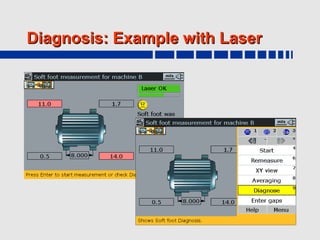

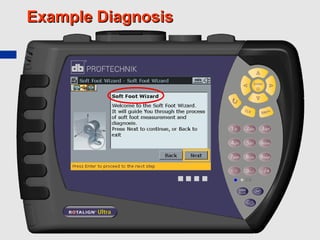

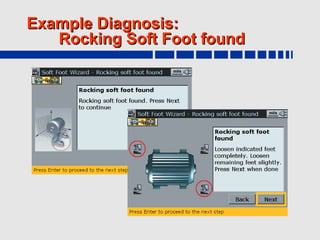

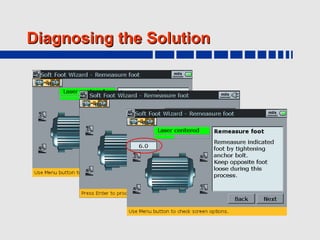

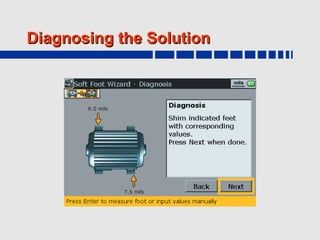

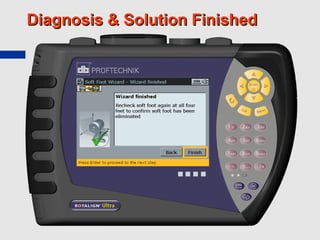

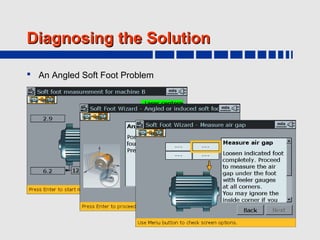

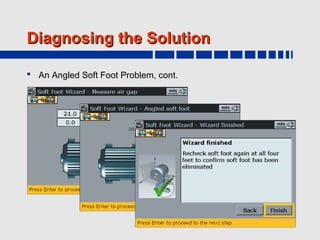

The document discusses soft foot diagnosis and correction using laser alignment tools. It describes different types of soft foot issues like rocking, angled, and induced soft foot. Rocking soft foot has higher values at diagonally opposed corners. The document shows an example of diagnosing and correcting a rocking soft foot issue using laser measurement values and suggested shim corrections. It emphasizes that the type of soft foot must be correctly identified to determine the proper correction method. Laser tools can accurately detect and diagnose soft foot issues to expedite the correction process.