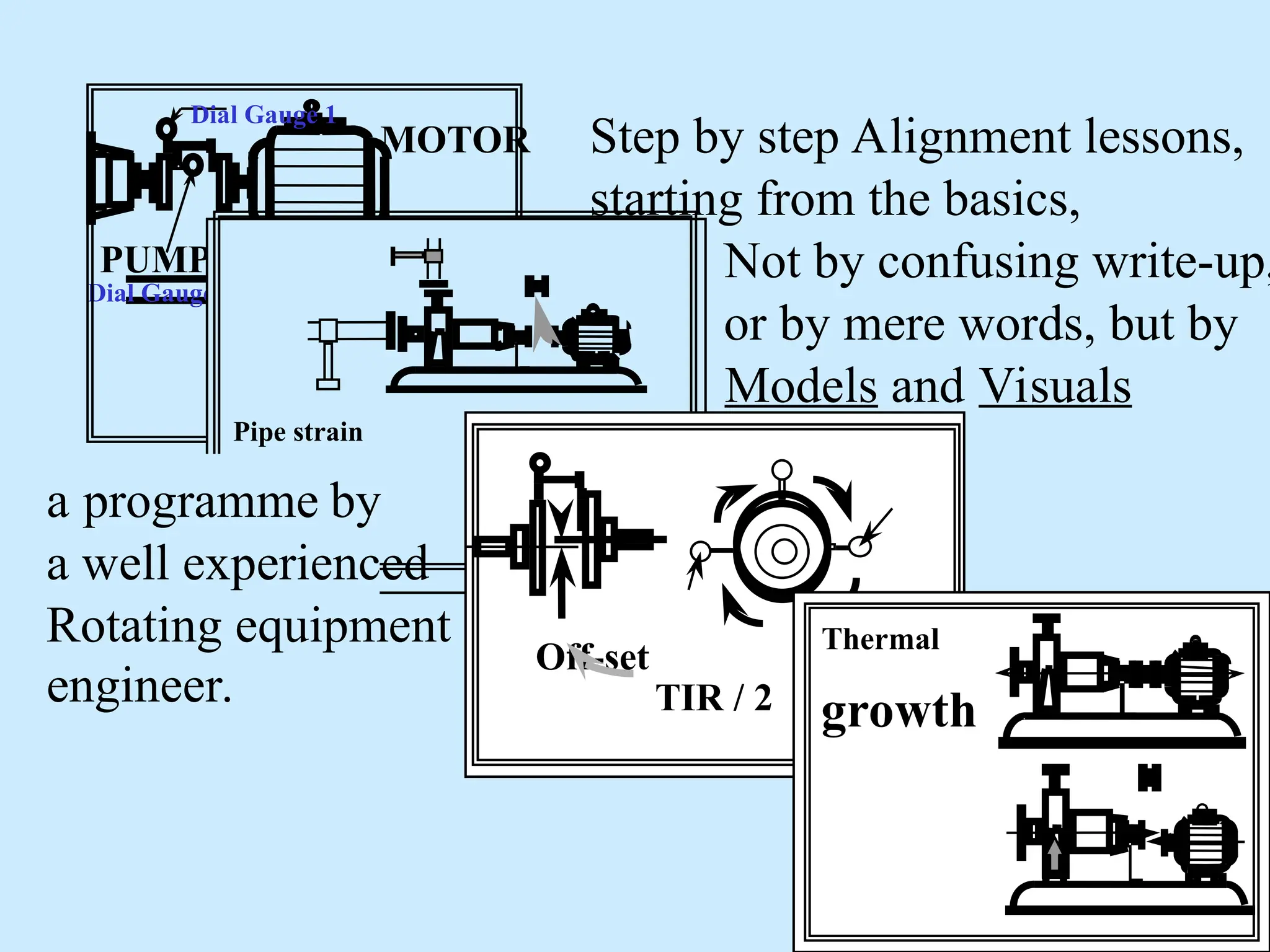

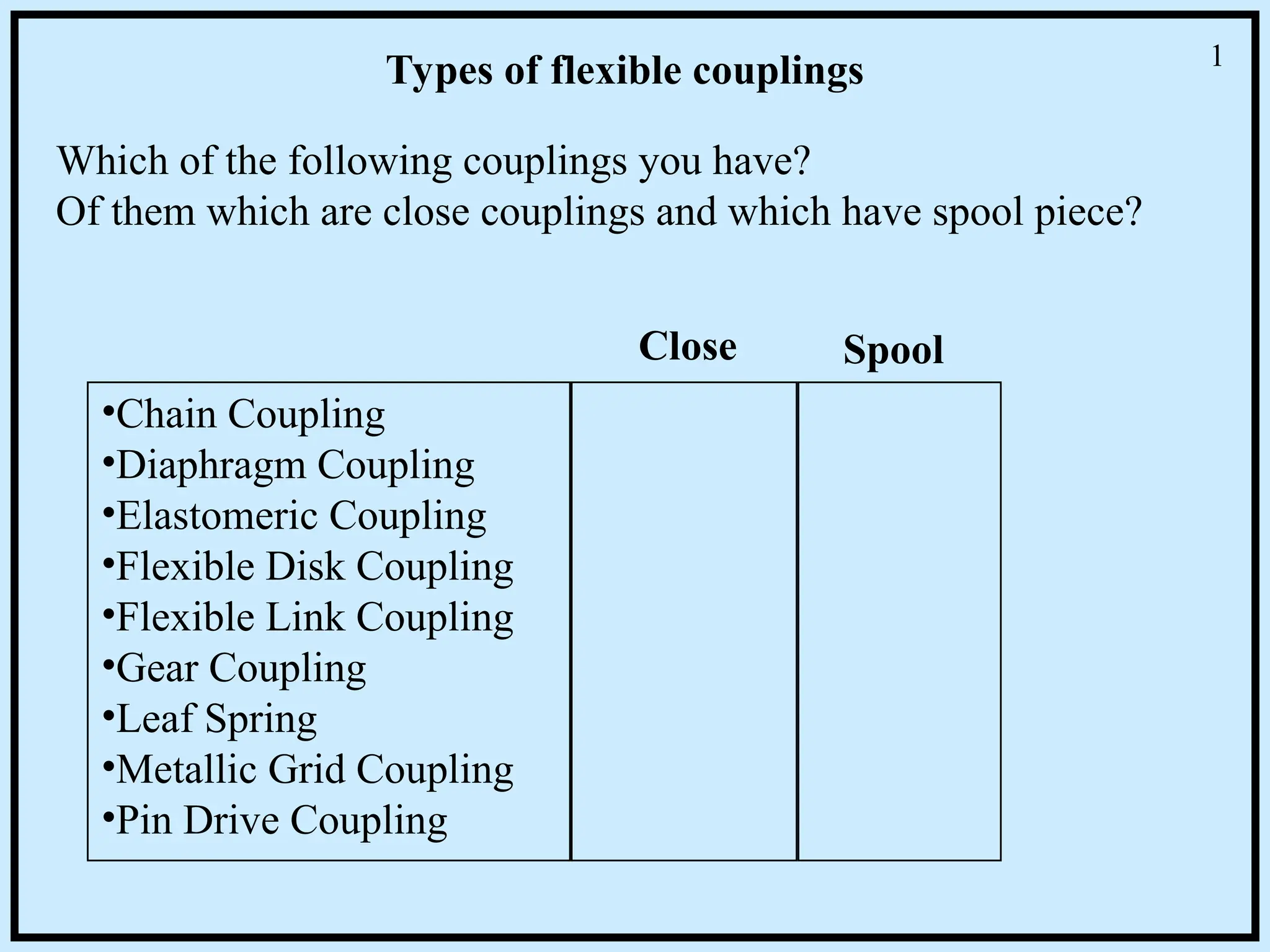

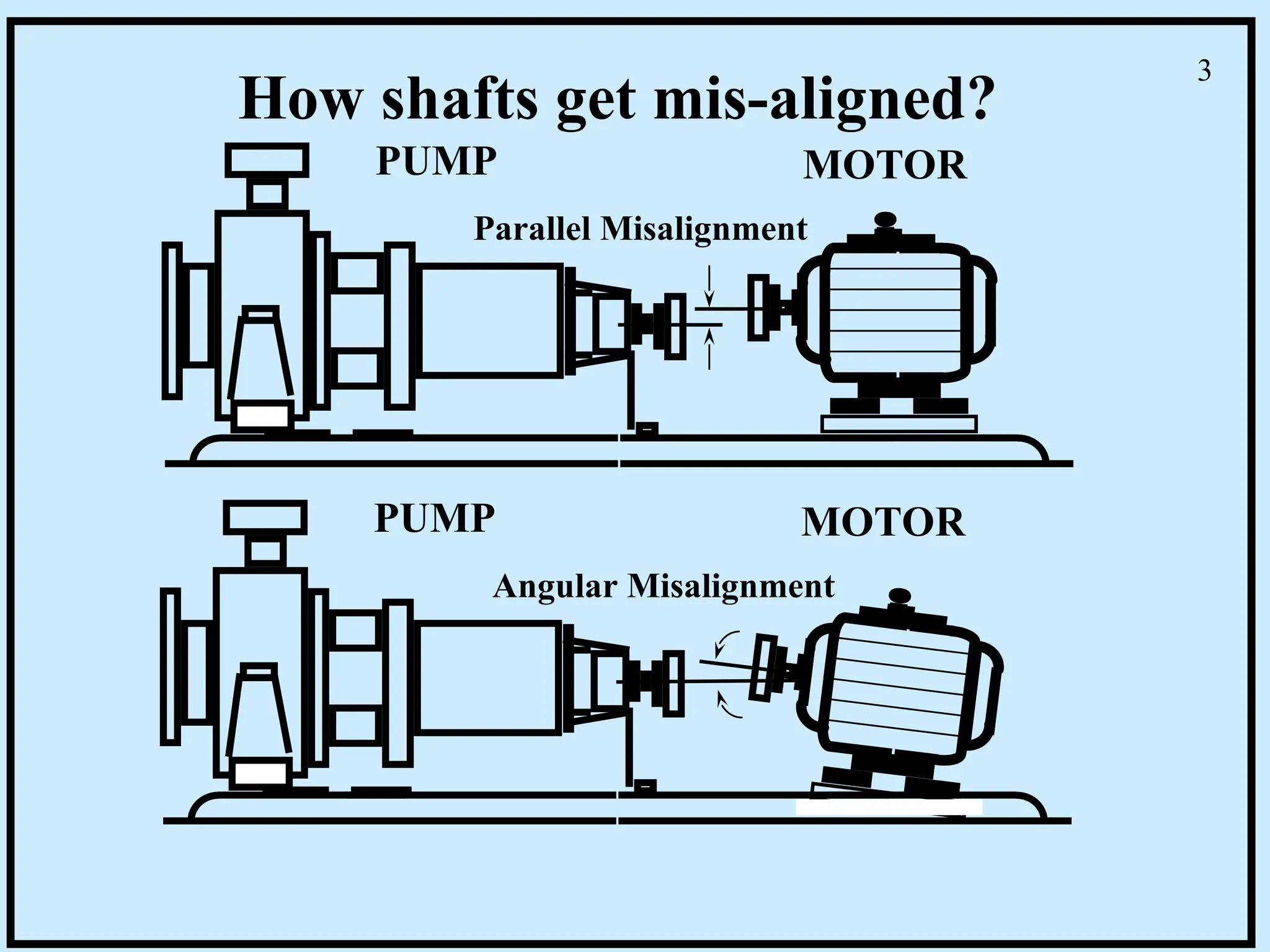

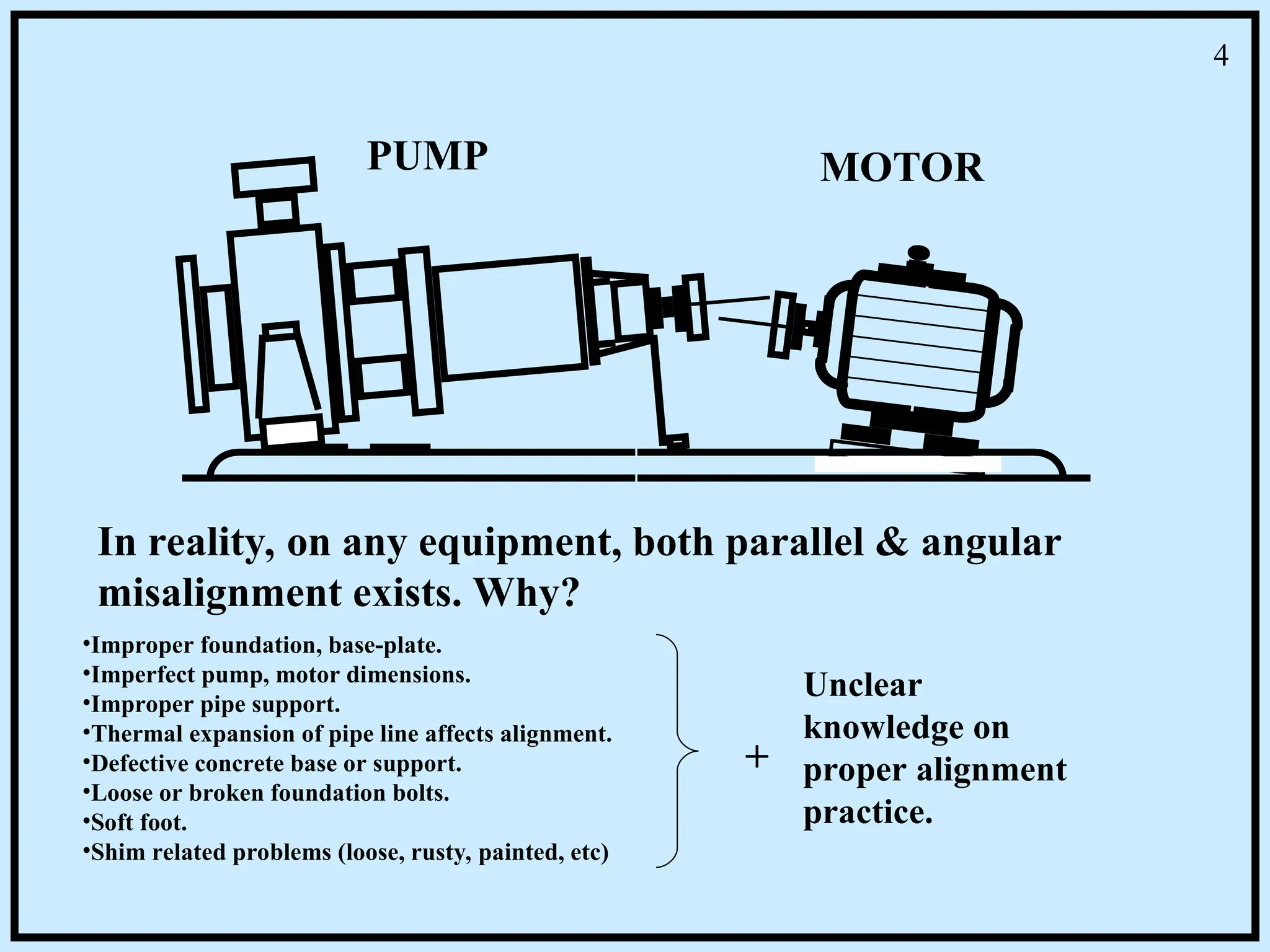

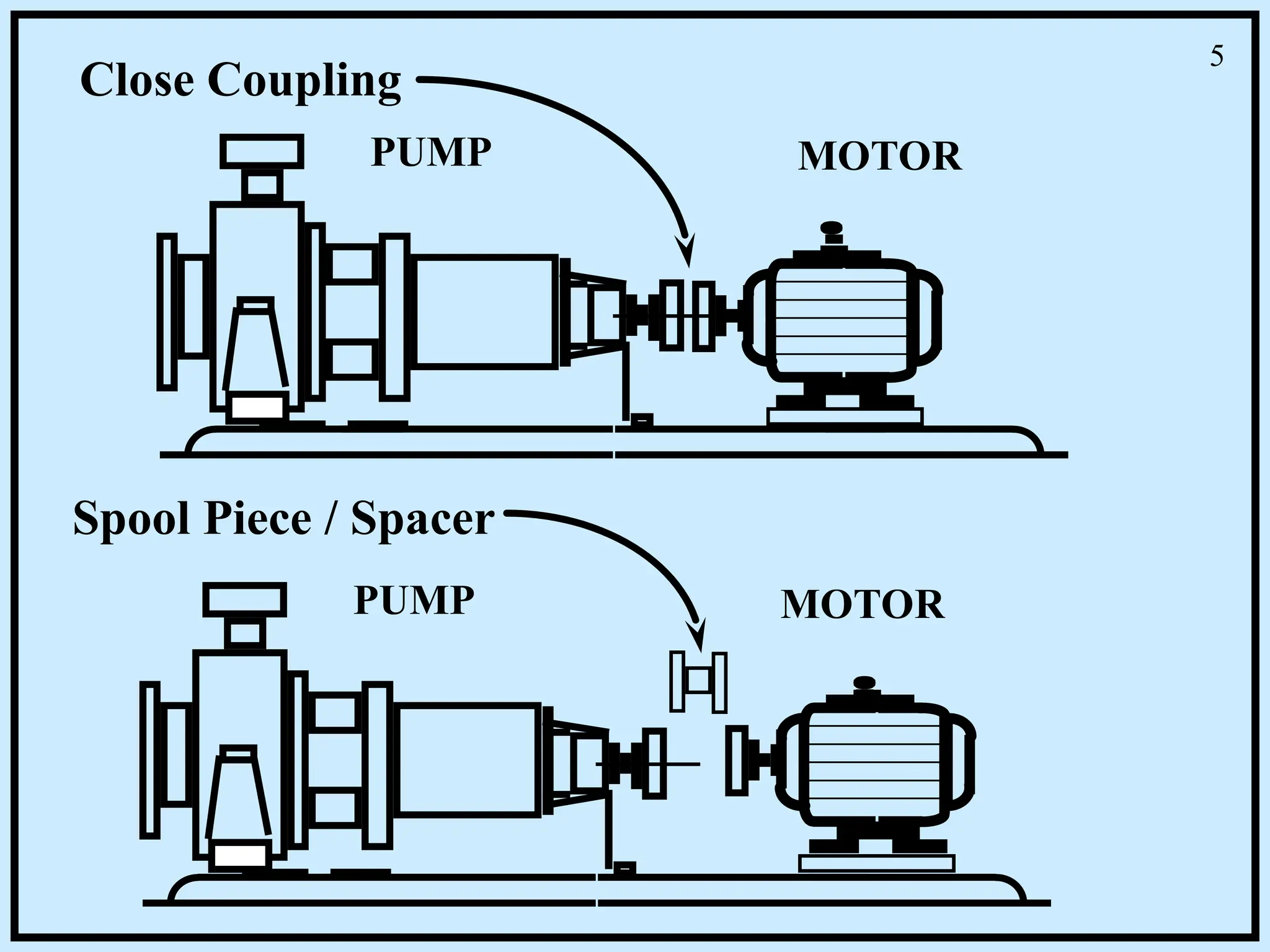

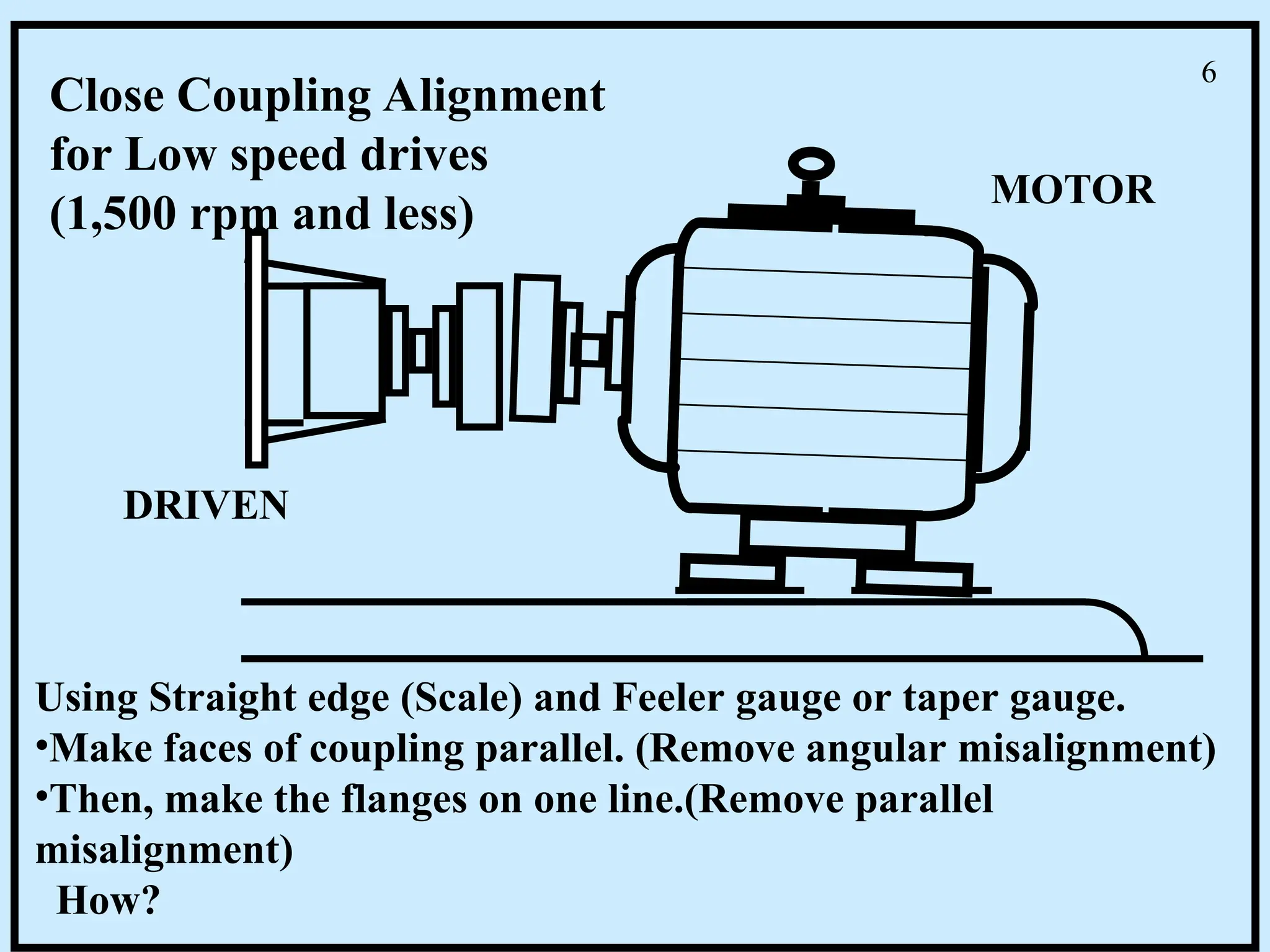

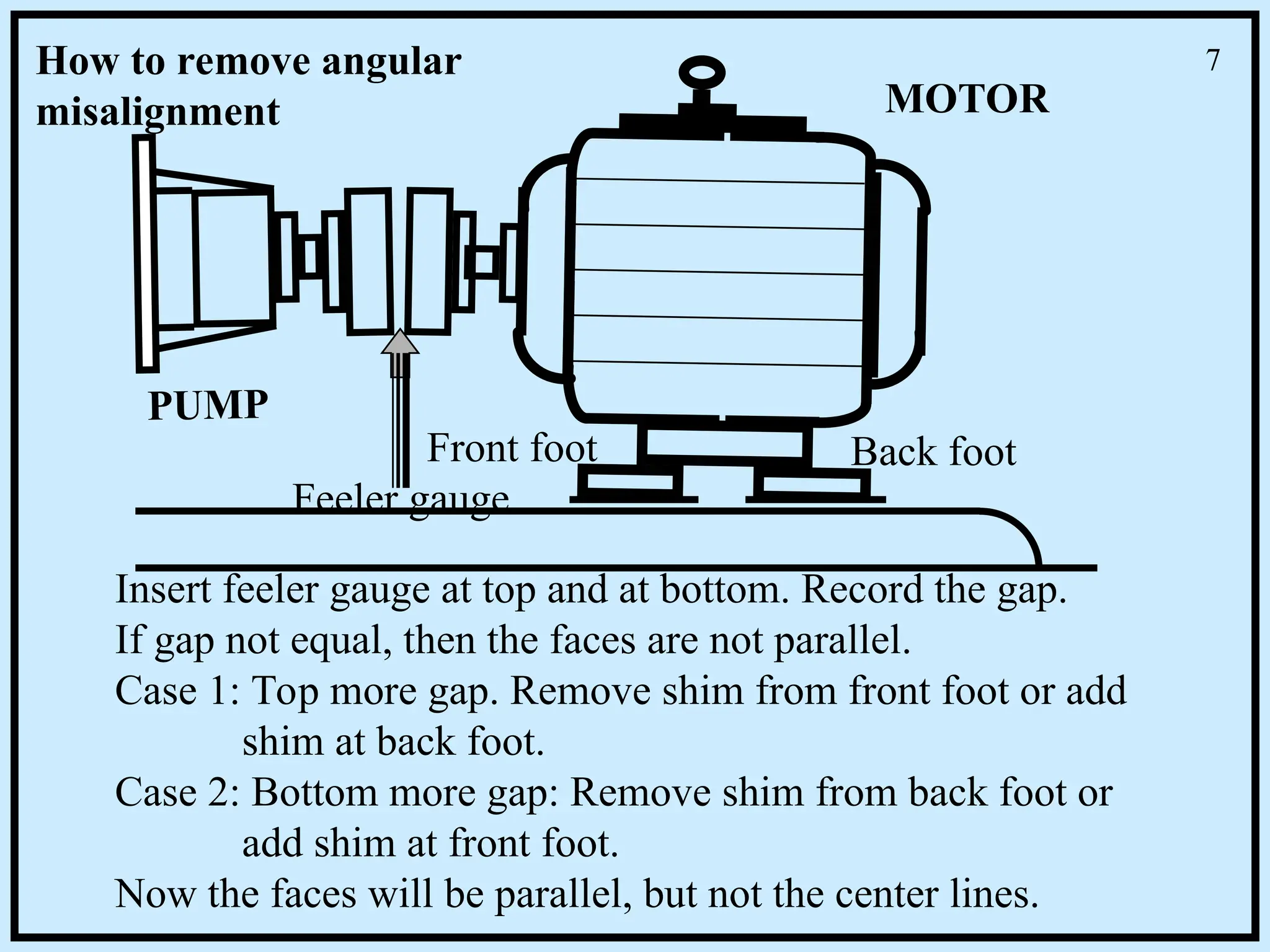

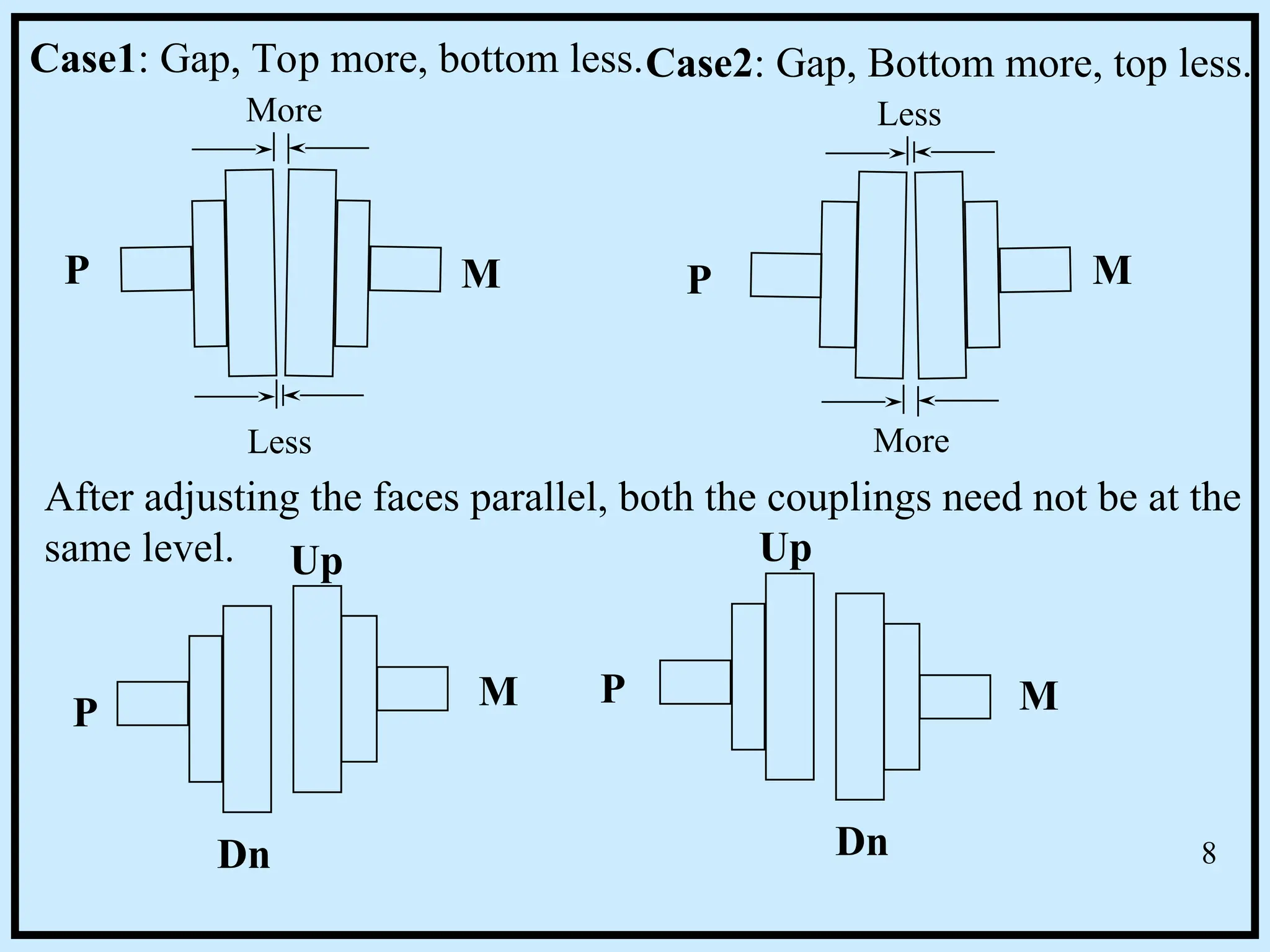

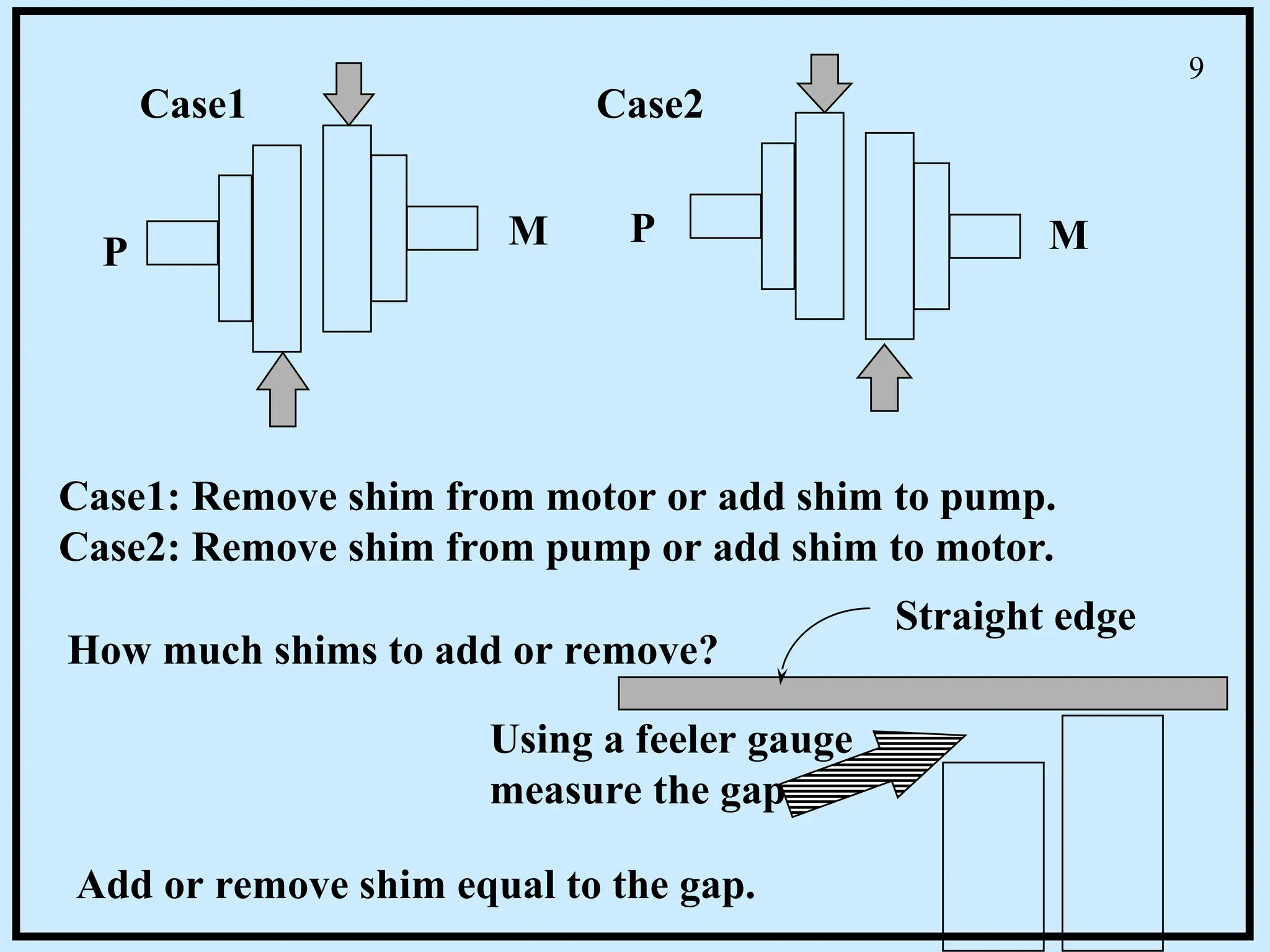

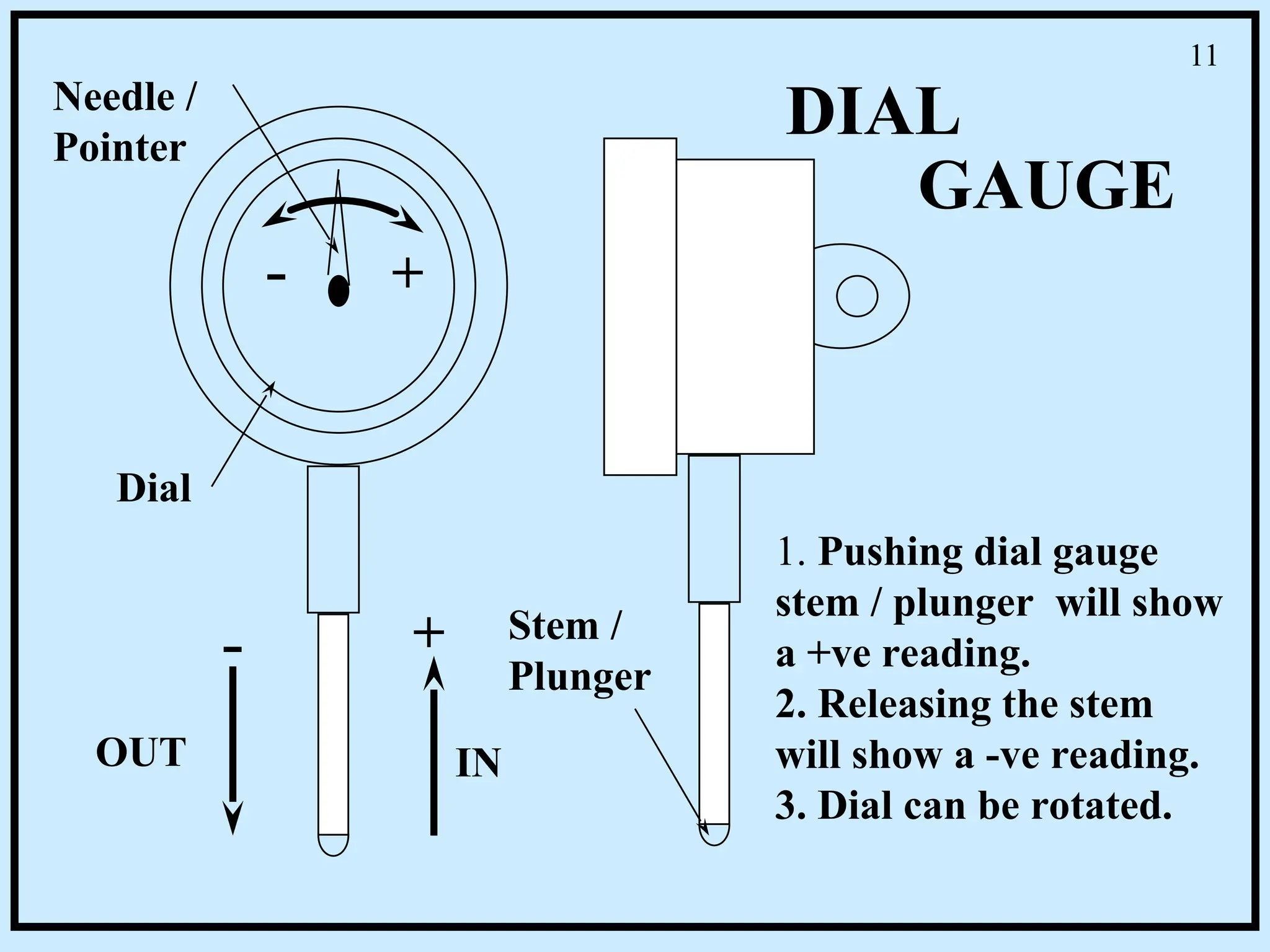

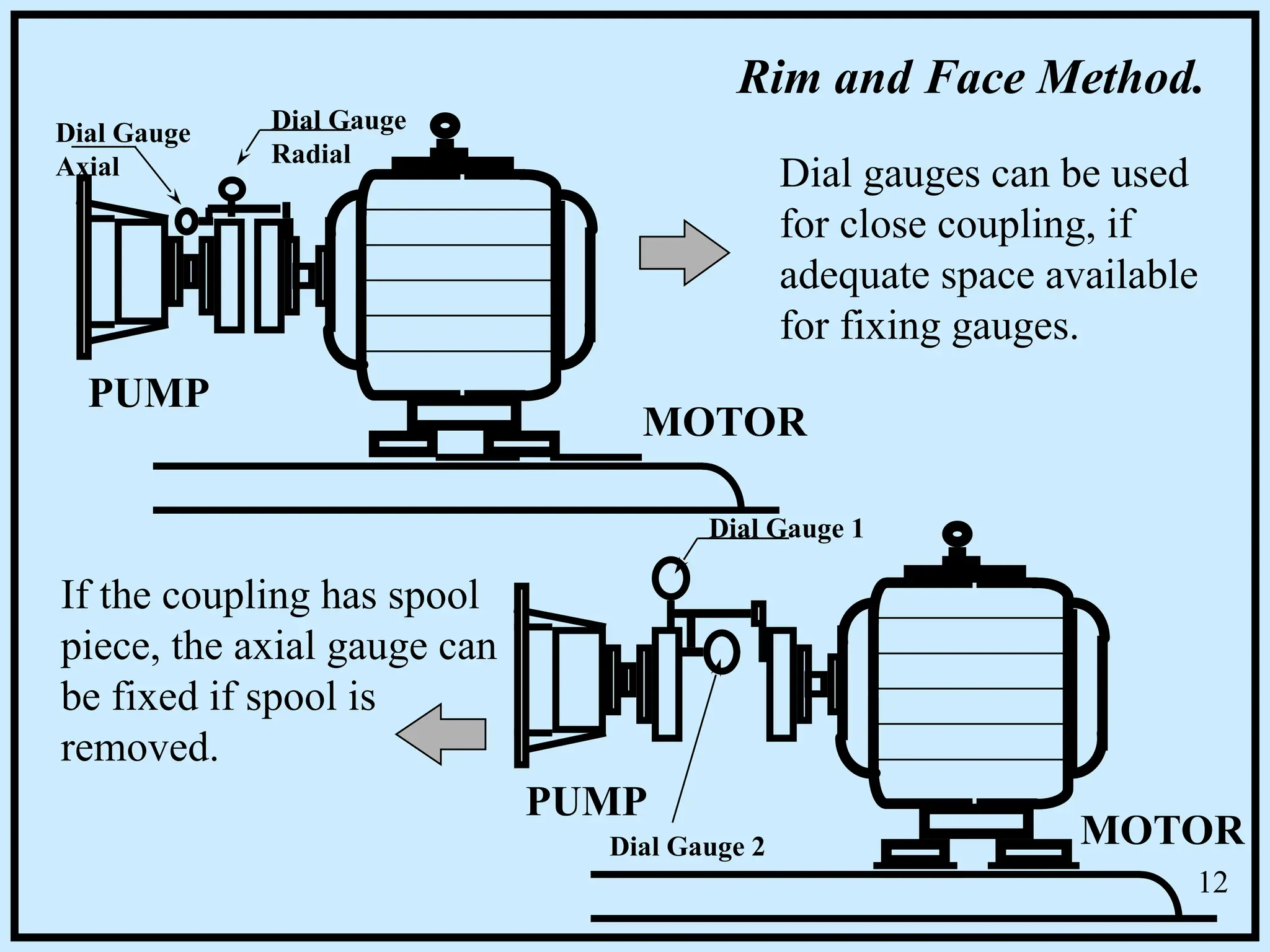

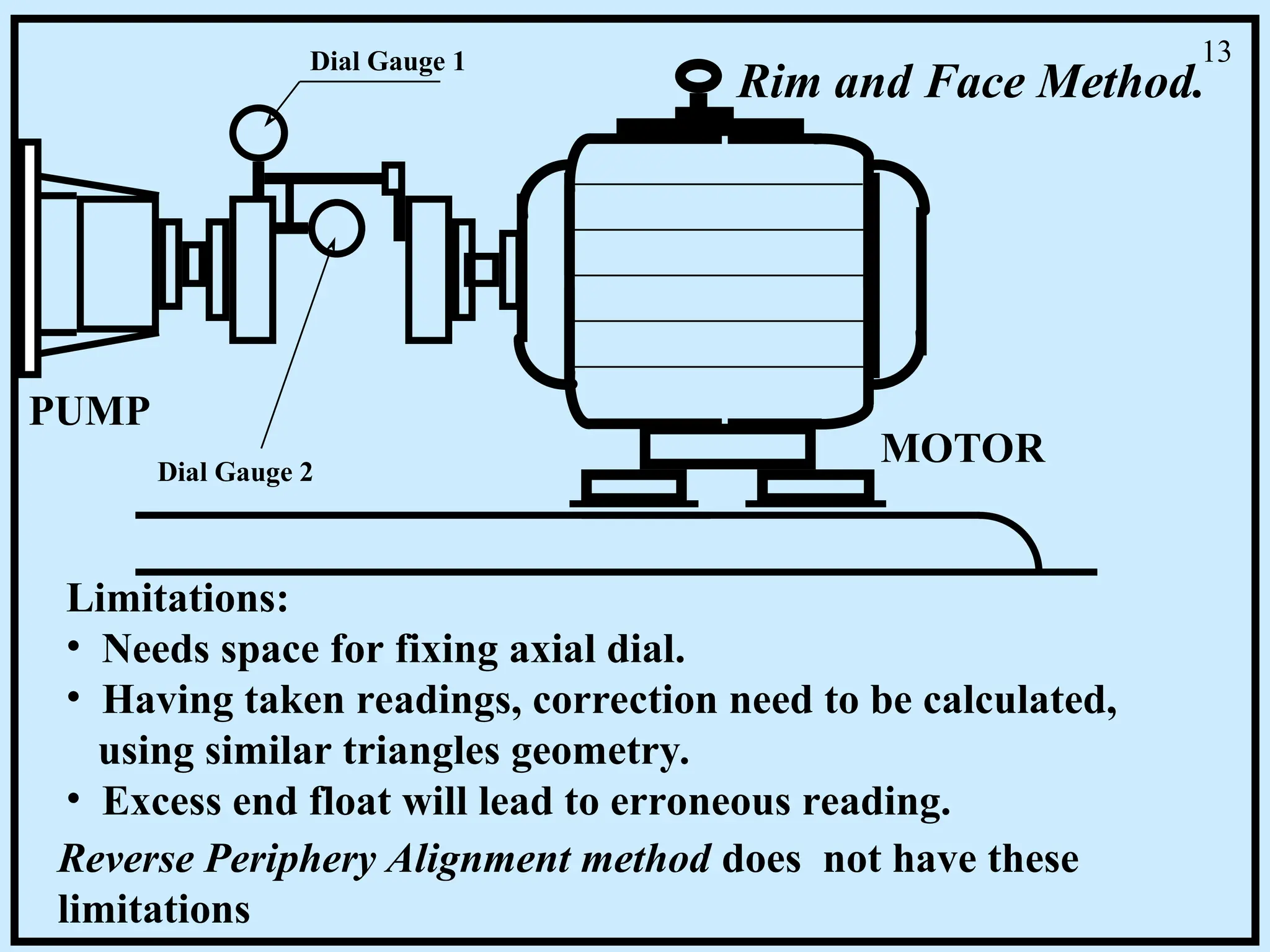

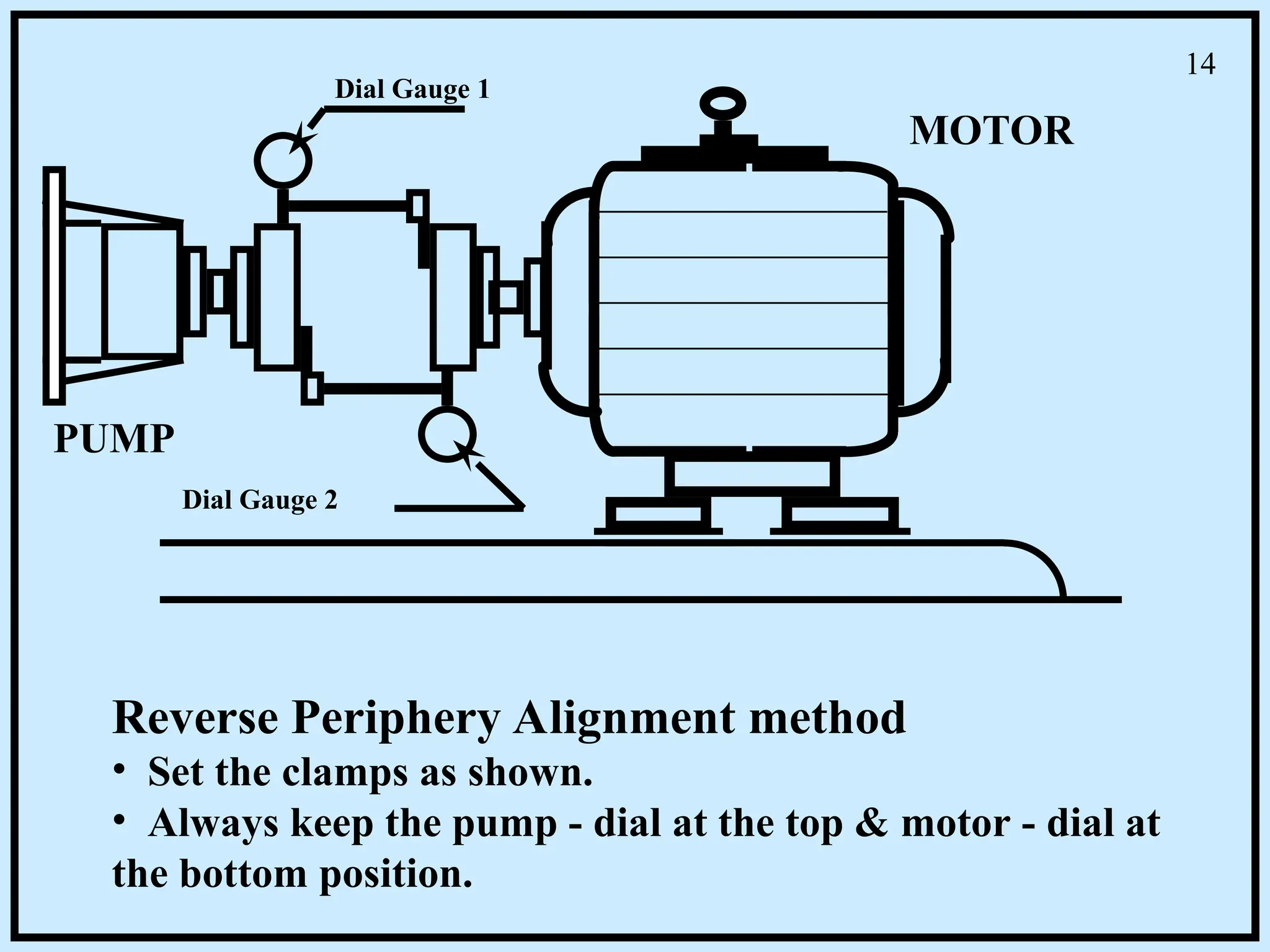

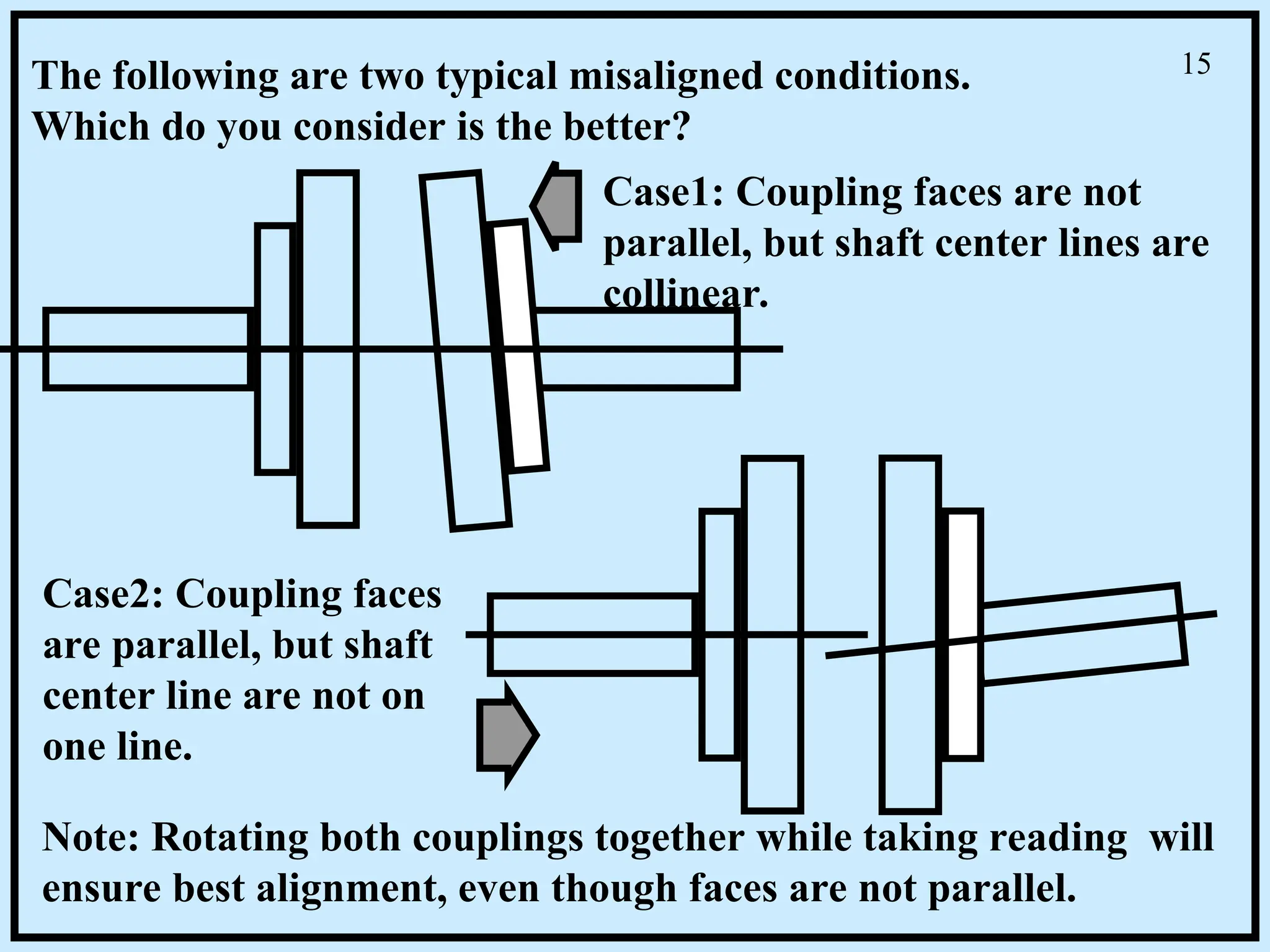

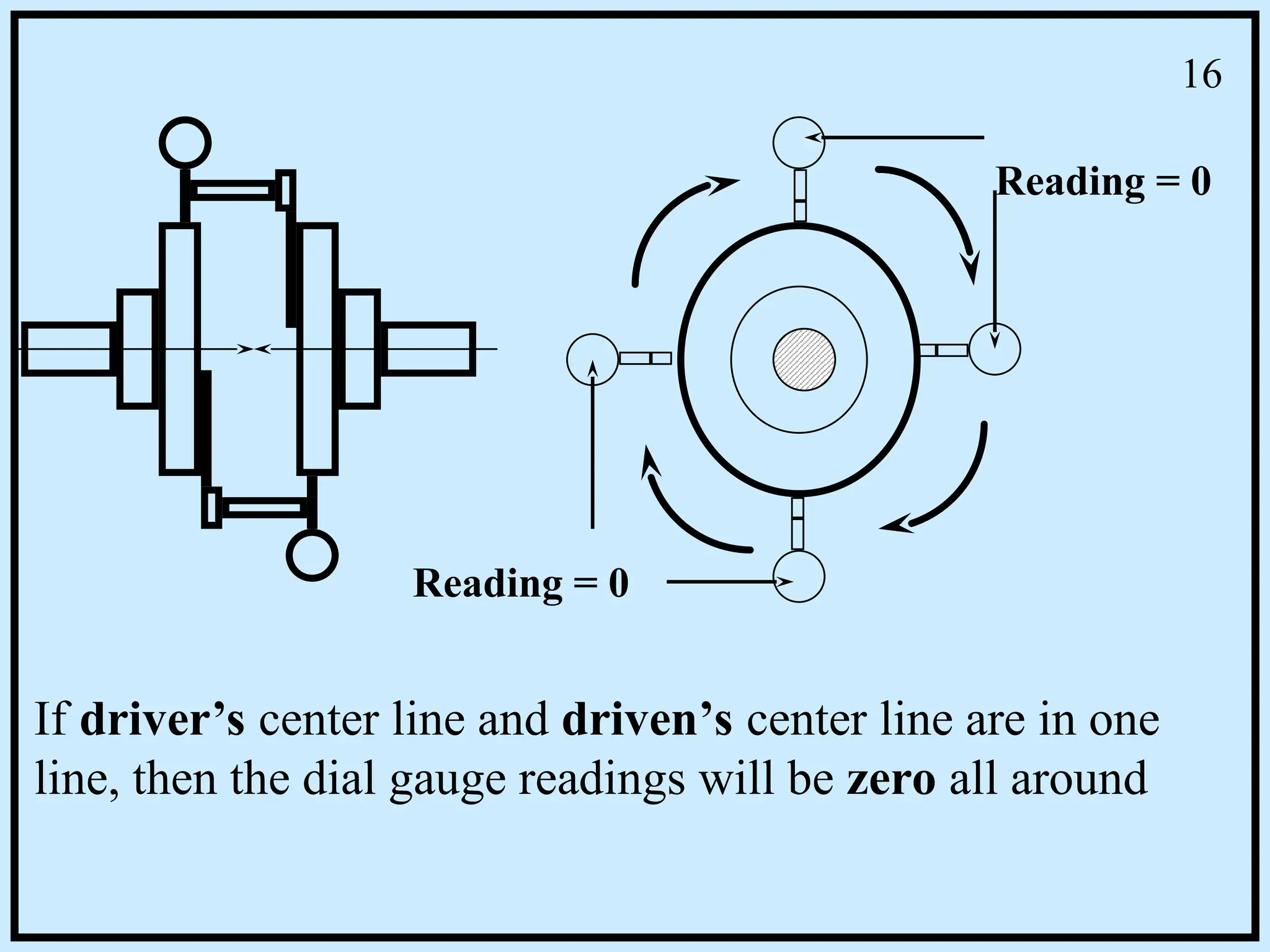

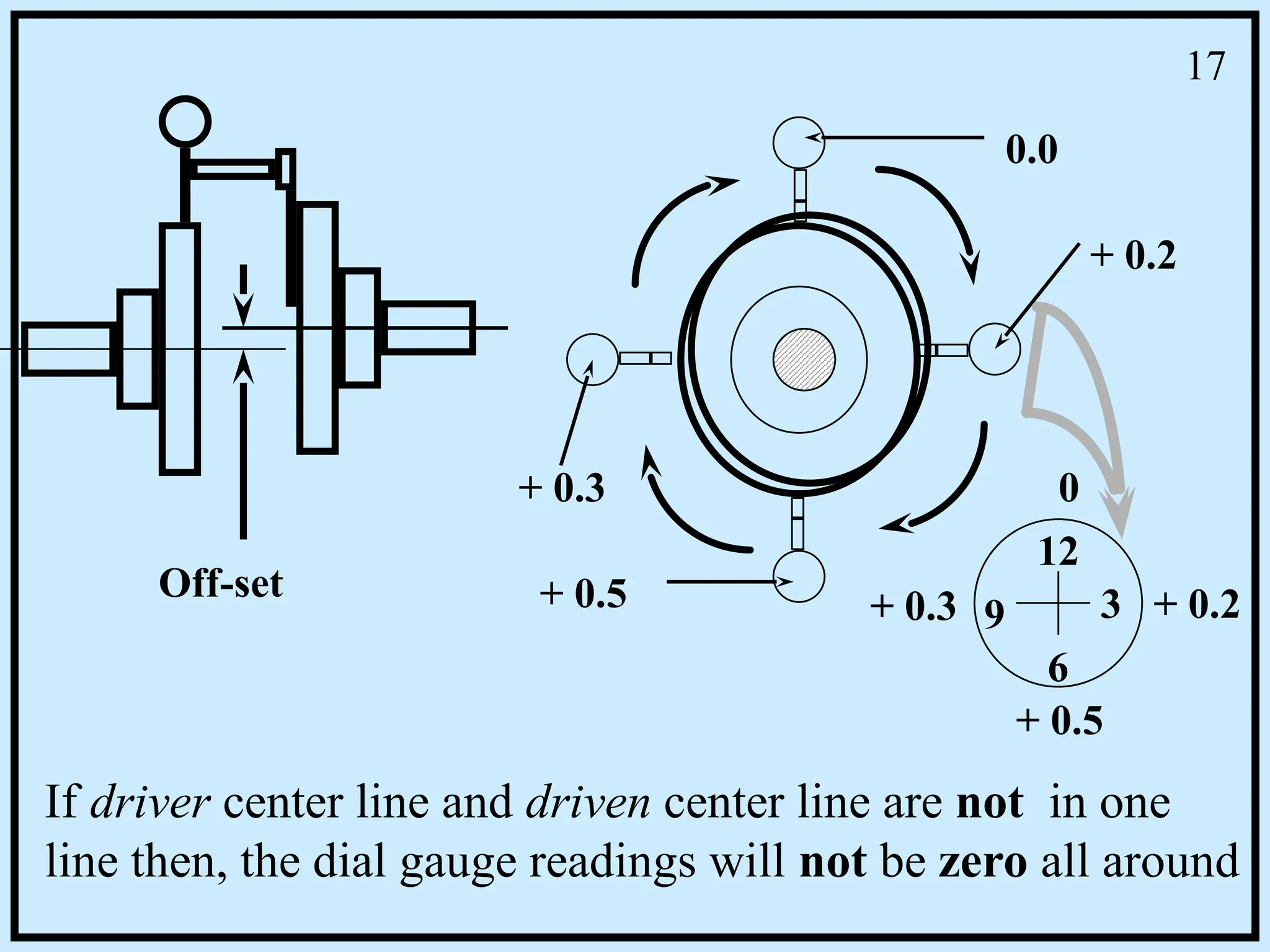

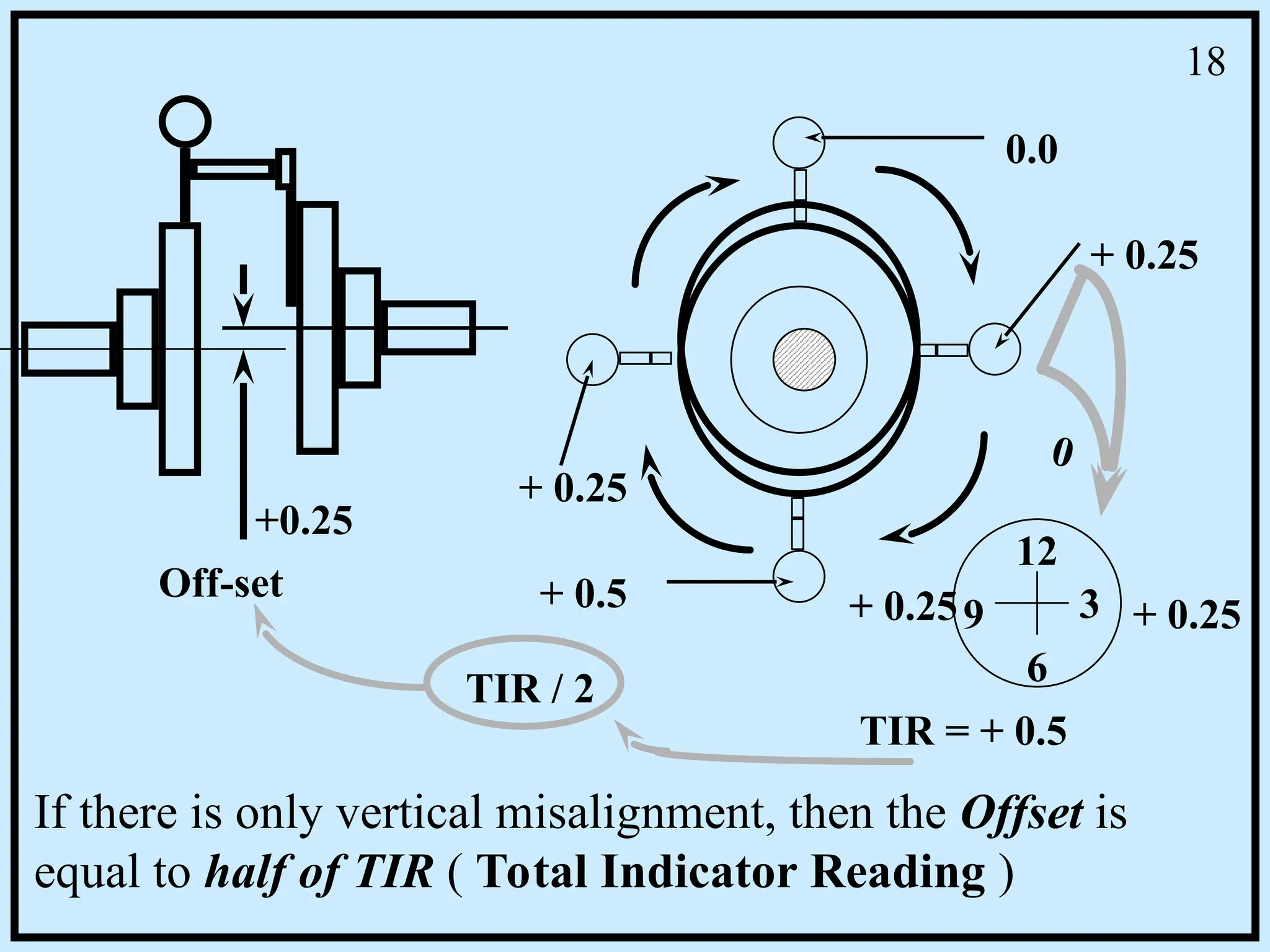

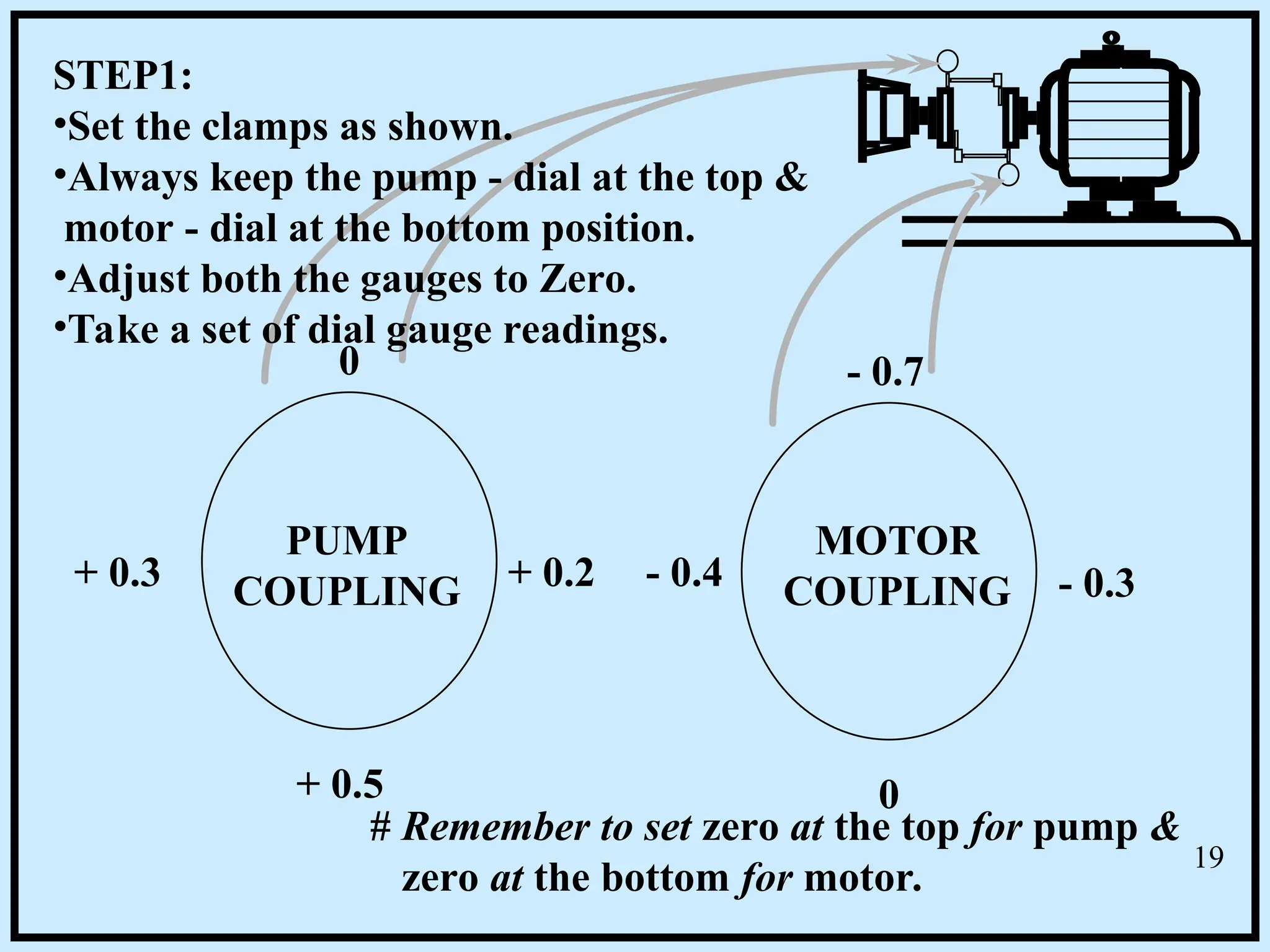

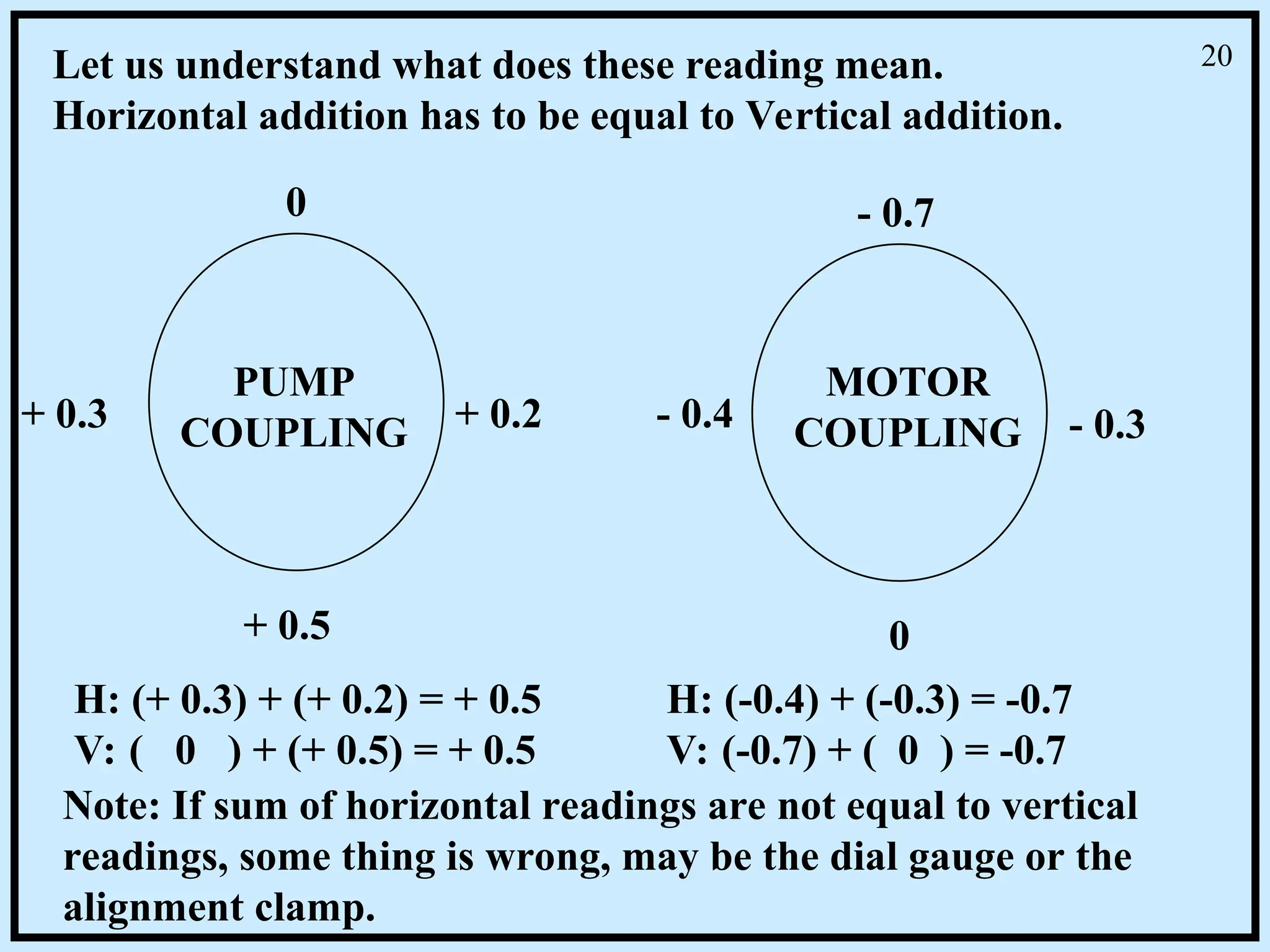

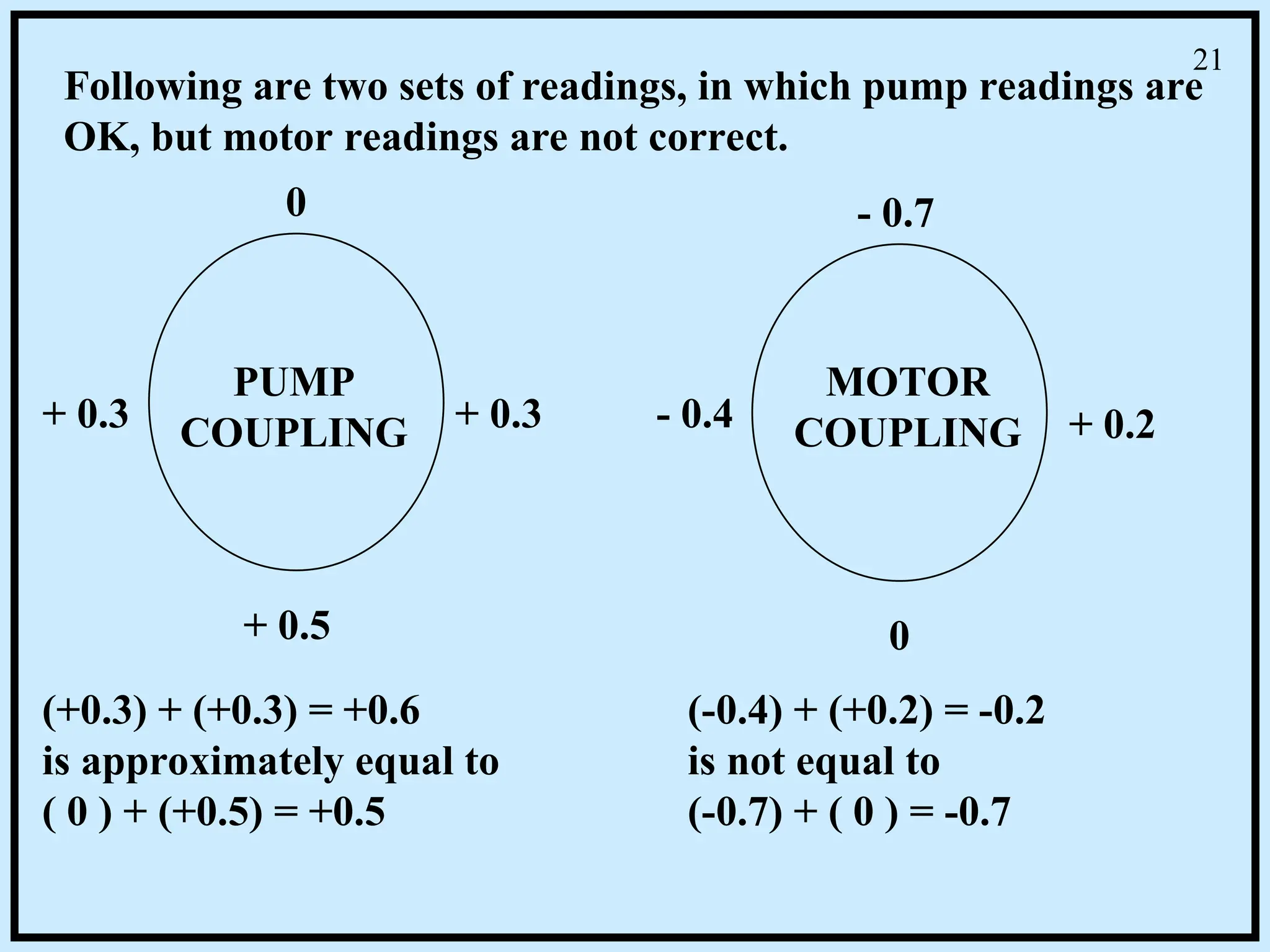

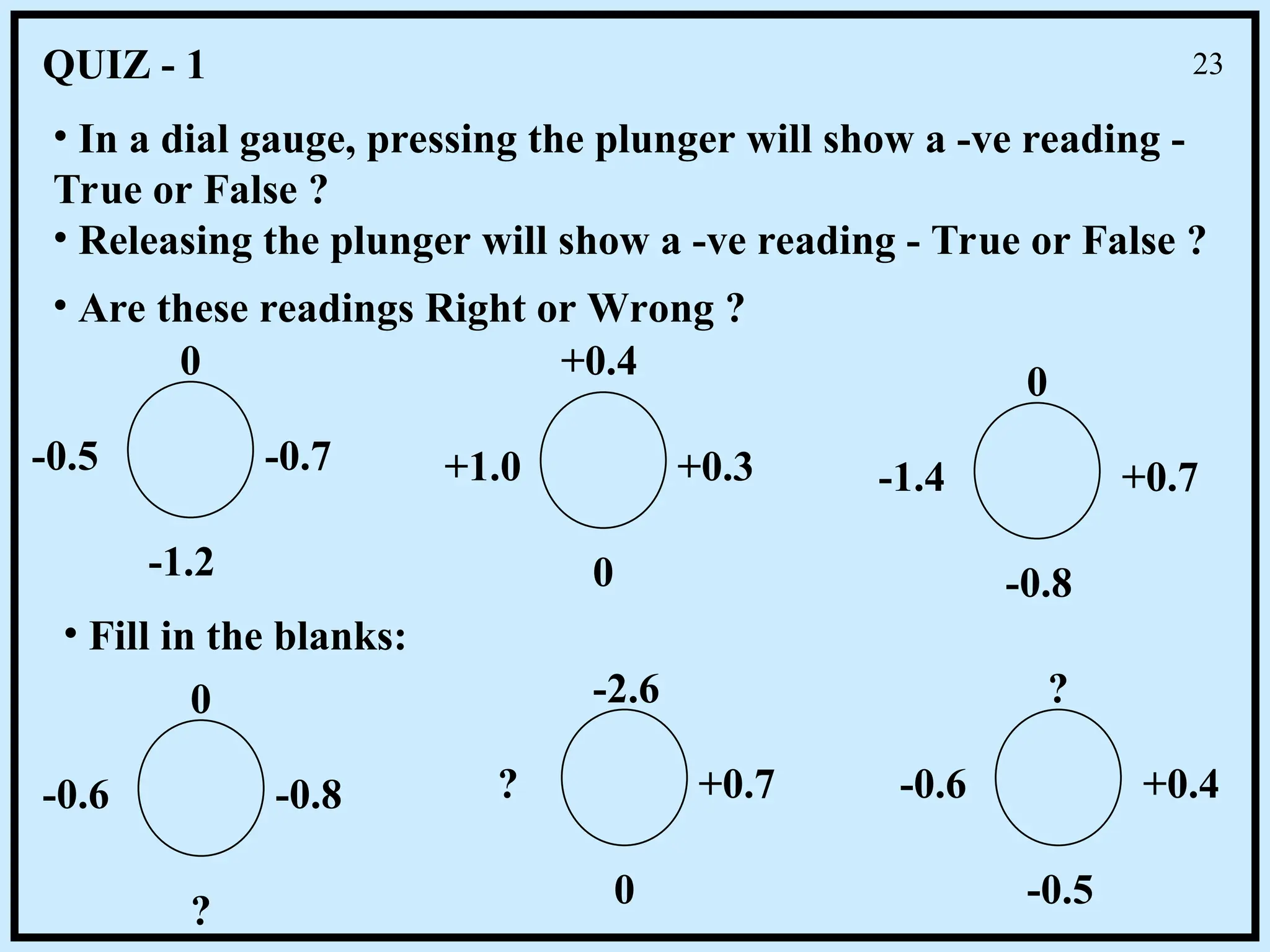

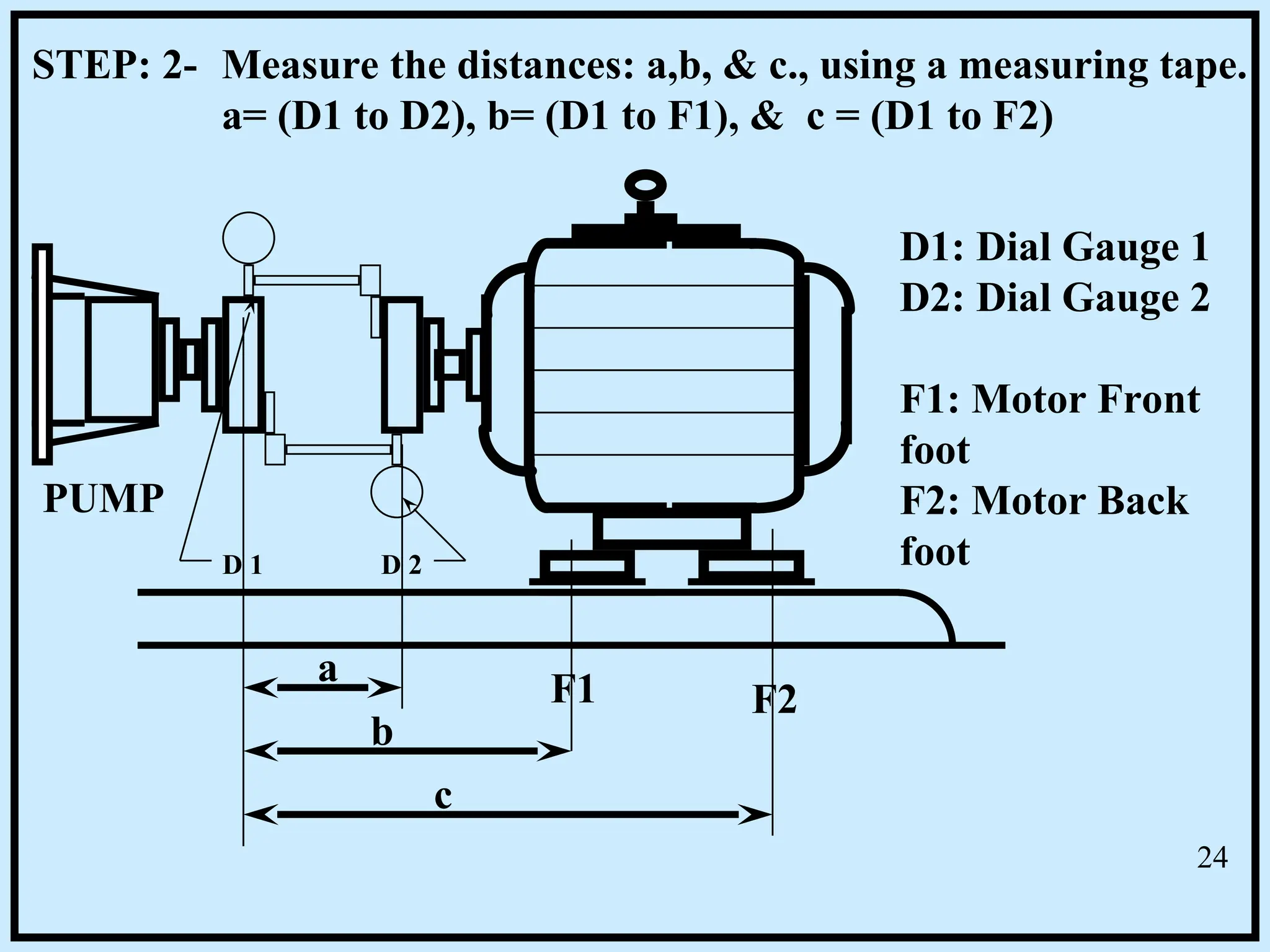

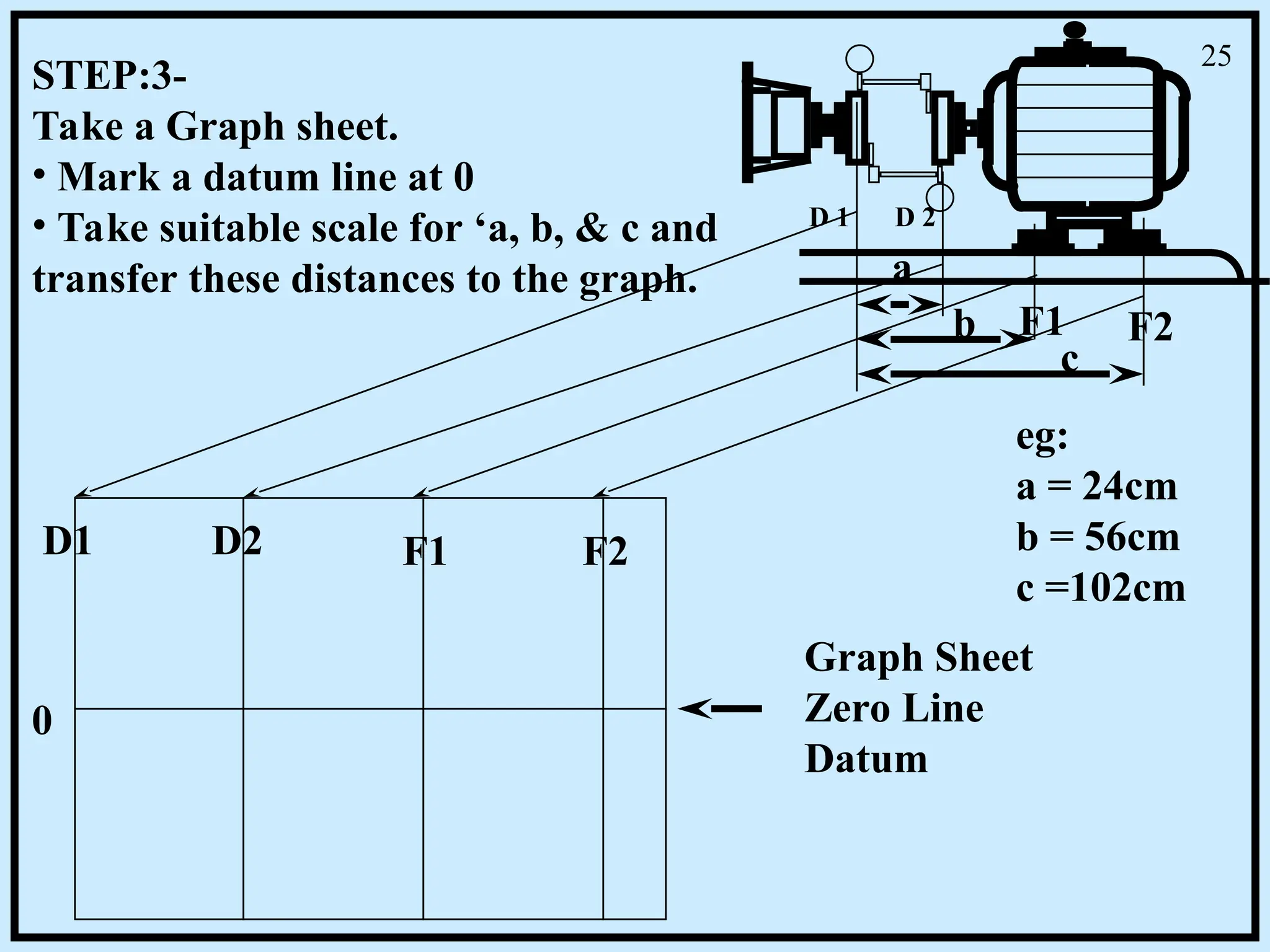

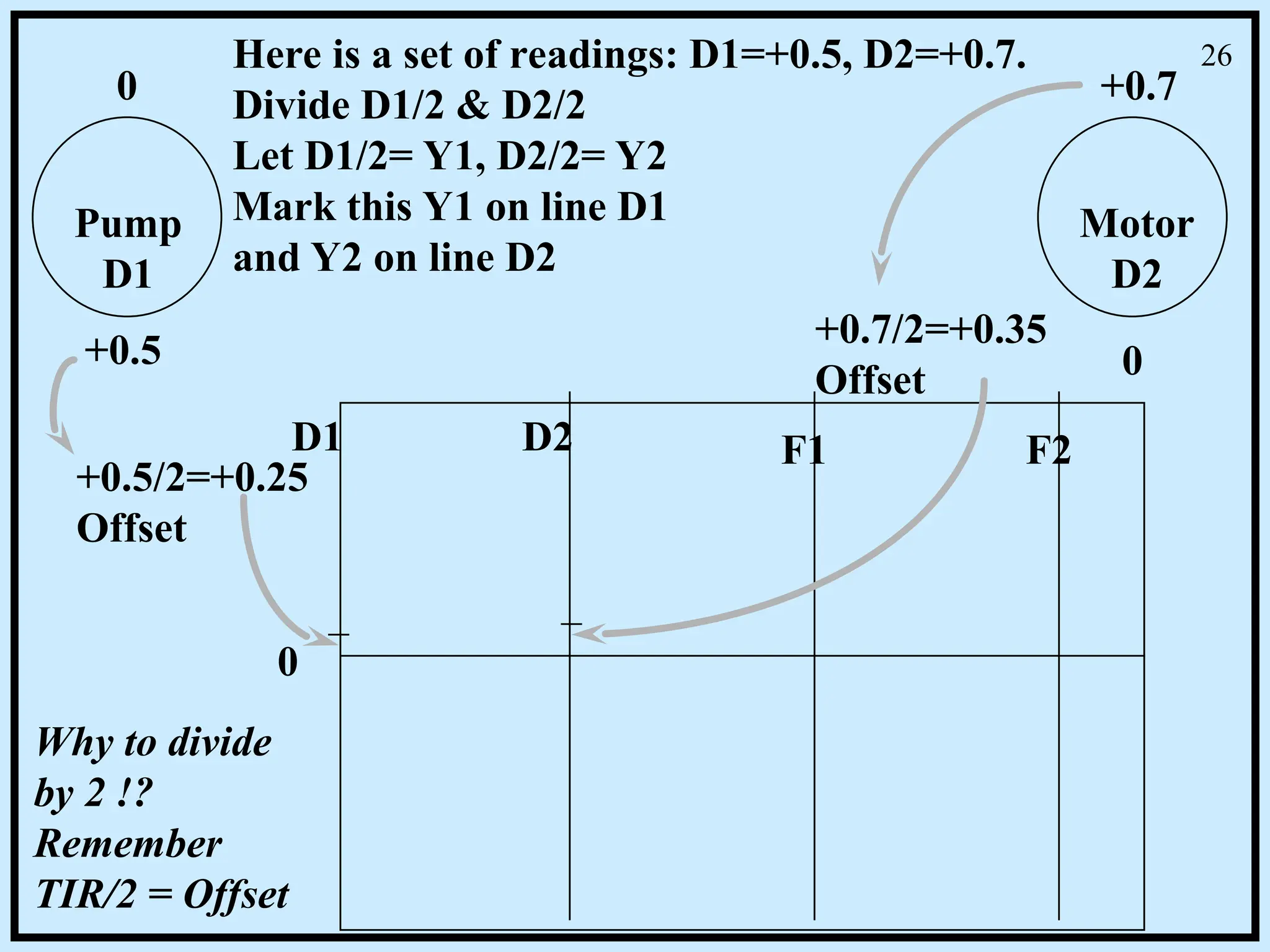

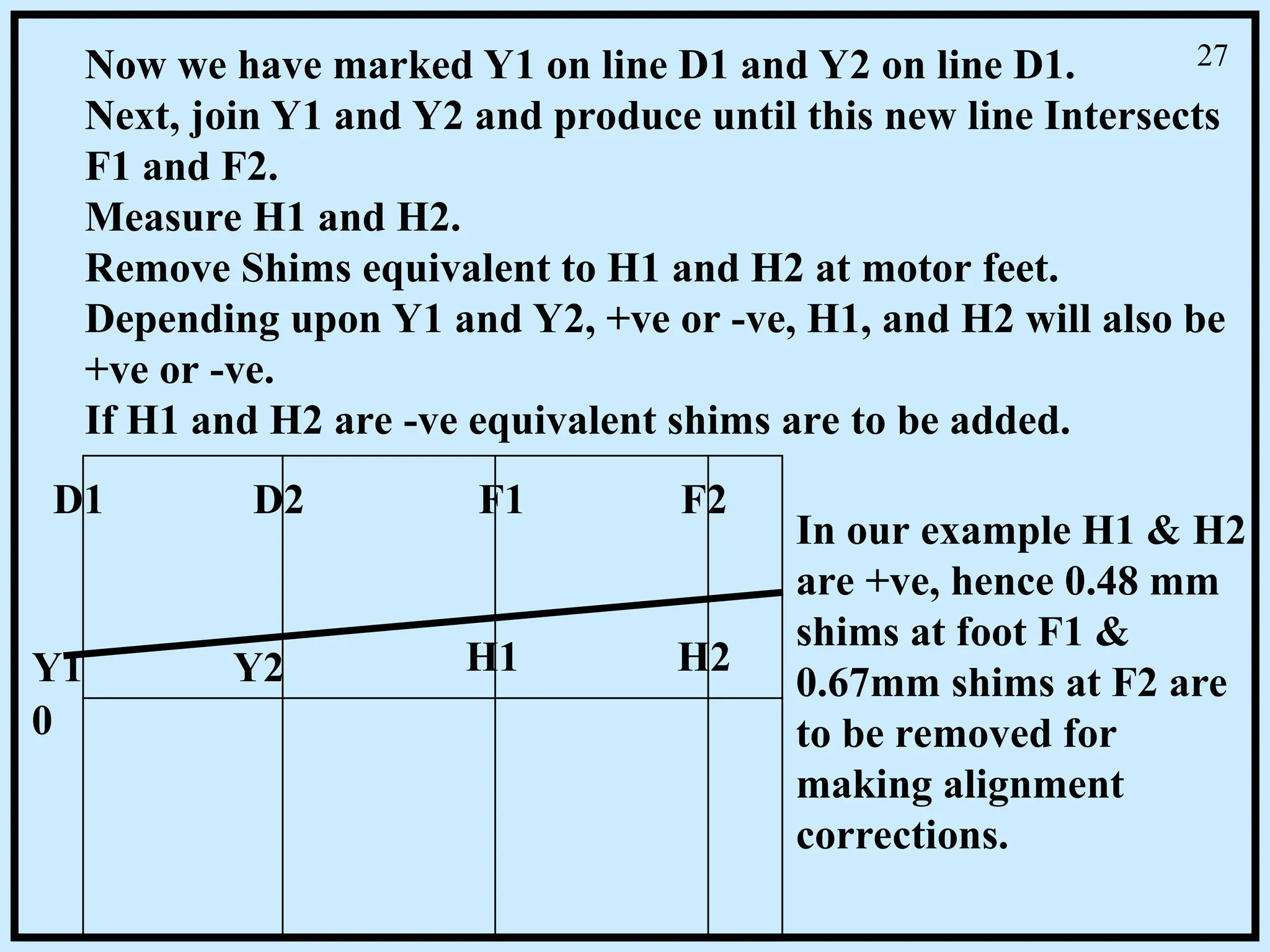

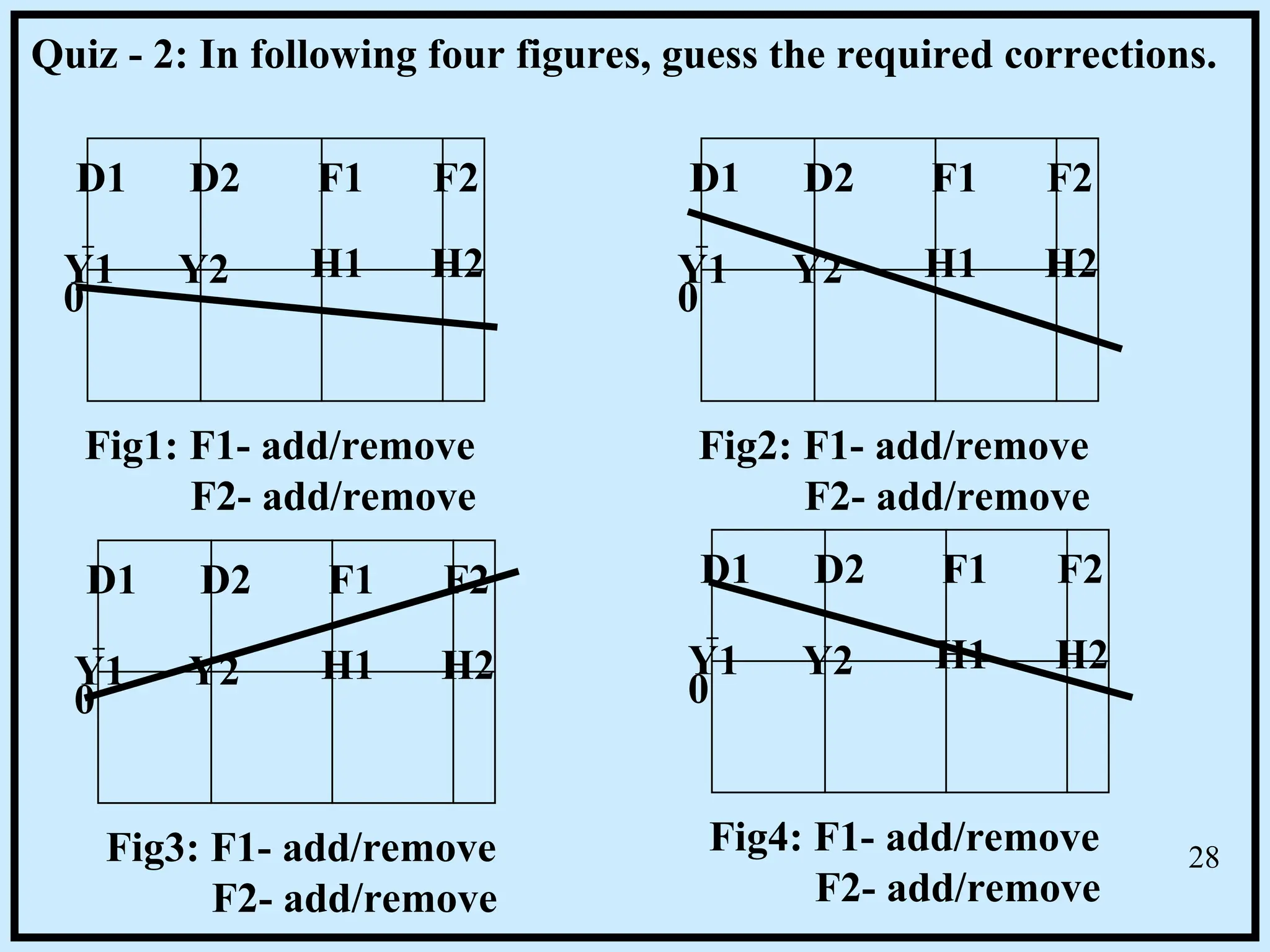

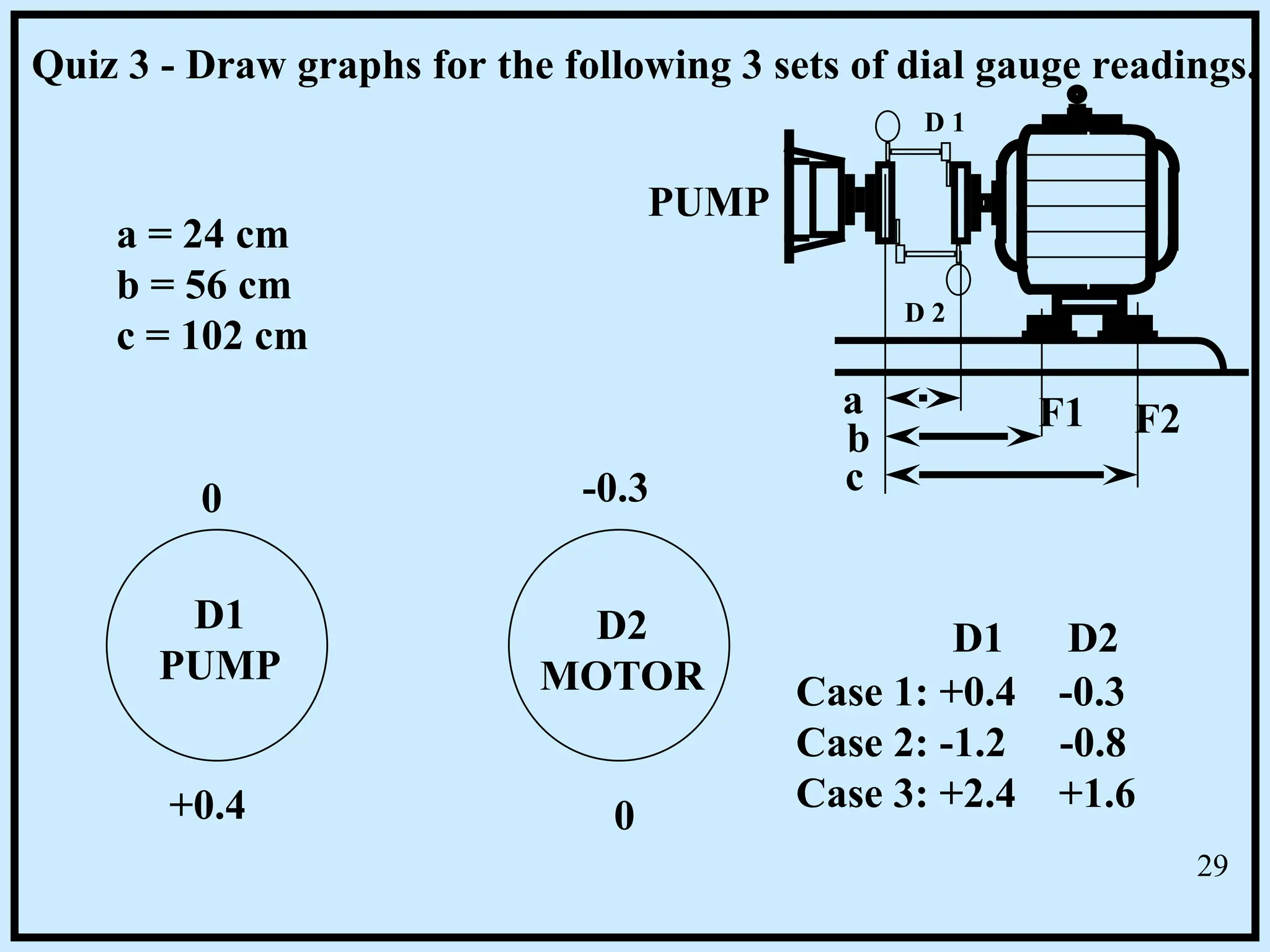

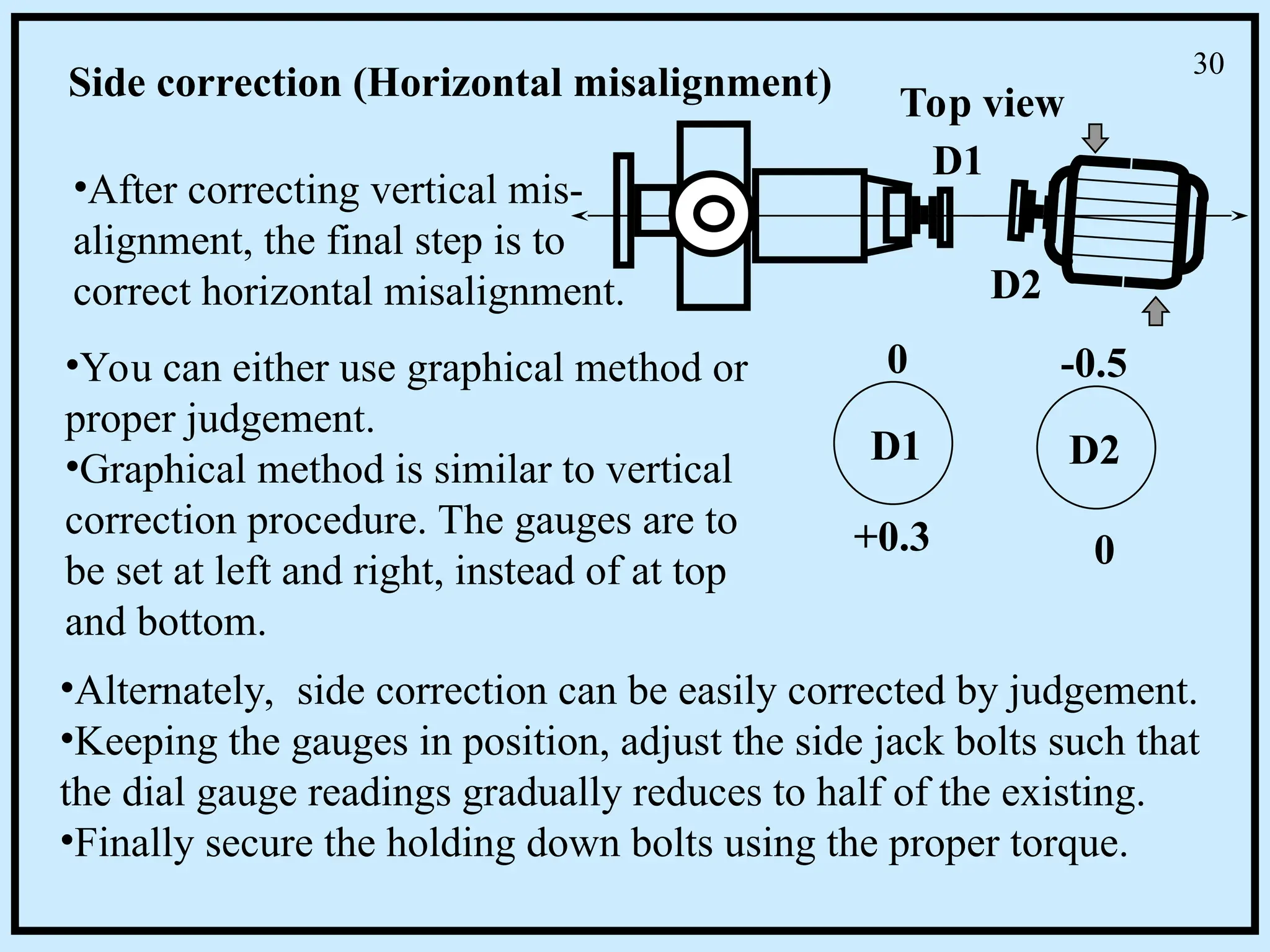

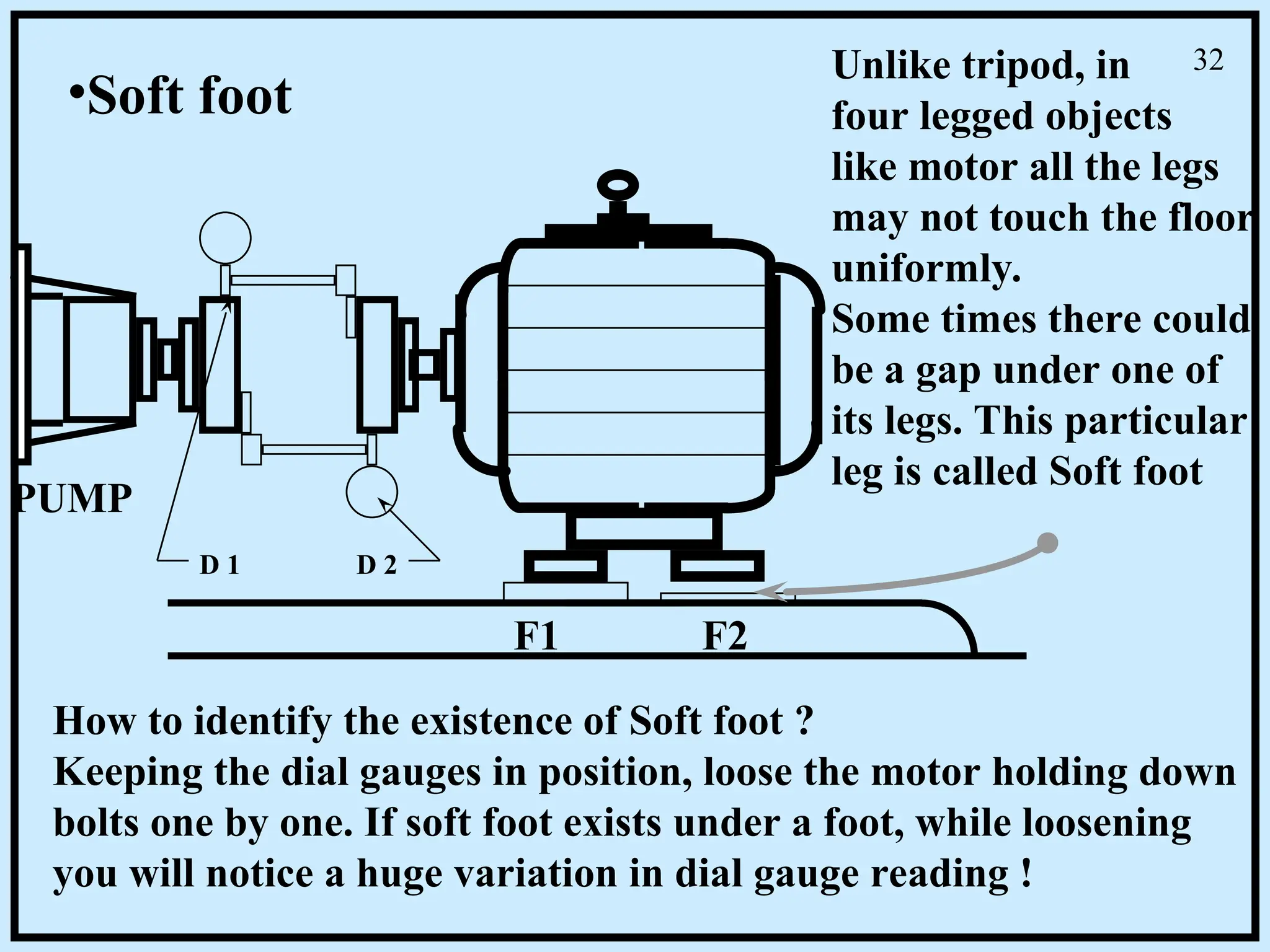

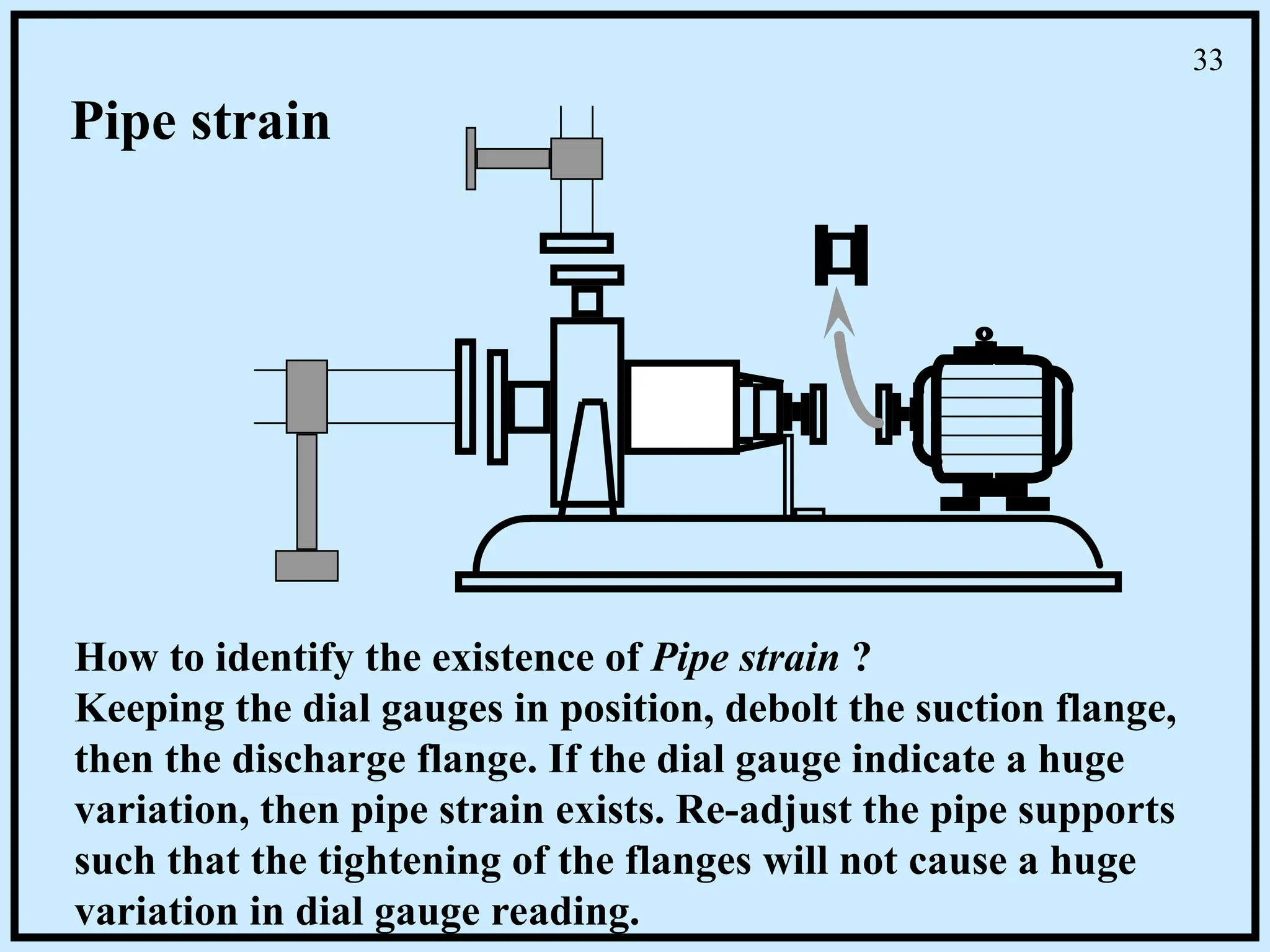

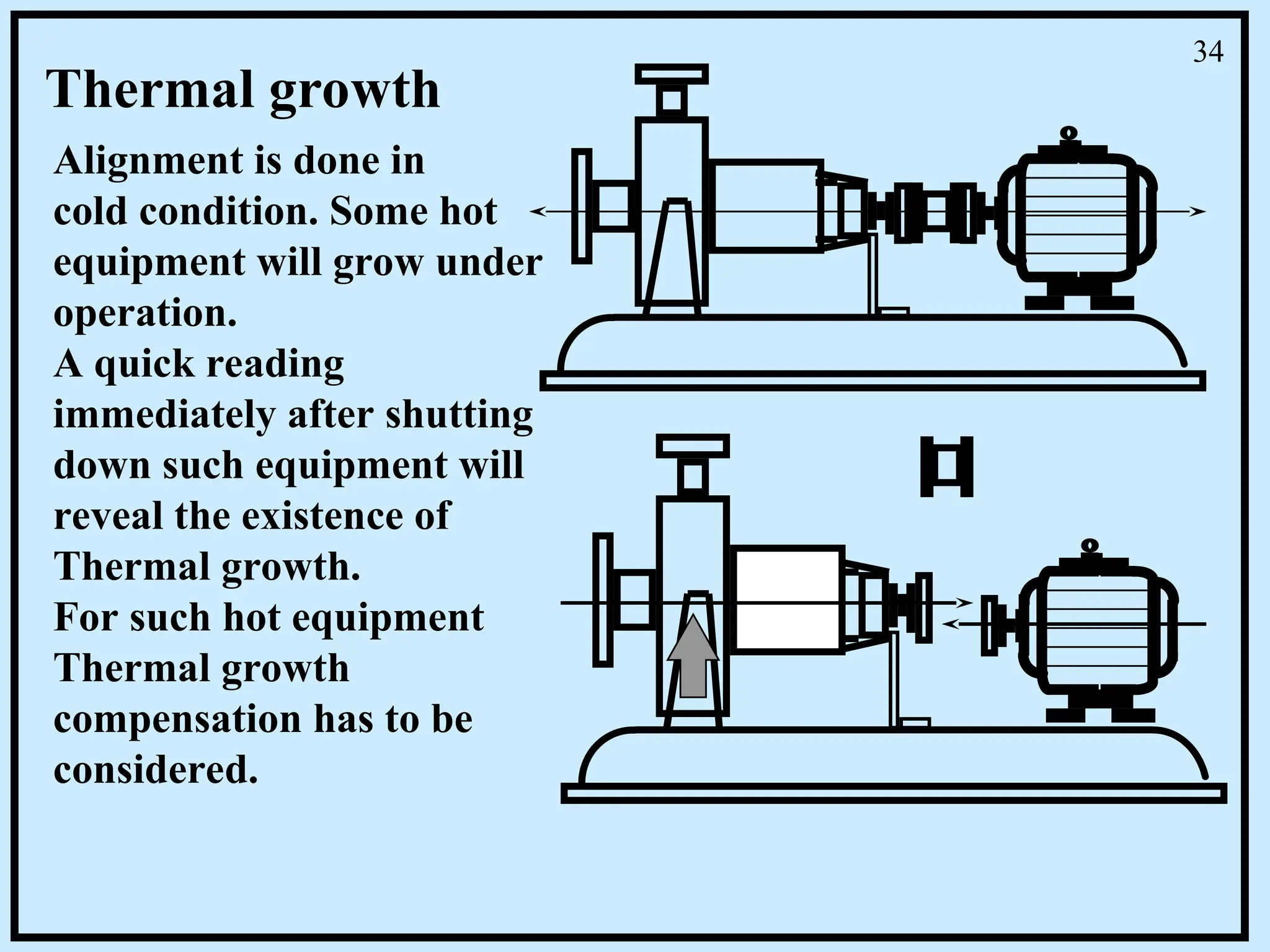

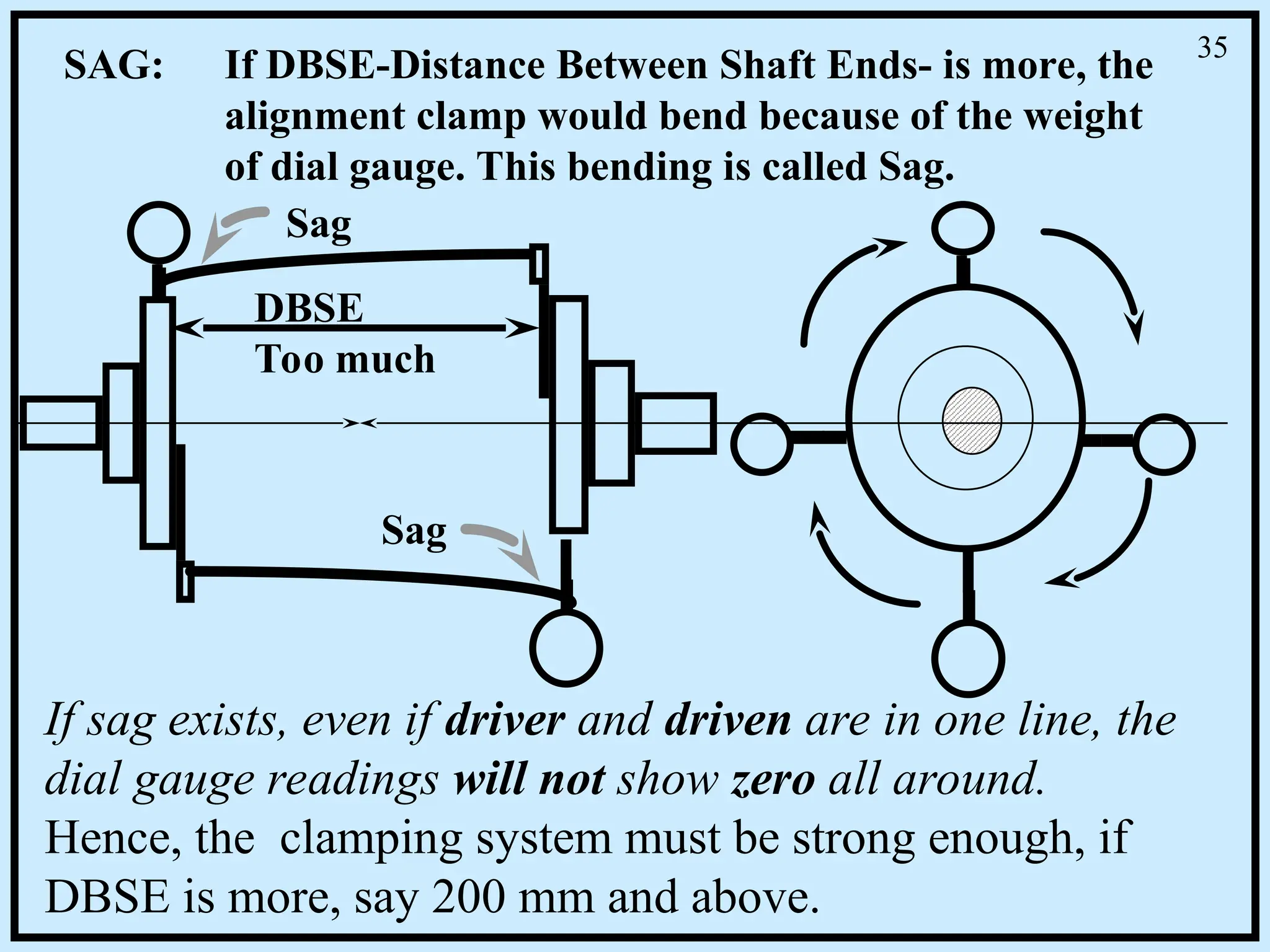

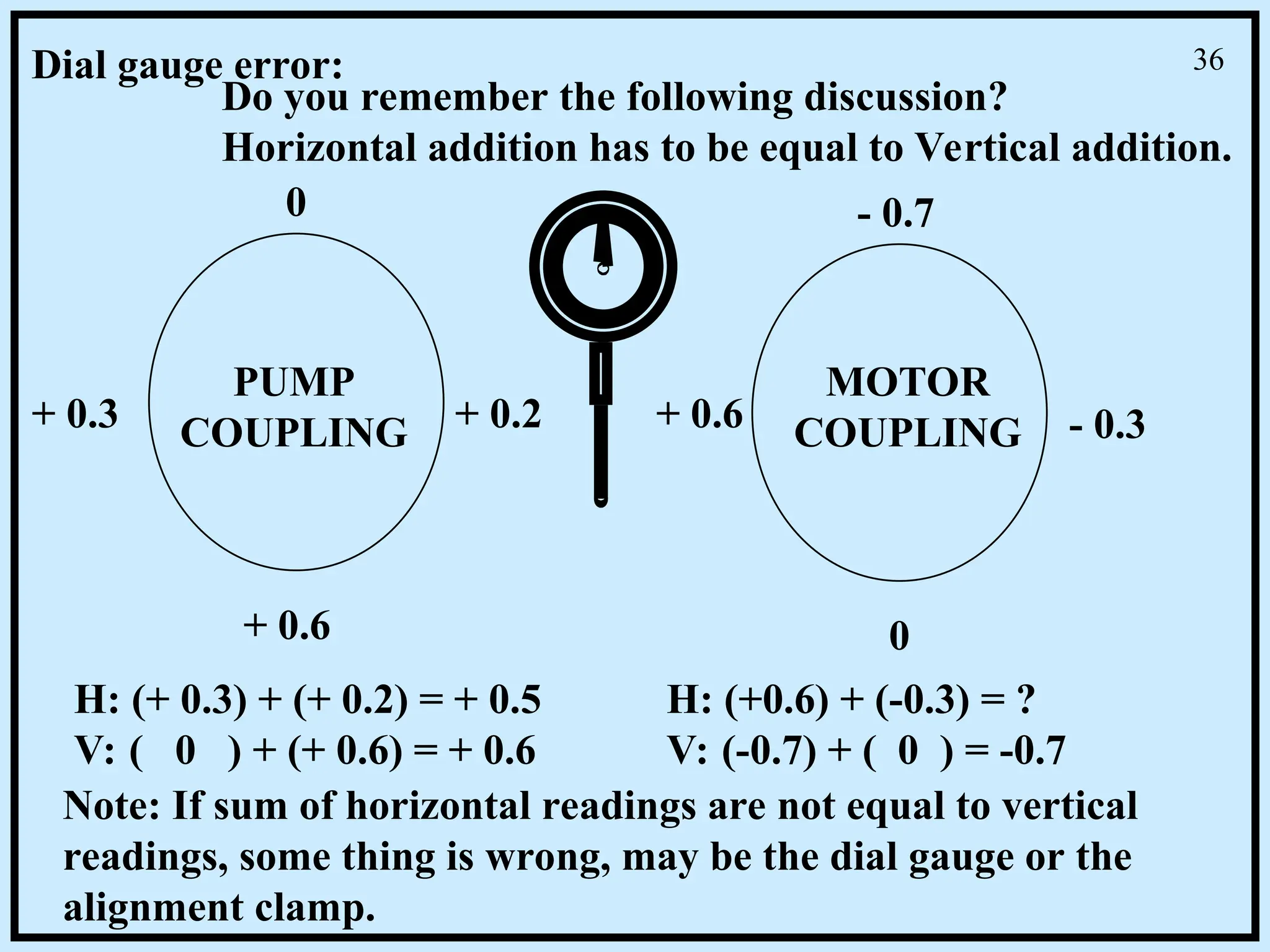

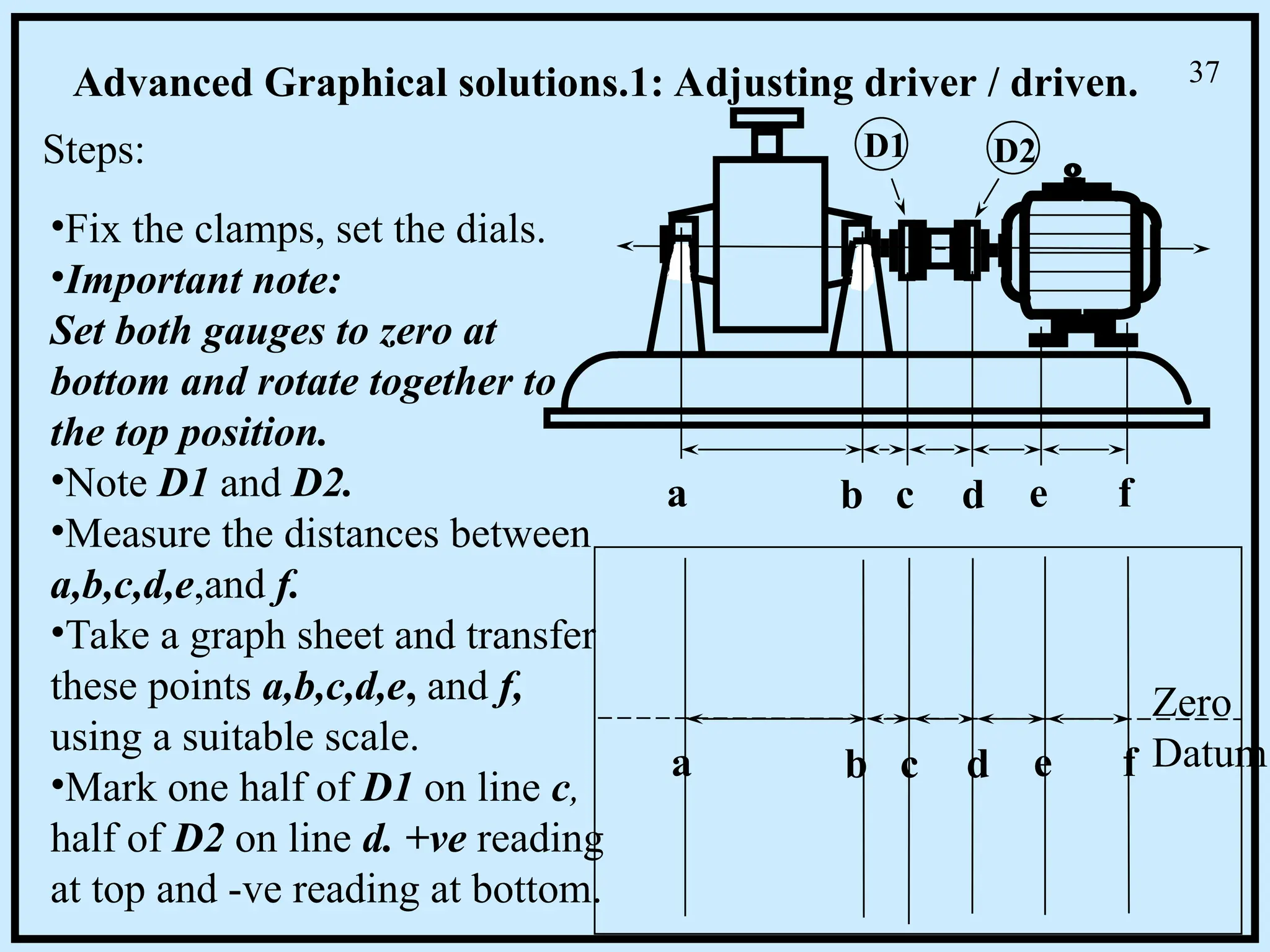

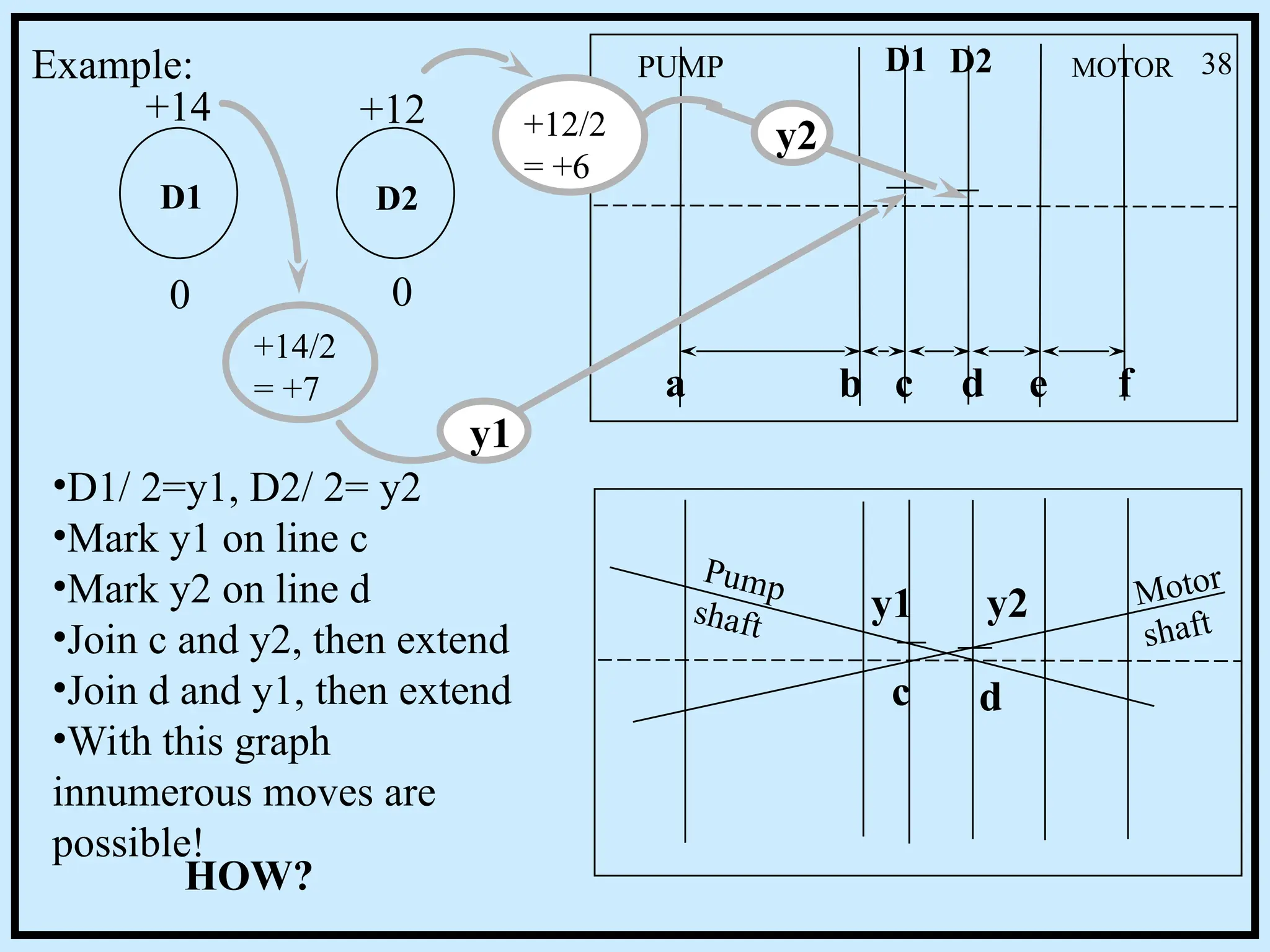

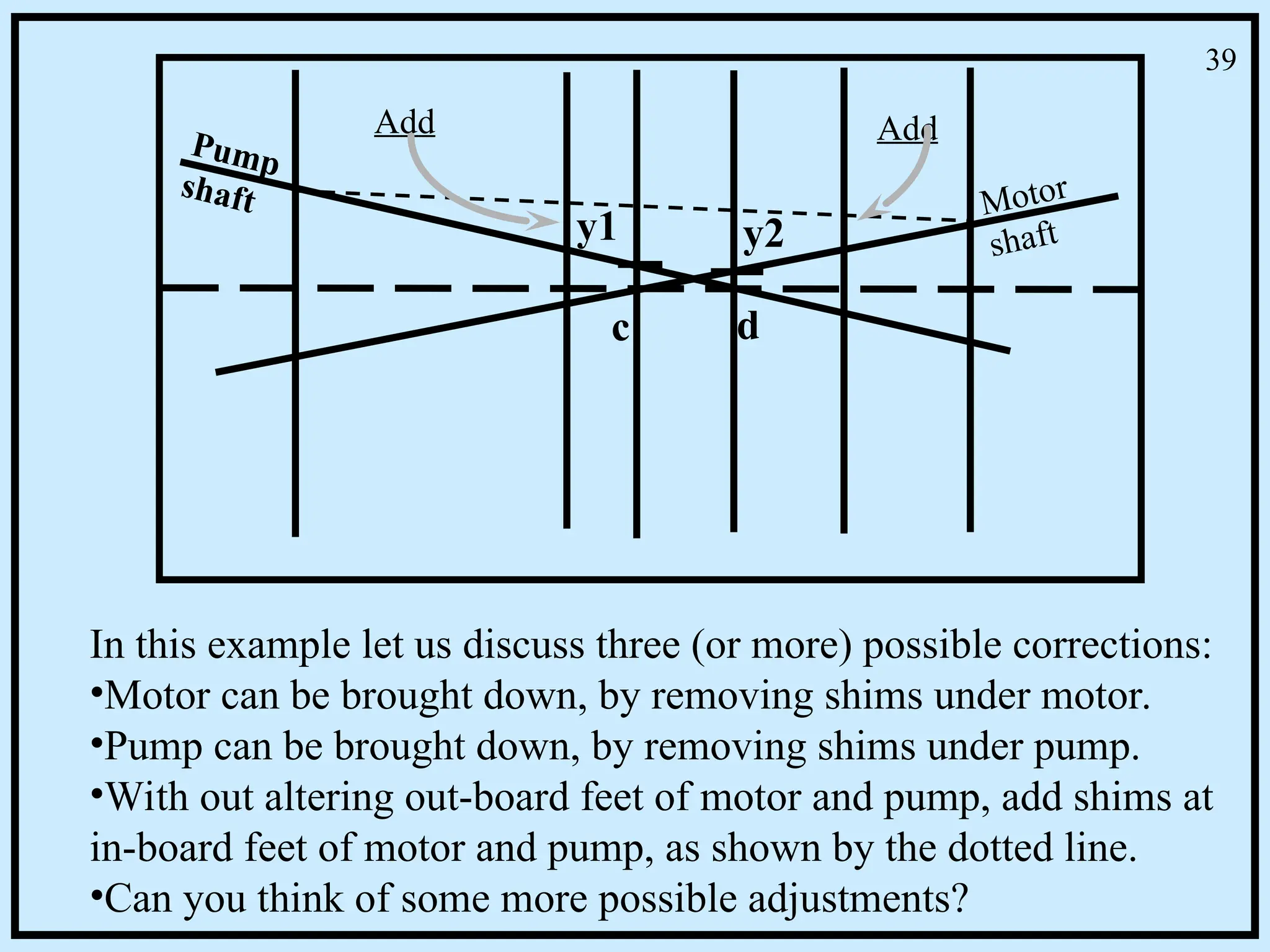

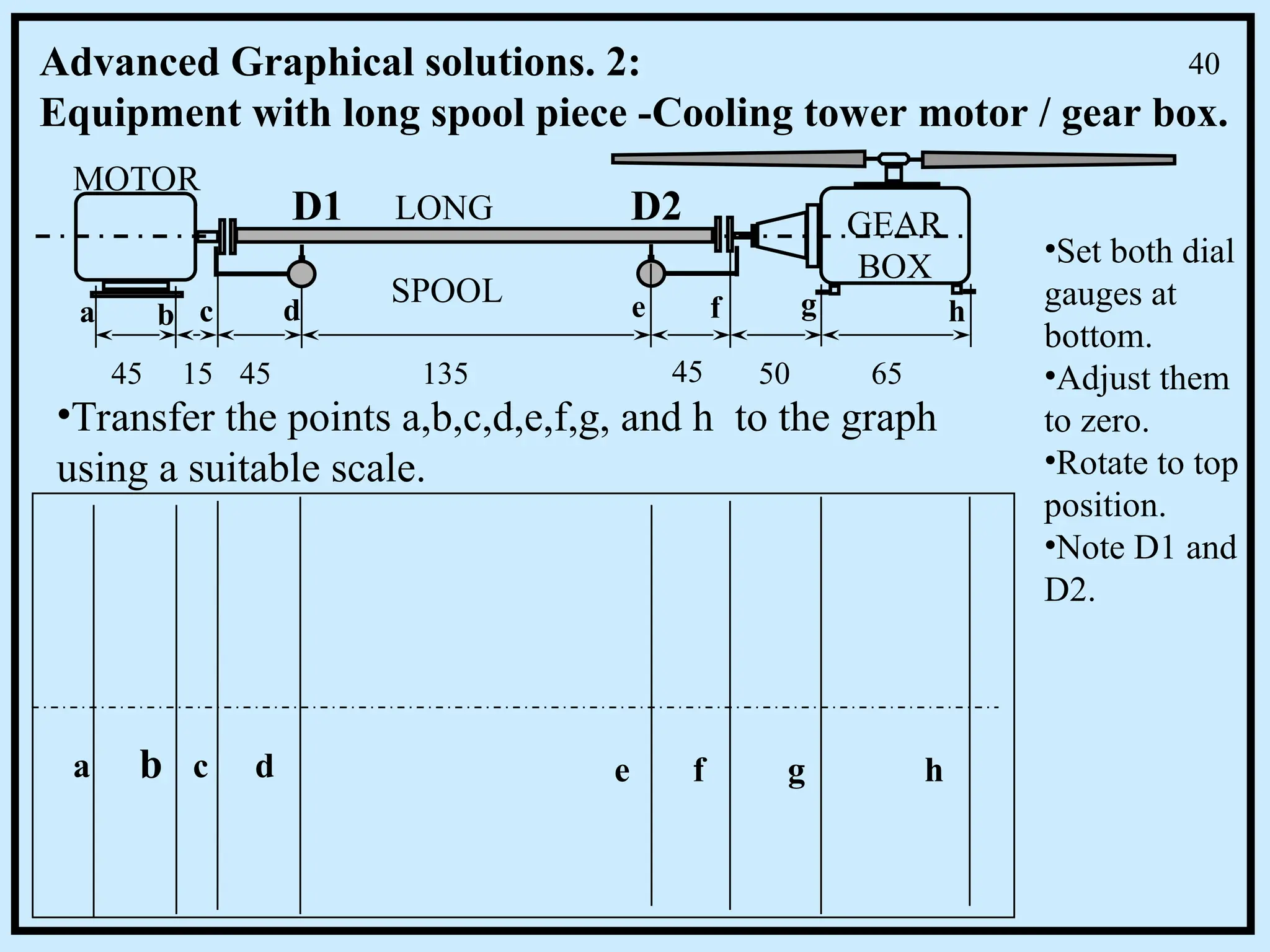

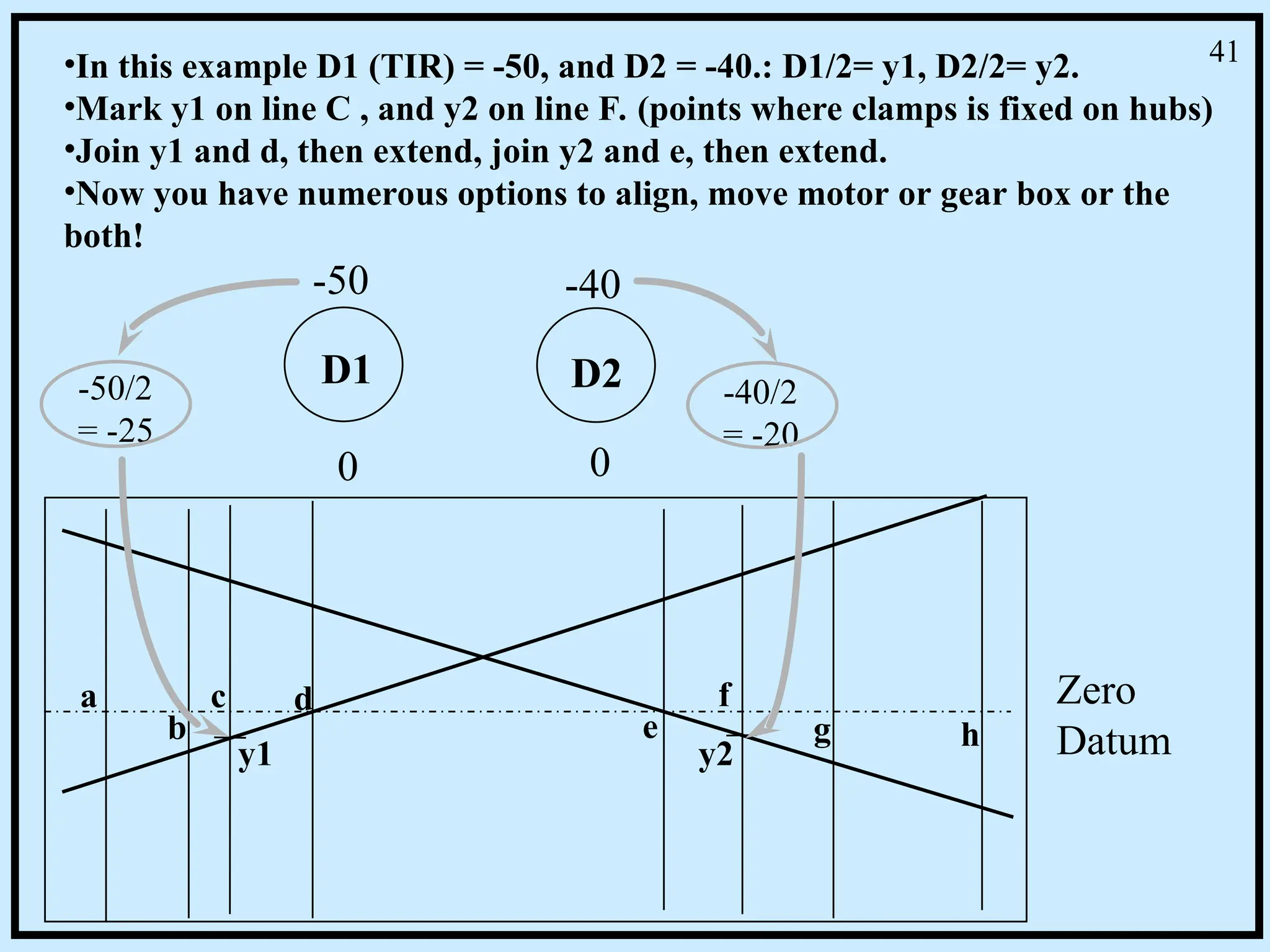

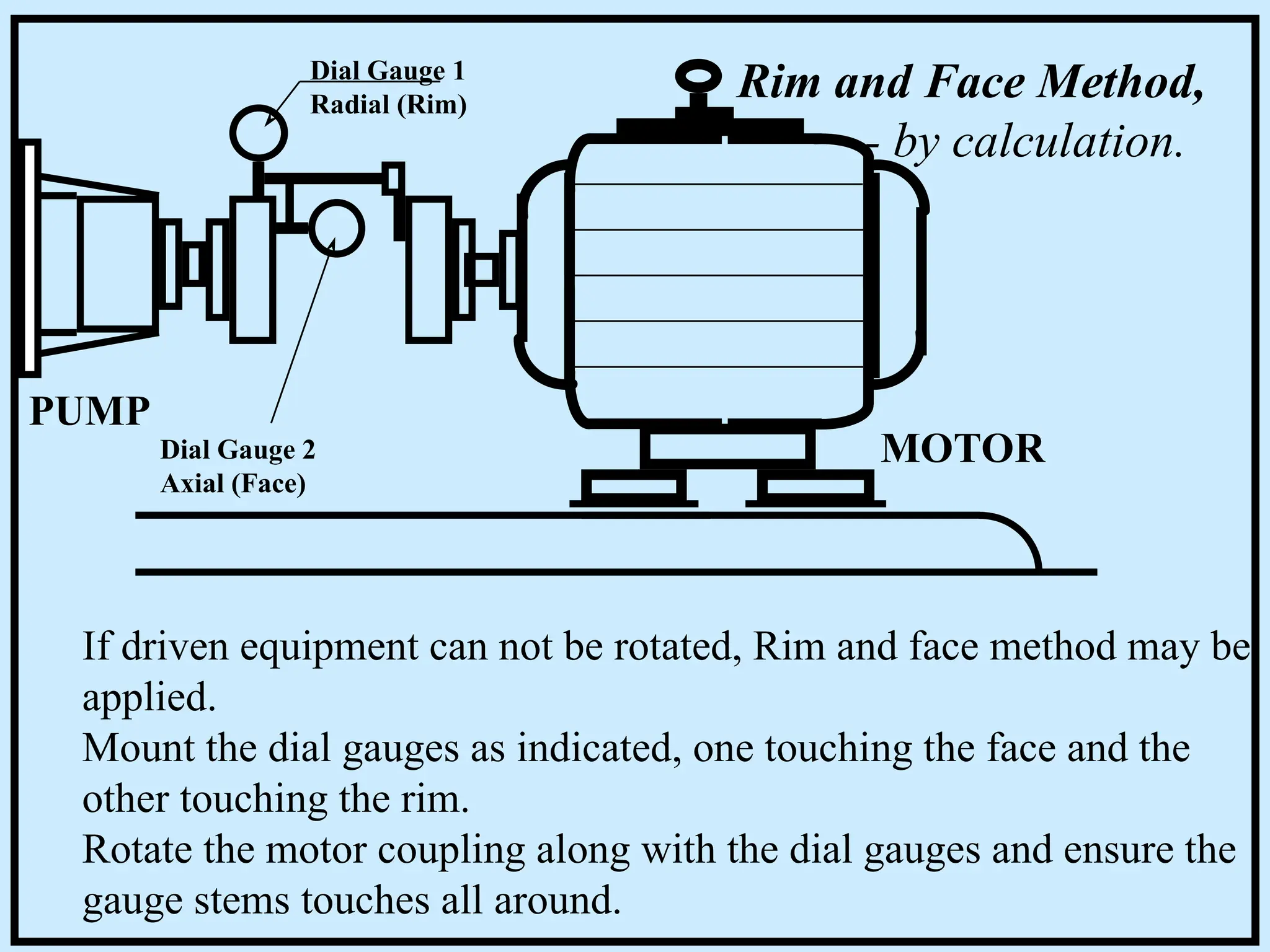

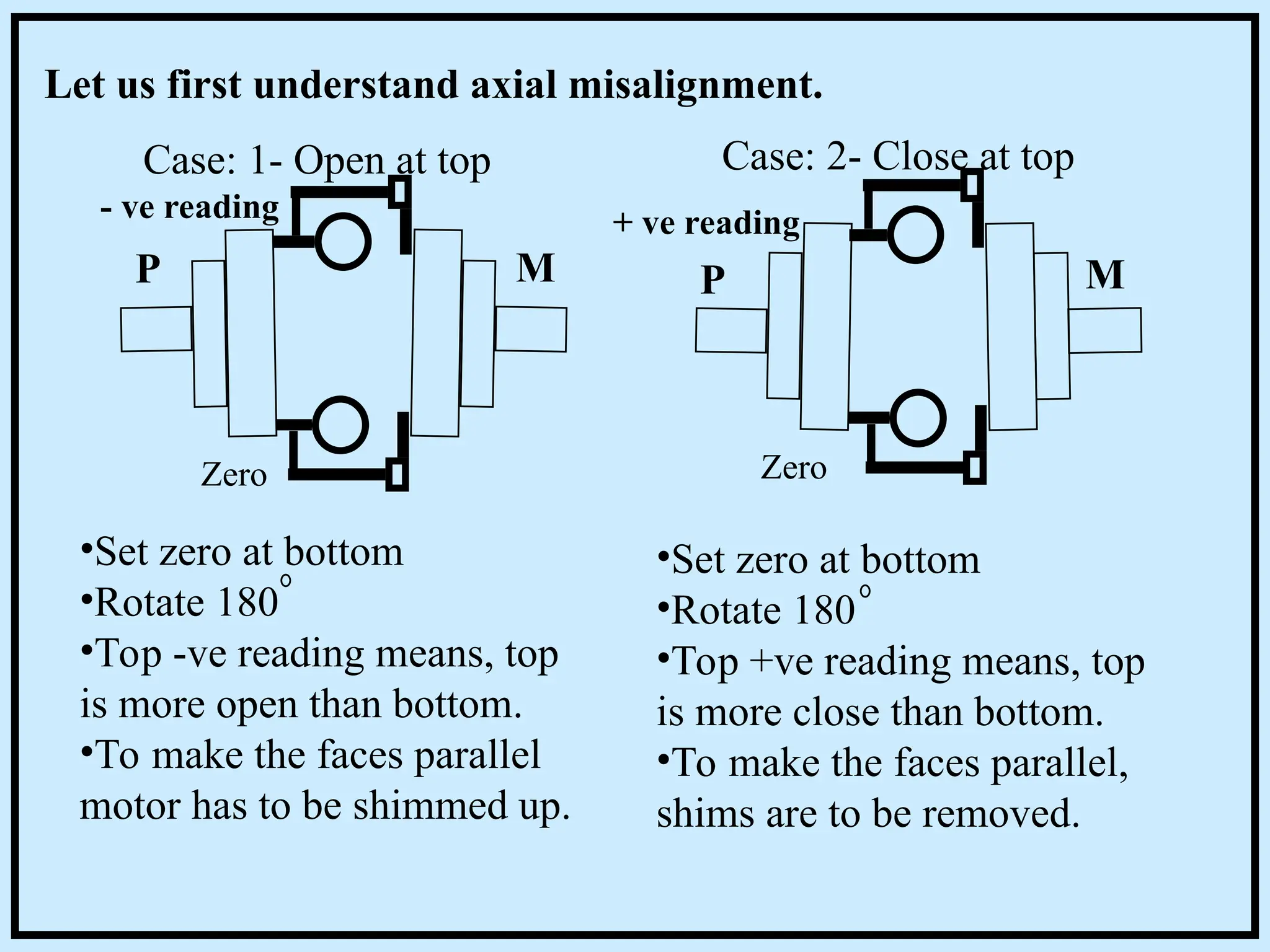

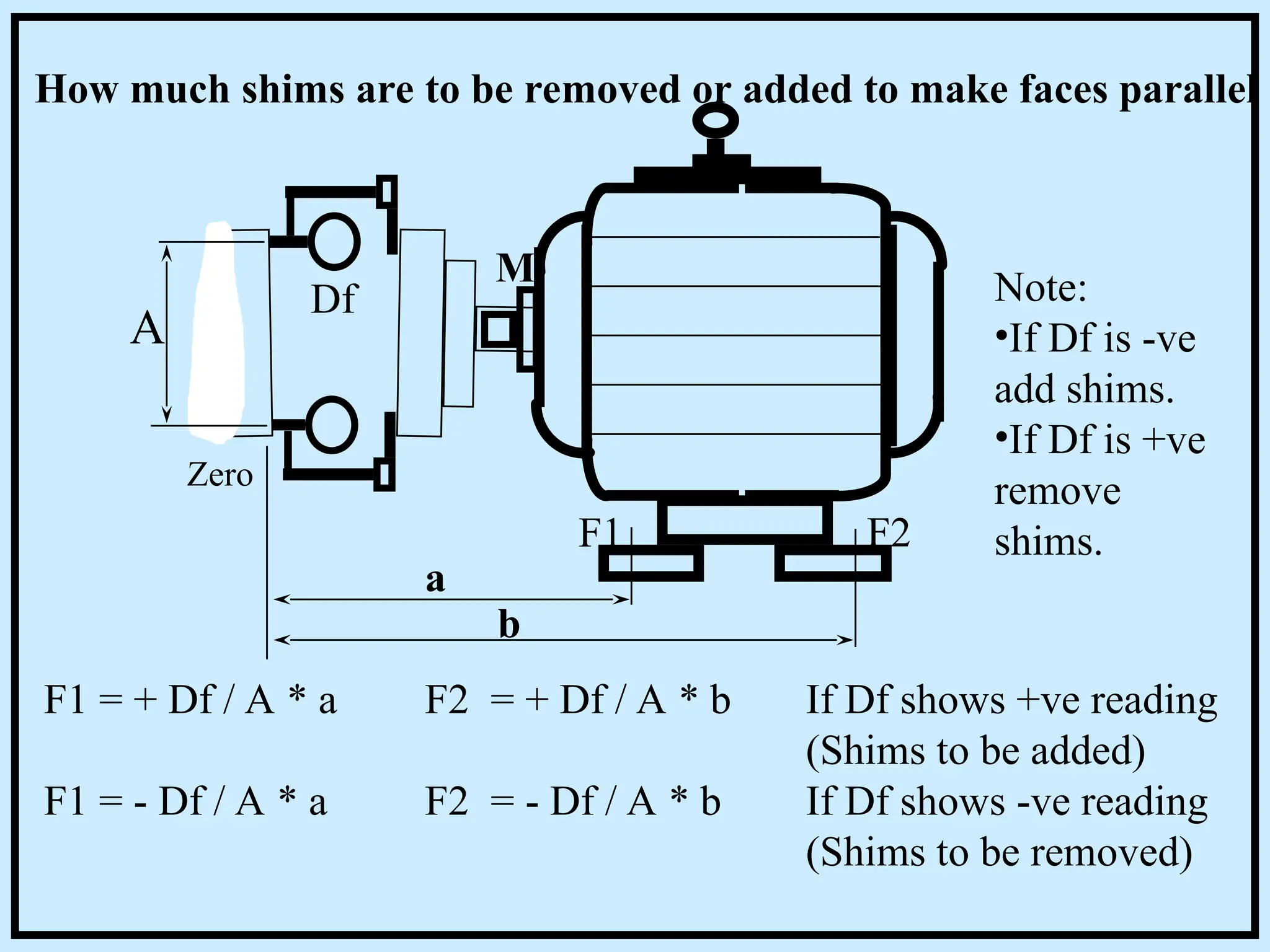

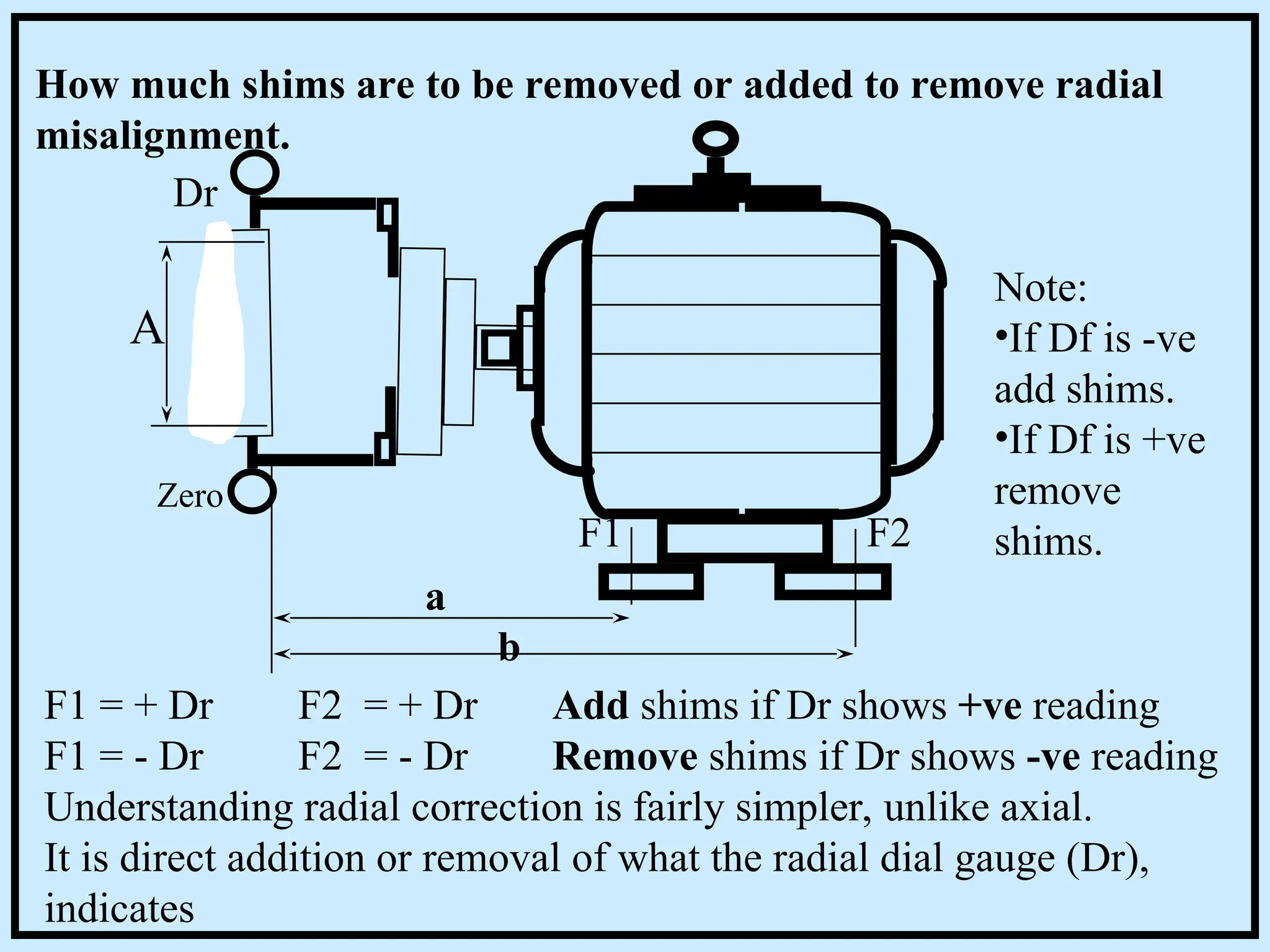

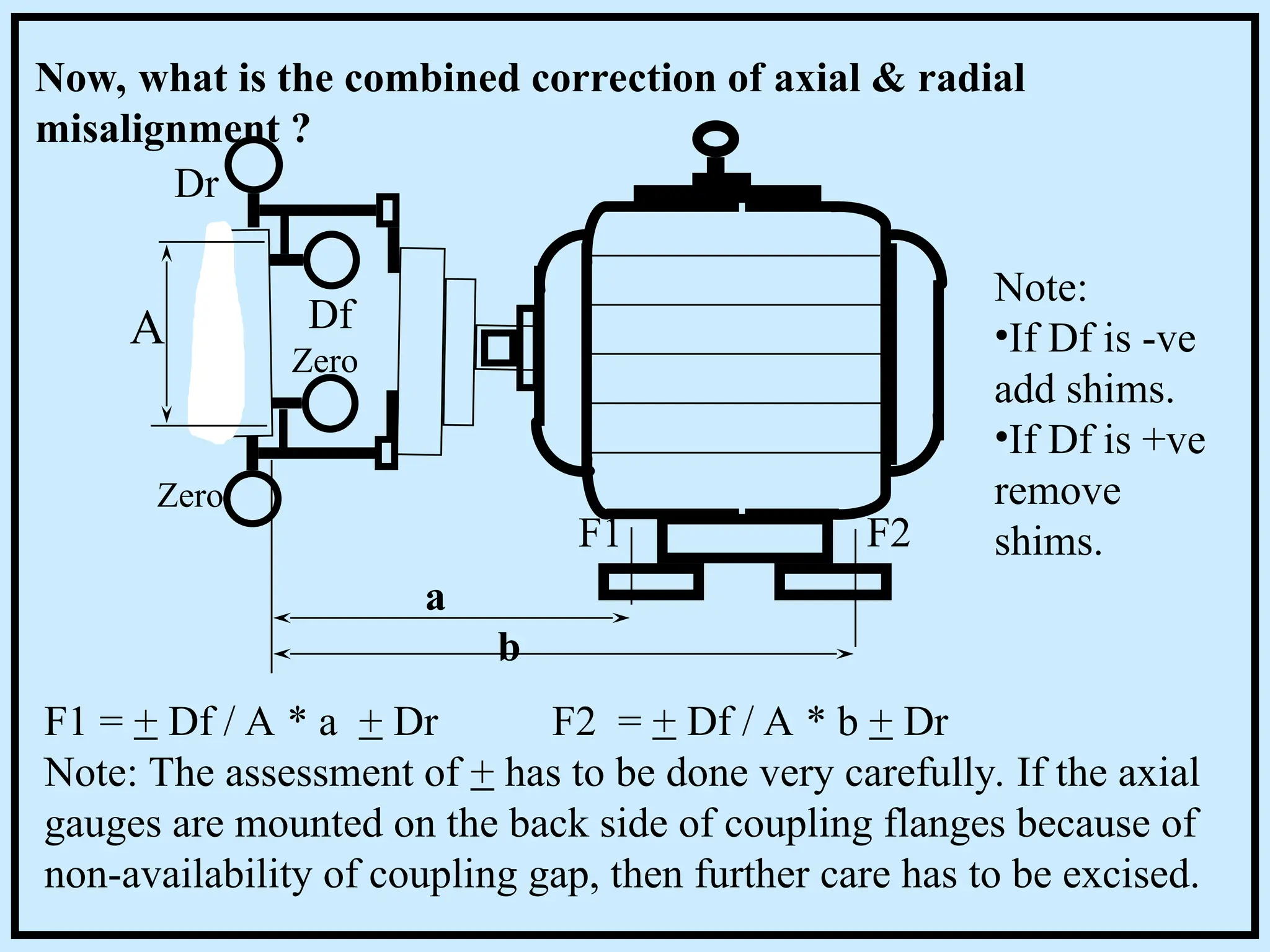

The document outlines a comprehensive training program on the alignment of motor-pump systems, focusing on methods and types of couplings, alignment issues, and the steps for effective equipment alignment. It explains the causes of misalignment and provides detailed instructions on using tools like dial gauges and various techniques for correction, including graphical methods and shimming procedures. Additionally, it highlights preconditions for alignment, addressing common challenges such as thermal growth, soft foot, and pipe strain.