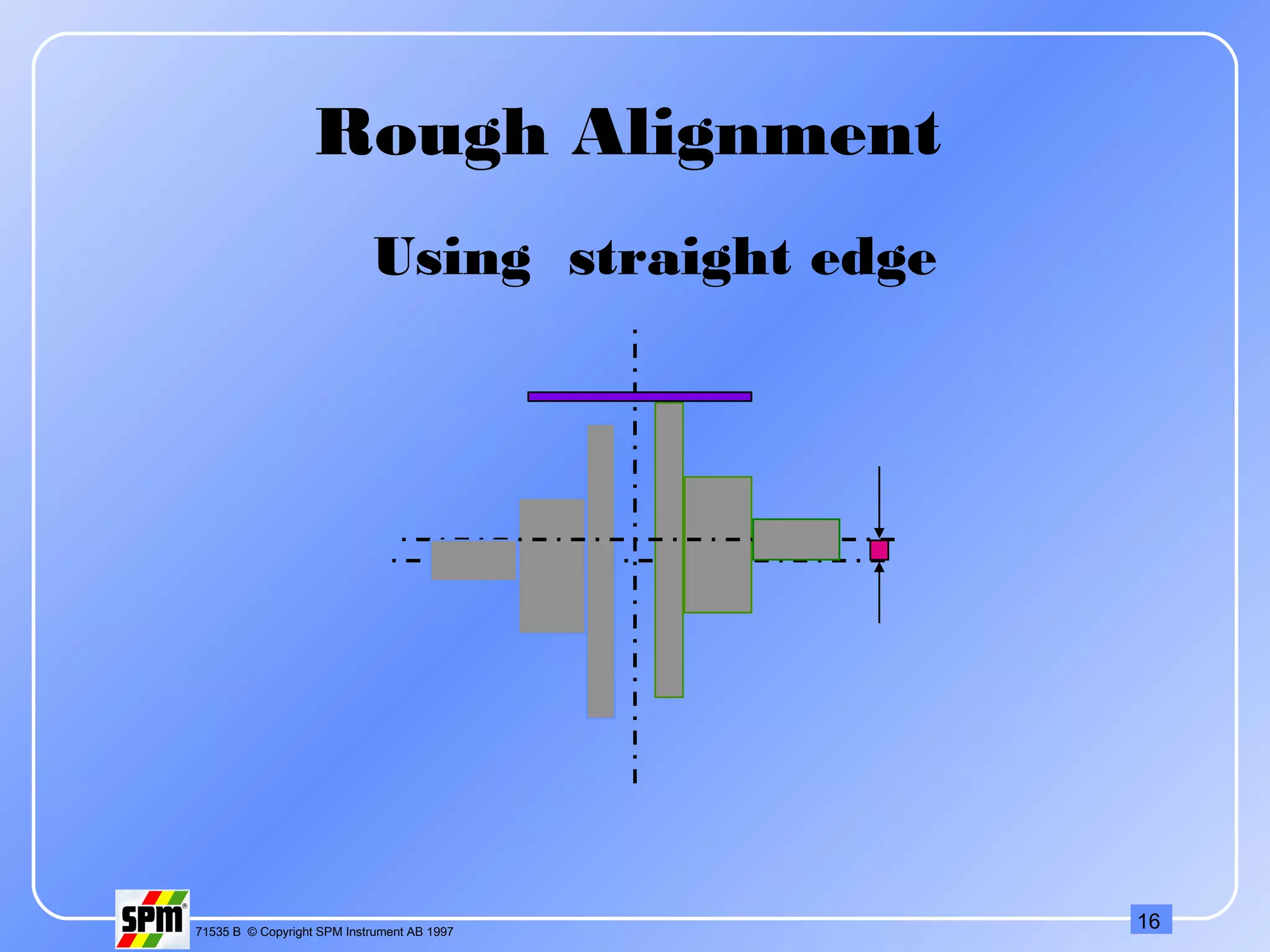

This document provides an overview of machine alignment, including definitions of different types of misalignment, causes of misalignment, effects of misalignment, and methods for detecting and correcting misalignment. It discusses alignment techniques such as using straight edges, dial indicators, and lasers. Precise alignment requires preparing machines by checking for issues like soft foot, pipe strain, coupling gaps, and runout before implementing alignment methods.