More Related Content

PPT

PPT

Mechanical Alignment of equipments in Industries PPTX

PPT

PDF

Pumps_alignment_1684283213.pdf PPTX

MACHINE ALIGNMENT.pptx. An Useful Presentation to understand Alignment Requir... PPTX

PPT

PRESENTATION-SHAFT ALIGNMENT.ppt for industries Similar to All about rotary equipment alignment problem

PDF

PPTX

FCG course alignment MACHINE COUPLING ALIGNMENT.pptx PPTX

Rotating Equipment Alignment Method.pptx PDF

Effects_of_Misalignment.pdf PPTX

PDF

Ludeca a practical-guide-to-shaft-alignment PPSX

PDF

An engineers guide 2012 making maintenance matter, pruftechnik PDF

compressor alignment procedure -1.pdf PPTX

Transcat and Fluke Present: Precision Shaft Alignment Made Easy PDF

Lecture01 maintenance installations in machinery PPT

Final alignment of rotary equipment like pump.ppt PPTX

1 Benefits of alignment FL presentation.pptx PPTX

PDF

PPT

PDF

PPT

PPTX

PDF

Laser shaft alignment system LASERALIGNBLUE - english Recently uploaded

PDF

lecture notes digital_design_examples.pdf PDF

Alternator Protection.pdf`djdjdjkdkdkdkdkd PDF

Finite Automata With Output - Moore and Mealy Machines definitions and Solved... PPTX

Unit II Introduction to C programming ppts PPTX

Why Hydraulic Flushing Should Never Be Skipped Before Commissioning PDF

Robert Walker Epps - A Football Coach PPTX

Training Notes_ SBPDCL Apprenticeship Program.pptx PPTX

low power design COURSE PREREQUISITES Digital System Design, VLSI Design & El... PDF

ENVIRONMENTAL ENGINEERING LABORATORY MANUAL UG Lab Manual - Dept of ESE.pdf PDF

Basics of Electronics Simplified by Akash.pdf.pdf.pdf PPTX

Amperes Circuital Law and its appliocations PPTX

CFP_Unit 3 Decision Control and Looping Statements PDF

Engineering Mindset for Everyday Leadership — James Afful [Emerging Leaders o... PPTX

Basics_of_Electronics_Simplebysreeragsr.pptx PDF

Environmental Engineering (3-0-2) Laboratory.pdf PDF

How to Write Research Papers NCBP D3.pdf PPT

5.1 Basic concept and hierarchy.ppt1234564 PPTX

GDG I²IT Freshers' Tech Kickoff Event, Pune PPTX

PEMET 413-COMPOSITE MATERIALS-2024 SCHEME-MOD1 LECTURE 5.pptx PPTX

Mathematics in Disaster Management school project All about rotary equipment alignment problem

- 1.

1

71535 B ©Copyright SPM Instrument AB 1997

Training Program

On

Machine Alignment

- 2.

2

71535 B ©Copyright SPM Instrument AB 1997

What is Alignment?

It is the correction of relative position of two

machines so that Center lines of two rotating shafts

form a straight line when the machines are working

at normal operating temperature.

- 3.

3

71535 B ©Copyright SPM Instrument AB 1997

Causes Of Misalignment

Thermal expansion - Most machines align cold.

Machine vibrations.

Forces transmitted to the machine by pipe or

support structure.

Soft foot.

Direct coupled machines are not properly aligned.

Poor workmanship.

- 4.

4

71535 B ©Copyright SPM Instrument AB 1997

Effects Of Misalignment

More than 50% problems are due to misalignment.

Causes vibration on the machine

Vibration destroys critical parts of machines like bearings, gears,

seals, coupling etc.

Breaks lubricant film inside the bearing and increase friction.

Increases load on the bearing.

Increase 2 - 17% power consumption.

Generates heat inside the coupling.

- 5.

5

71535 B ©Copyright SPM Instrument AB 1997

Types Of Misalignment

1. Off set

2. Angular

3. Skew - Combination of offset & angular

- 6.

6

71535 B ©Copyright SPM Instrument AB 1997

Offset Misalignment

Increases power

consumption of

the machine.

- 7.

7

71535 B ©Copyright SPM Instrument AB 1997

Effects pin bush

coupling more than

tyre coupling.

Angular Misalignment

- 8.

8

71535 B ©Copyright SPM Instrument AB 1997

Skewed Misalignment

- 9.

9

71535 B ©Copyright SPM Instrument AB 1997

Recognition Of

Misalignment

1. Excessive Radial & Axial vibration

2. Premature / repetitive failure of bearing, seal, coupling.

3. Loose coupling elements.

4. Leakage from the seal.

5. Loose base bolts.

6. Coupling become hot while running.

7. High casing temperature.

- 10.

10

71535 B ©Copyright SPM Instrument AB 1997

Scientific

Diagnosis Of Misalignment

1. Vibration Spectrum Analysis

2. Vibration Phase Analysis

3. Wear Particle Analysis

- 11.

11

71535 B ©Copyright SPM Instrument AB 1997

Angular - Axial vibration at 1X RPM

Offset - Radial vibration at 2X or 3X RPM

Harmonics (3X-10X) generates as severity increases.

•If the 2X amplitude more than 50% of 1X then coupling

damage

starts.

•If the 2X amplitude more than 150% of 1X then machine

should be

stopped for correction.

1. Vibration Spectrum Analysis

- 12.

12

71535 B ©Copyright SPM Instrument AB 1997

Angular - 1800

phase shift in the axial direction across

the coupling.

Offset - 1800

phase shift in the radial direction across

the coupling. 00

to 1800

phase shift occur as the sensor

moves from horizontal to the vertical direction of the

same machine.

Skew - 1800

phase shift in the axial or radial direction

across the coupling.

2. Vibration Phase Analysis

- 13.

13

71535 B ©Copyright SPM Instrument AB 1997

3. Wear Particle Analysis

Curly cutting wear particle of 5:1 to 50:1 aspect

ratio.

- 14.

14

71535 B ©Copyright SPM Instrument AB 1997

Types Of Couplings

Flexible : Pin bush, Tyre, Love joy,

ESBI Valkan tyre

Semi Flexible : Fluid

Rigid : Geared, Resilient

- 15.

15

71535 B ©Copyright SPM Instrument AB 1997

Flexible Coupling

Can flexible coupling take misalignment?

Flexible coupling can be used to take minor

misalignment but it will generate heat and

flexible members will fail prematurely.

- 16.

16

71535 B ©Copyright SPM Instrument AB 1997

Alignment Methods

1. Rough Alignment

(a) Using straight edge

(b) Twin wire method

2. Precision Alignment

(a) Face & Rim

(b) Reverse indicator

- 17.

17

71535 B ©Copyright SPM Instrument AB 1997

Using straight edge

Rough Alignment

- 18.

18

71535 B ©Copyright SPM Instrument AB 1997

Using twin wire

Rough Alignment

- 19.

19

71535 B ©Copyright SPM Instrument AB 1997

Face & Rim Method

- 20.

20

71535 B ©Copyright SPM Instrument AB 1997

Face & Rim Method

Advantages:

1. Good for large dia. coupling hubs where the shafts are close together.

2. To be used where one of the shafts can not rotate during alignment.

3. Easy to use.

Disadvantages:

1. Difficult to take face readings, if there is axial float in

the shaft.

2. Requires removal of coupling spool.

3. More complex alignment calculation.

- 21.

21

71535 B ©Copyright SPM Instrument AB 1997

Reverse Indicator Method

- 22.

22

71535 B ©Copyright SPM Instrument AB 1997

Reverse Indicator Method

Advantages:

1. More accurate than face & rim

method.

2. Readings are not affected by axial

float.

3. Possible to keep the coupling spool.

Disadvantages:

1. Both shafts have to be rotated.

2. Should not be used on close coupled shafts.

3. Difficult to take readings on long shaft.

- 23.

23

71535 B ©Copyright SPM Instrument AB 1997

L

D/

2

Which Method To Be Used?

If L > D Reverse Indicator

- 24.

24

71535 B ©Copyright SPM Instrument AB 1997

Calculation can be

made for each of the

method to verify the

readings.

Combination Method

- 25.

25

71535 B ©Copyright SPM Instrument AB 1997

Off Set Angular

RPM mm mm / 100 mm

0000 - 1000 0.13 0.10

1000 - 2000 0.10 0.08

2000 - 3000 0.07 0.07

3000 - 4000 0.05 0.06

4000 - 5000 0.03 0.05

Alignment Tolerance

- 26.

26

71535 B ©Copyright SPM Instrument AB 1997

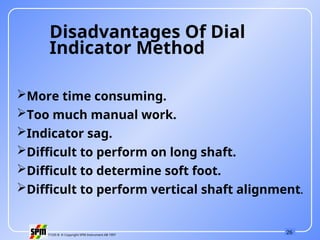

Disadvantages Of Dial

Indicator Method

More time consuming.

Too much manual work.

Indicator sag.

Difficult to perform on long shaft.

Difficult to determine soft foot.

Difficult to perform vertical shaft alignment.

- 27.

- 28.

28

71535 B ©Copyright SPM Instrument AB 1997

Angled Foot

Short Foot

Soft Foot

- 29.

29

71535 B ©Copyright SPM Instrument AB 1997

Tightening Of Holding Down Bolts

- 30.

30

71535 B ©Copyright SPM Instrument AB 1997

Perpendicular to

the coupling

surface.

Fixing Of Dial Gauge

- 31.

31

71535 B ©Copyright SPM Instrument AB 1997

Rules For Good Alignment

Clean the machine base. Remove rust burrs

etc.

Use steel or brass shims.

Check indicator sag.

Check soft foot.

Check dial gauges before taking readings.

Use correct bolt tightening procedure.

Don’t lift the machine more than necessary.

Try to put the stem of dial gauge

perpendicular to

the surface of coupling.

Use jack bolts.

- 32.

32

71535 B ©Copyright SPM Instrument AB 1997

Laser Alignment

- 33.

33

71535 B ©Copyright SPM Instrument AB 1997

Light Amplified By Stimulated Emission Of Radiation

Laser was originally emitted by charge sent

through

a gas mixture of Helium & Neon.

Now it emitted by a low power semi conductor

diode

with collimating lenses.

Modulated to avoid interference from other light

source

It is collinear.

Single wave length of 670 nm.

Laser

- 34.

34

71535 B ©Copyright SPM Instrument AB 1997

Laser Alignment

Advantages:

1. Easy to use.

2. Use Reverse Indicator Method.

3. Machine does the calculations.

4. 0 - 20m max. working distance.

5. Selectable high resolution 0.1, 0.01, 0.001mm.

6. No indicator sag.

7. Soft foot measurement program.

8. Horizontal shaft alignment with mim 600

rotation.

9. Vertical shaft alignment program.

10.Thermal or offset compensation.

- 35.

35

71535 B ©Copyright SPM Instrument AB 1997

11. Machine train alignment program.

12. Cardon shaft alignment.

13. Straightness, Flatness, Perpendicularly,

Parallelism measurement.

14. Spindle alignment.

15. Static feet correction.

16. Continuos monitoring.

- 36.

- 37.

- 38.

38

71535 B ©Copyright SPM Instrument AB 1997

Graphical representation

- 39.

39

71535 B ©Copyright SPM Instrument AB 1997

Stationery Machine Movable Machine

+

+

Graphical representation

- 40.

40

71535 B ©Copyright SPM Instrument AB 1997

Graphical representation

Example 1

(Reverse Indicator Method)

SM Dial Reading: -1.50 mm

MM Dial Reading : +0.5 mm

Scale: Y-axis = 10:1

X-axis = 1: 5

- 41.

41

71535 B ©Copyright SPM Instrument AB 1997

+

+

Graphical representation

- 42.

42

71535 B ©Copyright SPM Instrument AB 1997

Graphical representation