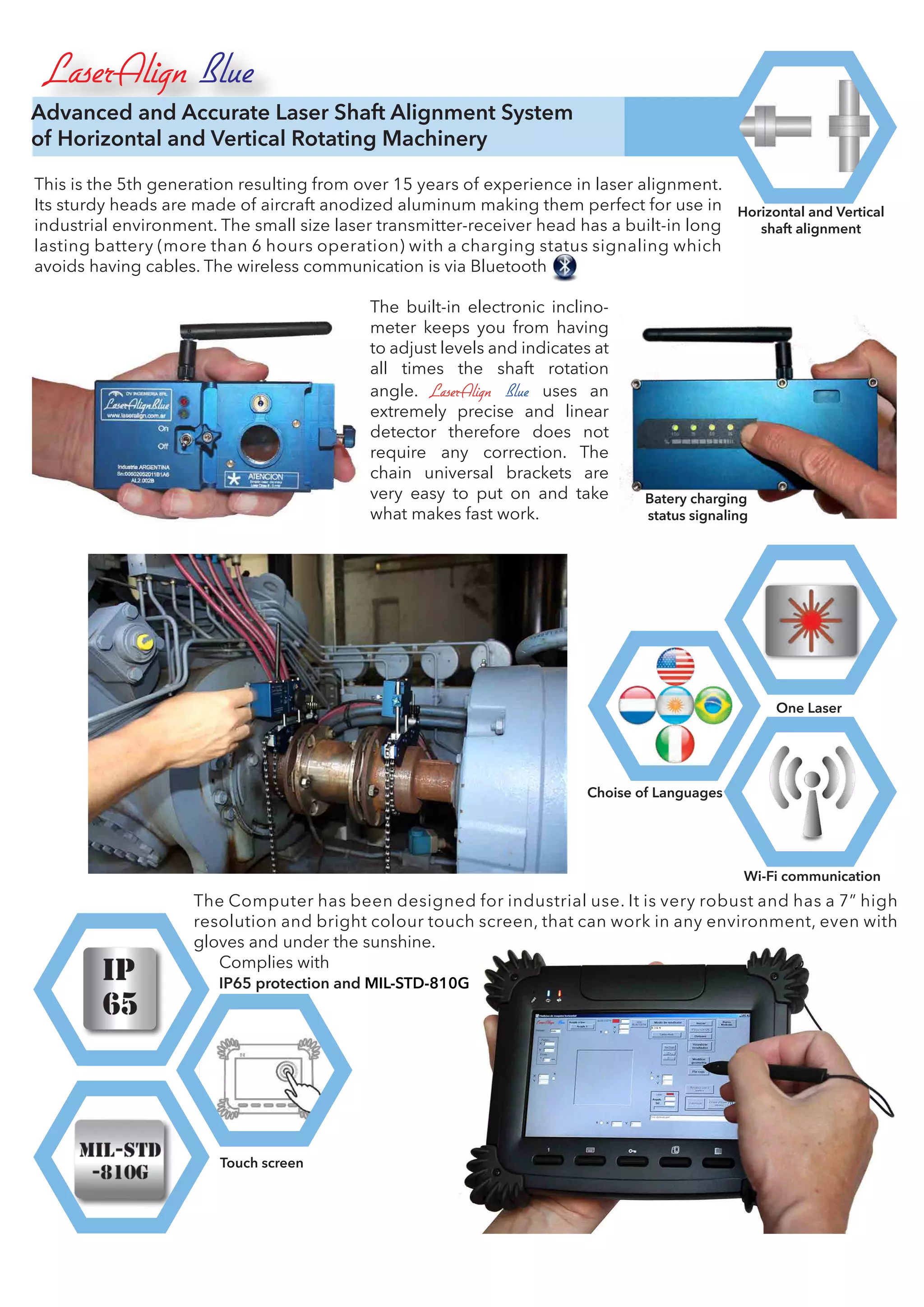

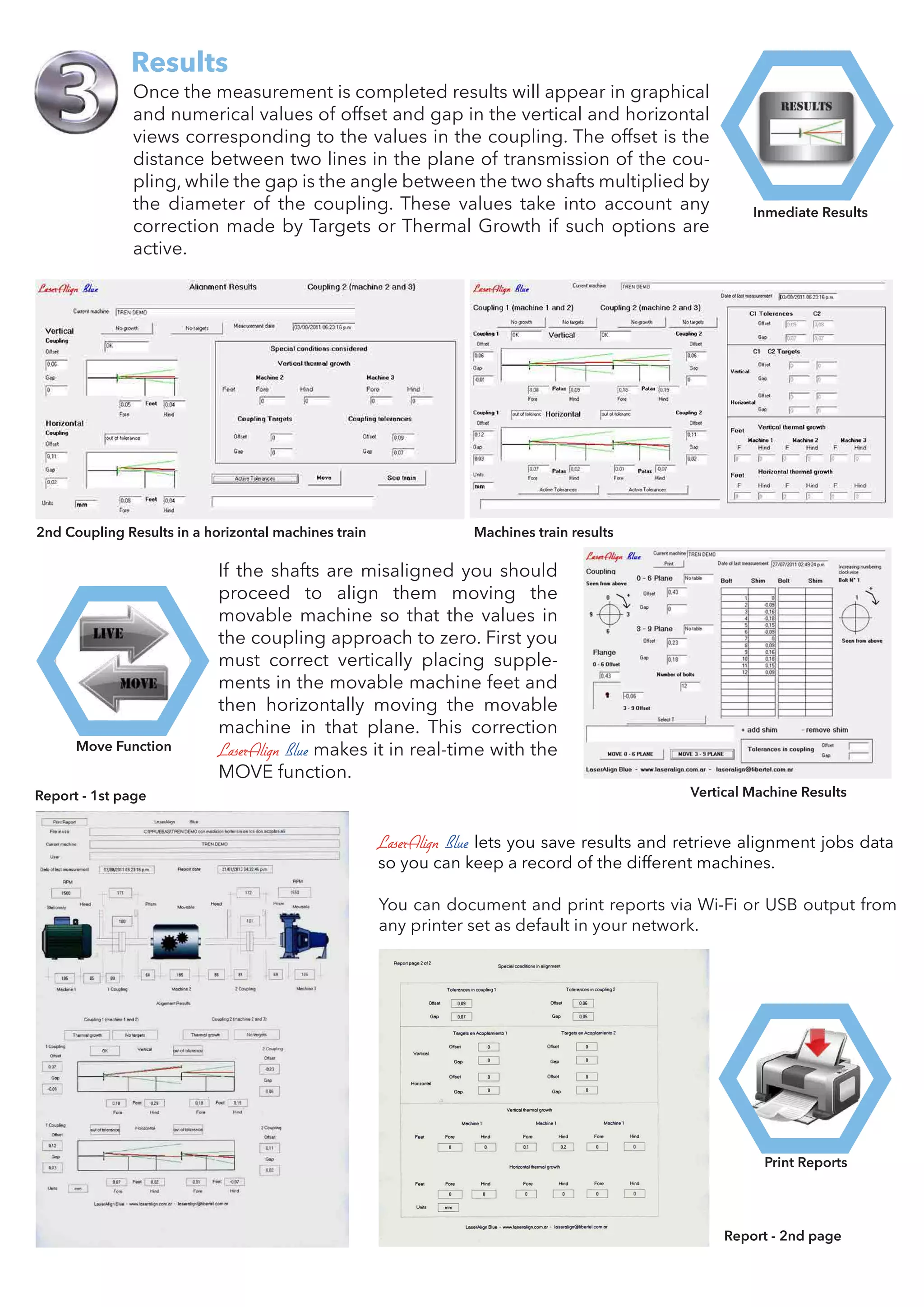

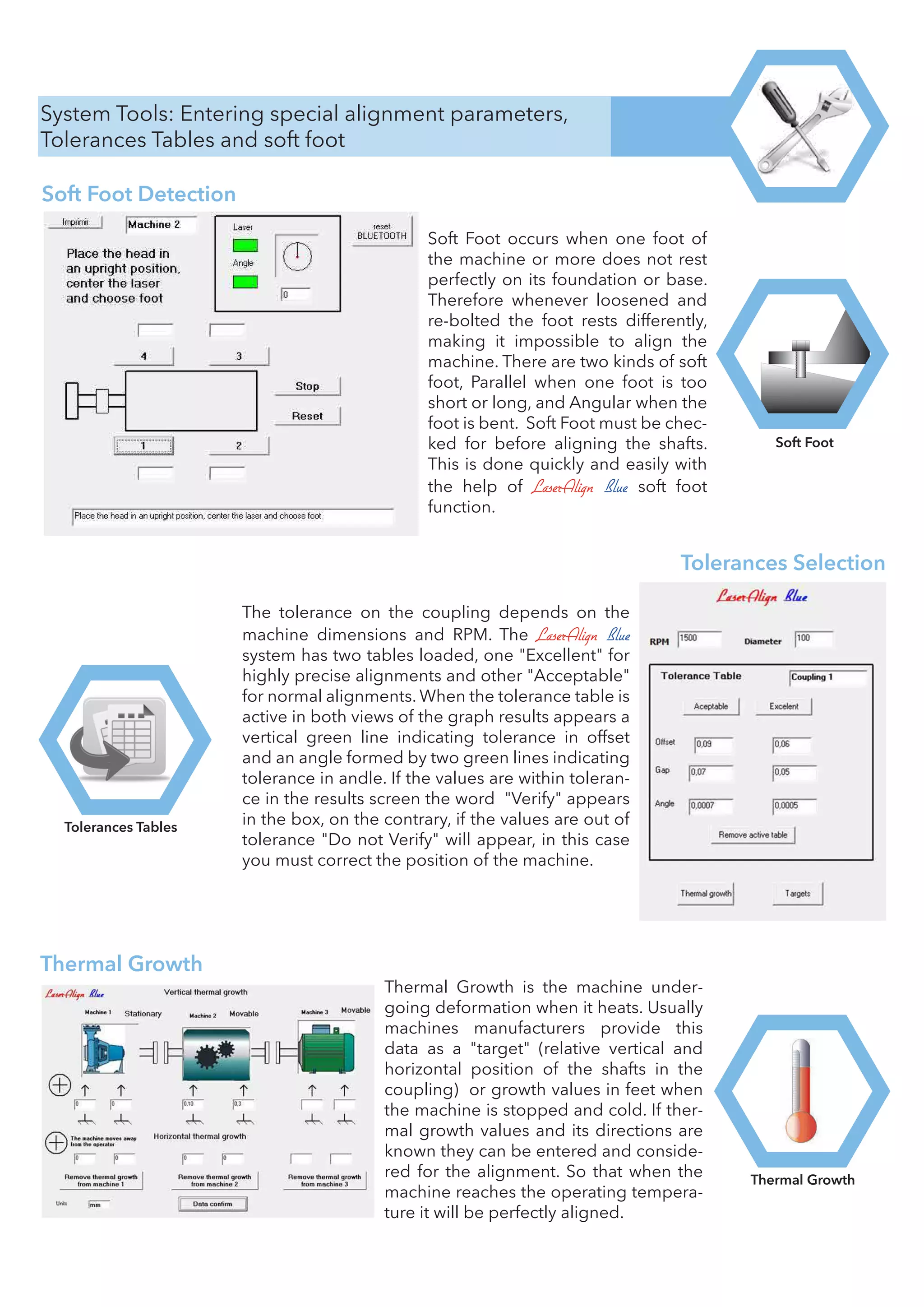

Laseralign Blue is an advanced laser shaft alignment system designed for both horizontal and vertical machinery, featuring a built-in electronic inclinometer and Bluetooth communication. It allows for easy measurements and corrections in real-time, while its robust design ensures functionality in industrial environments with various settings for machine types and operational tolerances. The system simplifies the alignment process, supports data management and reporting, and includes features for thermal growth and soft foot detection.