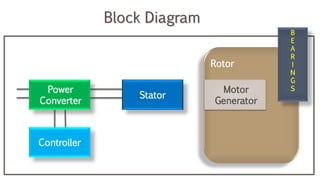

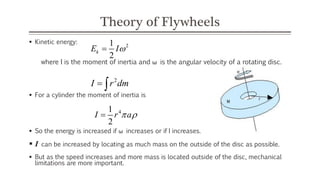

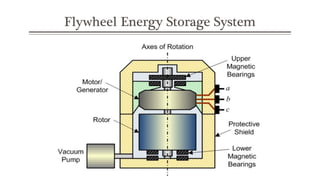

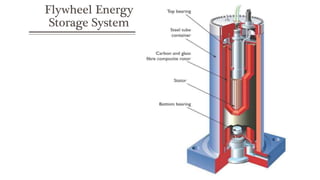

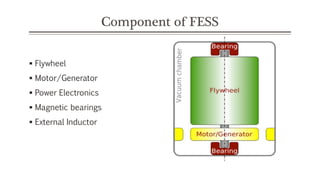

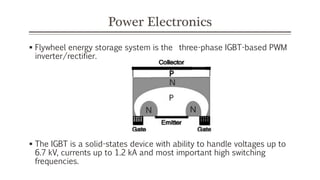

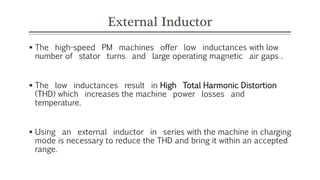

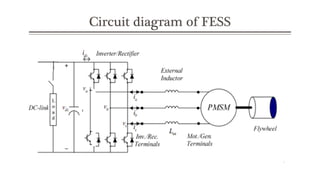

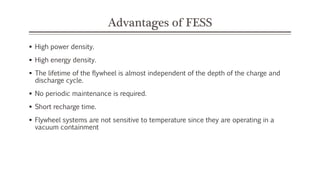

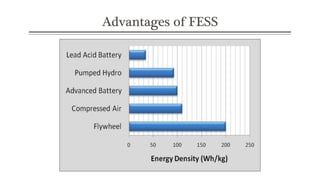

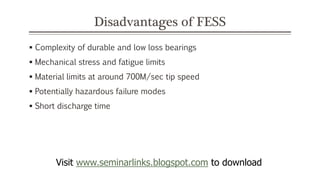

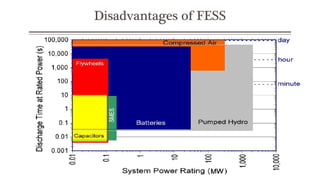

The document discusses flywheel energy storage systems, which mechanically store energy through a rotating mass for efficient energy management. Key components include the flywheel itself, a motor/generator, power electronics, and magnetic bearings, which collectively facilitate rapid energy transfer and high efficiency. Flywheel systems offer benefits such as high power density and minimal maintenance, but face challenges like material limits and potential failure modes.