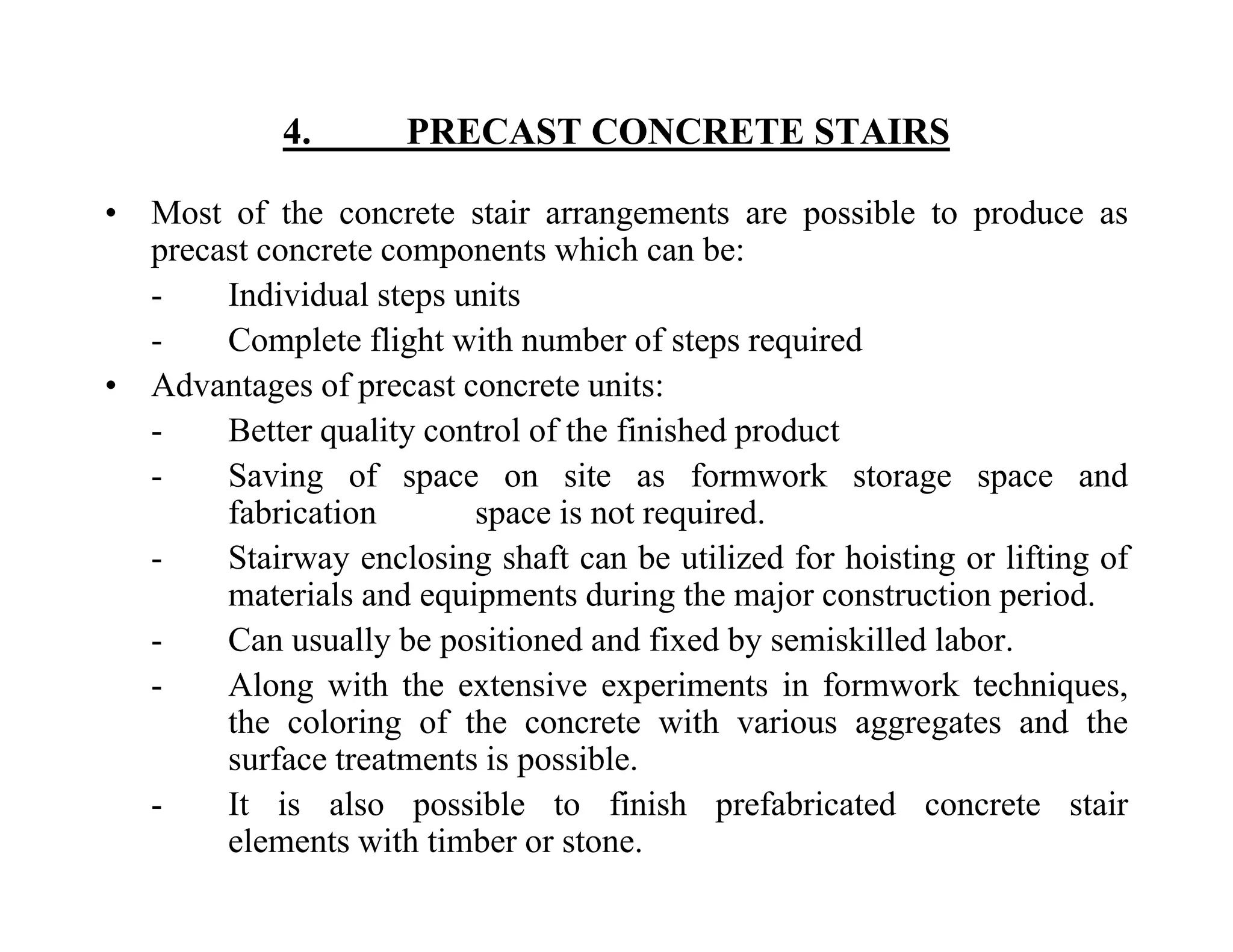

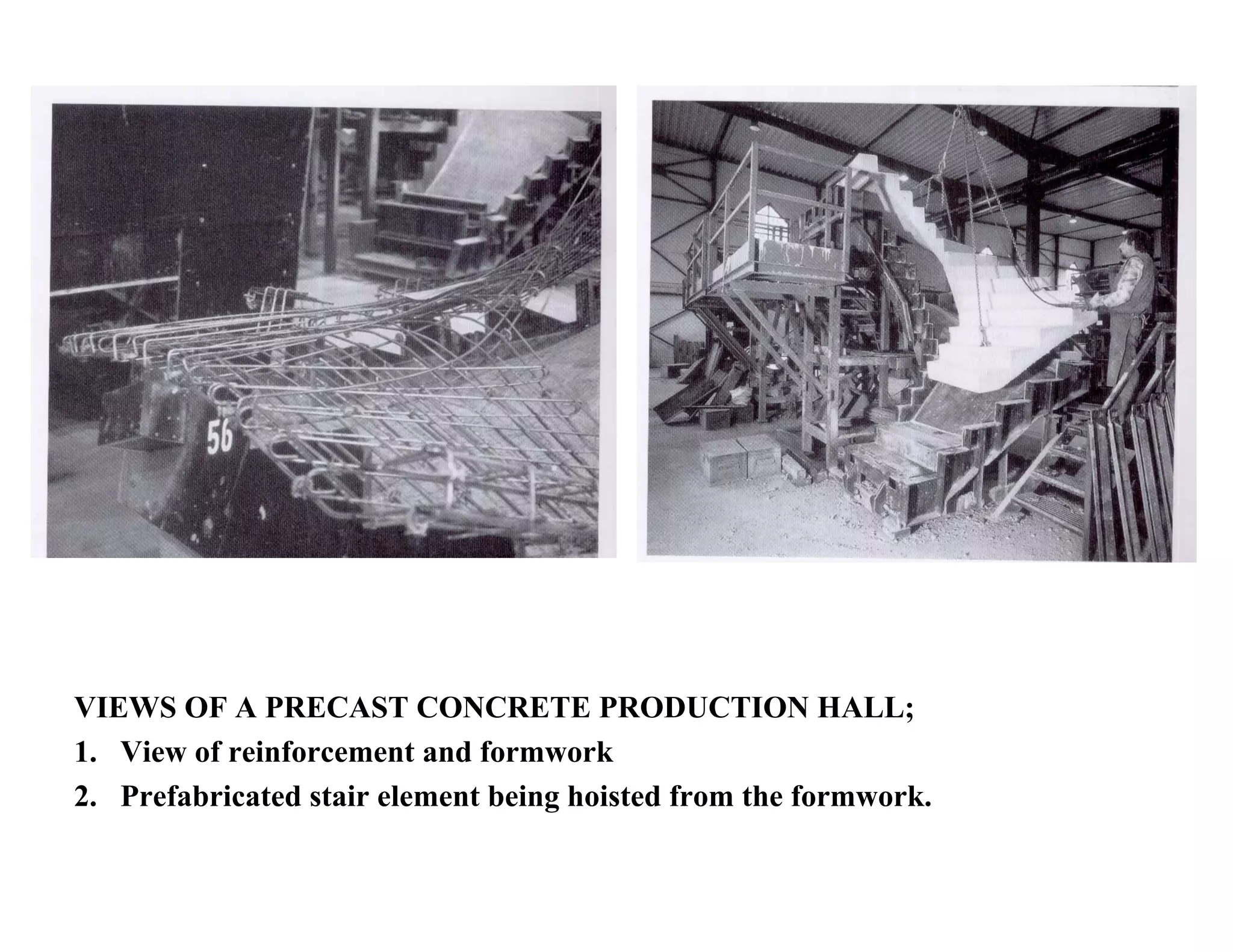

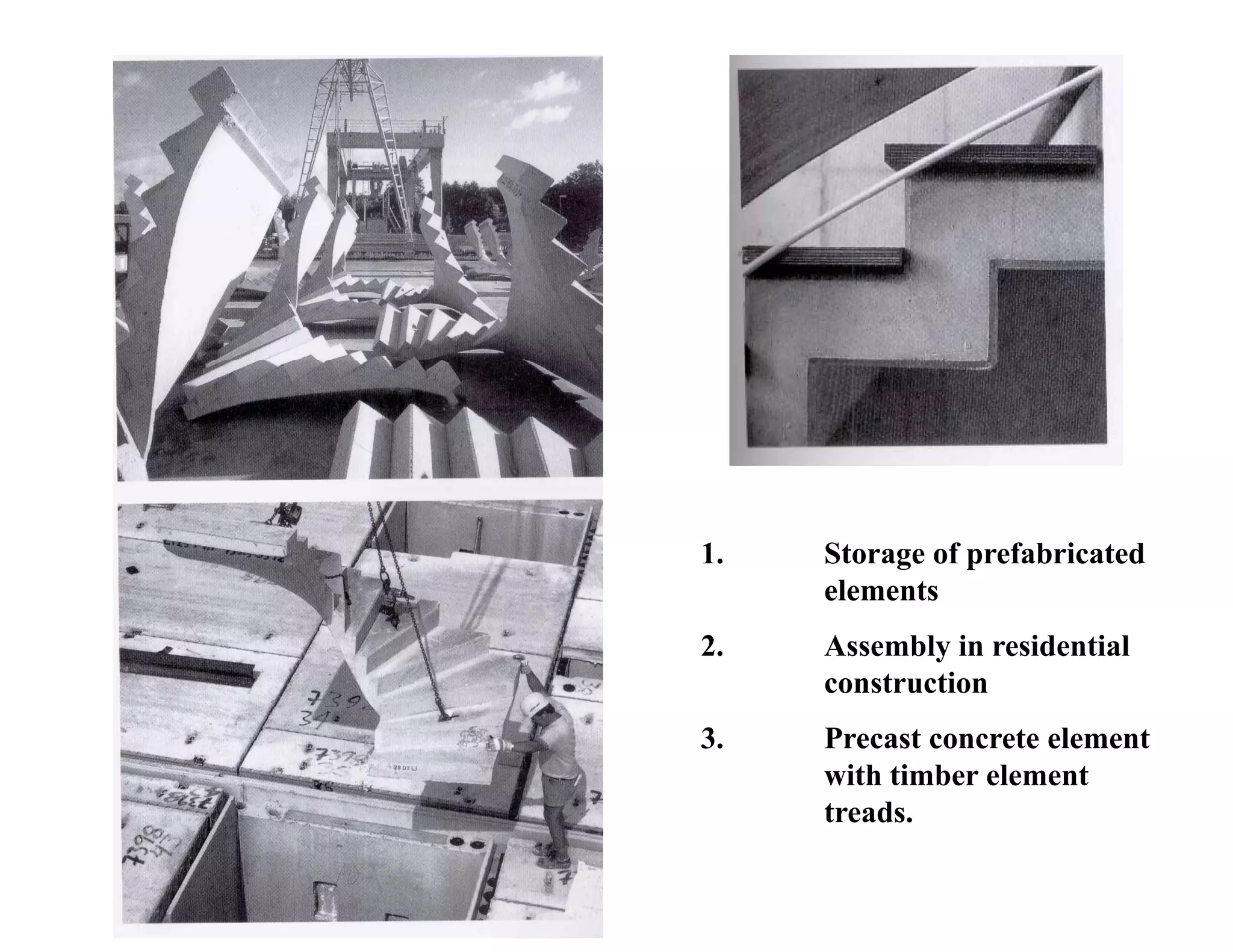

This document discusses precast concrete stairs, which can be produced as individual step units or complete flights. Advantages include better quality control, space savings on site, and the ability to position units with semi-skilled labor. Common precast step units include rectangular cantilever, spandrel cantilever, and sector-shaped cantilever units. The document also outlines different configurations for in situ and precast concrete stairs and shows pictures from a precast concrete production hall.