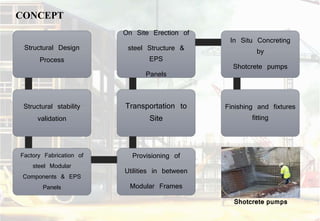

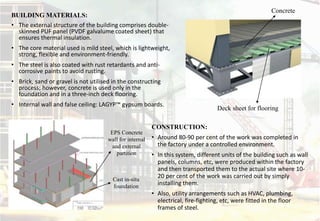

The document summarizes a case study of the Instacon Tower constructed in Mohali, India in 2012. The prefabricated steel structure was constructed in 48 hours using modular steel components fabricated off-site. Around 80-90% of the construction was completed in a controlled factory environment before components were transported and assembled on site. The modular construction approach using prefabricated steel components resulted in faster construction at lower cost compared to traditional methods.