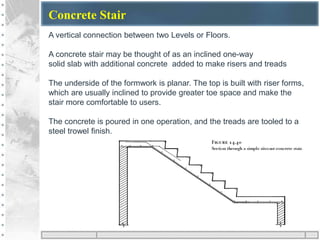

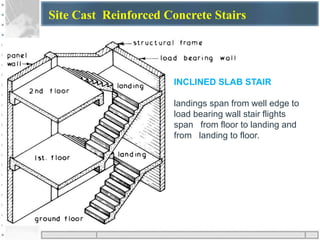

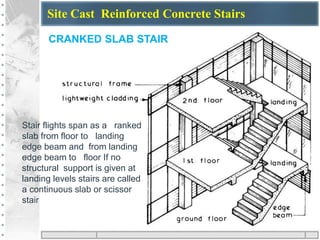

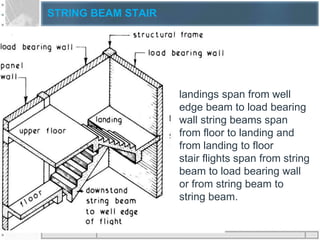

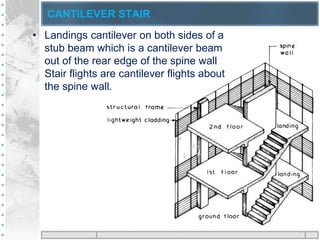

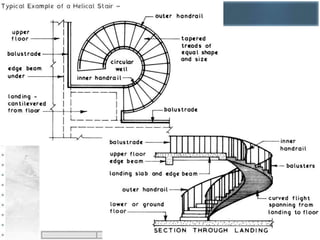

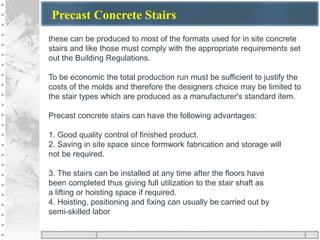

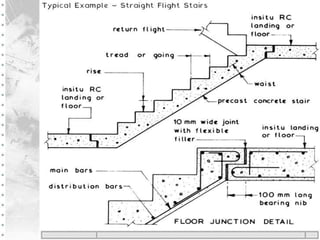

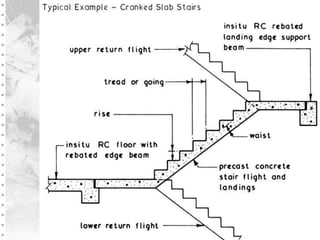

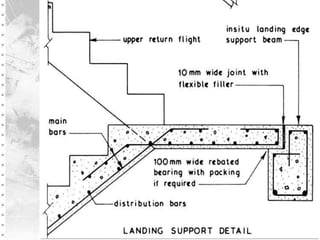

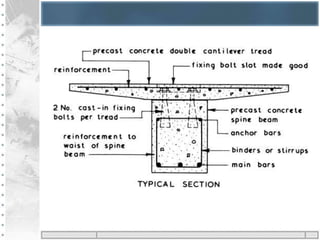

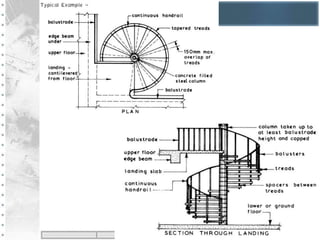

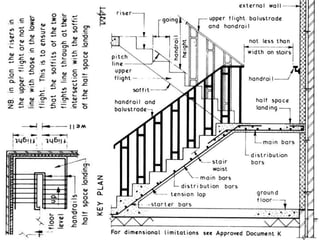

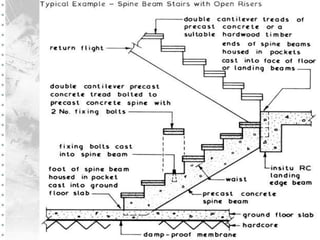

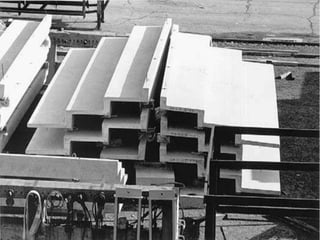

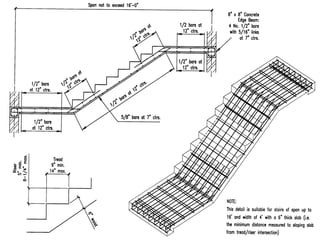

The document outlines the major elements of frame structures including foundations, columns, slabs, beams, and stairs, as well as detailing various types of concrete stairs such as inclined, cantilever, and spiral designs. It discusses construction techniques for both site-cast and precast concrete stairs, emphasizing compliance with building regulations and the advantages of precast methods. Additionally, it notes the aesthetic aspects and structural requirements for different stair types, particularly in safety-related scenarios.