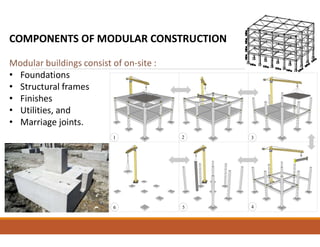

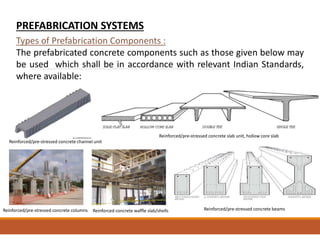

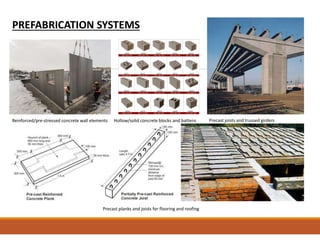

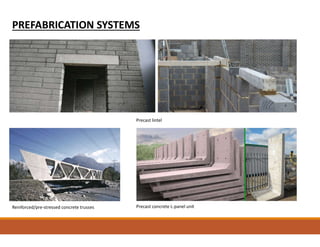

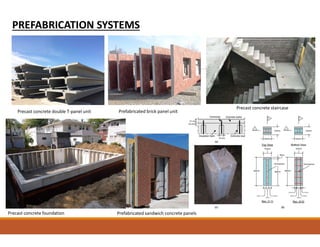

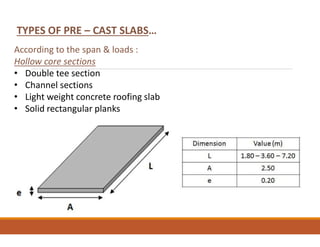

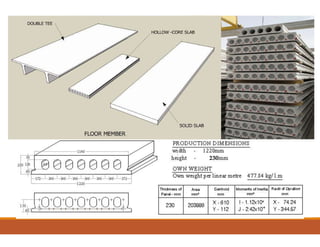

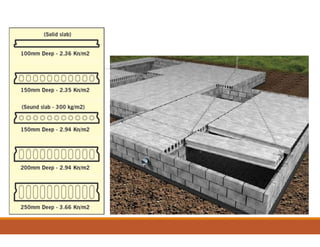

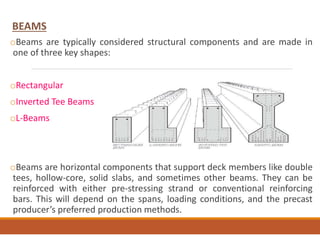

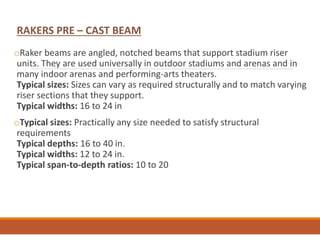

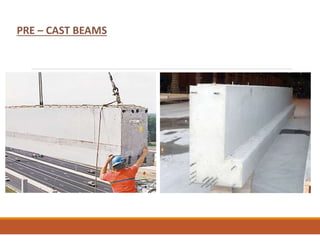

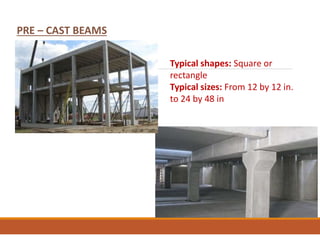

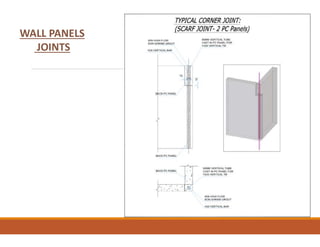

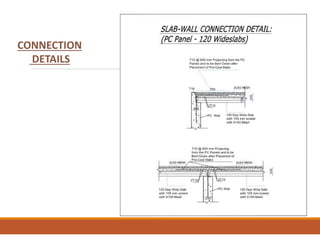

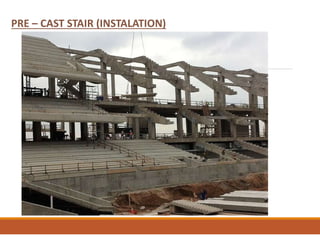

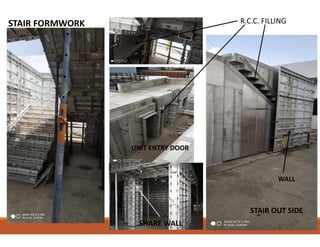

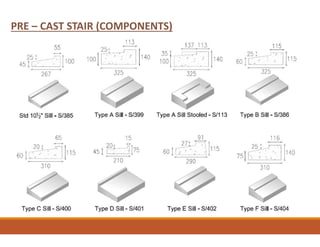

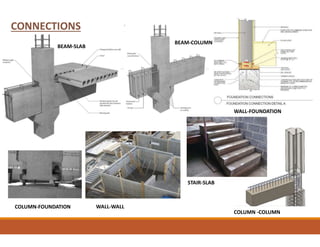

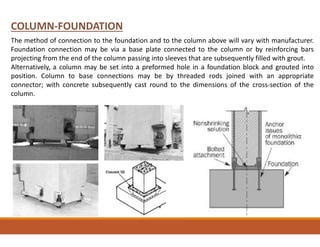

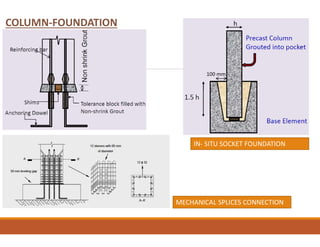

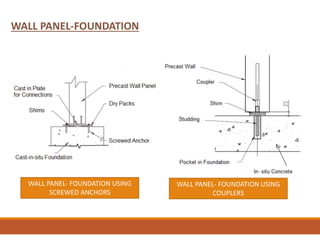

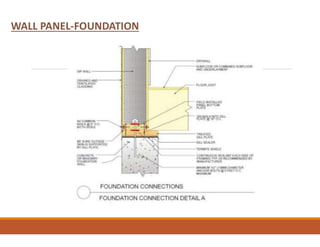

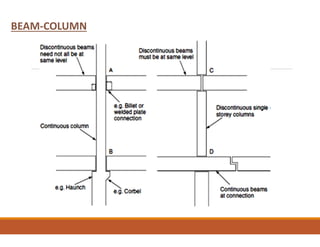

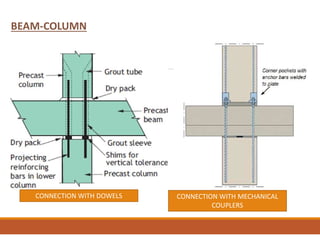

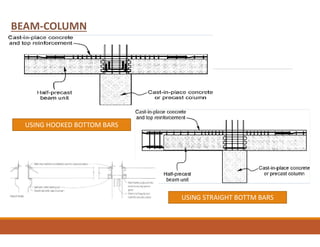

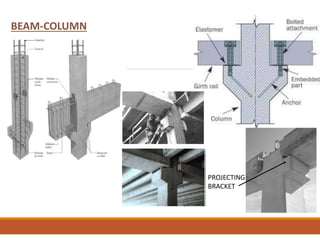

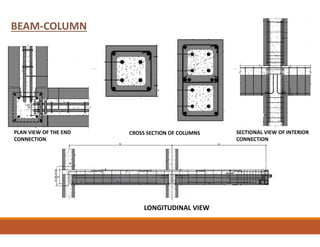

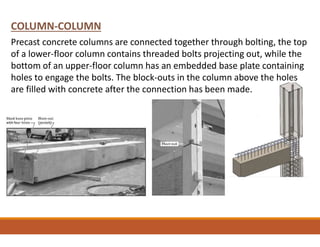

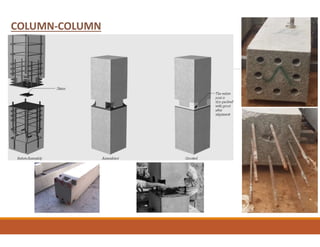

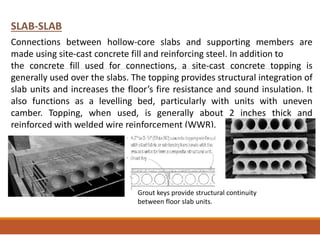

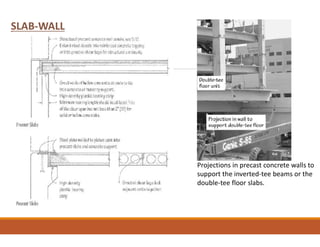

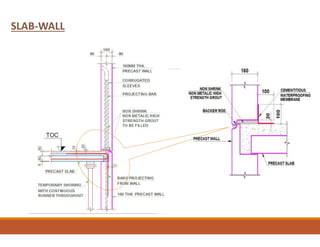

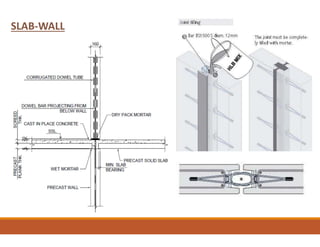

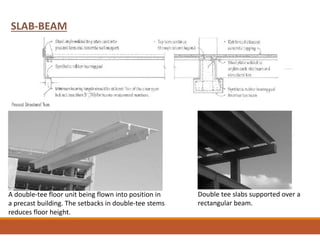

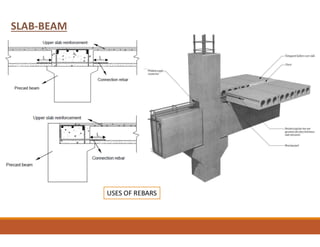

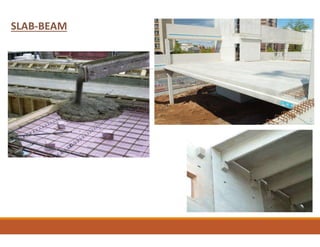

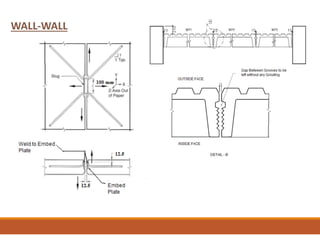

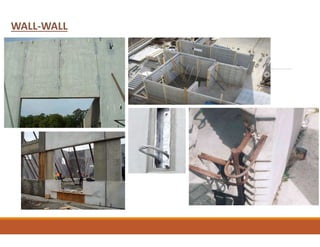

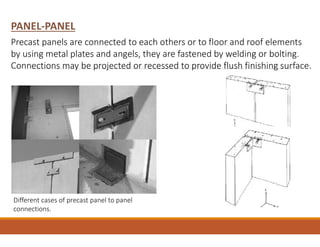

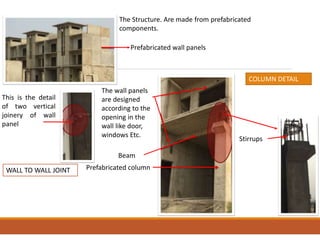

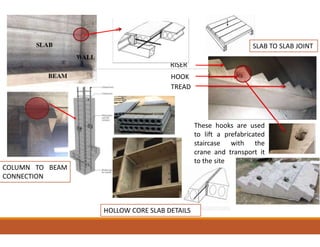

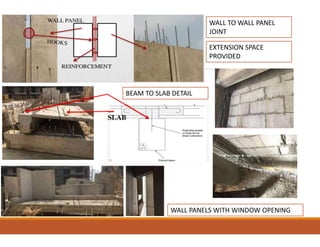

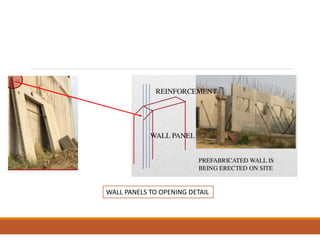

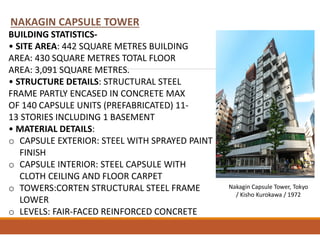

This document discusses modular and prefabricated construction components used in precast concrete buildings. It describes the key components that can be prefabricated off-site such as walls, floors, beams, columns, stairs, and their connections. These include different types of precast walls, slabs, beams shaped as I-beams, L-beams or rectangular, and dimensions for efficient construction. Connection details are provided for beam-column, wall-foundation, and other joints.