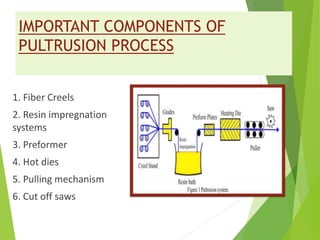

Pultrusion is a continuous manufacturing process for composite materials with constant cross-sections, utilizing essential components like fiber creels, resin impregnation systems, and hot dies. It allows for the production of complex shapes but primarily accommodates constant cross-sectional profiles, presenting some disadvantages, such as limitations on fiber orientation control and susceptibility to voids if improperly managed. The process is cost-effective compared to some other methods but requires a significant initial investment and has varying production speeds based on shape complexity.