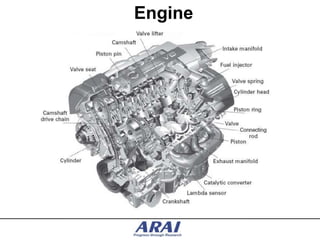

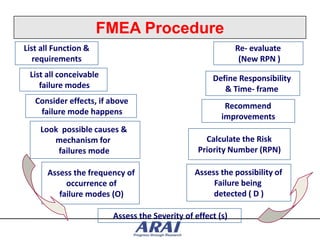

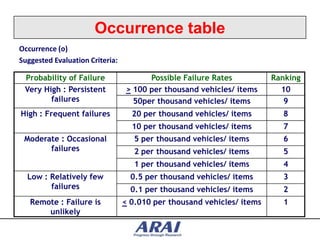

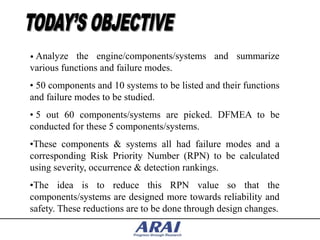

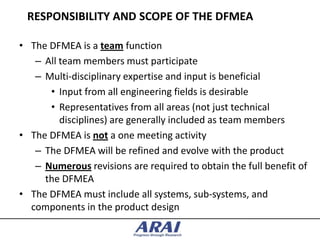

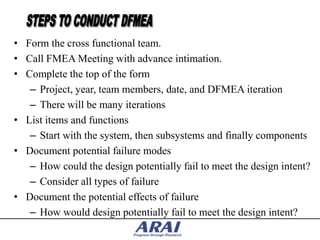

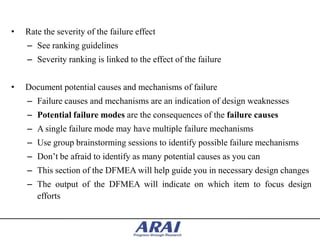

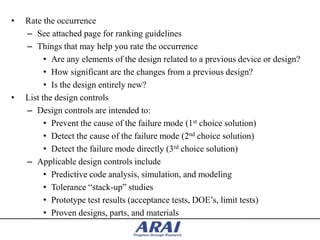

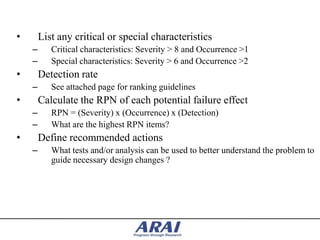

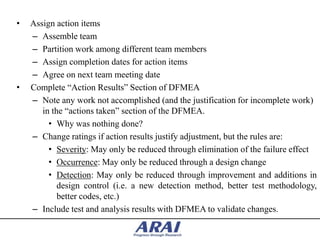

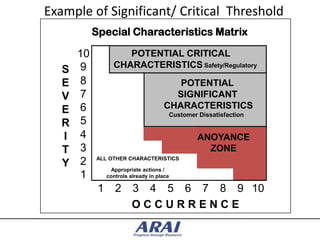

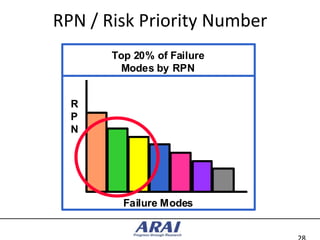

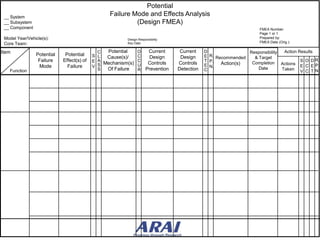

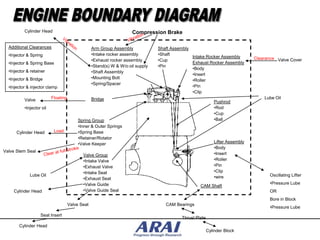

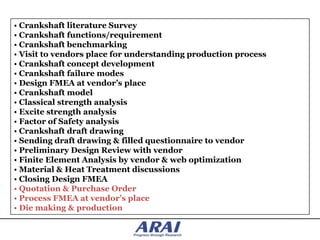

The document discusses failure mode and effects analysis (FMEA) of engine systems to identify potential failures, analyze their causes and effects, and determine corrective actions to improve reliability. It provides details on conducting a DFMEA, including assembling a cross-functional team, documenting functions and potential failure modes, analyzing severity, occurrence, and detection of failures, and calculating a risk priority number. The goal is to iteratively conduct the DFMEA, take corrective actions, and reduce the risk priority numbers to design more reliable engine components and systems.

![• Major Input Data (at Max BMEP operating point) :-

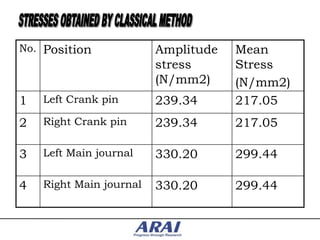

Sr. No. Parameter Value

1 Main Brg Centre Distance [mm] 100.oo

2 Section modulus of left crank web [mm3] 2008.63

3 Section modulus of Right crank web [mm3] 2008.63

4 Thickness of left and right webs [mm] 20.5

5 Eq length of left crank web [mm] 116.00

6 Eq length of right crank web [mm] 116.00

7 Crank pin / main journal fillet radius [mm] 3.5

8 Material of Crankshaft (Present ) 30CrNiMo8

9 UTS crankshaft material [N/mm2] 1250

10 Fatigue Strength of CS material [N/mm2) 510

11 Engine Speed [rpm] 2000](https://image.slidesharecdn.com/dfmeaforenginesystems-121123072808-phpapp01/85/Dfmea-for-engine-systems-42-320.jpg)