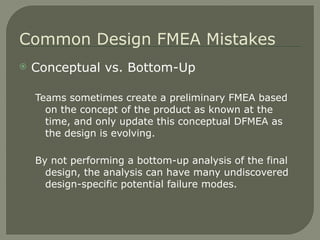

The document discusses common mistakes in design failure mode and effects analysis (DFMEA). It recommends (1) not wasting time arguing over ratings, (2) rating the occurrence of failure causes rather than just occurrence, (3) considering preventability rather than just detection, (4) updating the DFMEA often as the design evolves, and (5) evolving the DFMEA from an initial conceptual analysis to a bottom-up analysis of the final design.