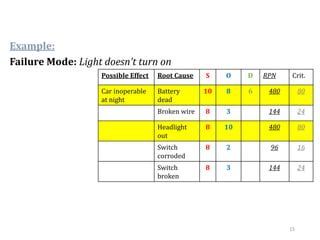

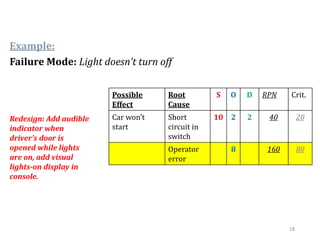

The document discusses Failure Mode Effects and Analysis (FMEA), a systematic approach for identifying potential failures in a design or process and assessing their impact. It outlines the history of FMEA, its processes, benefits, and provides a step-by-step method for conducting FMEA, including risk prioritization. Examples illustrate the application of FMEA in assessing failure modes, consequences, and mitigation strategies to enhance product safety and reliability.