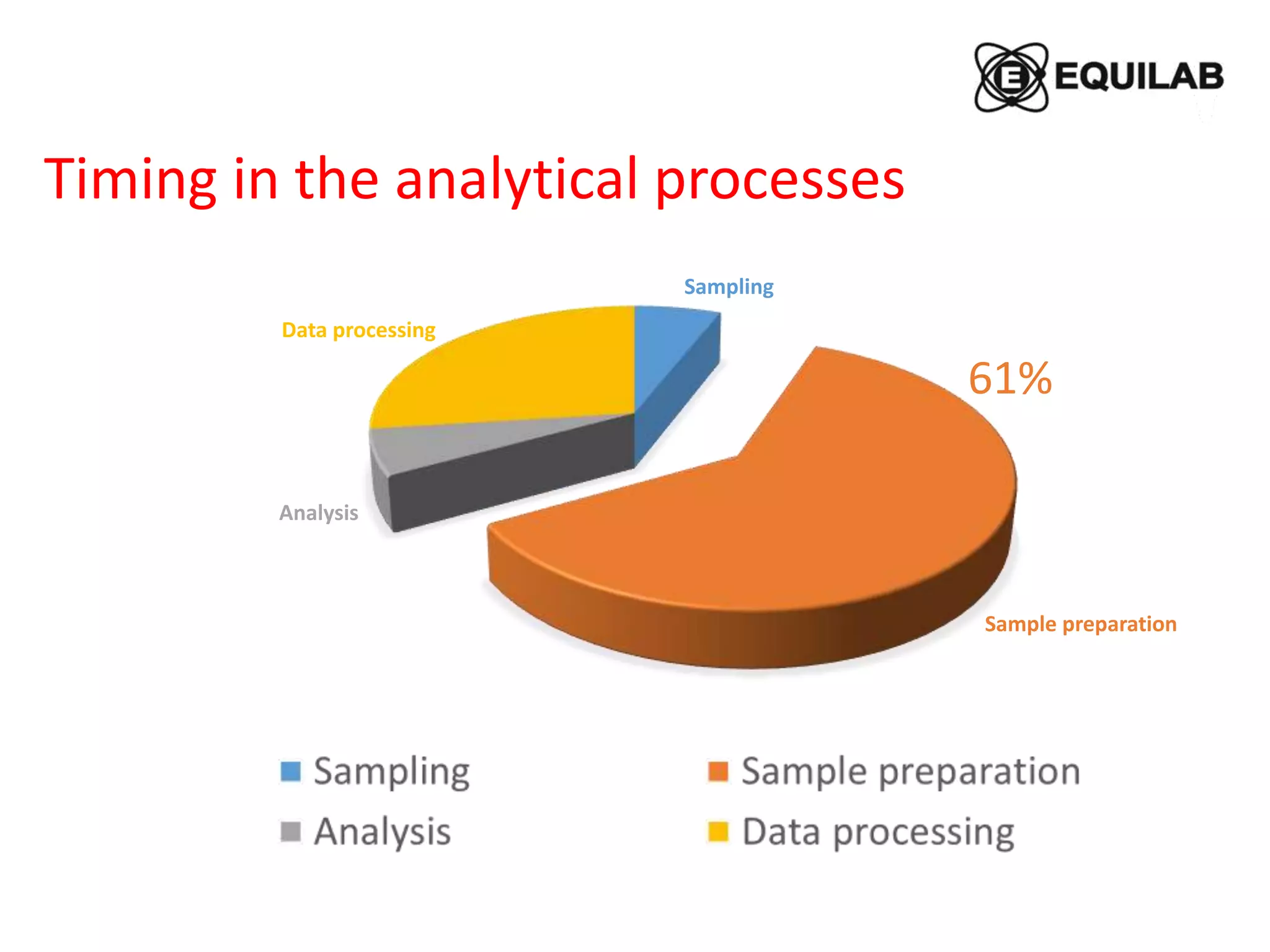

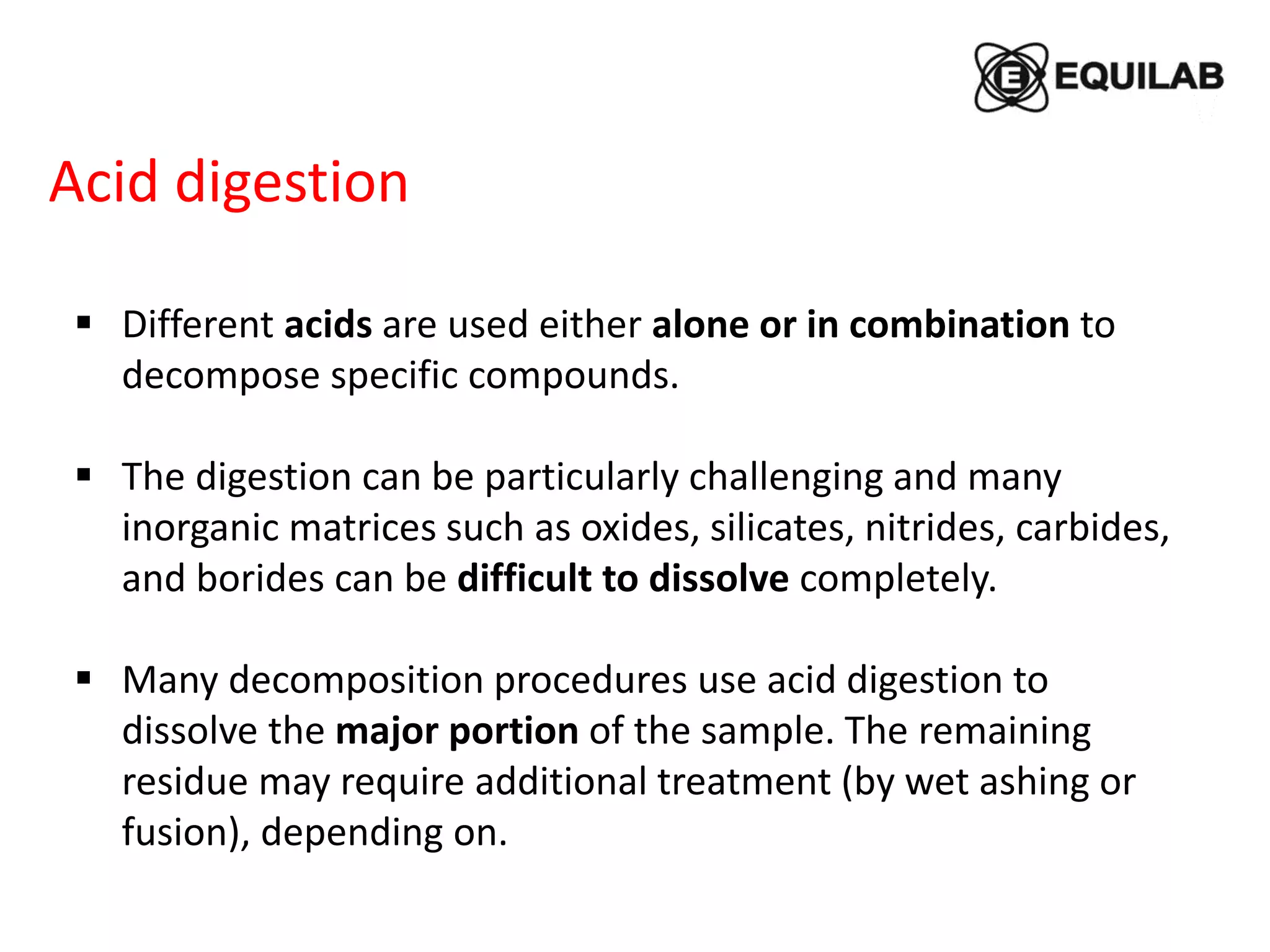

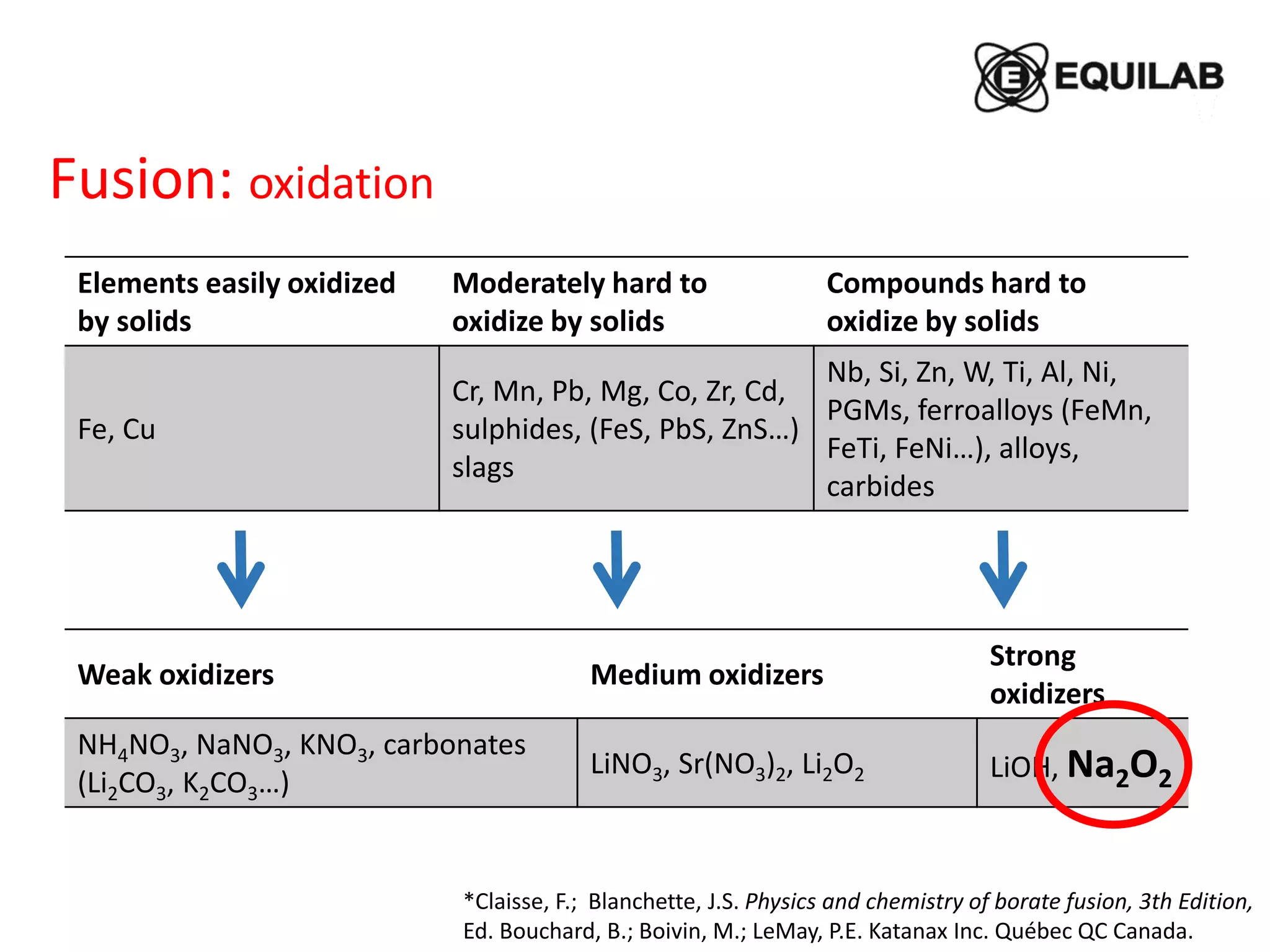

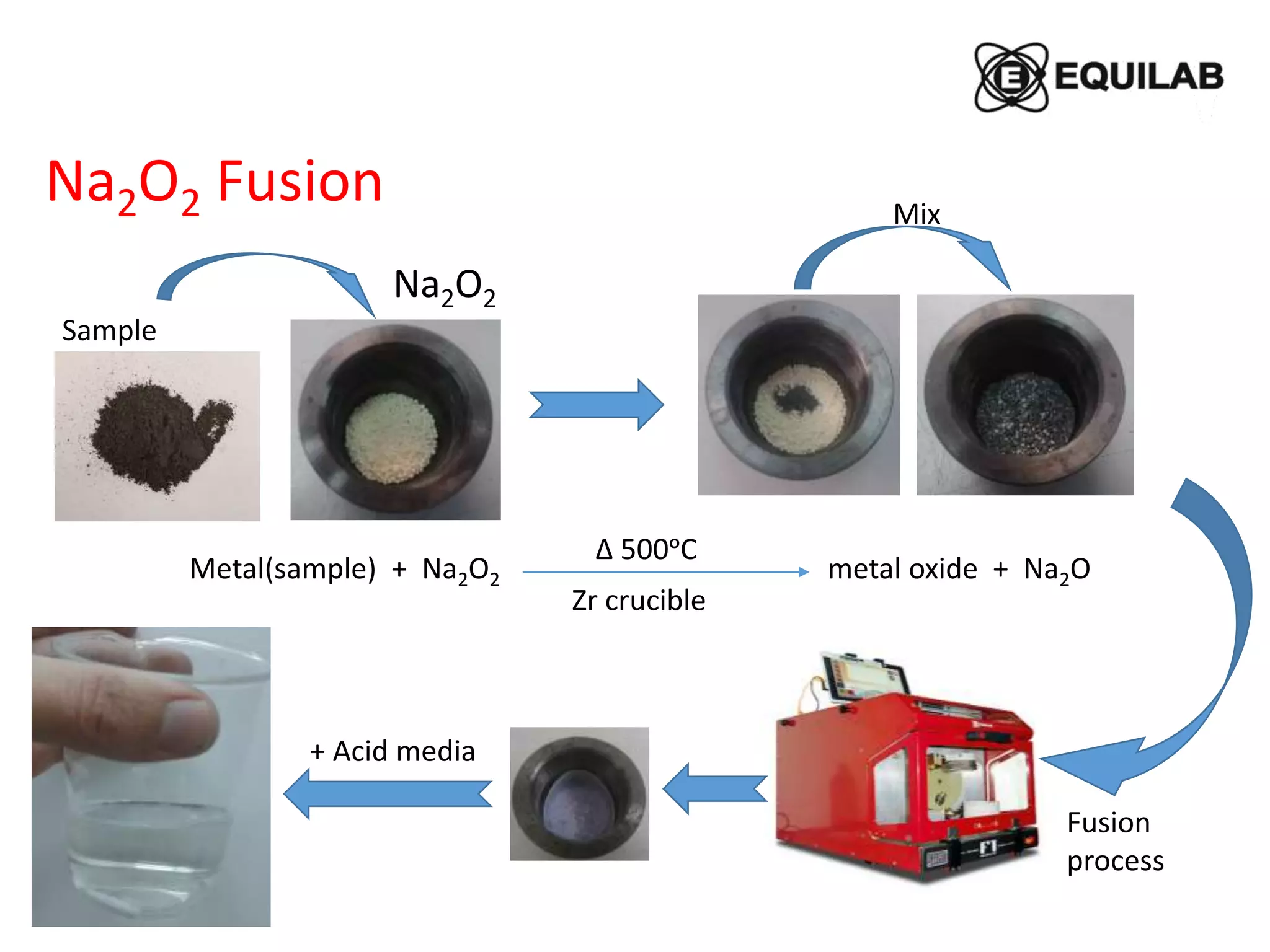

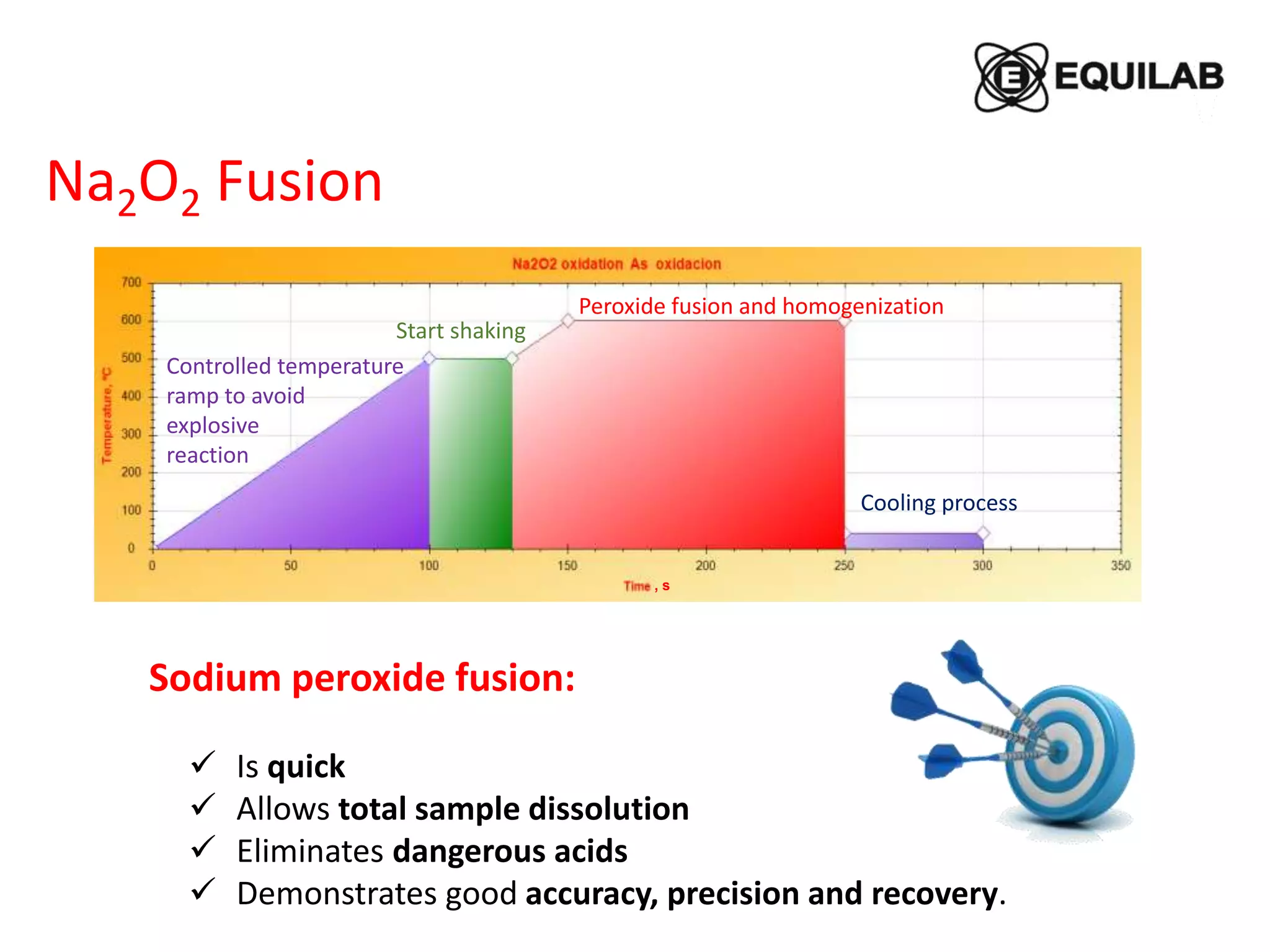

Sodium peroxide fusion is an effective sample dissolution technique that provides complete digestion of samples in a short period of time. It avoids the use of dangerous acids and allows for accurate, precise, and reproducible analysis by ICP-OES and ICP-MS. The process involves mixing the sample with sodium peroxide flux in a crucible, heating to melt and fuse the mixture, then dissolving the cooled fused bead in acid for elemental analysis. Sodium peroxide fusion has been shown to quantitatively dissolve a variety of materials like minerals, alloys, and precious metals samples.

![Na2O2 Fusion: Rare earth elements by ICP-OES and ICP-MS

Application note, 2018. Analysis of Rare Earth Elements by ICP-OES and ICP-MS Potentials and Limitations.

Analytik Jena AG, an Endress+Hauser Company. Jena Germany. www.analytik-jena.com

Sample preparation:

Porcelain crucible (30 x 30 mm) in a muffle

100 mg of ground sample 200- mesh

600 mg sodium peroxide

480 ± 10ᵒC, 30 min

Dissolved in a aqueous HCl + HNO3

Element

CRM GBW 7103

(GSR-1) Granite

powder [mg/kg]

Measured

[mg/kg]

Recovery

[%]

MDL

[mg/kg]

La 54 ± 4 53.4 99 0.14

Ce 108 ± 7 112 112 0.85

Pr 12.7 ± 0.8 12.2 96 1.55

Nd 47 ± 4 48.6 106 0.34

Sm 9.7 ± 0.8 9.23 95 0.65

Eu 0.85 ± 0.07 0.71 84 0.04

Gd 9.3 ± 0.7 10.3 111 0.36

Dy 10.2 ± 0.4 10.6 104 0.32

Er 6.5 ± 0.3 7.0 108 0.15

Ho 2.05 ± 0.17 2.22 108 0.11

Yb 7.4 ± 0.5 7.67 104 0.34

Lu 1.15 ± 0.09 1.11 97 0.19

Instrument: HR ICP-OES PlasmaQuant®

PQ 9000 Elite

Nebulizer Parallel path, PFA

Spray Chamber PTFE cyclonic, 50 mL

Torch Single slot quartz torch

Injector 2.0 mm alumina

Plasma Gas (L/min) 15

Aux Gas (L/min) 1.0

Neb Gas (L/min) 0. 5

Sample Rate (mL/min) 1.5

Plasma view axial](https://image.slidesharecdn.com/sampledissolution-190312161906/75/Sample-Dissolution-19-2048.jpg)