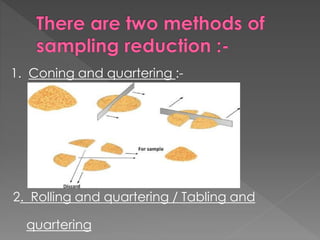

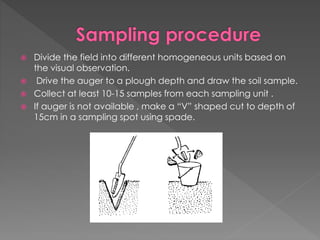

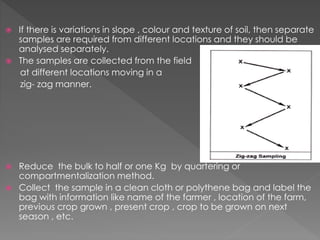

This document discusses methods for sampling solids and soils. There are two main methods for reducing bulk solids: coning and quartering, and rolling and quartering. For soil sampling, a plan should be developed and composite samples taken from uniform field areas under 40 acres. Samples should be taken after harvest at consistent times and depths. Proper tools like probes and bags should be used safely. Soil testing facilitates fertilizer decisions and nutrient management. Coal and particulate samples help determine properties like calorific value, moisture, and ash content.