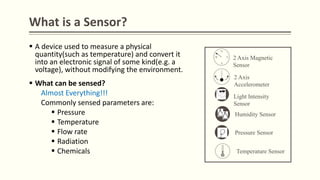

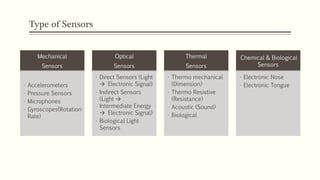

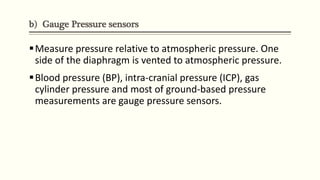

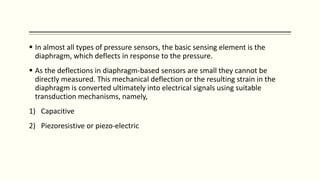

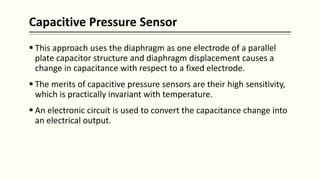

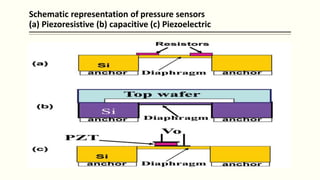

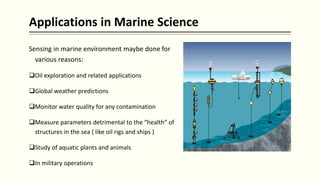

MEMS (Micro-Electro-Mechanical Systems) integrates electrical and mechanical components on a chip to create miniature sensing devices with various applications, including accelerometers and pressure sensors. These sensors are advantageous due to their small size, lower power consumption, high sensitivity, and cost-effectiveness. Key types of sensors discussed include mechanical, optical, thermal, and chemical sensors, all of which have diverse applications in fields like aerospace, biomedical, and marine environments.