This document discusses flow through pipes, including:

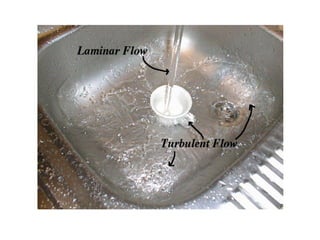

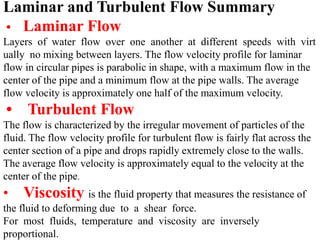

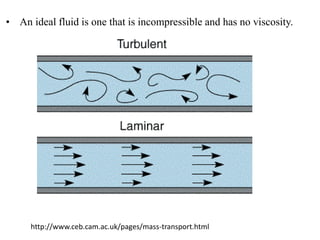

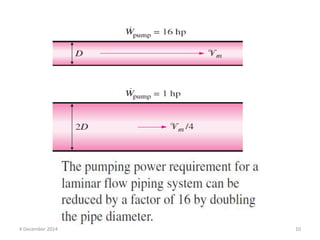

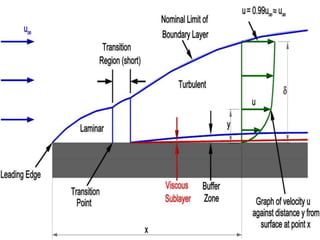

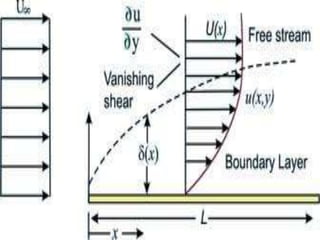

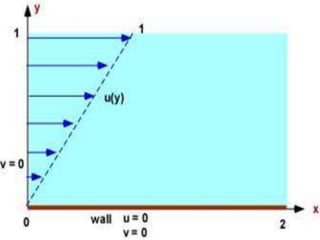

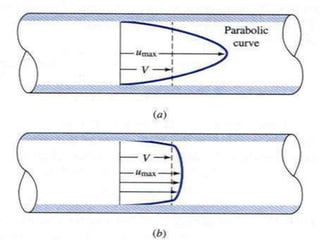

- Laminar and turbulent flow characteristics defined by Reynolds number

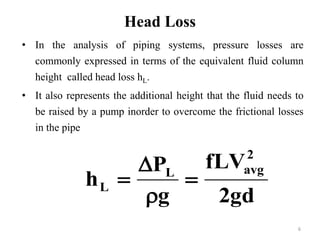

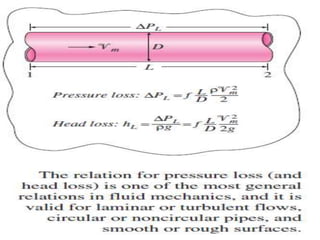

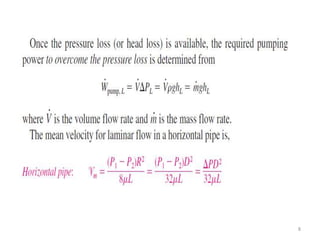

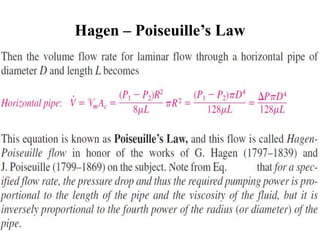

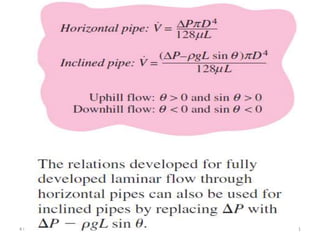

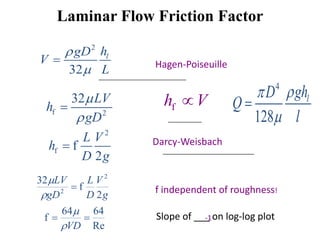

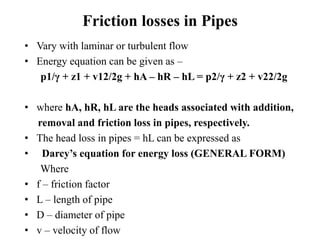

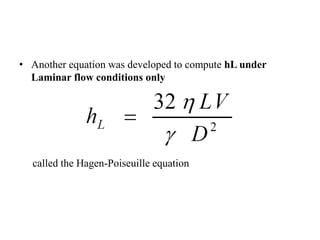

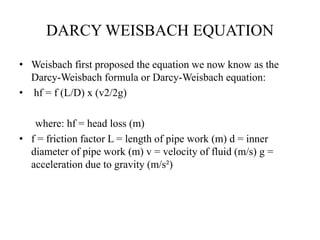

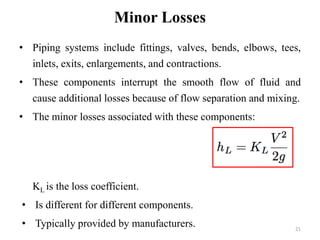

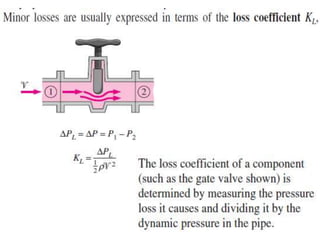

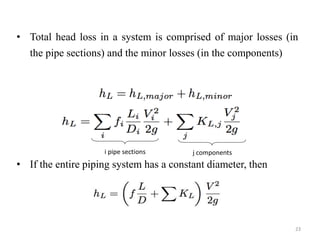

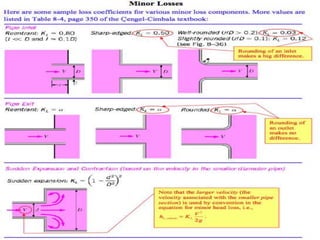

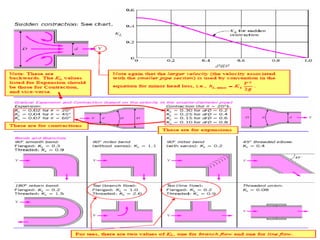

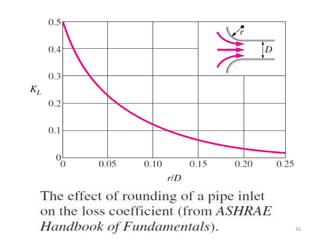

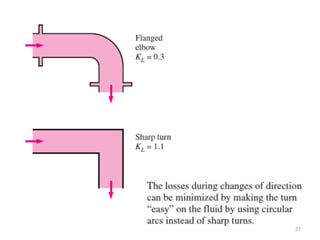

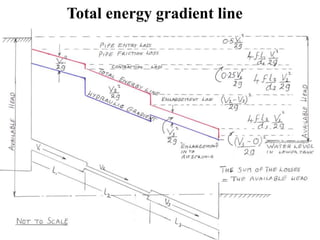

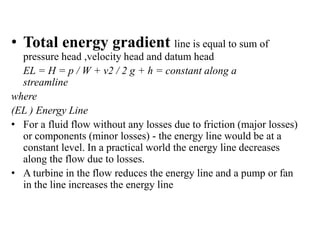

- Head losses calculated using Darcy-Weisbach and minor loss equations

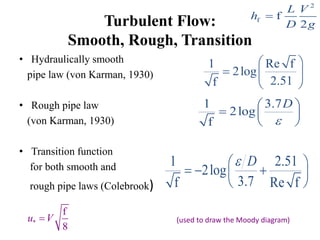

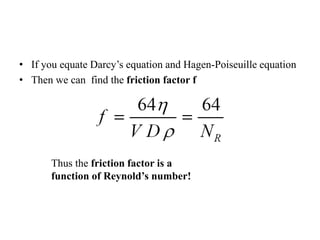

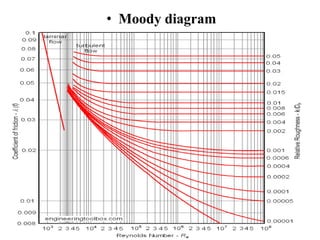

- Friction factors determined from Moody diagrams for laminar and turbulent flows

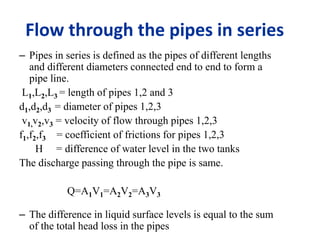

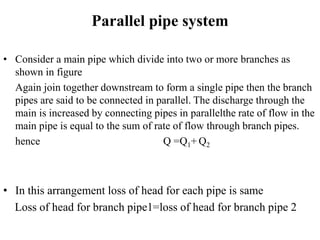

- Total head loss in a pipe system equals major losses in pipe sections plus minor losses from fittings