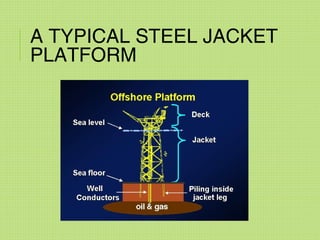

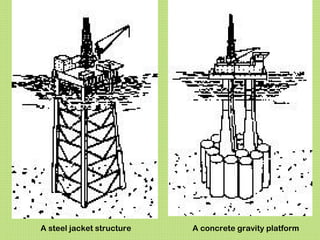

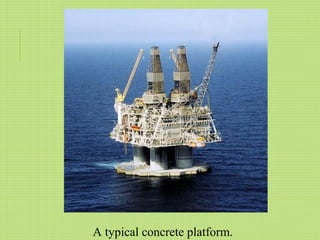

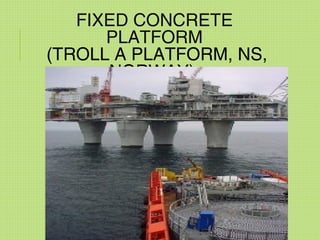

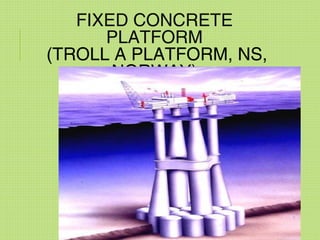

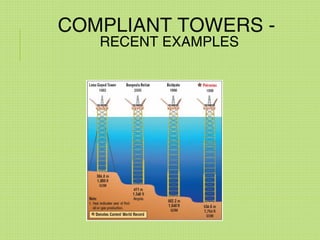

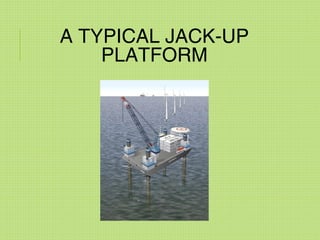

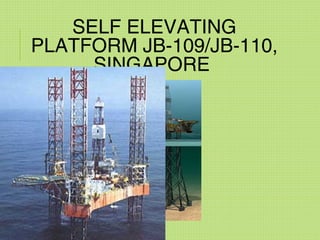

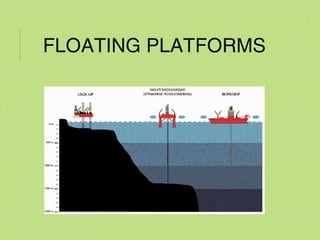

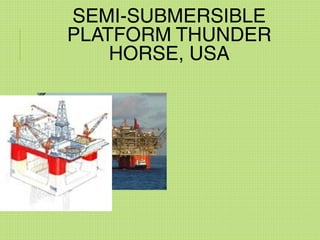

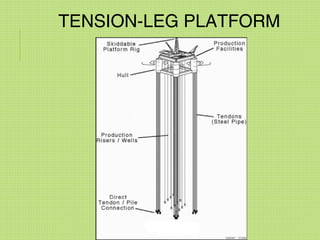

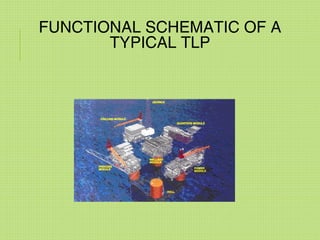

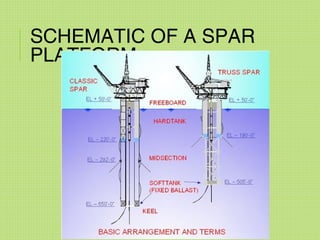

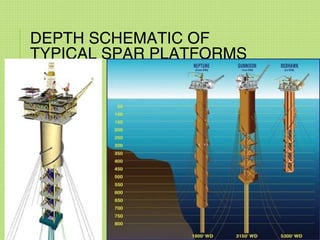

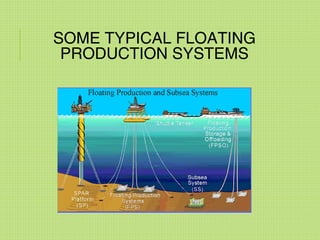

Offshore platforms are large structures located at sea that house crews and machinery used for exploring and producing natural resources like fossil fuels from under the ocean bed. There are various types of offshore platforms including fixed platforms, compliant towers, jack-up platforms, semi-submersible platforms, drillships, tension-leg platforms, SPAR platforms, and unmanned installations. Over 6,500 offshore oil and gas platforms are located around the world, with the largest numbers in the Gulf of Mexico, Asia, and Europe. Platforms can be either fixed to the seabed or floating, and are used to extract resources from shallow to very deep waters.