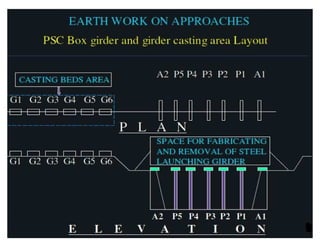

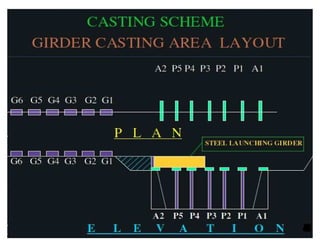

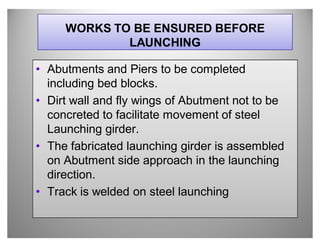

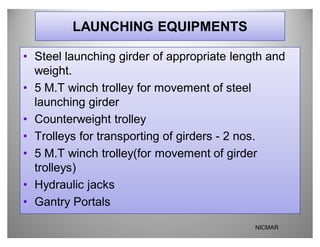

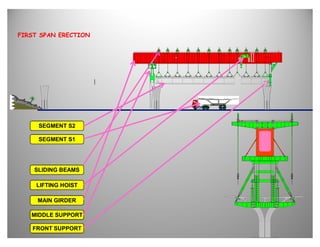

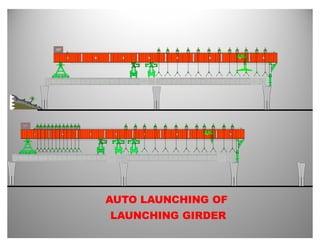

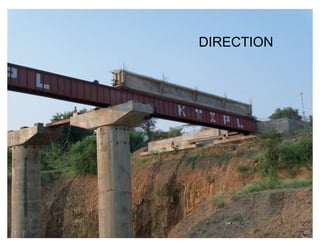

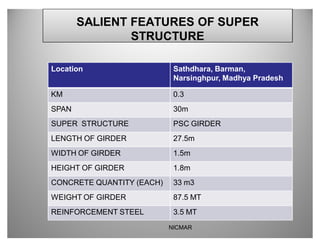

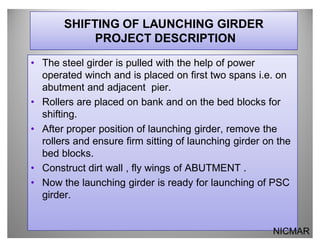

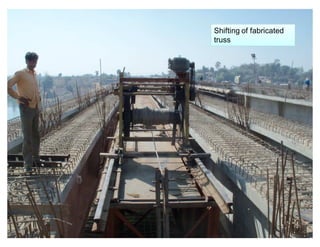

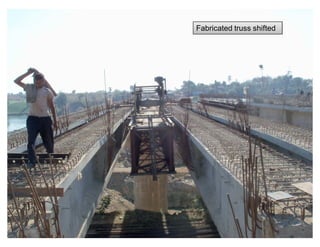

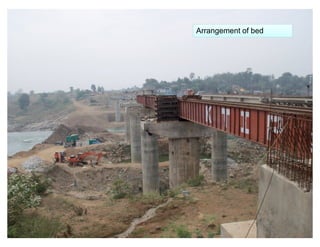

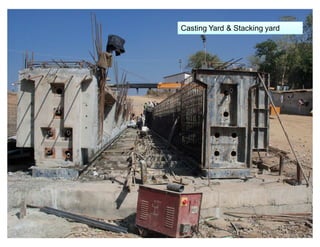

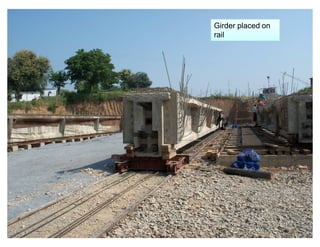

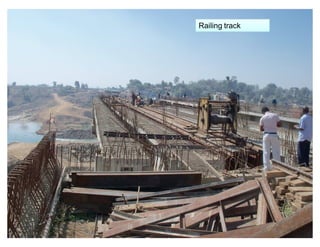

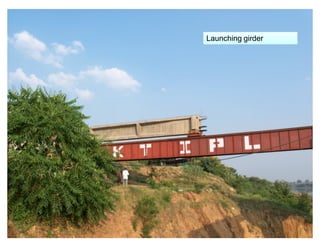

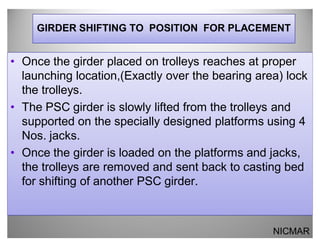

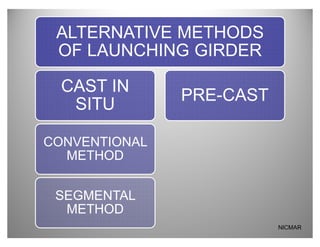

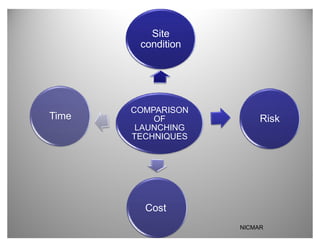

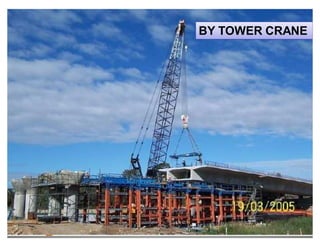

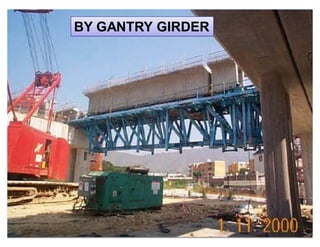

This document provides information about launching girders for bridge construction. It discusses the necessary preparations before launching including completing abutments and piers. It describes the launching equipment used such as the steel launching girder, winches, and trolleys. The document outlines the process for shifting the launching girder and launching precast concrete girders segment by segment onto the bridge. It compares different launching techniques and discusses advantages such as allowing construction at any height and simultaneous work on substructure and superstructure.