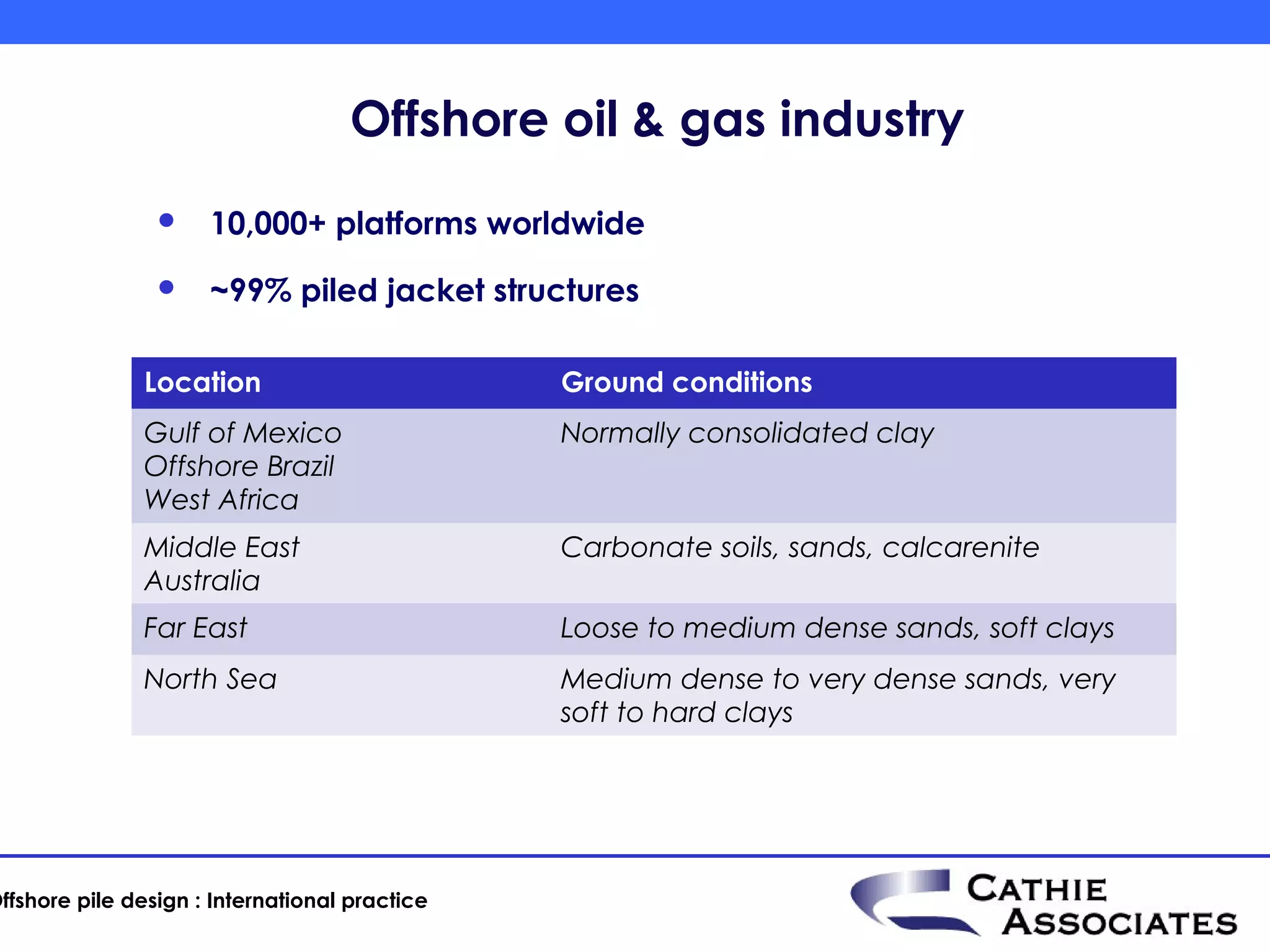

The document outlines international practices in offshore pile design within the oil and gas industry, emphasizing the extensive experience and safety measures for both small and large projects. It discusses various standards and methods for pile resistance, driveability, and monitoring, while also addressing innovations and reliability of designs in the context of risk aversion. The insights on tripod structures highlight key design issues, showing their advantages over monopiles, and stress the importance of adopting practical solutions based on existing industry experience.

![CPT method – application by Shell

Dynamic SRD [MN] Dynamic SRD [MN]

0 4 8 12 16 20 0 4 8 12 16

0 0

5 ICP

API

20

10

15

40

20

25 ICP

60 API

m

m

w

w

a

a

o

e

o

e

n

n

B

B

P

P

S

S

]

[

r

]

[

r

t

t

f

f

l

i

l

i

30

35 80

Overy (2007) The Use of ICP Design Methods for the

Foundations of Nine Platforms installed in the UK North Sea, Int.

Offshore Site Investigation and Geotechnics Conference

Offshore pile design : International practice](https://image.slidesharecdn.com/piledesignaccordingtointernationalpractice06-121016084206-phpapp01/75/Offshore-pile-design-according-to-international-practice-14-2048.jpg)

![Pile driving monitoring – signal matching

G-OCTOPUS

C126 UW PDM OLOWI PILE DRIVING ANALYZER ®

PDA OP: ACR-MHA Version 2009.098.061

PILE C1

JACKET WHT-A

BN 3/828

30/07/2009 18:23:25

80000 Signal matching (CAPWAP/TNOWAVE)

7.16 EMX 845.1 kN-m

kN m/s E2E 828.6 kN-m

CSI 229.6 MPa

F Iteratively modifying V numerical soil model until the

a EF2 848.7 kN-m

E2F 843.1 kN-m

calculated reflective wave matches the measured waveEV2 877.5 kN-m

RMX 18448 kN

DMX 30.3 mm

DFN 14.0 mm

B w o 12

lo N. 63

8 0 .0

00 kN

LE 39.970 m

AR 2759.57 cm^2 W pM

u sd

W pCt

u p

EM 207413 MPa

51.2ms SP 77.5 kN/m3

15.60 ms WS 5123.0 m/s

Measured upward and 2 6 .7

66 EA/C 11173 kN-s/m

80000 downward waves 80000

15

LP 25.750 m

45 ms

kN kN

F12 A2 6 L/c

WD WU

- 6 67

26 .

F1: [898W] 132.7 (1)

F2: [904W] 130.2 (1)

A2: [29997] 1035 g's/v (1) Measured and

calculated

upward waves

- 0 00

80 .

51.2ms

Offshore pile design : International practice](https://image.slidesharecdn.com/piledesignaccordingtointernationalpractice06-121016084206-phpapp01/75/Offshore-pile-design-according-to-international-practice-23-2048.jpg)

![Tripod and monopile loads

Bending moment at mudlevel during 50 year severe sea state

350000

Tripod Pile Monopile

300000

250000

200000

150000

100000

50000

0

-50000 0 20 40 60 80 100 120 140

M

m

N

o

n

b

e

k

s

-100000

r

t

]

[

-150000

-200000

time [s]

Axial (vertical) force at mudlevel during 50 year severe sea state

10000

Monopile Tripod Pile max compression Tripod max tension

5000

0

0 20 40 60 80 100 120 140

-5000

-10000

-15000

M

m

N

o

b

e

k

c

s

-20000

r

]

[

f

-25000

-30000

time [s]

Offshore pile design : International practice](https://image.slidesharecdn.com/piledesignaccordingtointernationalpractice06-121016084206-phpapp01/75/Offshore-pile-design-according-to-international-practice-28-2048.jpg)