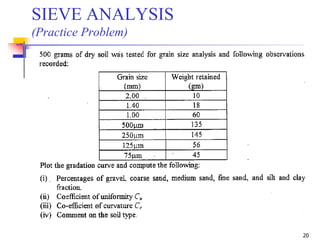

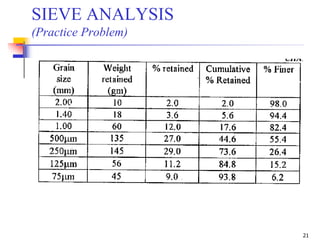

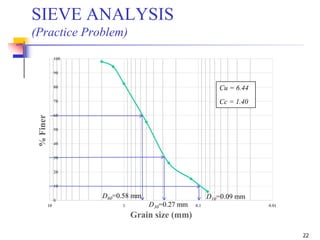

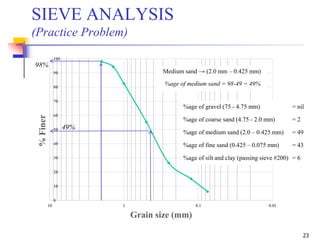

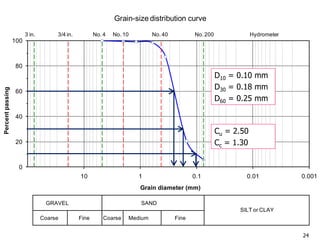

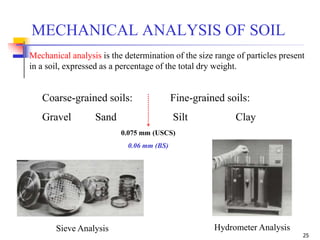

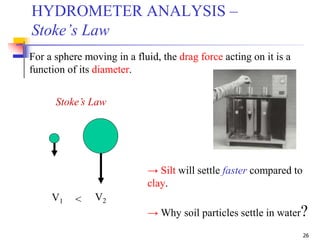

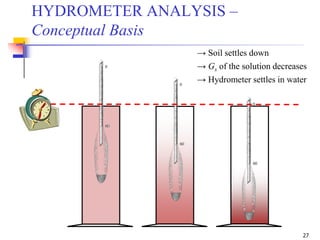

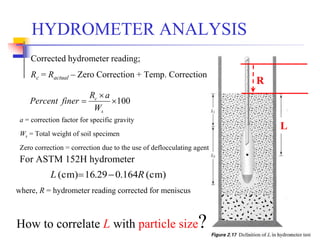

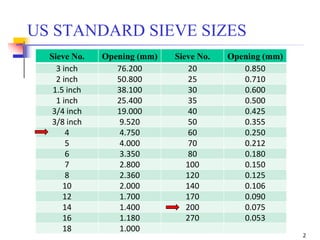

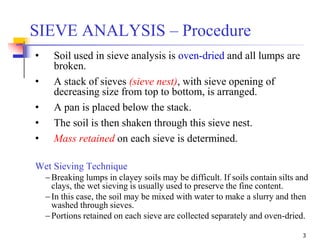

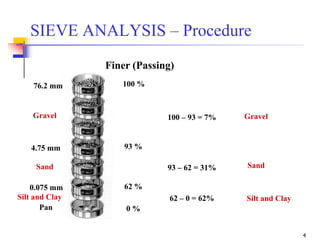

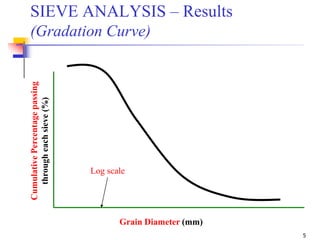

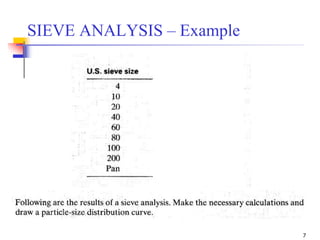

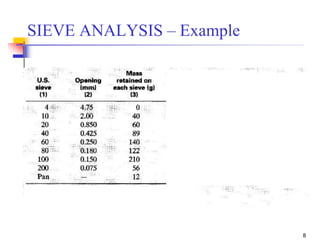

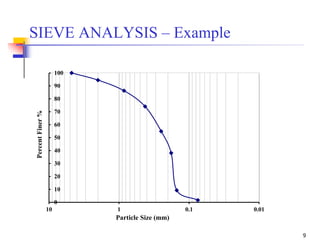

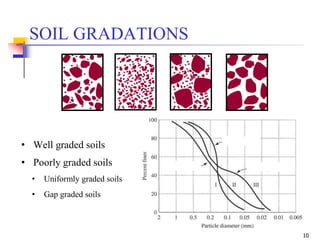

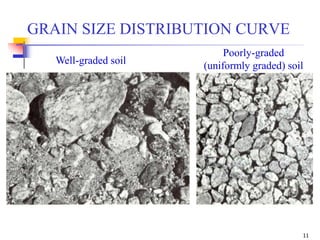

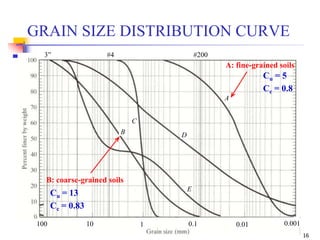

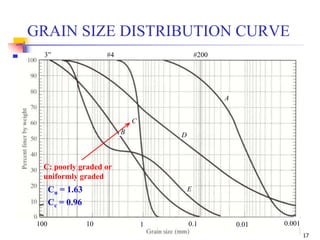

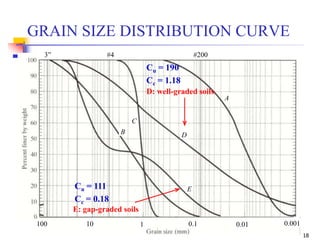

This document provides an overview of sieve analysis and grain size distribution in geotechnical engineering, including standard sieve sizes and procedures for both dry and wet sieving techniques. It details the calculation methods for cumulative percentages retained and passing through each sieve, as well as classifications of soil gradation. Additionally, it covers hydrometer analysis principles, including Stoke's Law and how to determine soil particle sizes in suspension.

![1

Geotechnical Engineering–I [CE-221]

BSc Civil Engineering – 4th Semester

by

Dr. Muhammad Irfan

Assistant Professor

Civil Engg. Dept. – UET Lahore

Email: mirfan1@msn.com

Lecture Handouts: https://groups.google.com/forum/#!forum/geotech-i

Lecture # 7

14-Feb-2017](https://image.slidesharecdn.com/7-180923180808/85/Geotechnical-Engineering-I-Lec-7-Sieve-Analysis-2-1-320.jpg)

![6

SIEVE ANALYSIS – Calculations

Sieve

No.

Diameter

(mm)

Wt. of soil

retained

(gm)

Cumulative

soil weight

retained on

each sieve

(gm)

Cumulative

percentage

retained (%)

Cumulative

percentage

passing (%)

(Col. 1) (Col. 2) (Col. 3) (Col. 4) (Col. 5) (Col. 6)

(Col. 4) = (Col. 3) + (Col. 4) of previous line

(Col. 5) = [(Col. 4)/Total wt.] x 100

(Col. 6) = 100 – (Col. 5)](https://image.slidesharecdn.com/7-180923180808/85/Geotechnical-Engineering-I-Lec-7-Sieve-Analysis-2-6-320.jpg)

![19

SIEVE ANALYSIS – Calculations

Sieve

No.

Diameter

(mm)

Wt. of soil

retained

(gm)

Cumulative

soil weight

retained on

each sieve

(gm)

Cumulative

percentage

retained (%)

Cumulative

percentage

passing (%)

(Col. 1) (Col. 2) (Col. 3) (Col. 4) (Col. 5) (Col. 6)

(Col. 4) = (Col. 3) + (Col. 4) of previous line

(Col. 5) = [(Col. 4)/Total wt.] x 100

(Col. 6) = 100 – (Col. 5)](https://image.slidesharecdn.com/7-180923180808/85/Geotechnical-Engineering-I-Lec-7-Sieve-Analysis-2-19-320.jpg)