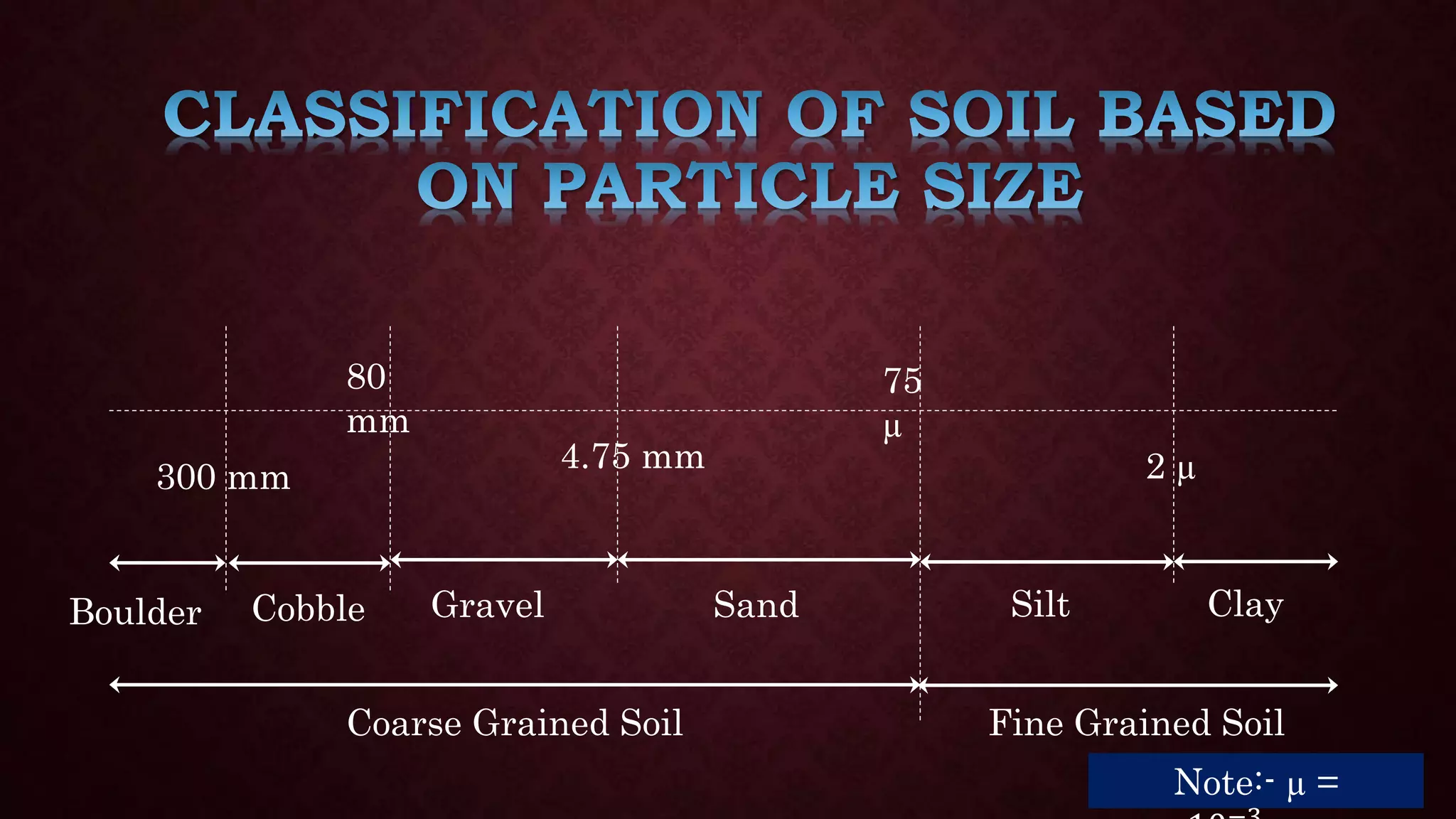

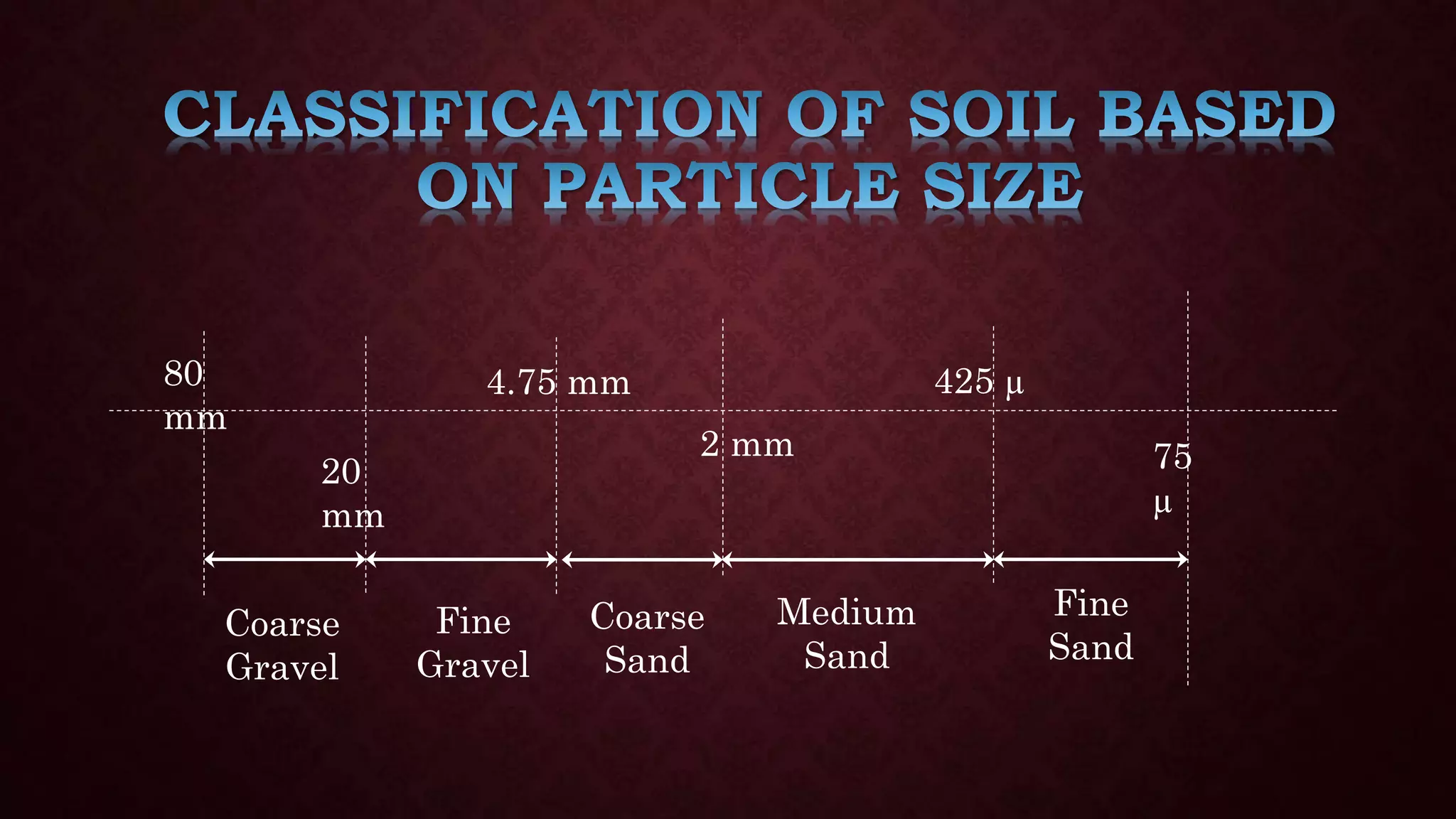

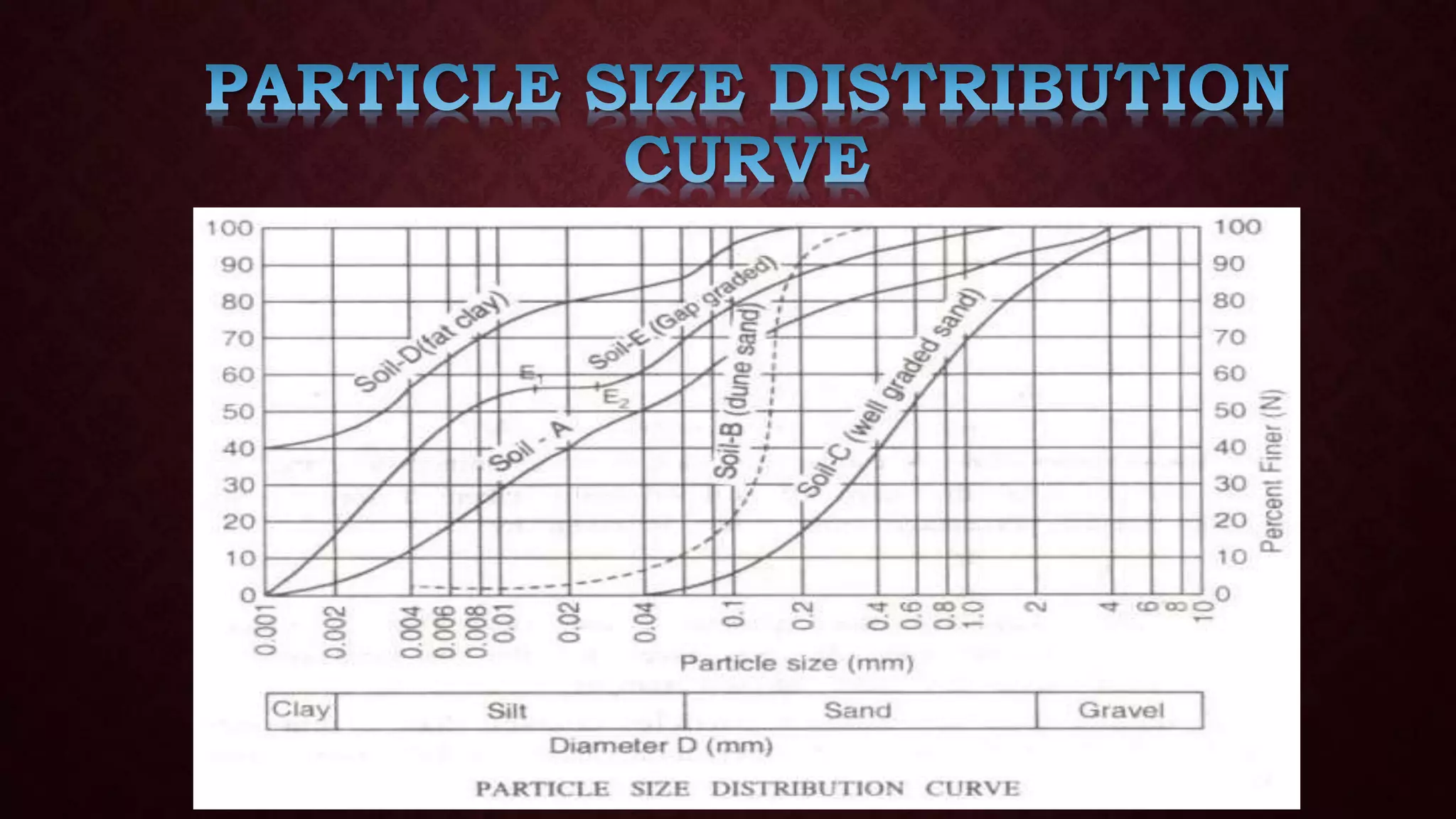

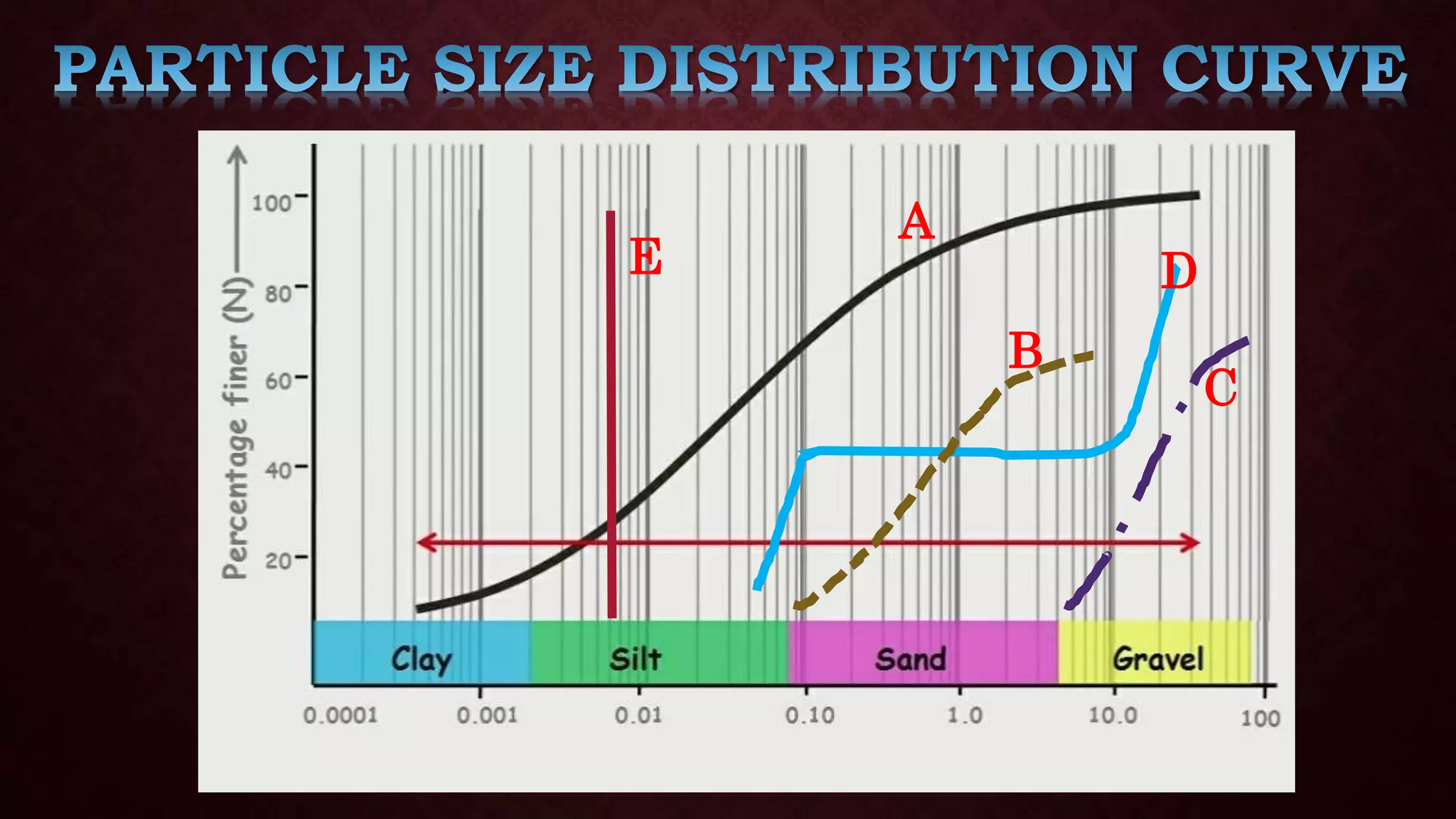

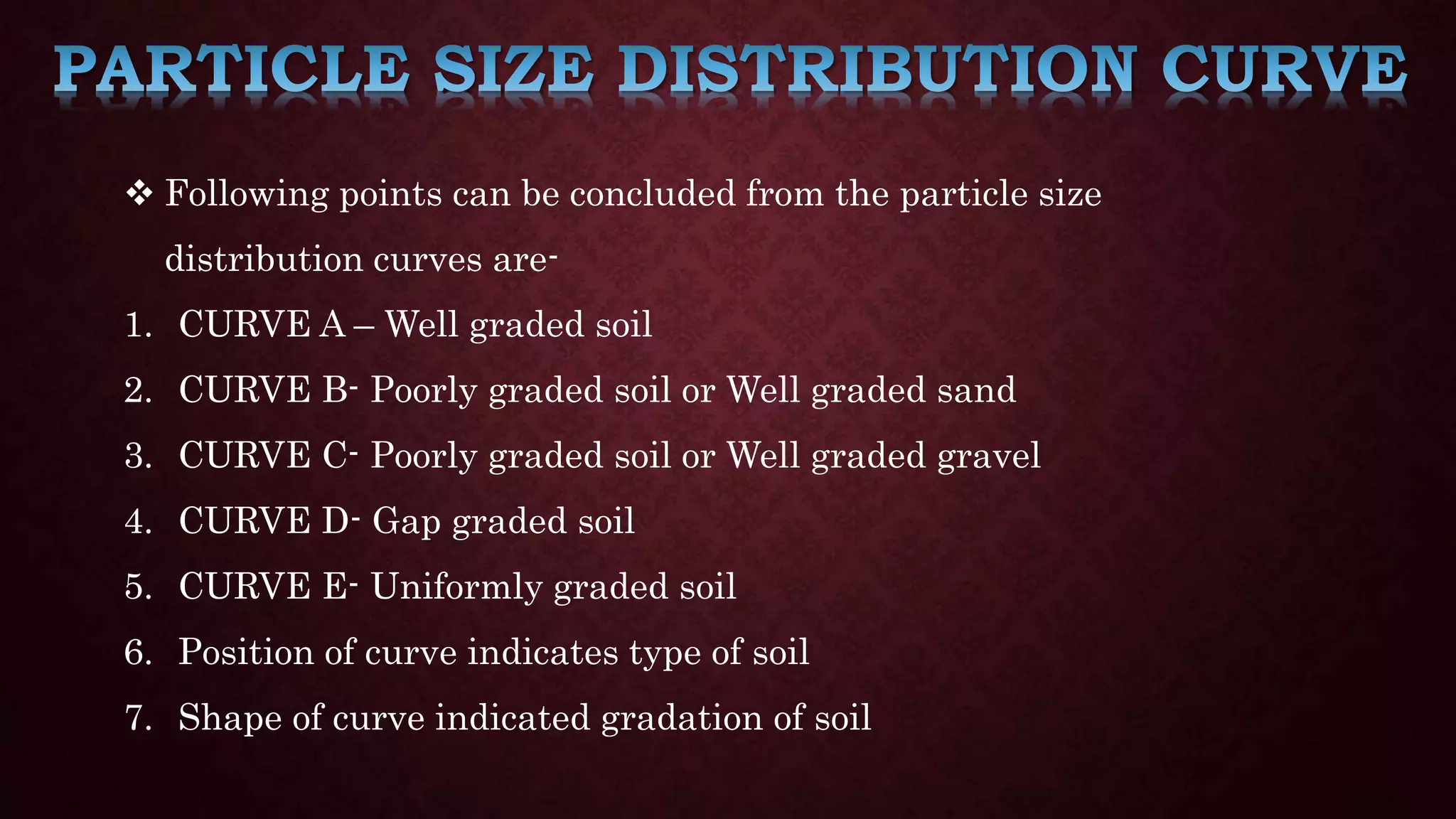

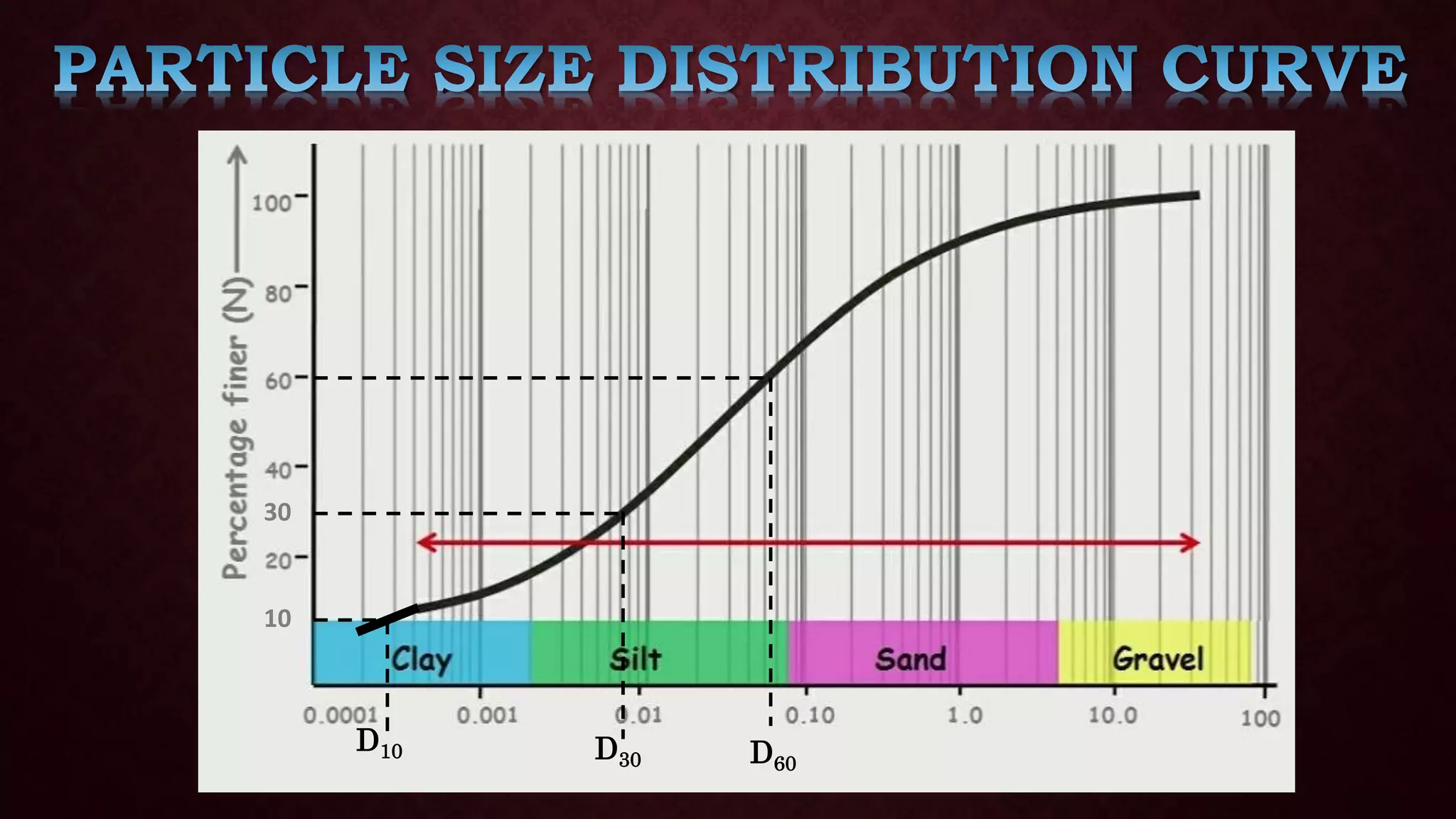

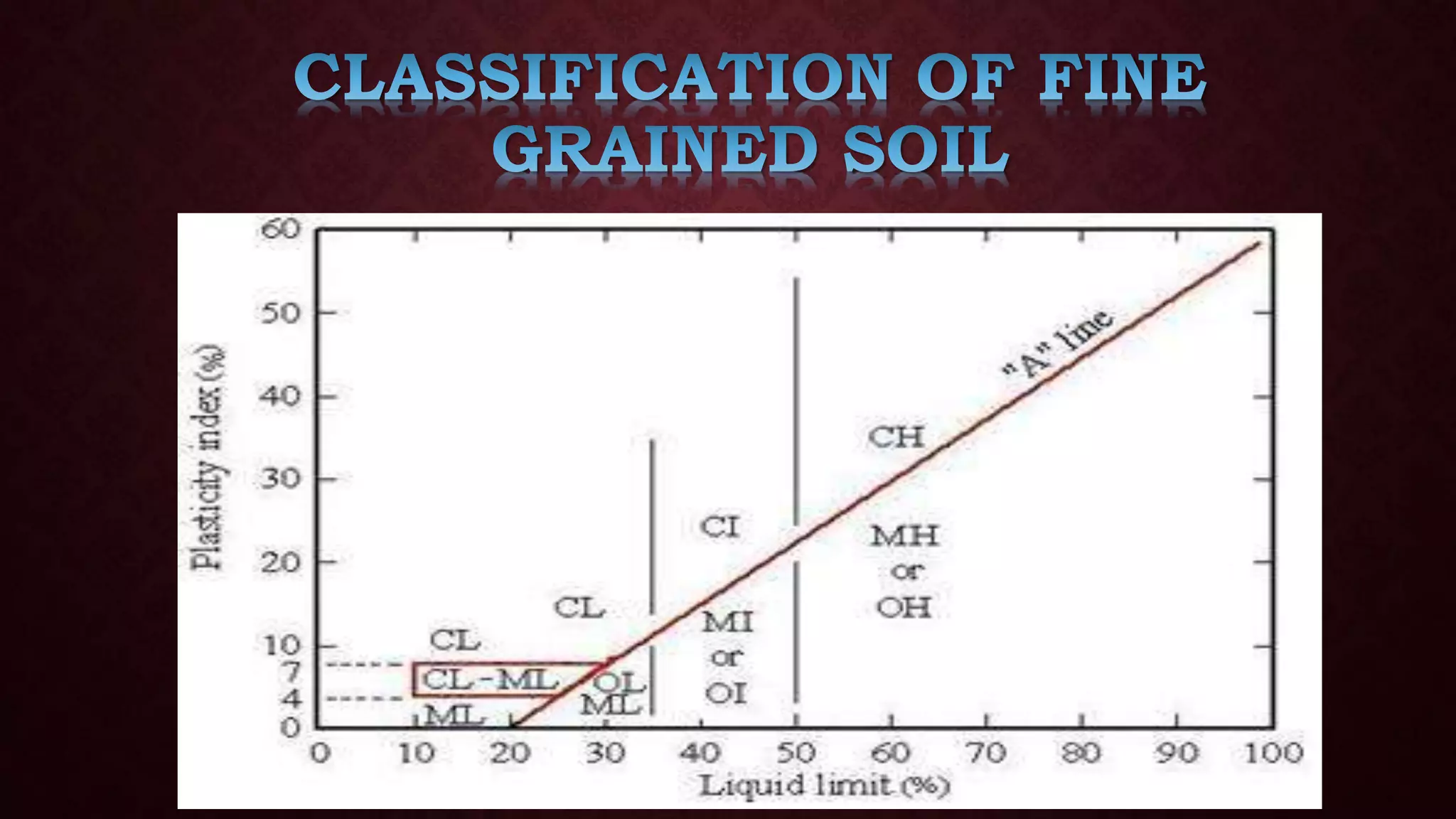

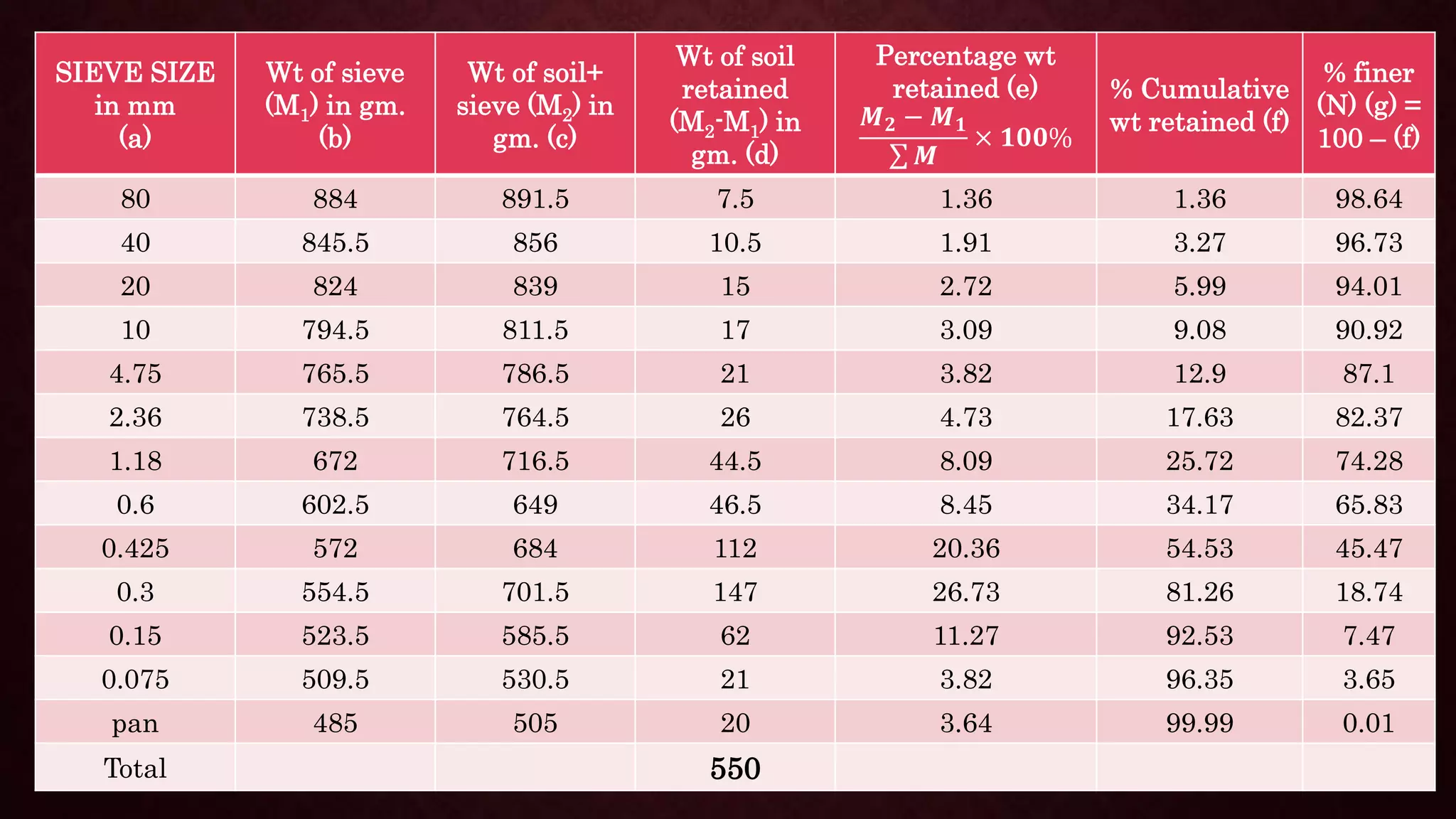

This document describes procedures for determining the grain size distribution of soils through sieve analysis and sedimentation tests. It explains that soils can be classified as coarse-grained if particles are larger than 75 micrometers, and fine-grained if smaller. Sieve analysis involves shaking soils through a series of sieves to separate grains by size, while sedimentation tests use pipette or hydrometer methods for fine soils. The results characterize the soil type, gradation, and engineering properties.