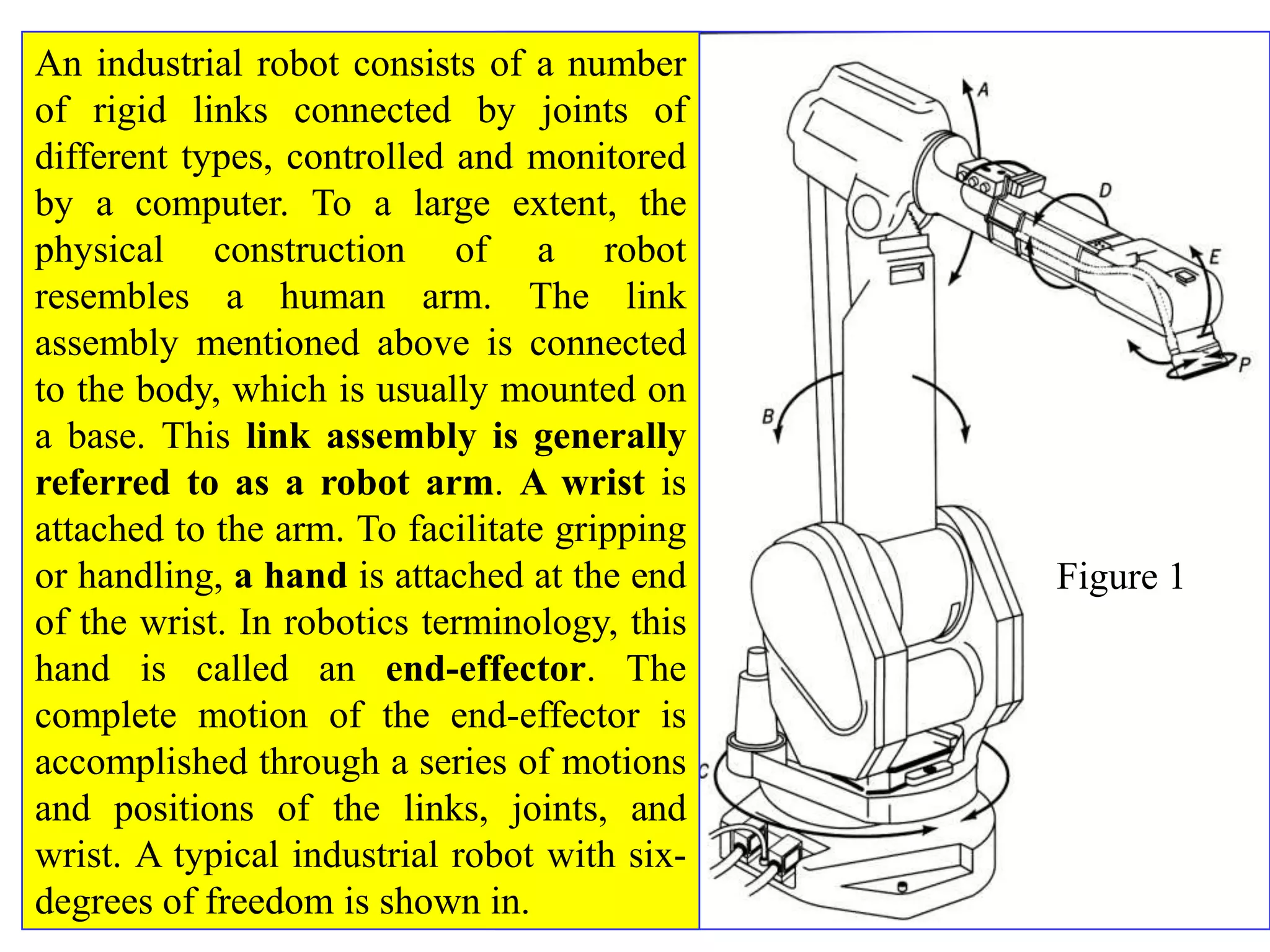

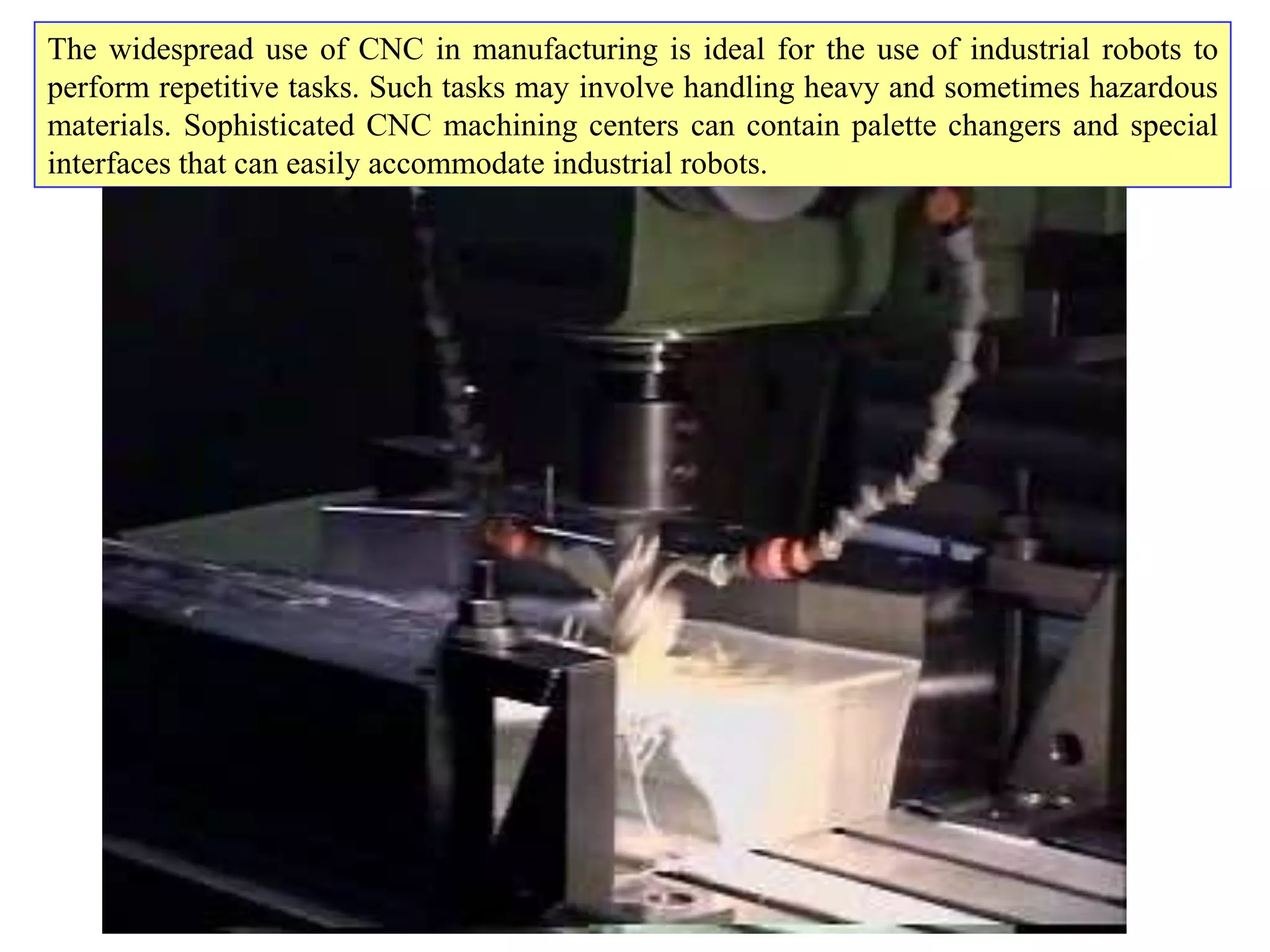

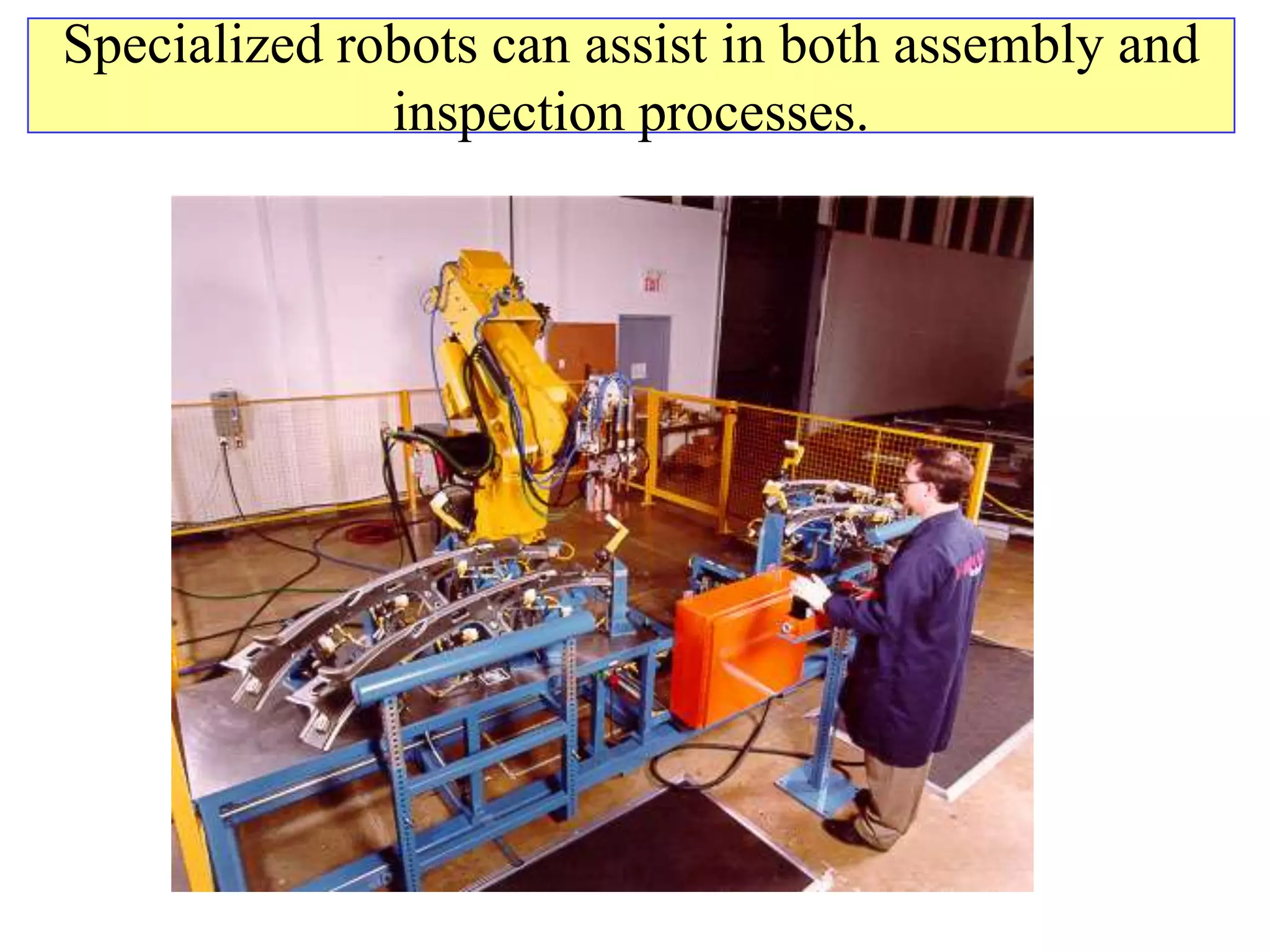

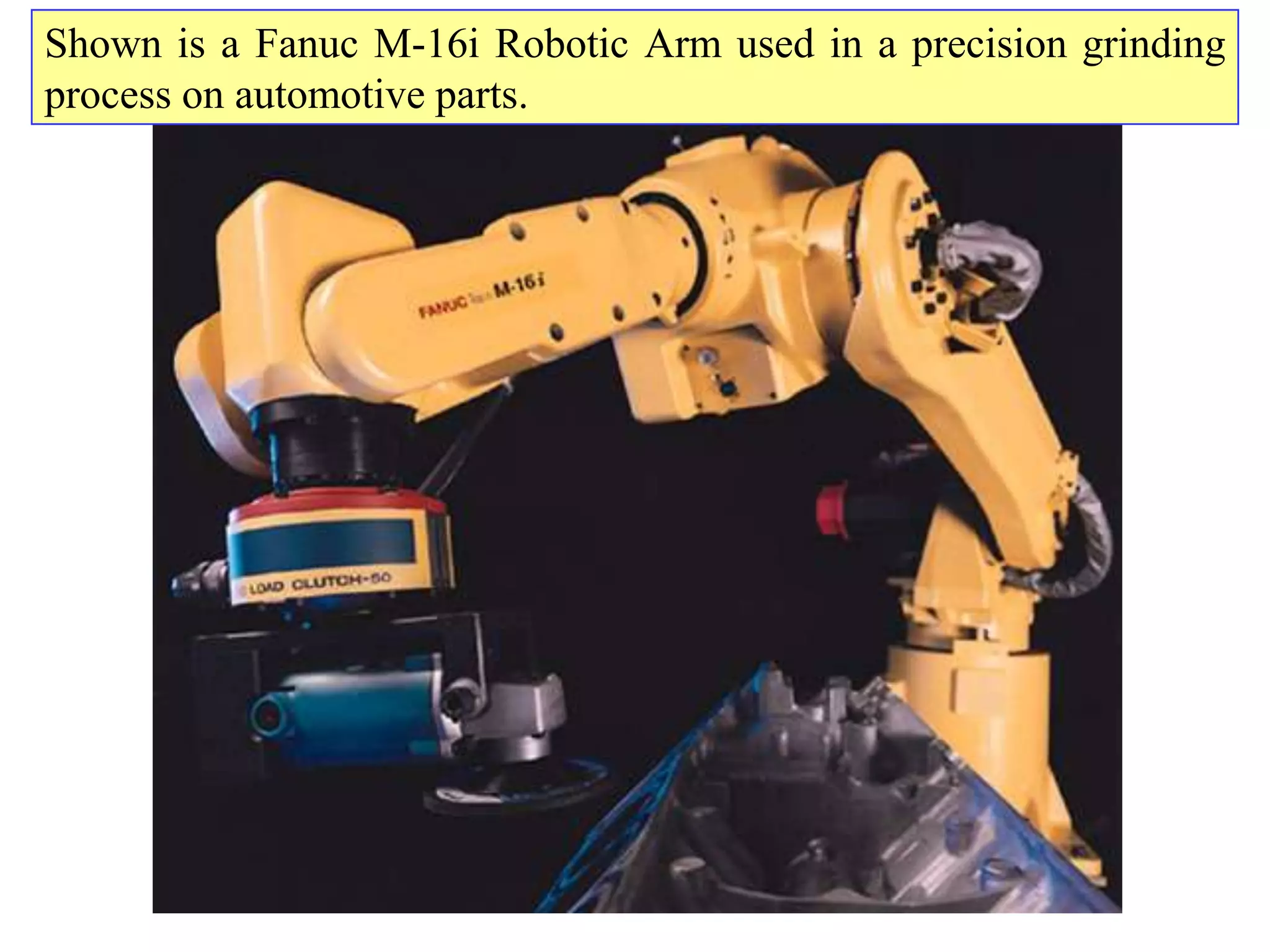

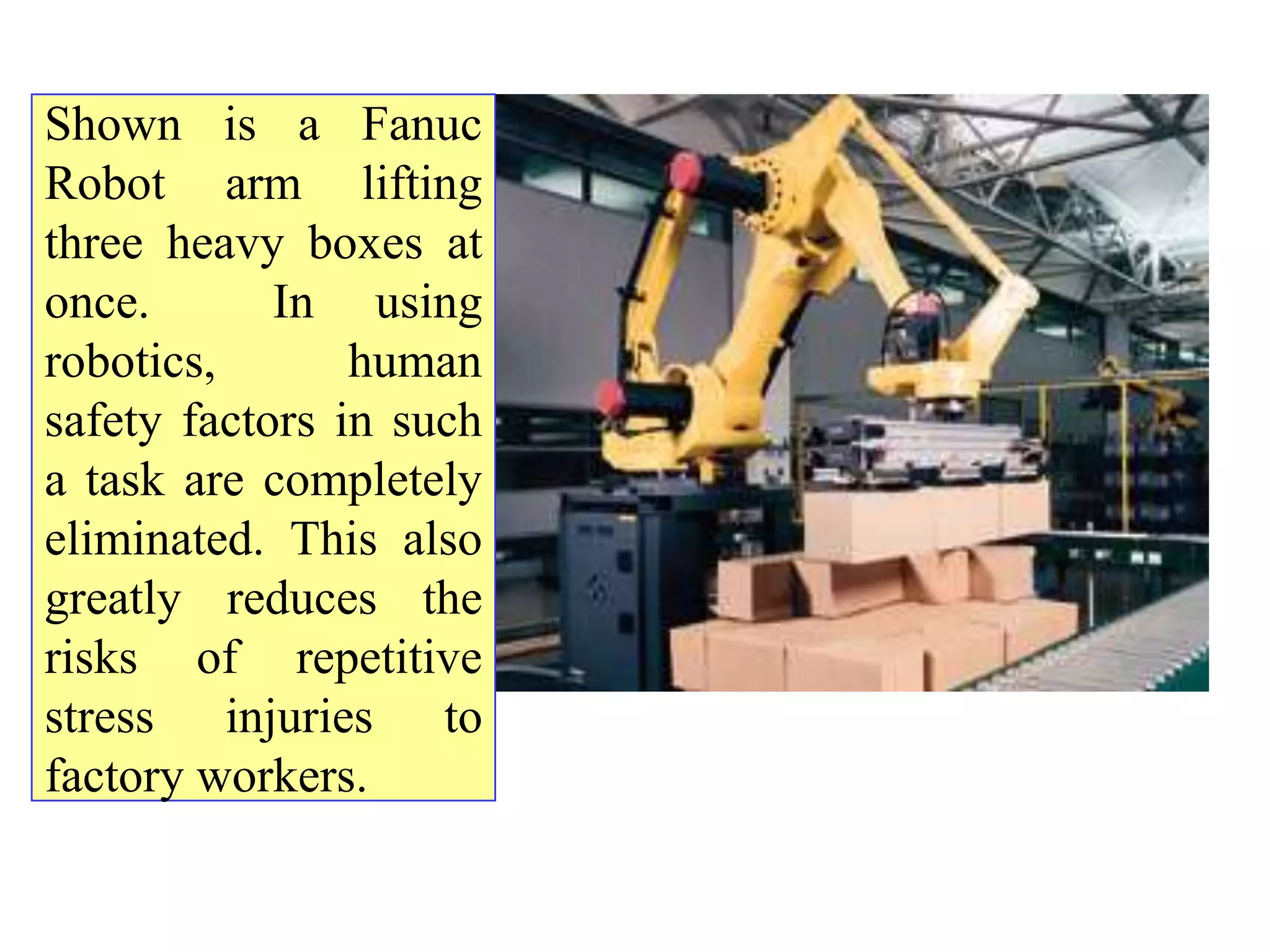

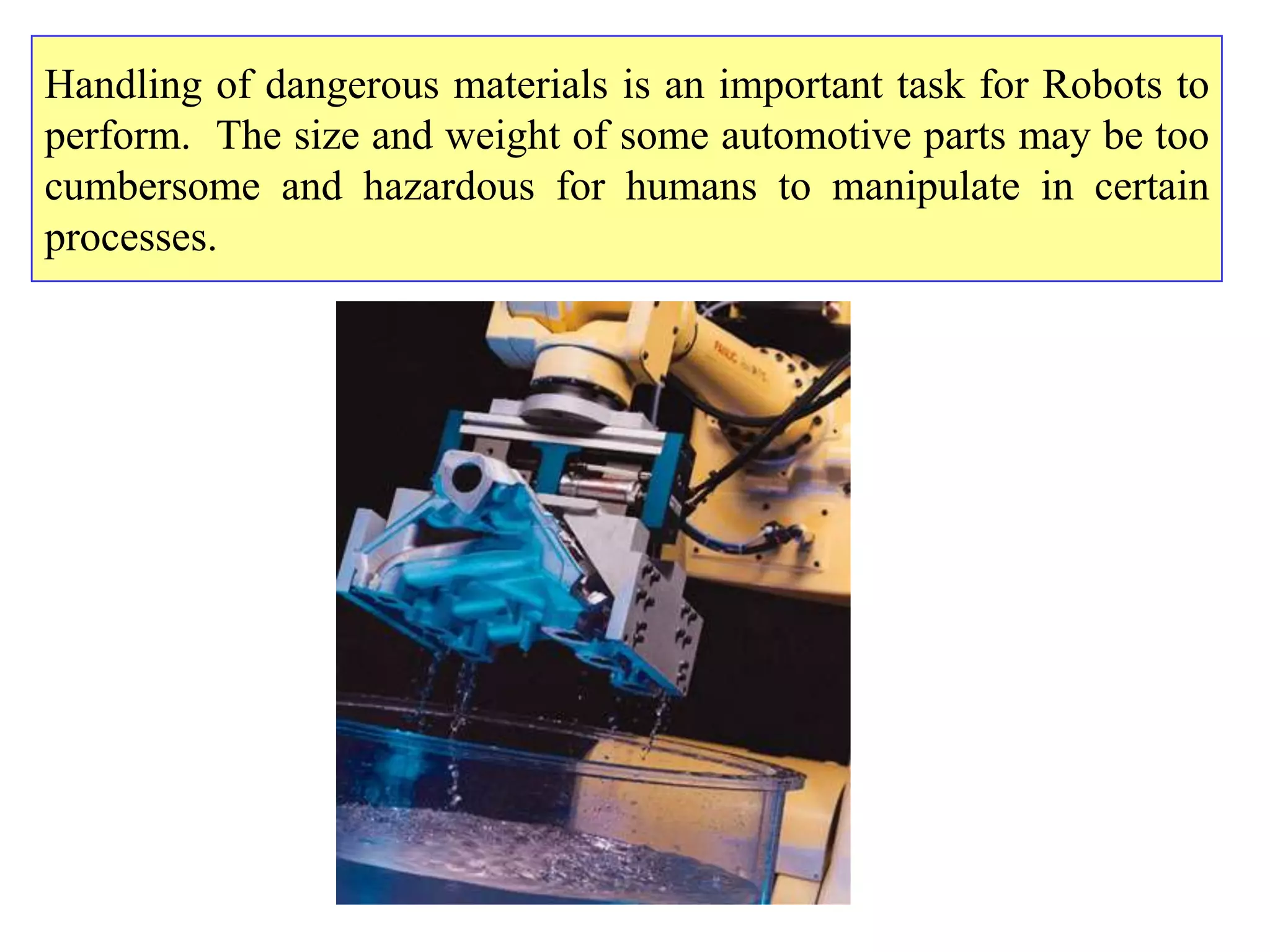

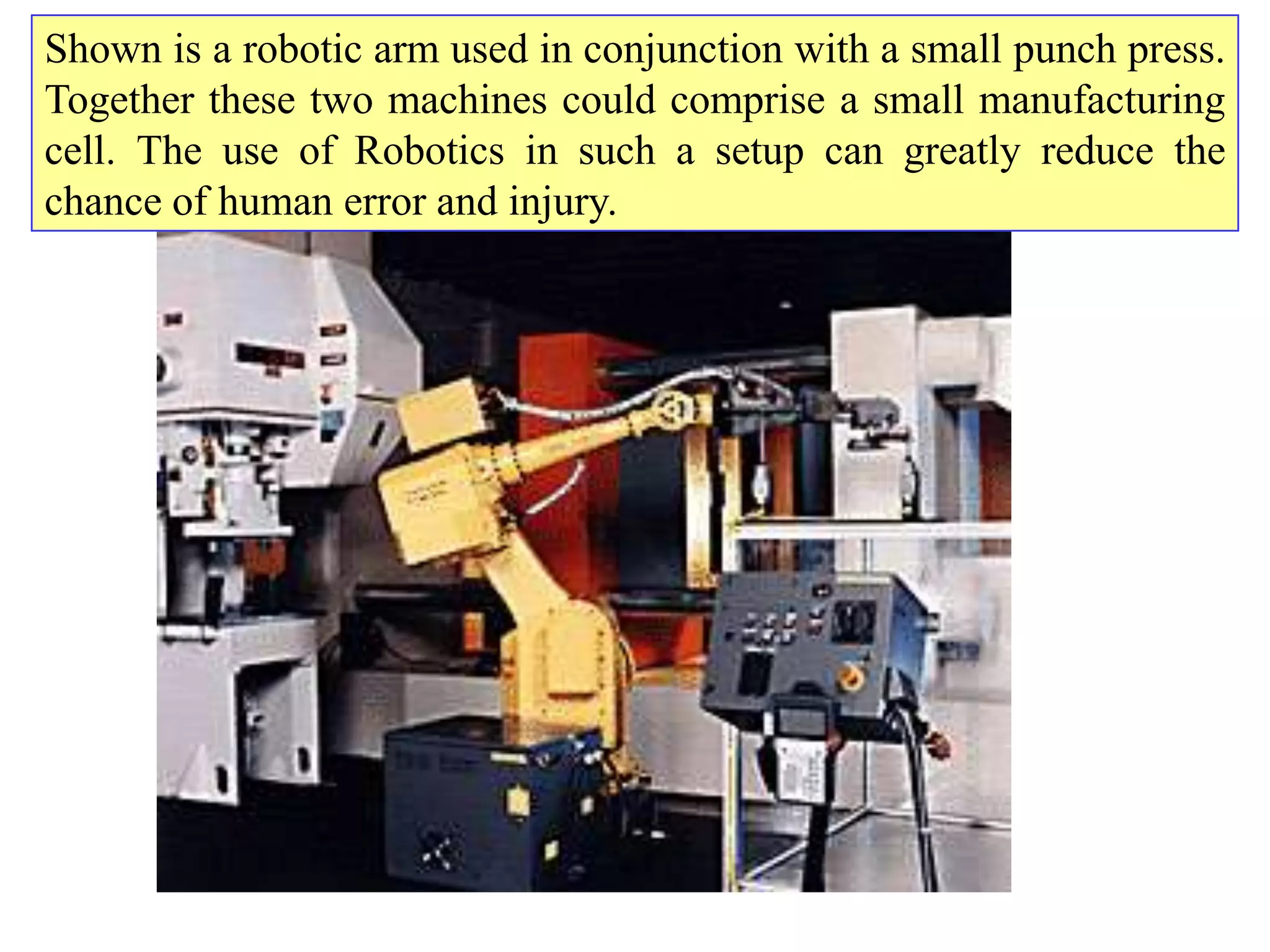

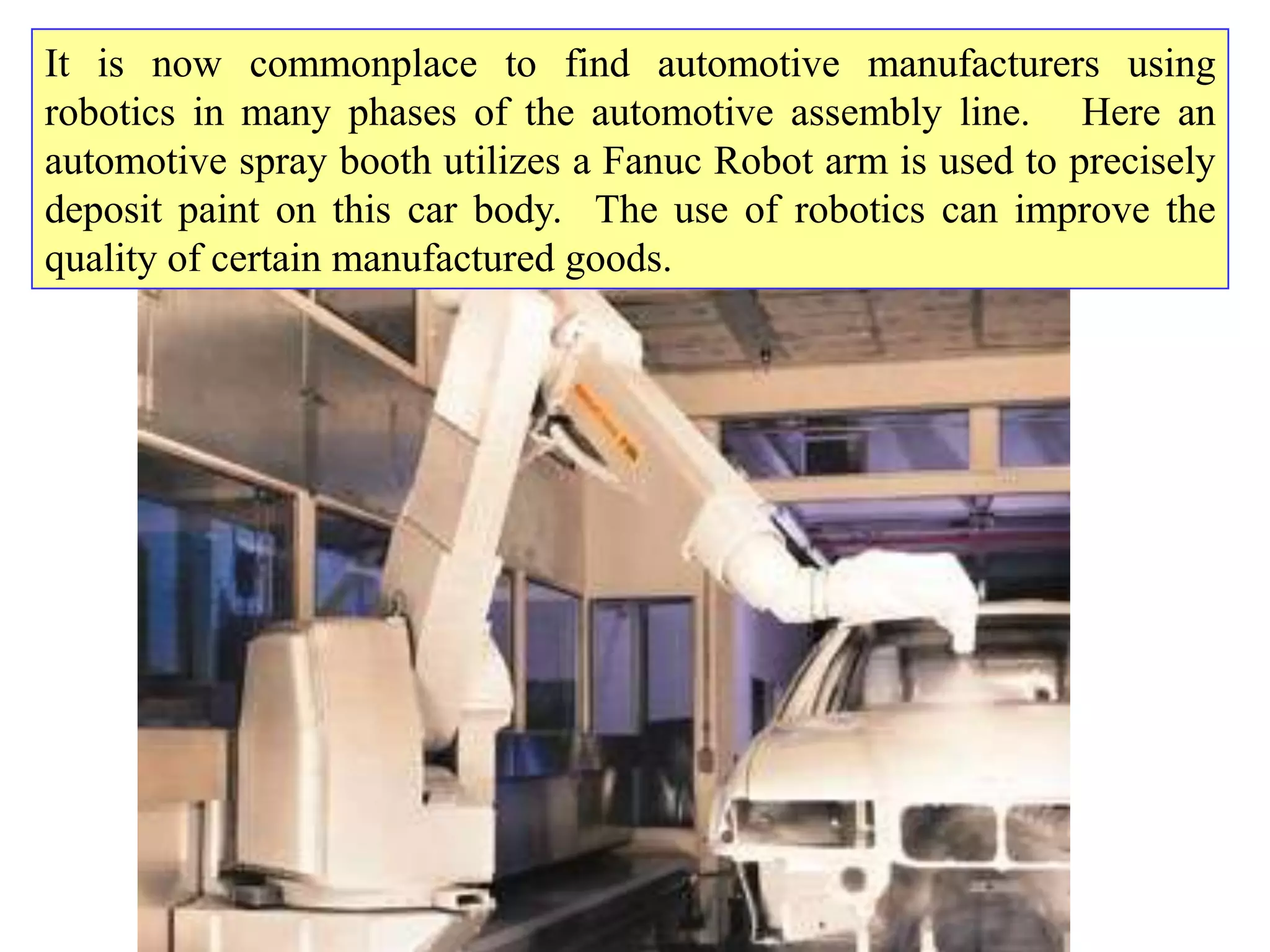

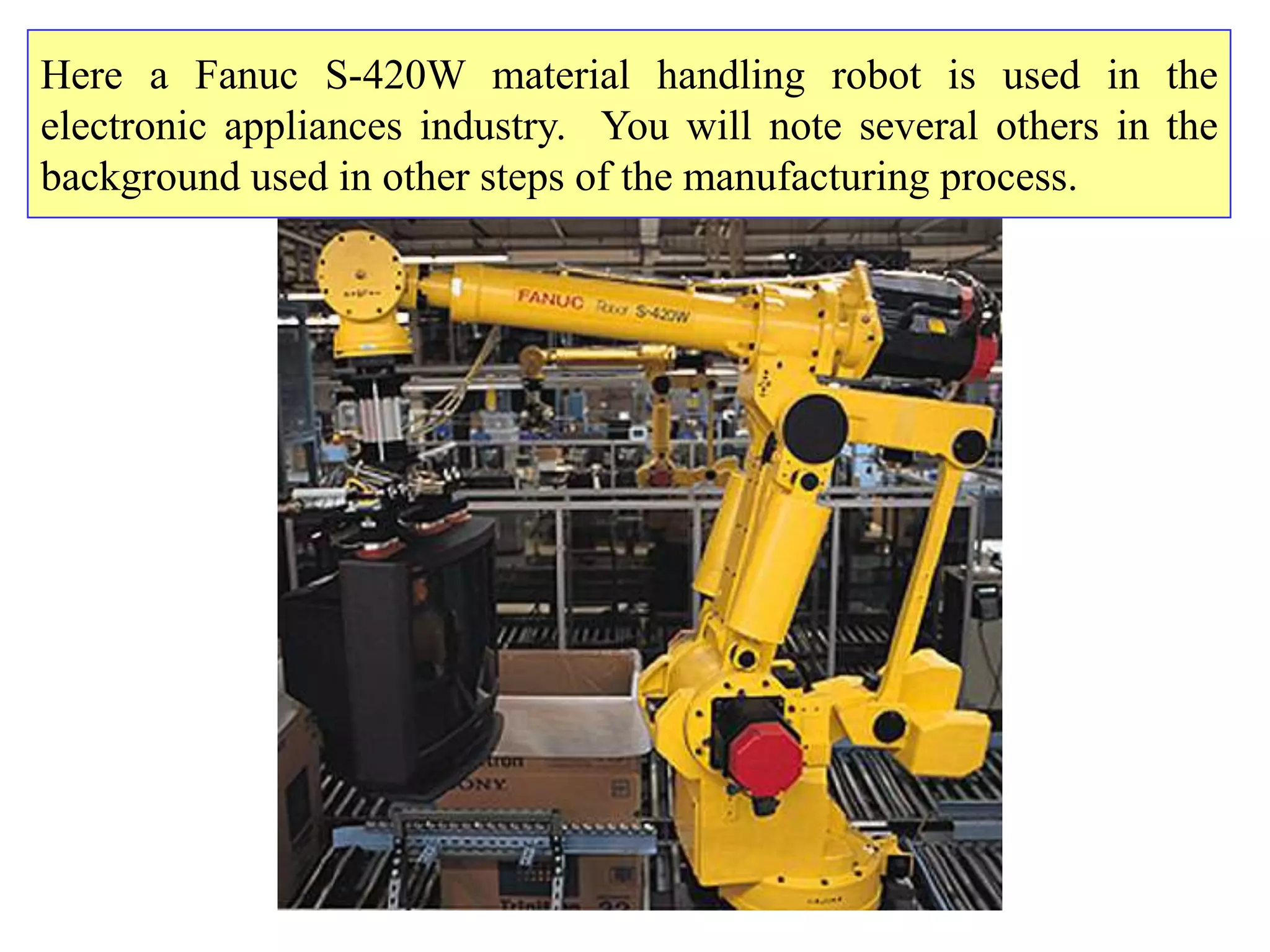

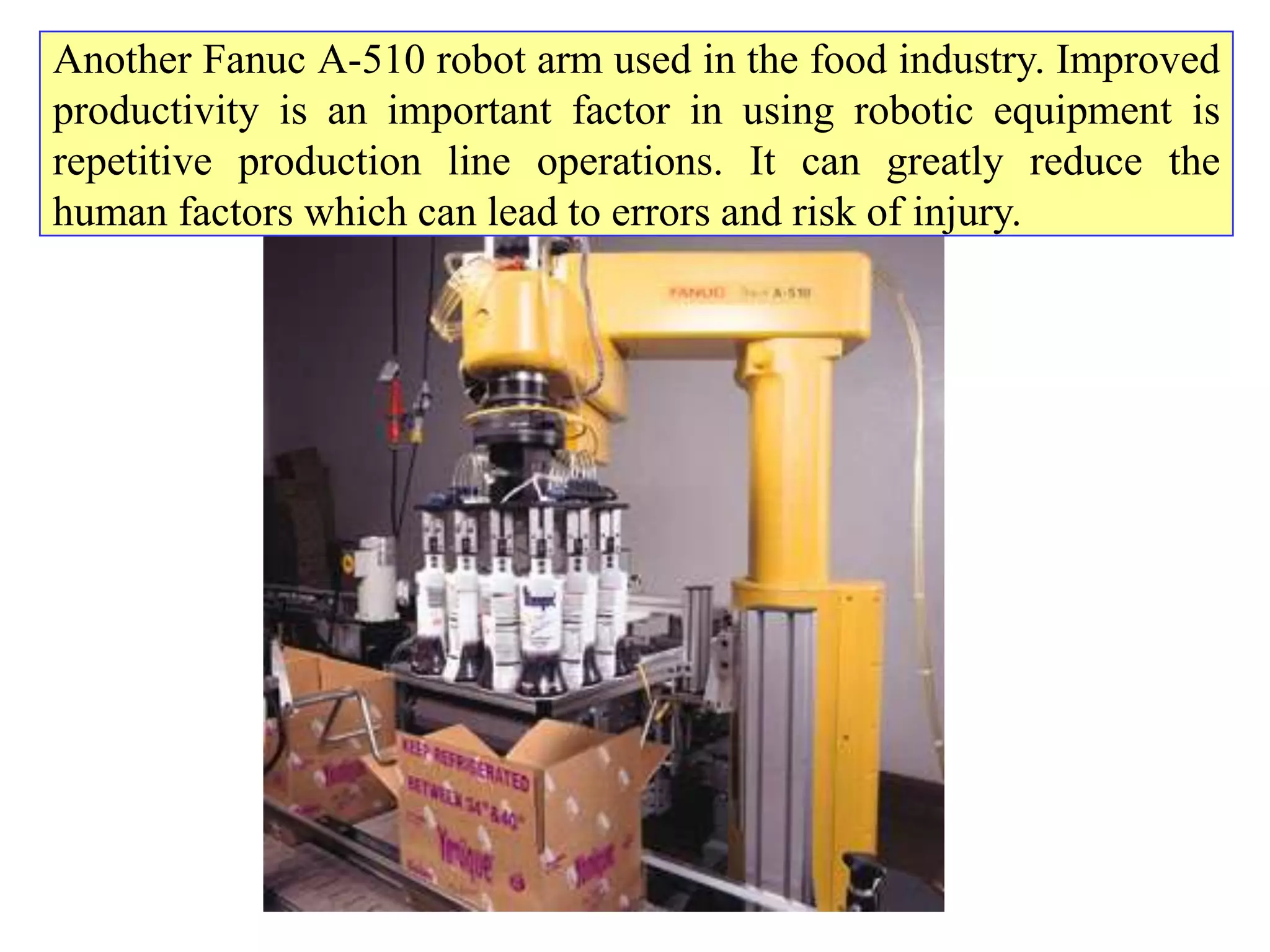

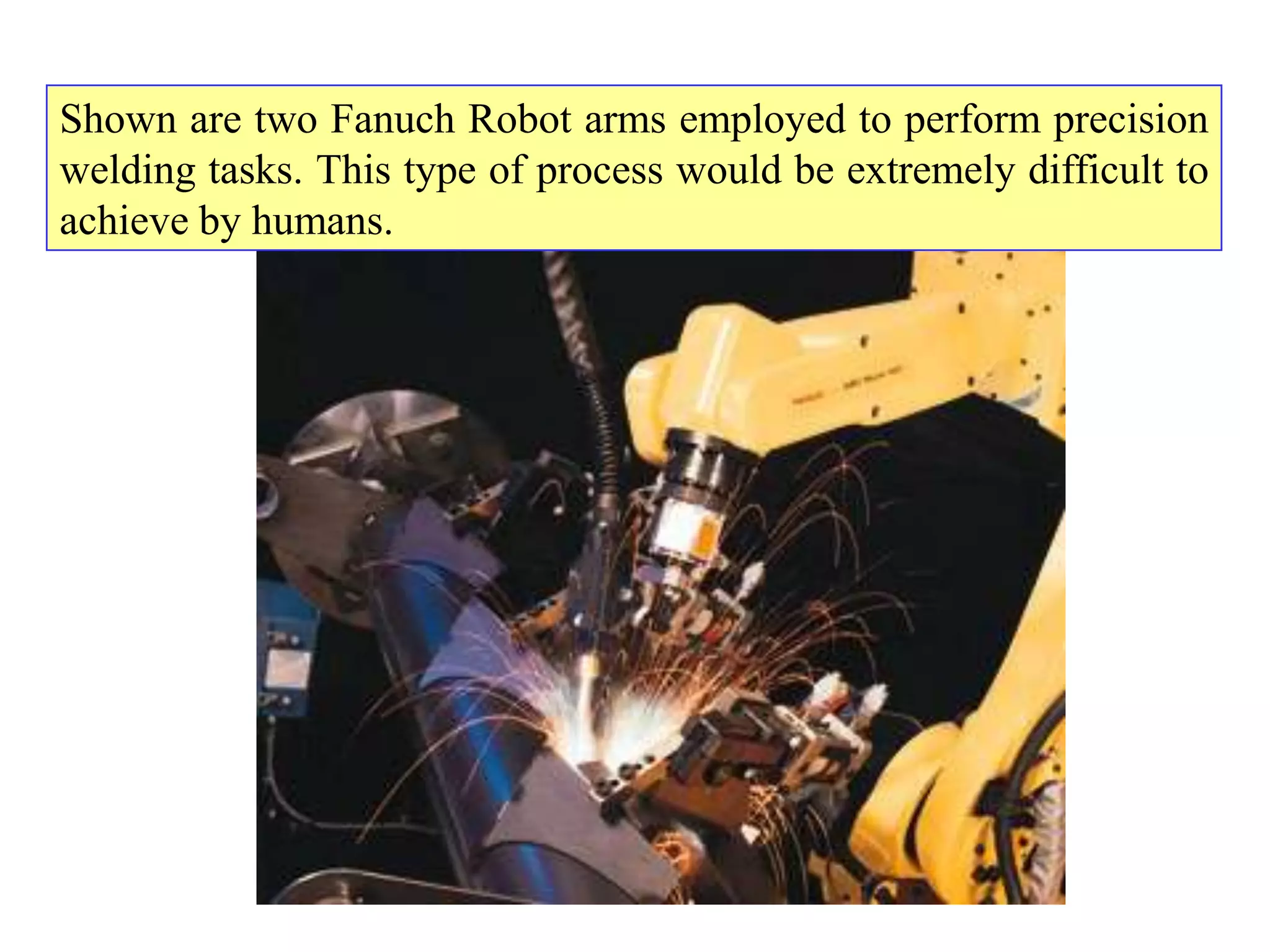

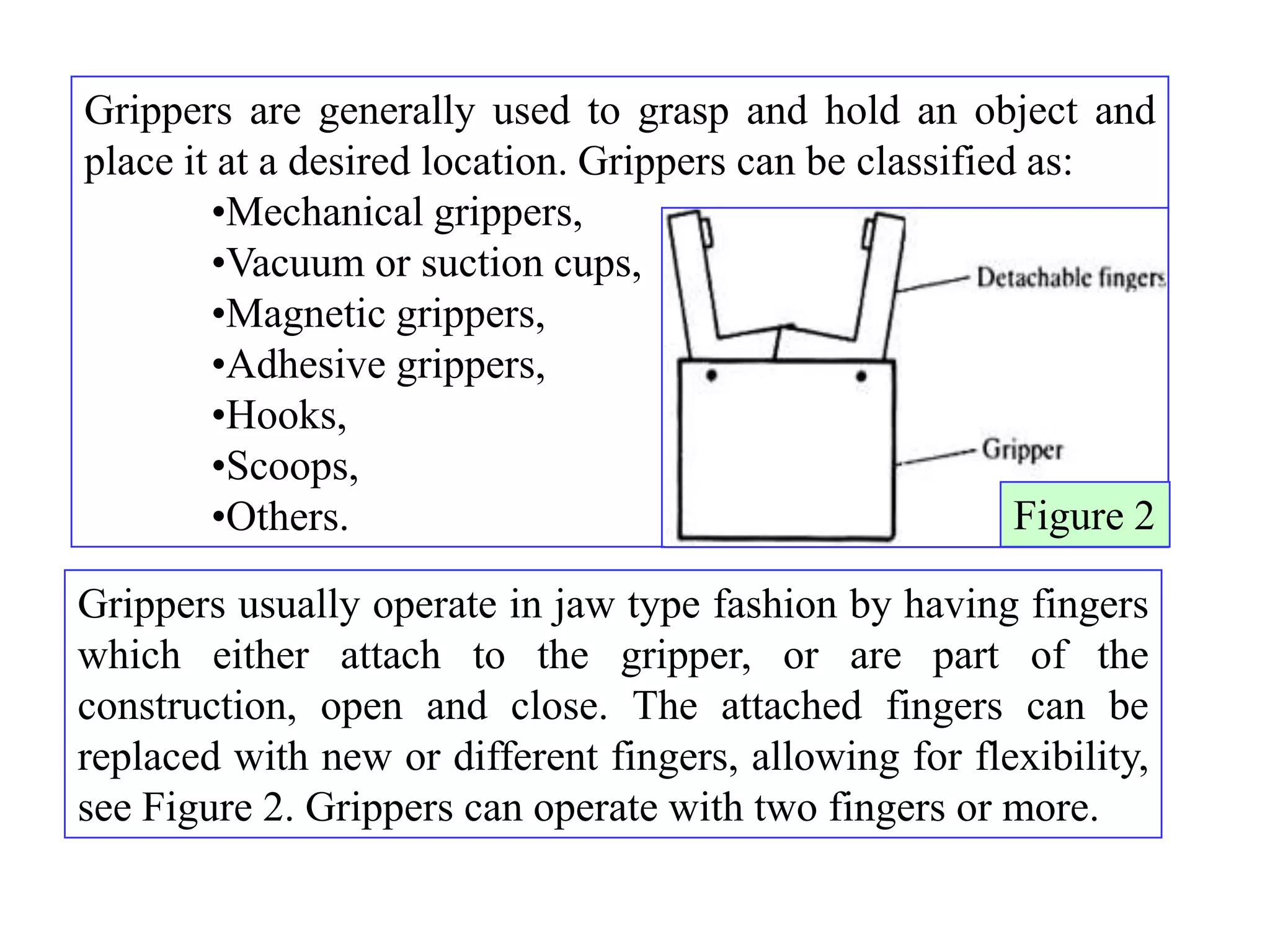

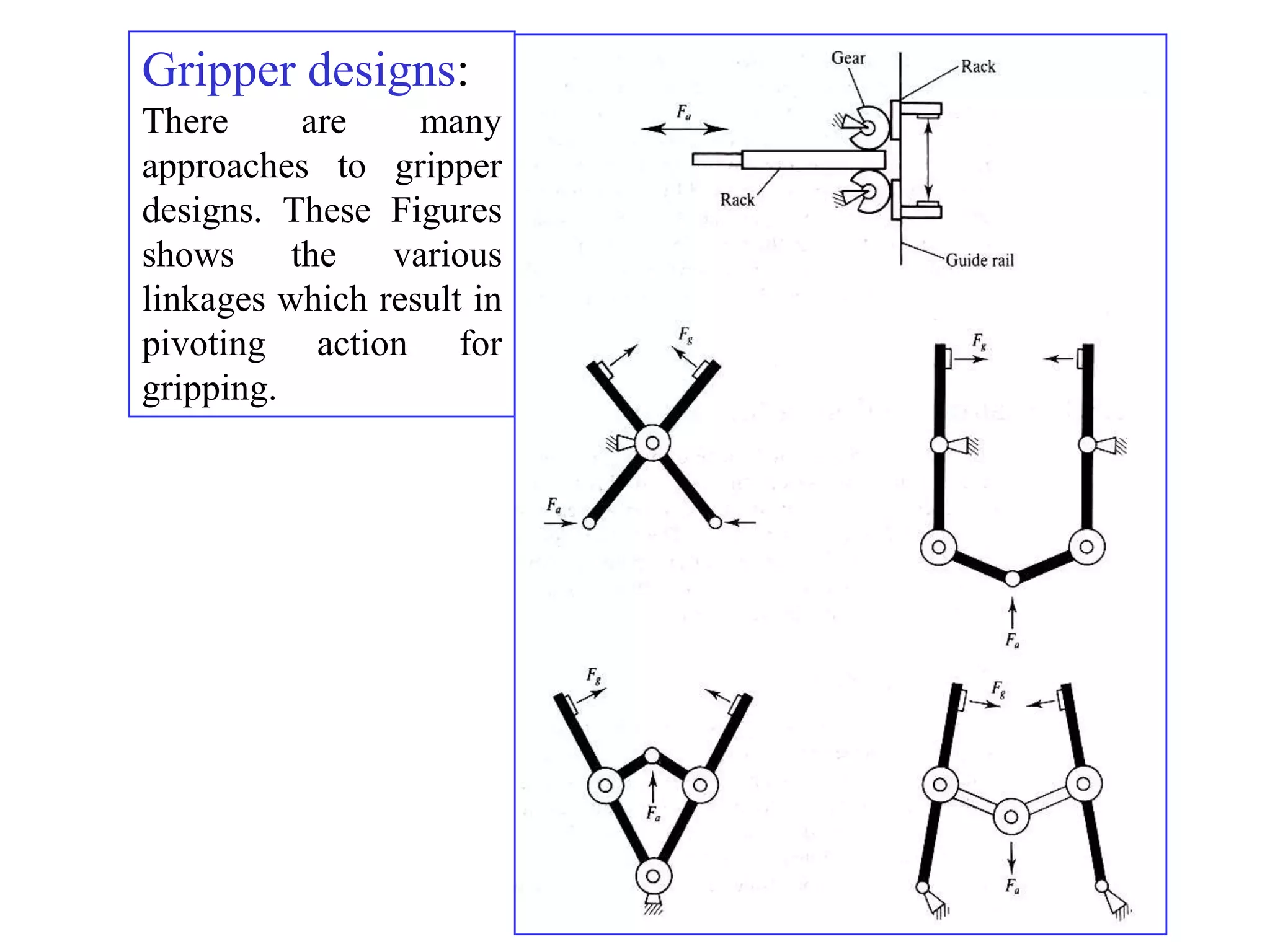

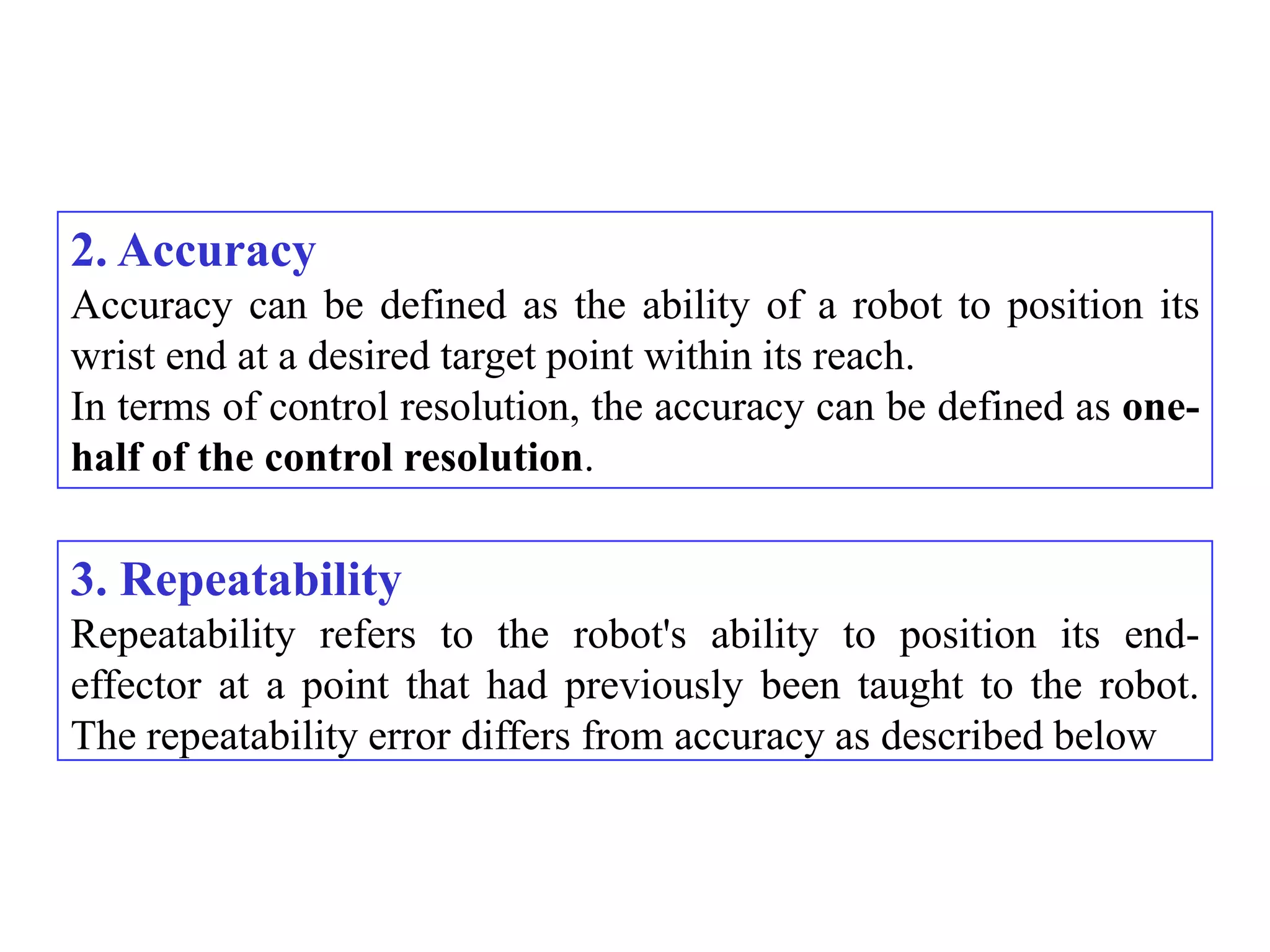

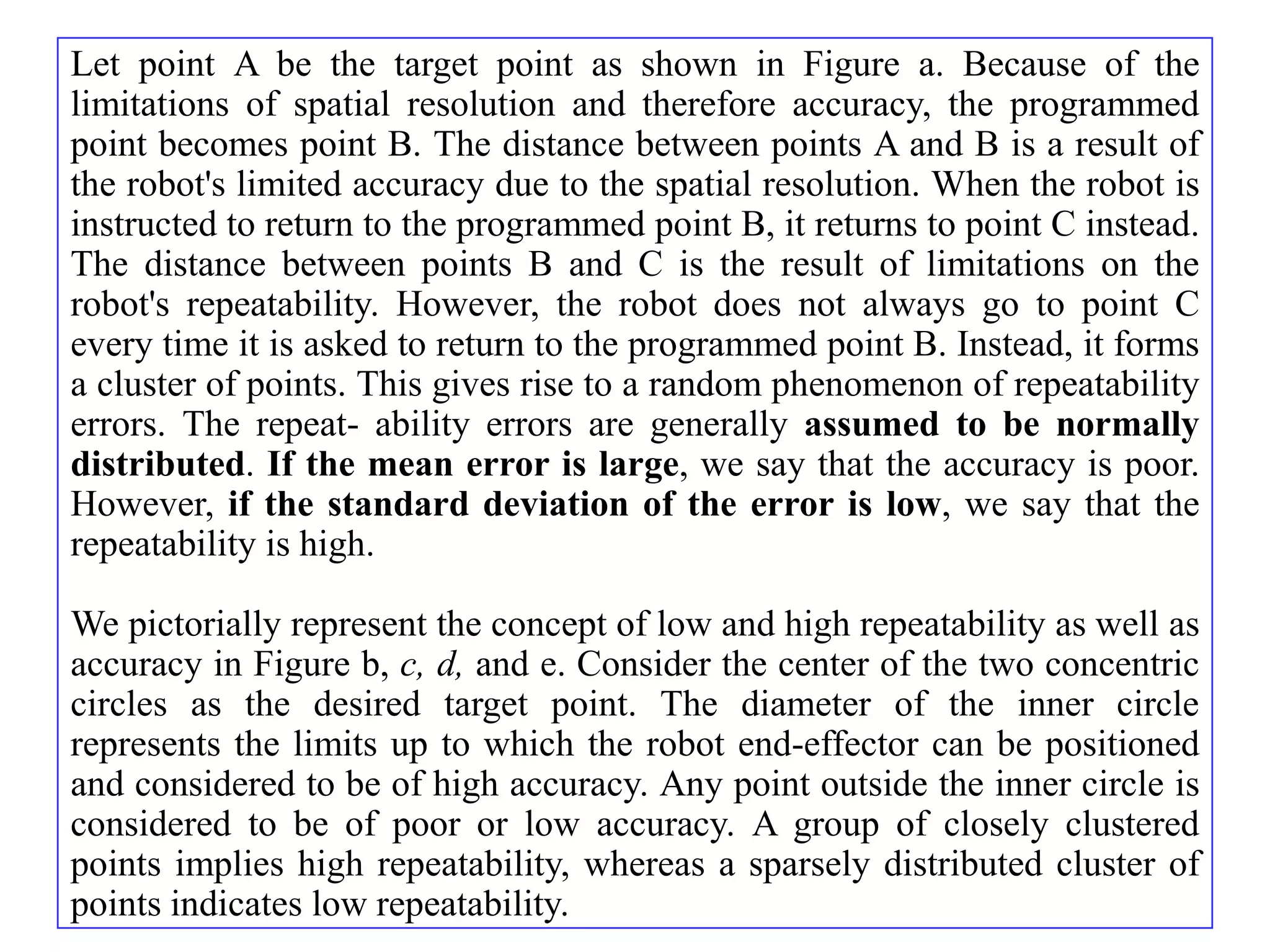

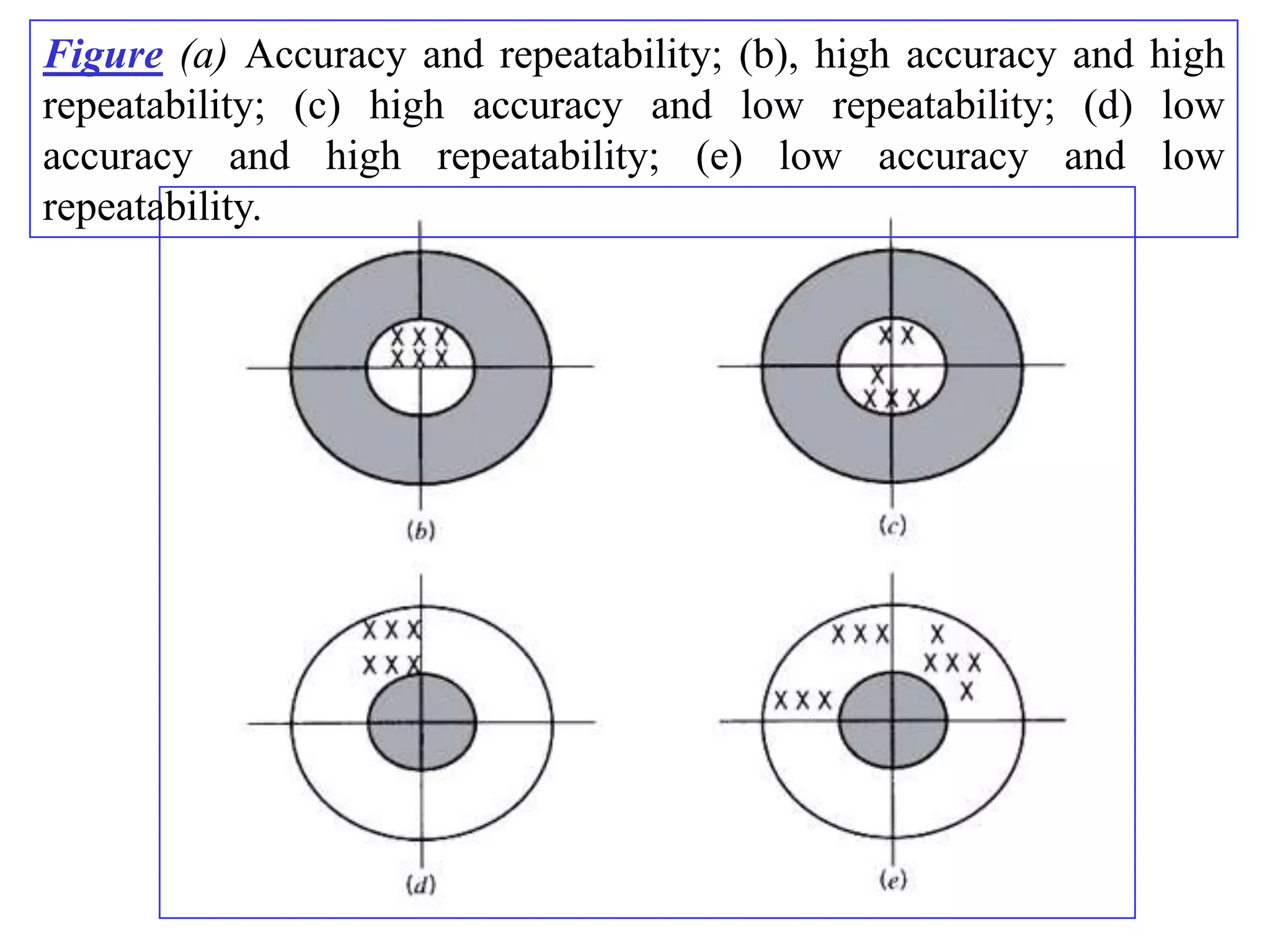

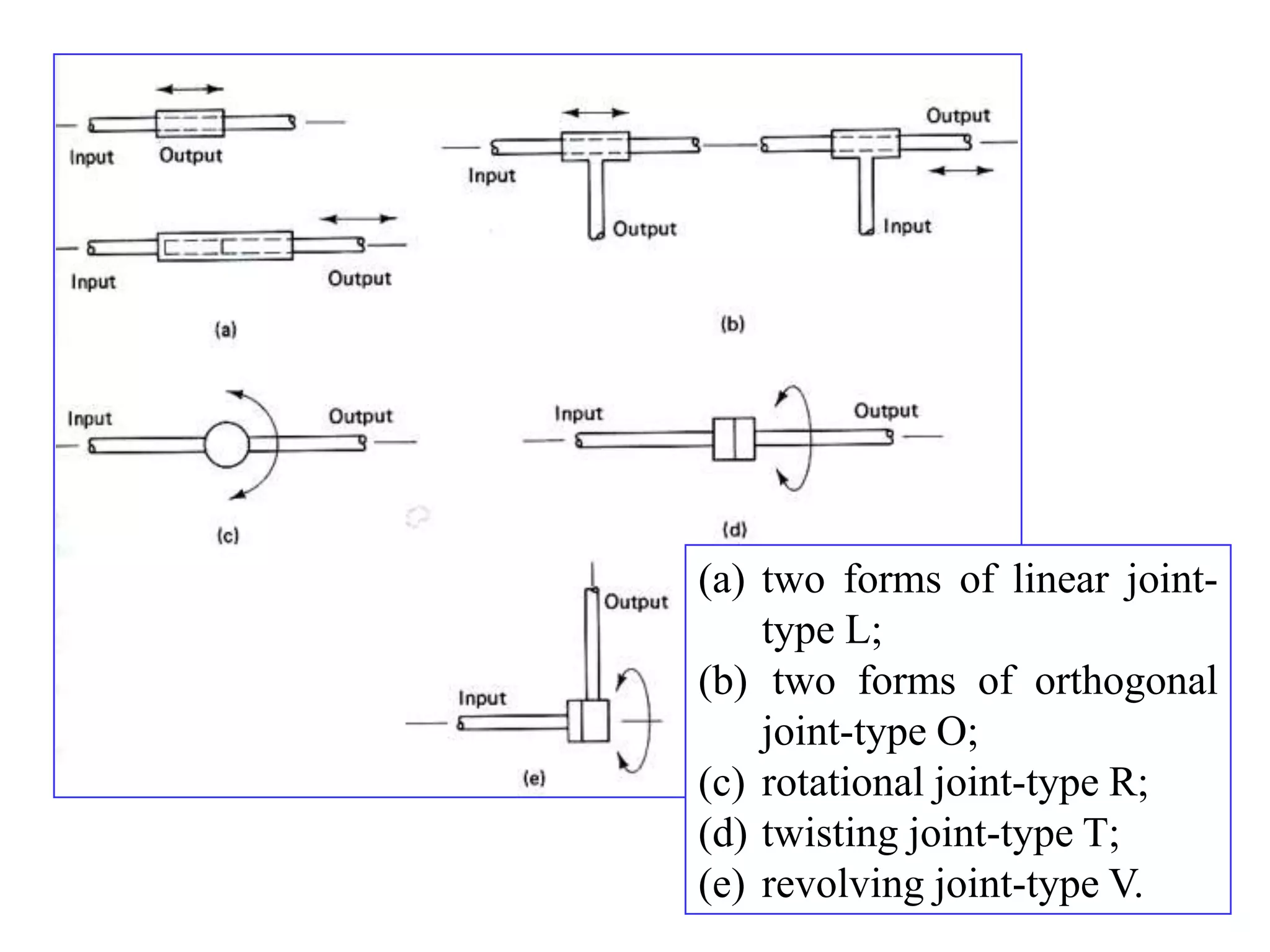

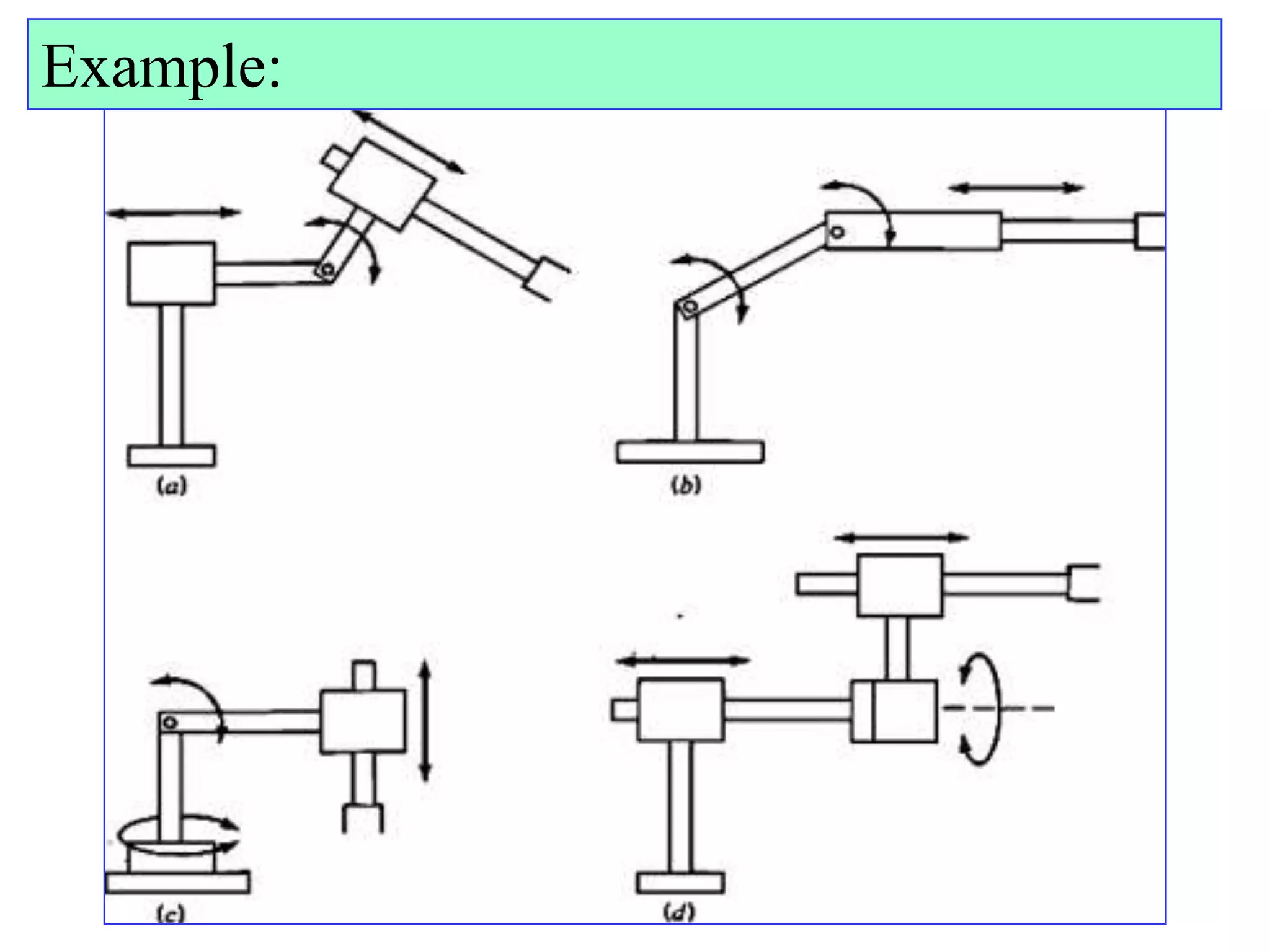

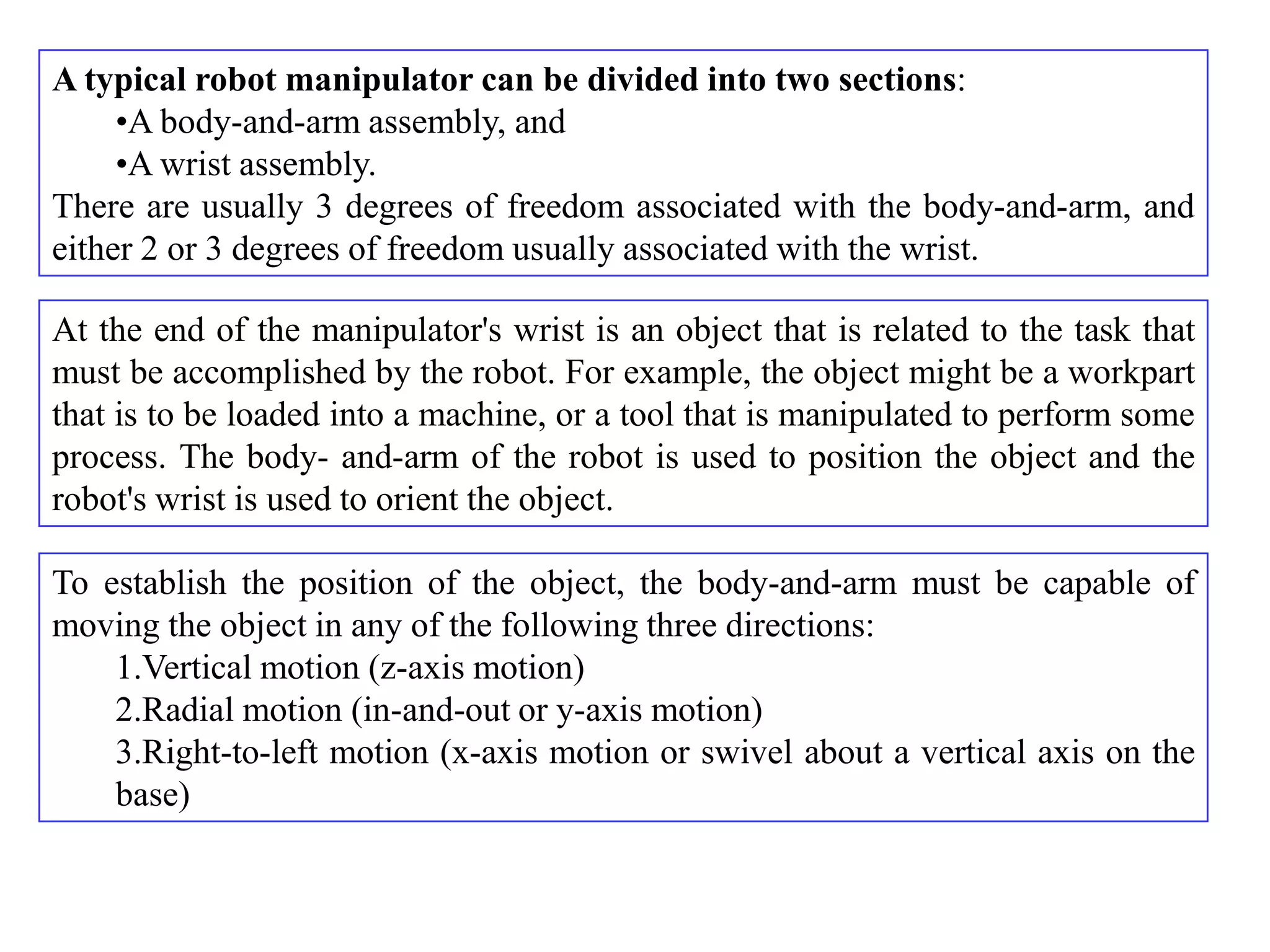

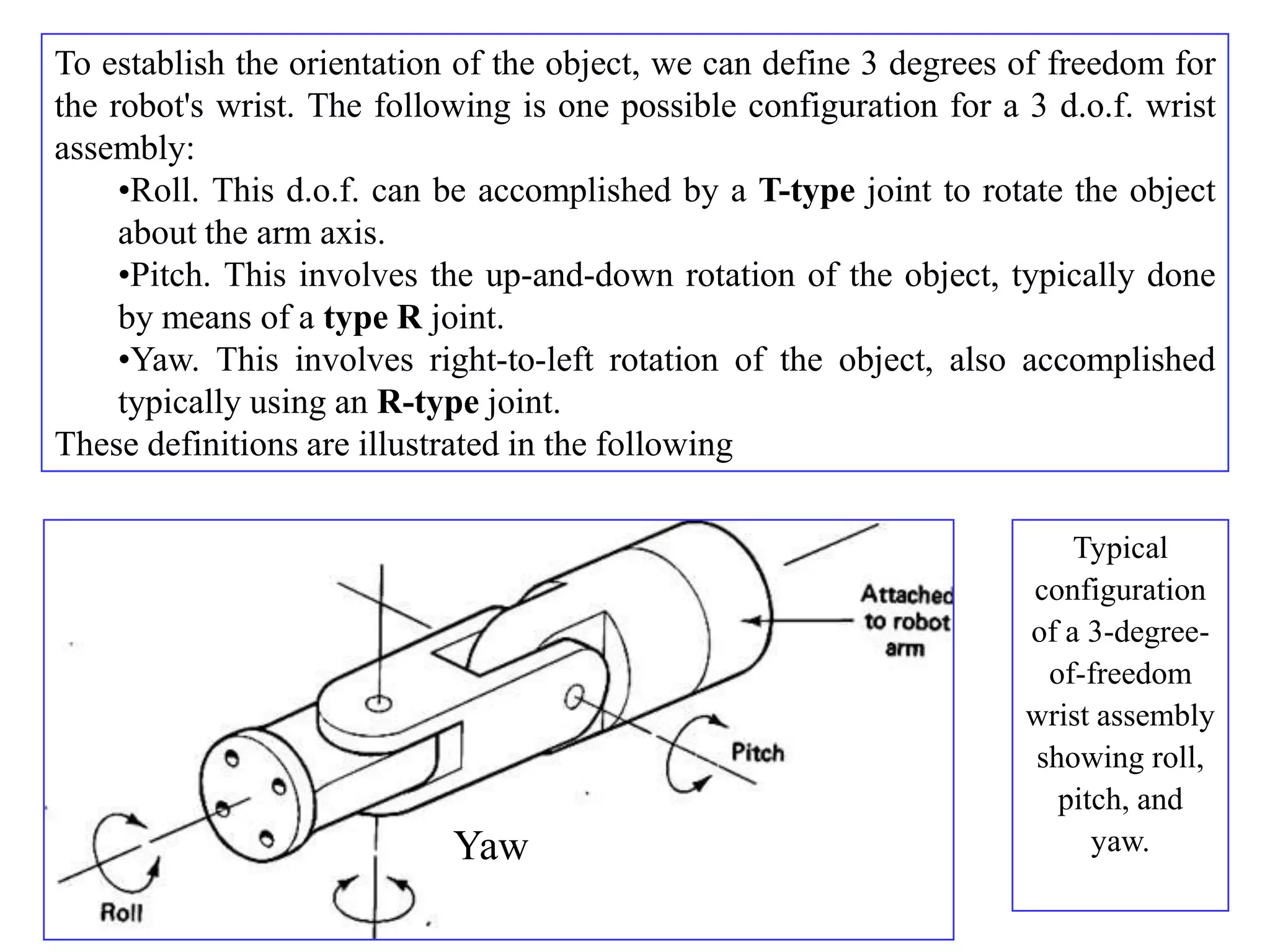

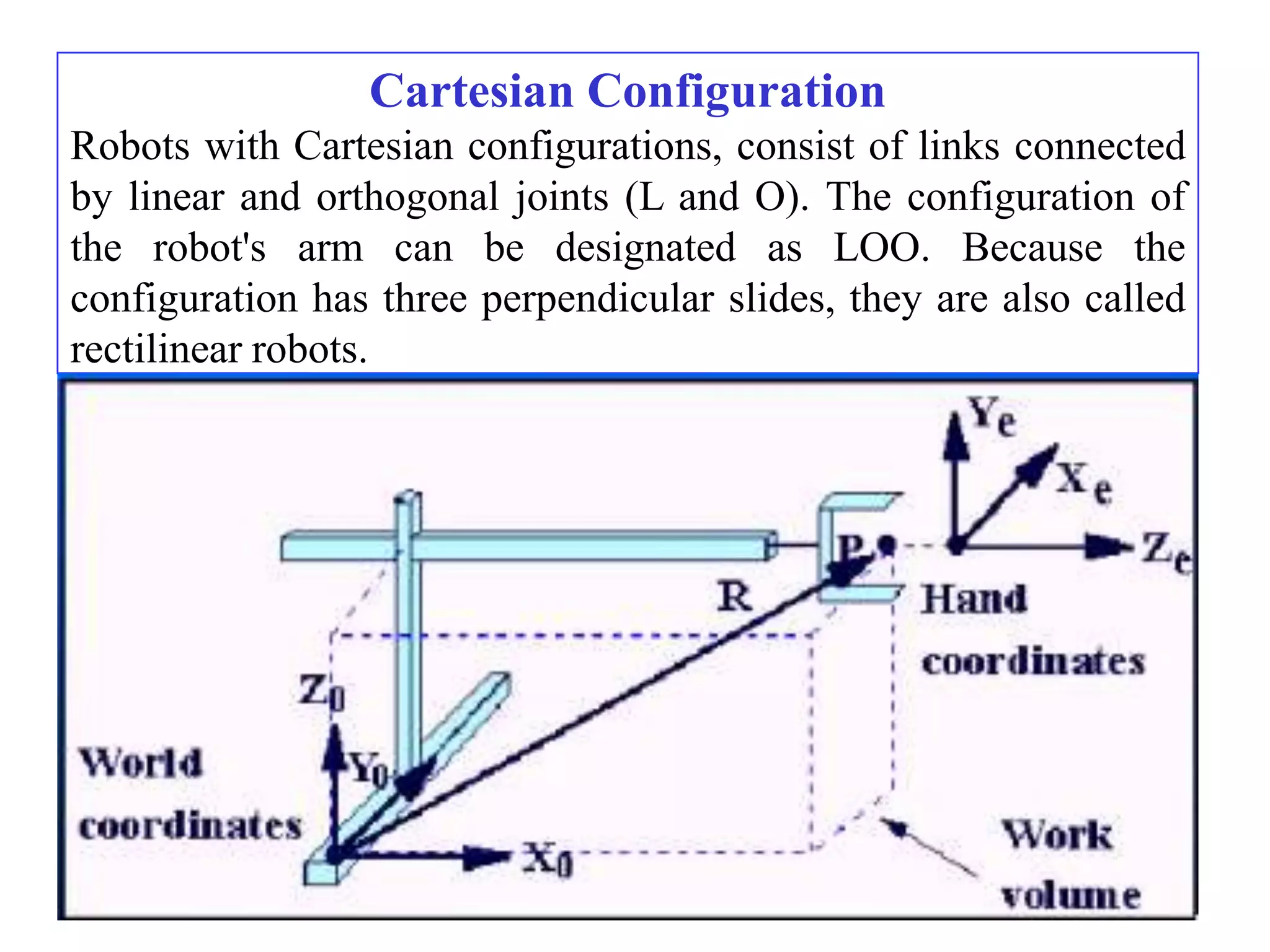

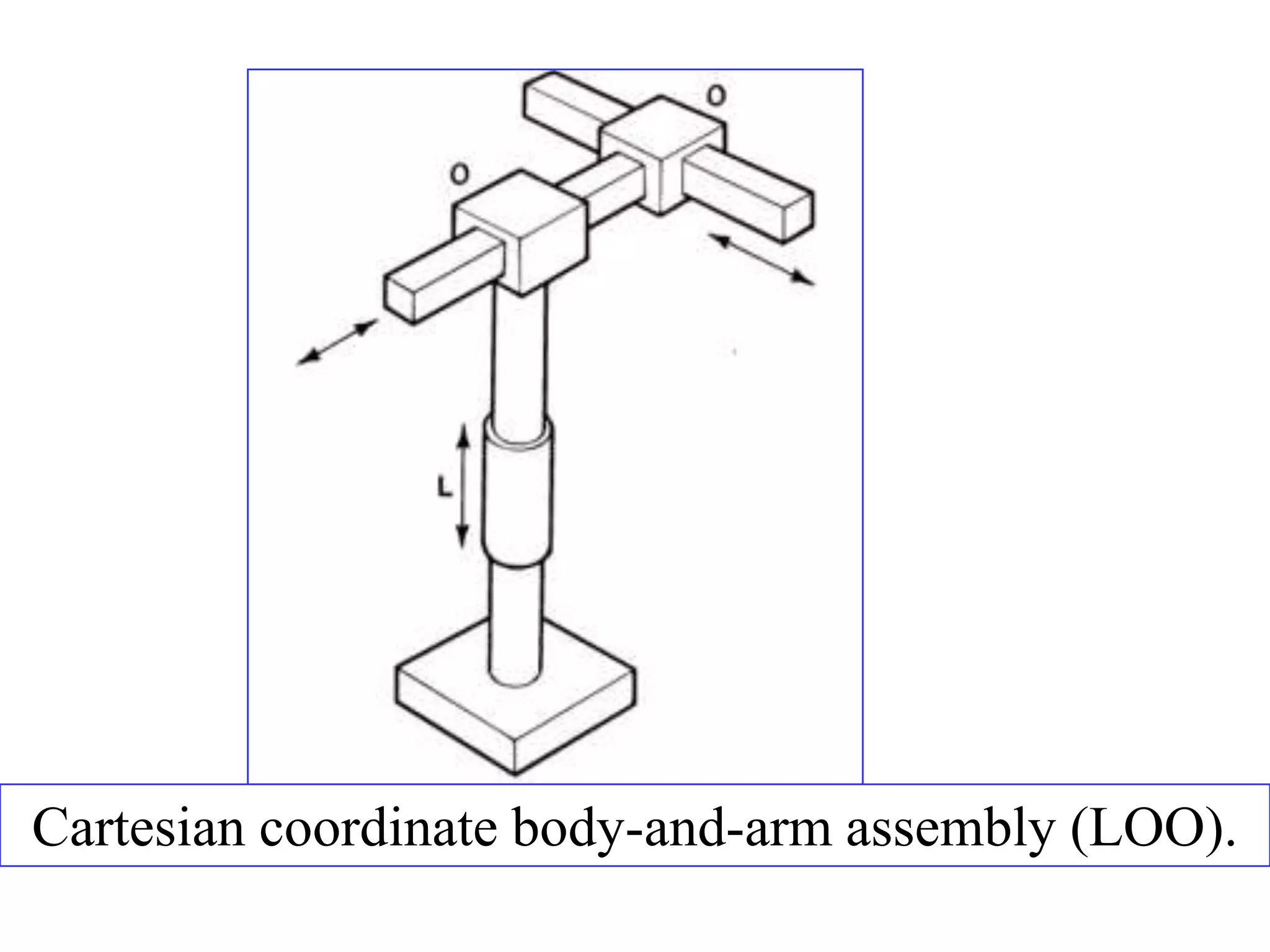

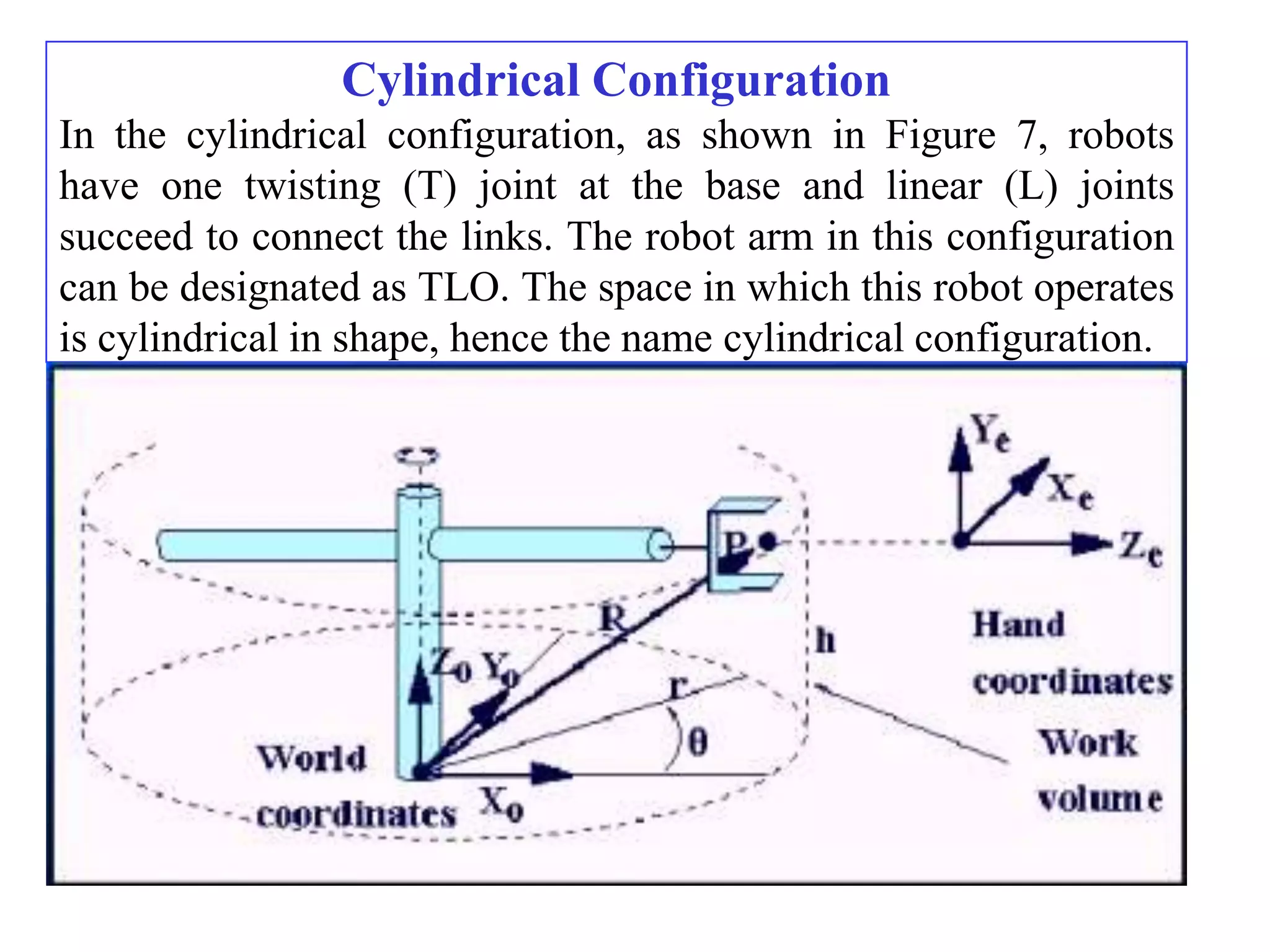

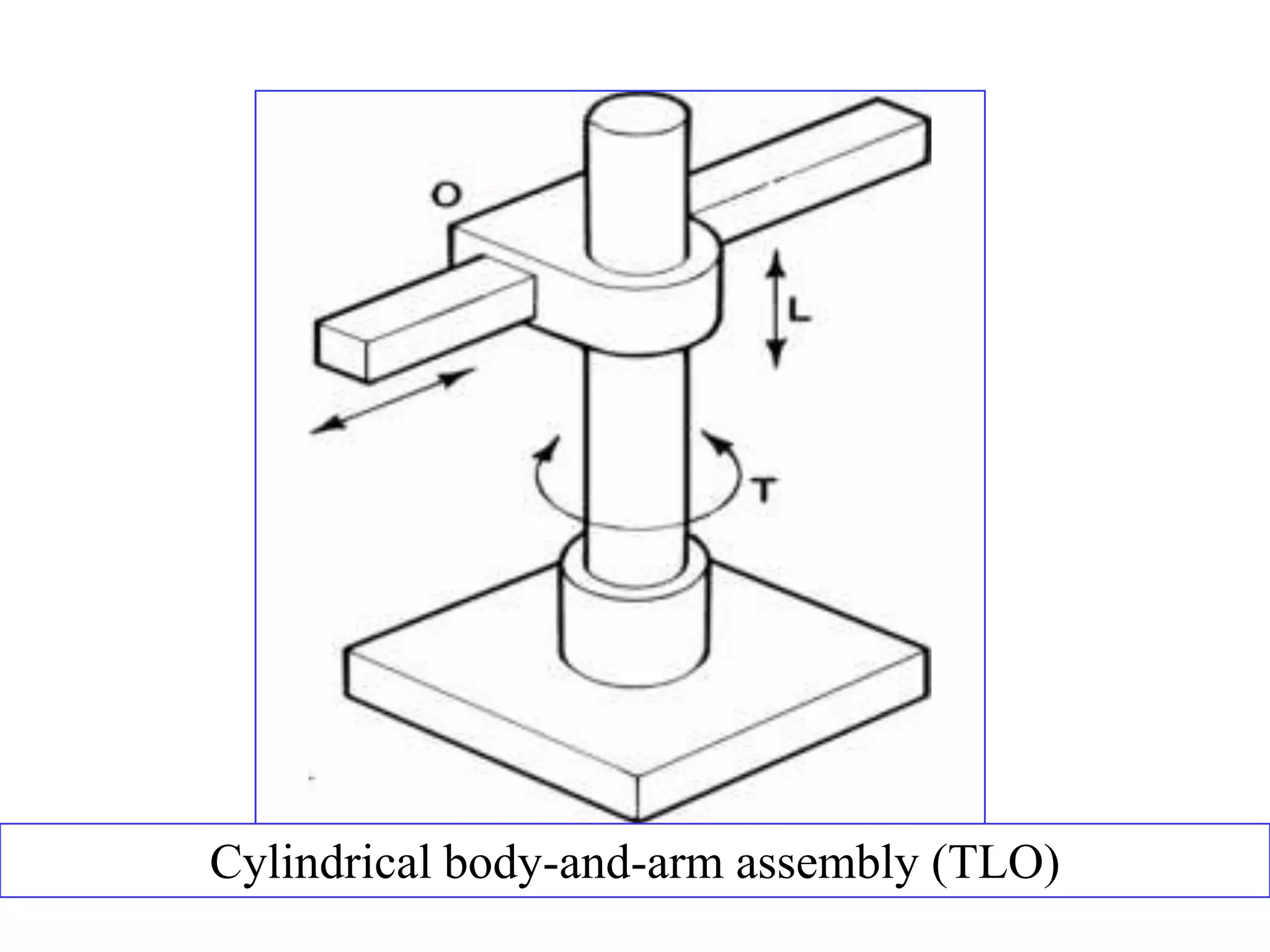

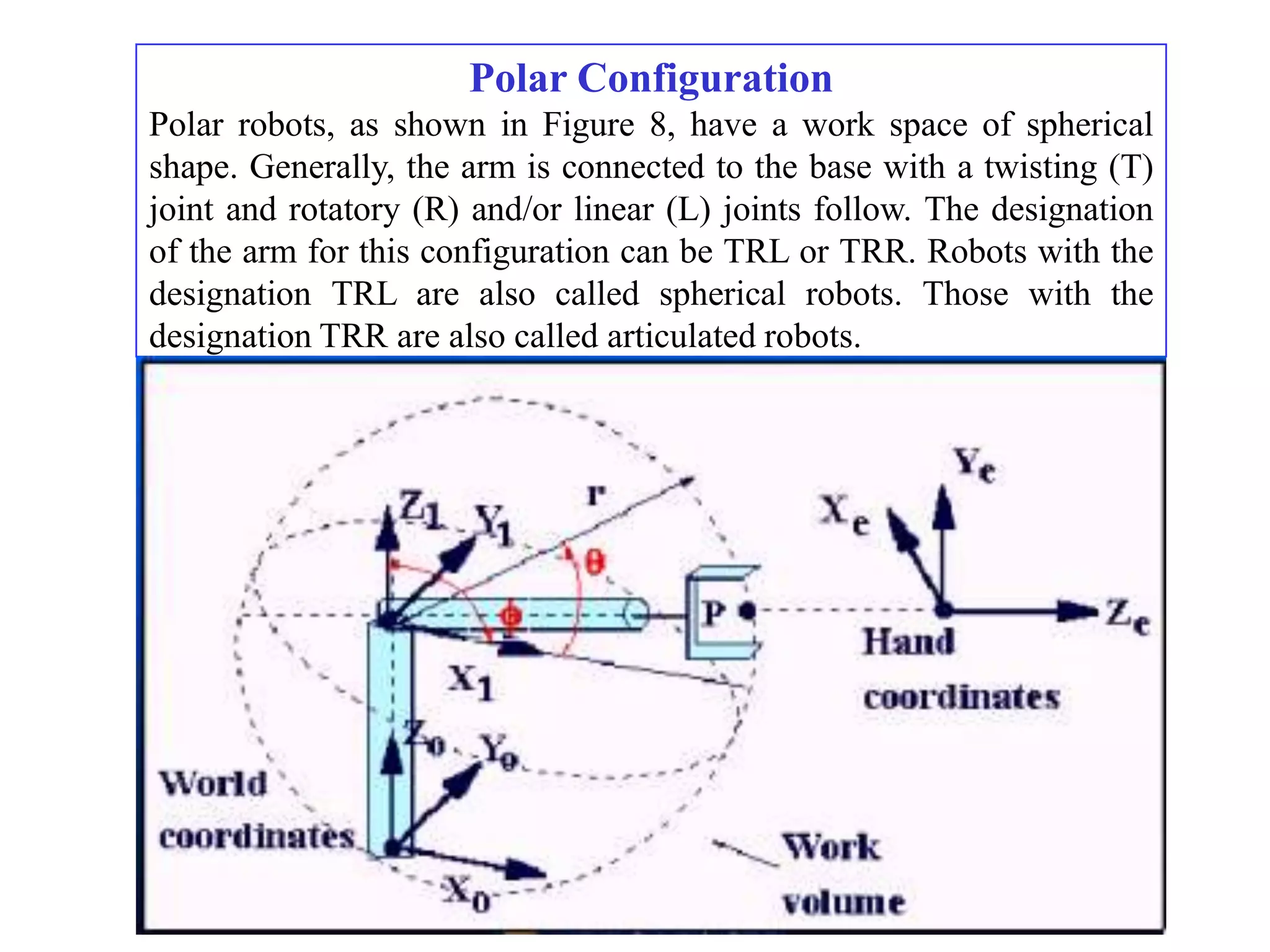

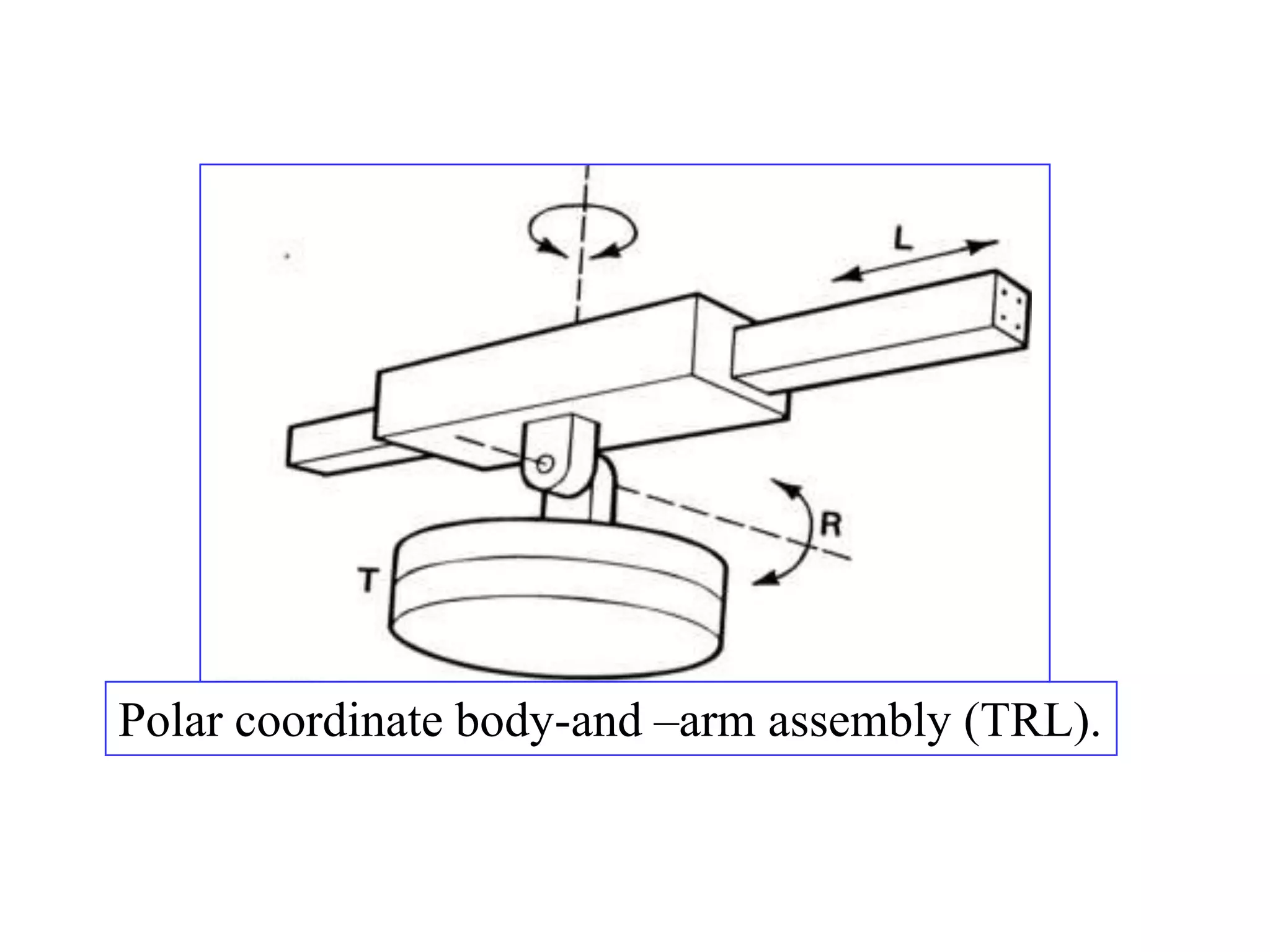

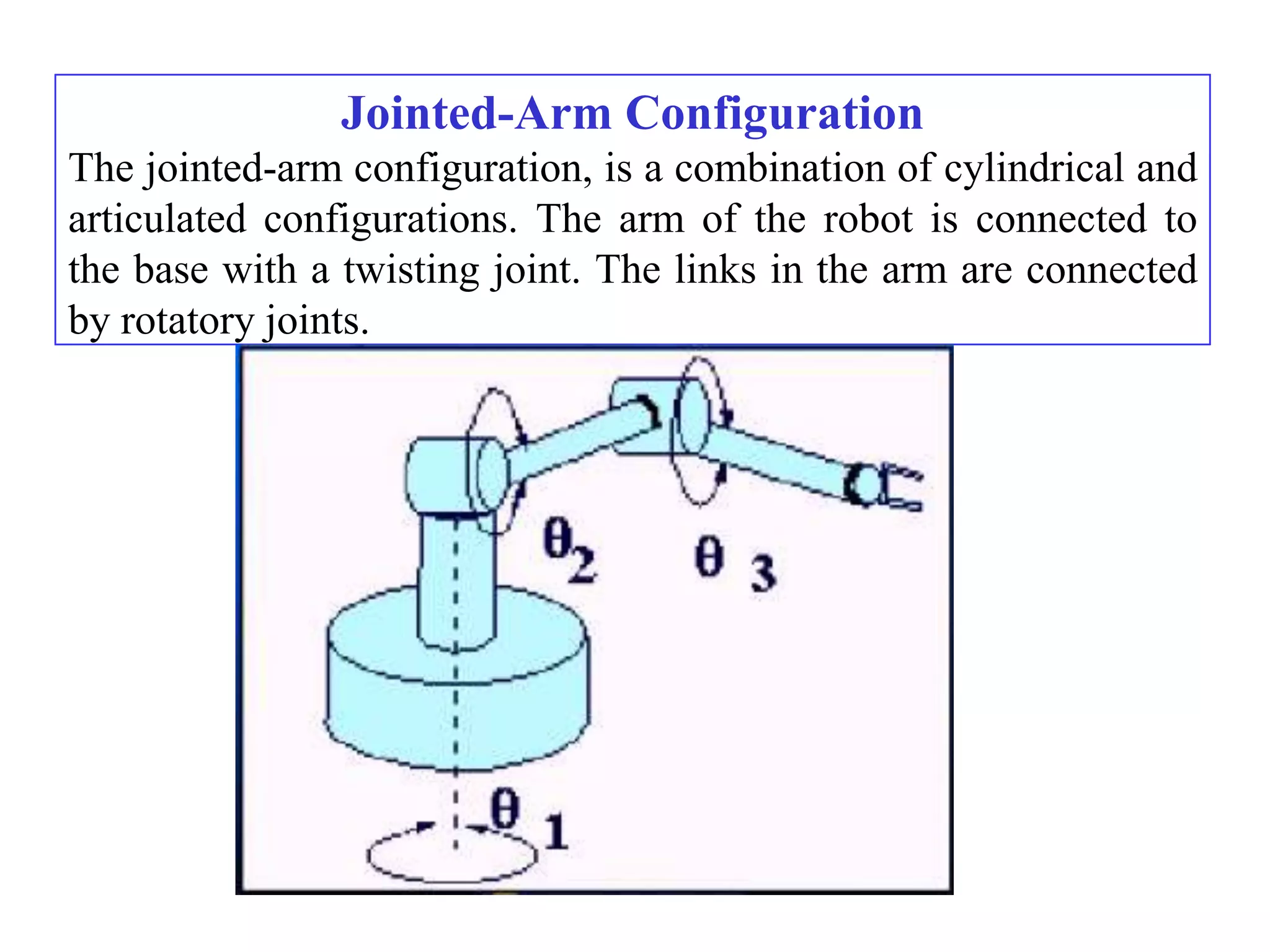

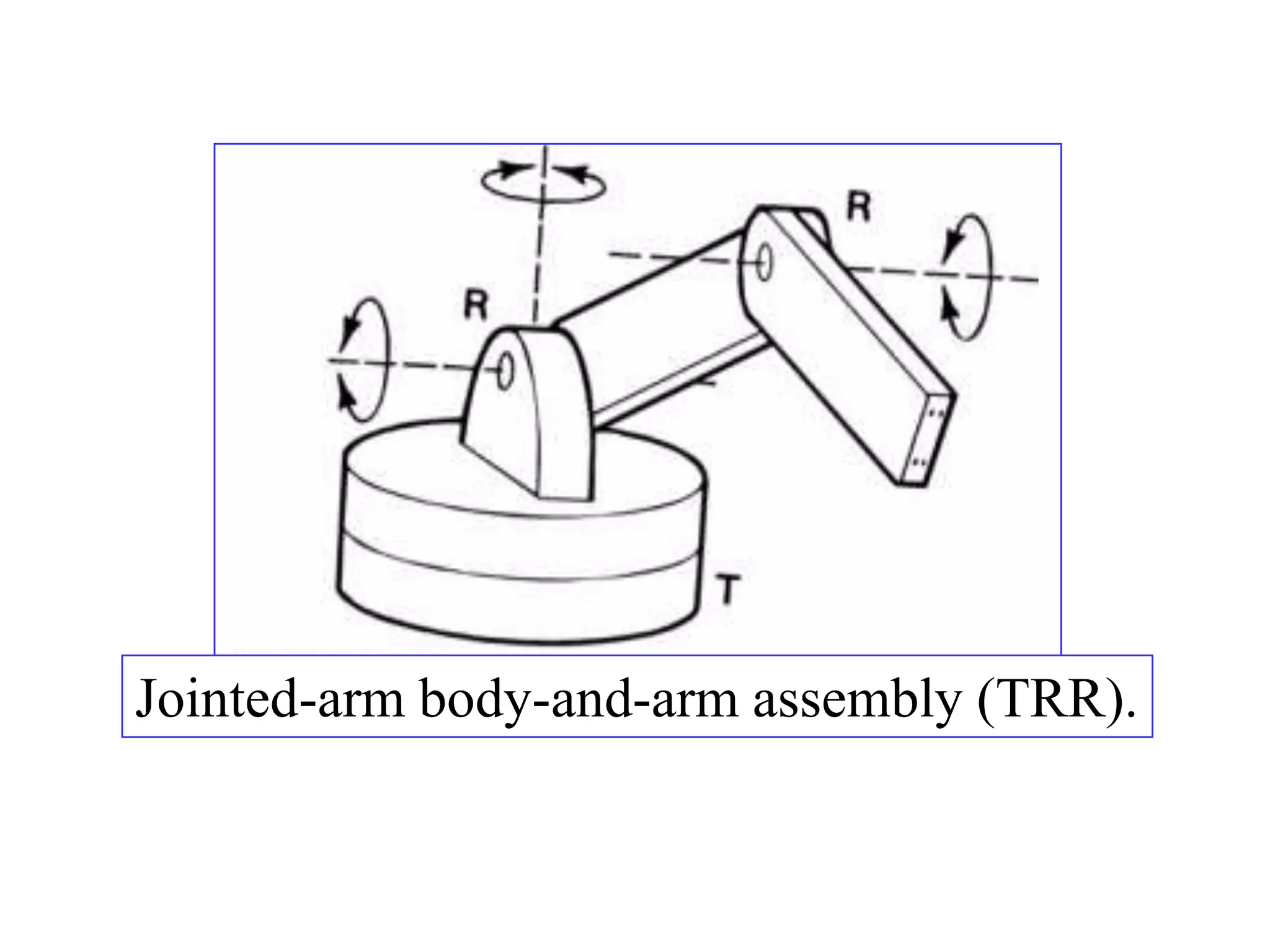

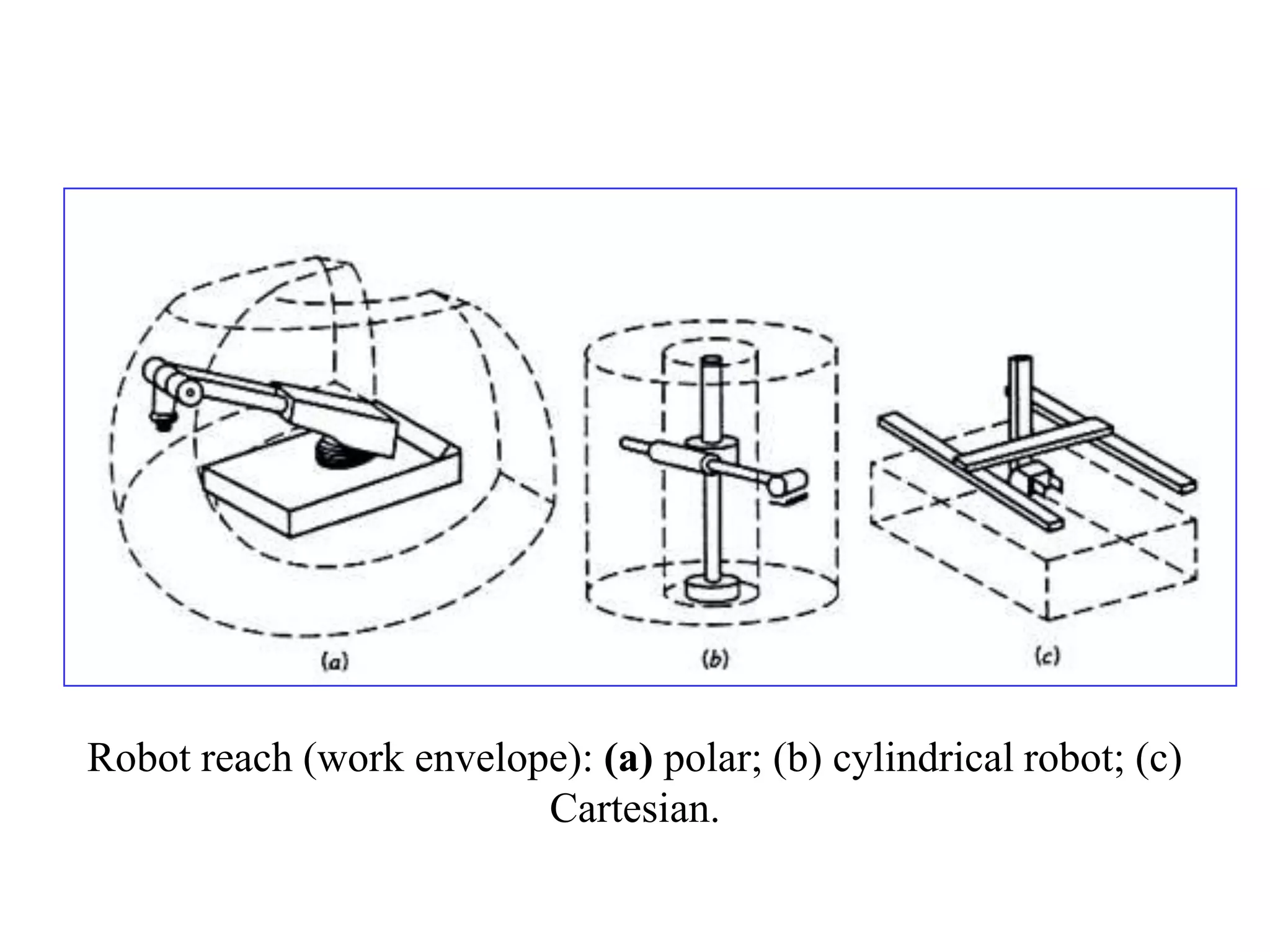

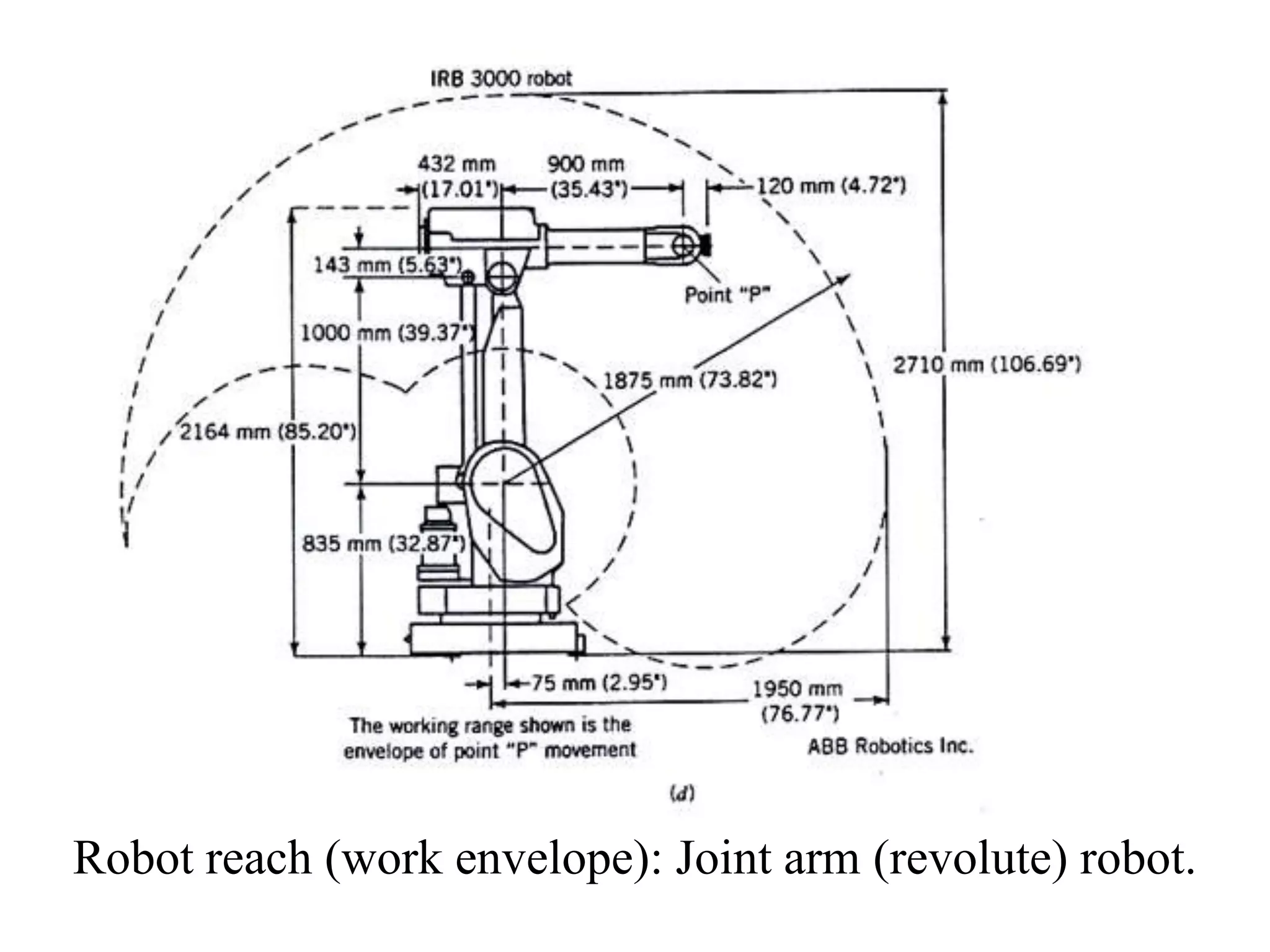

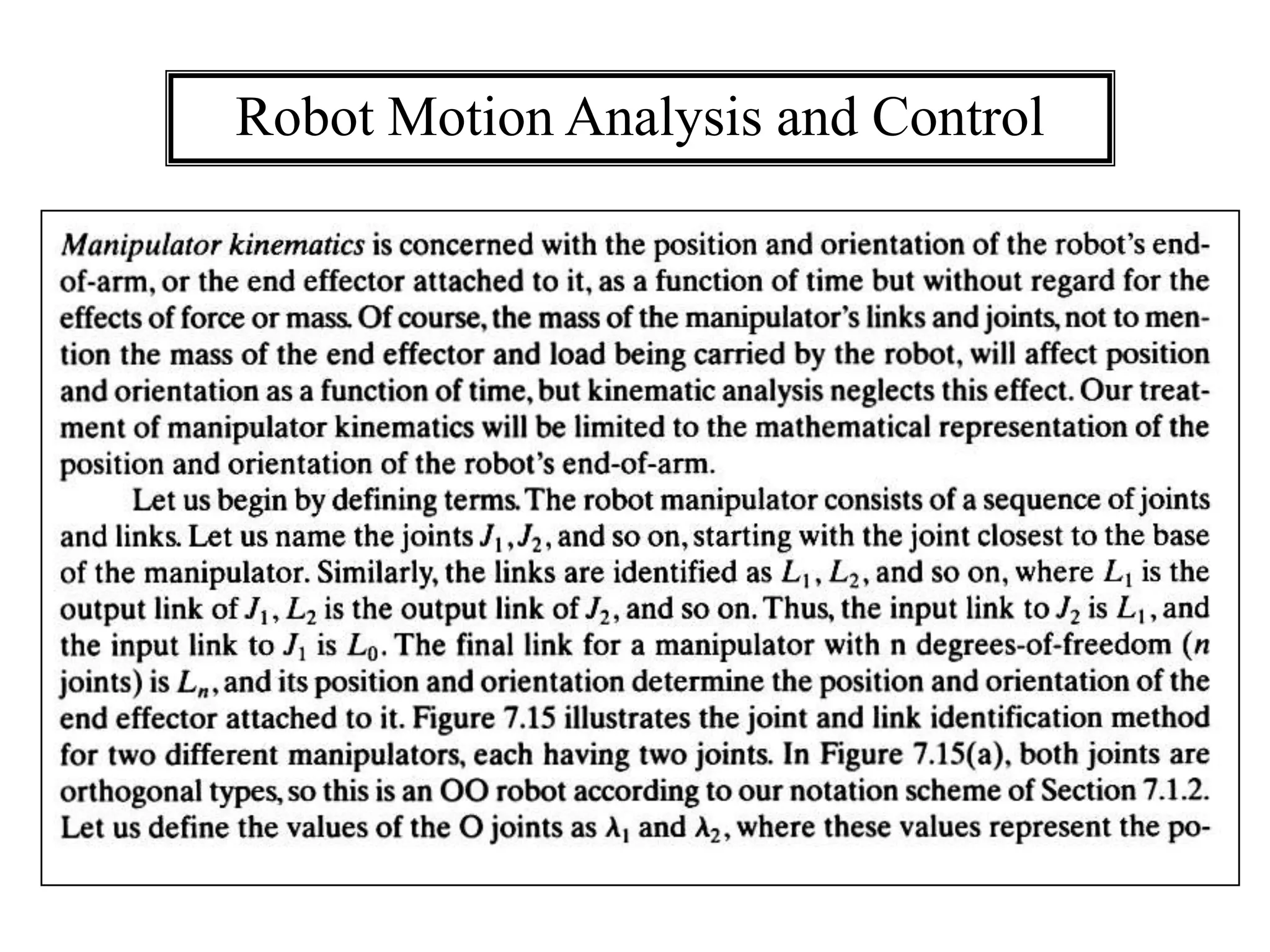

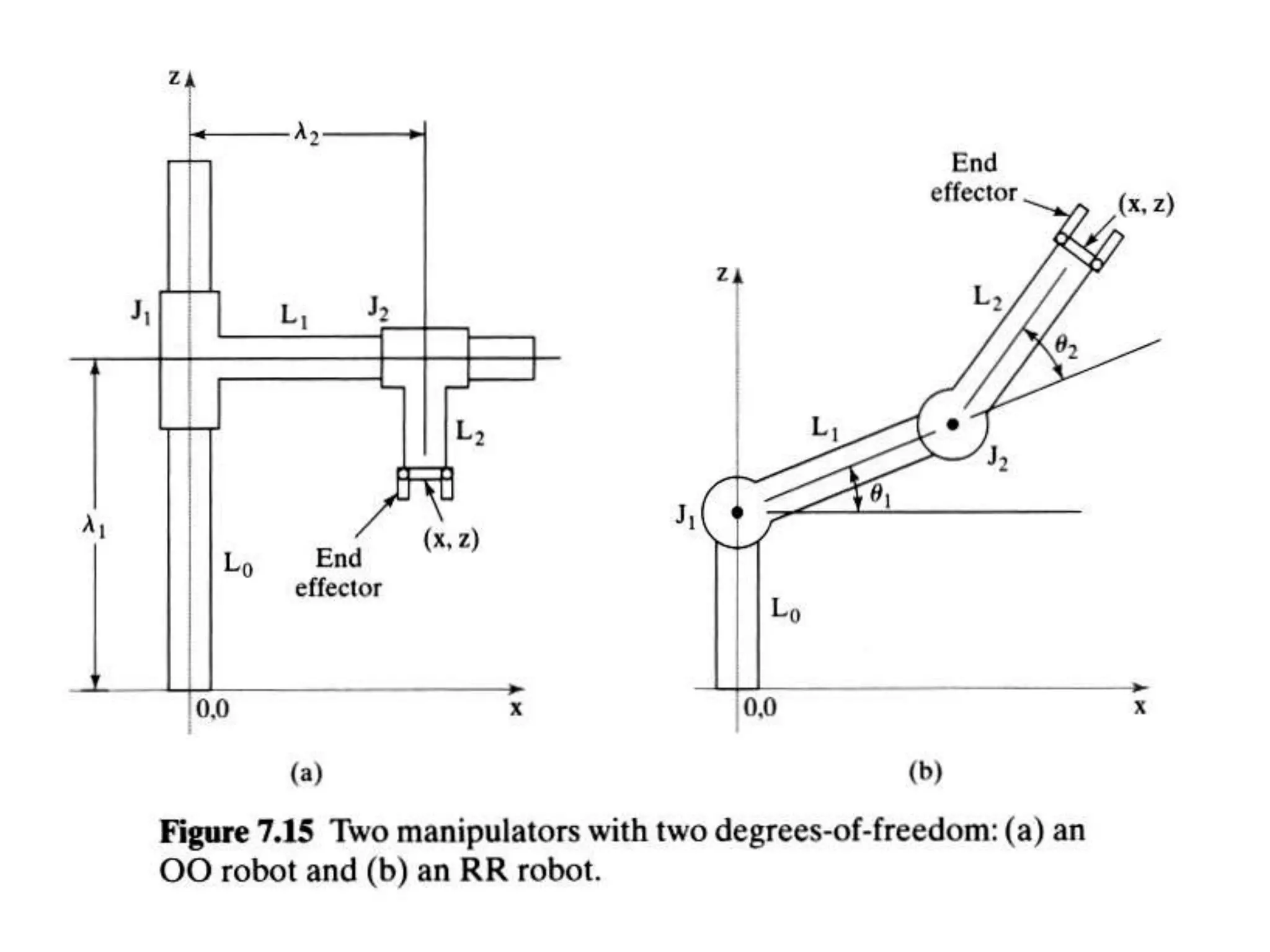

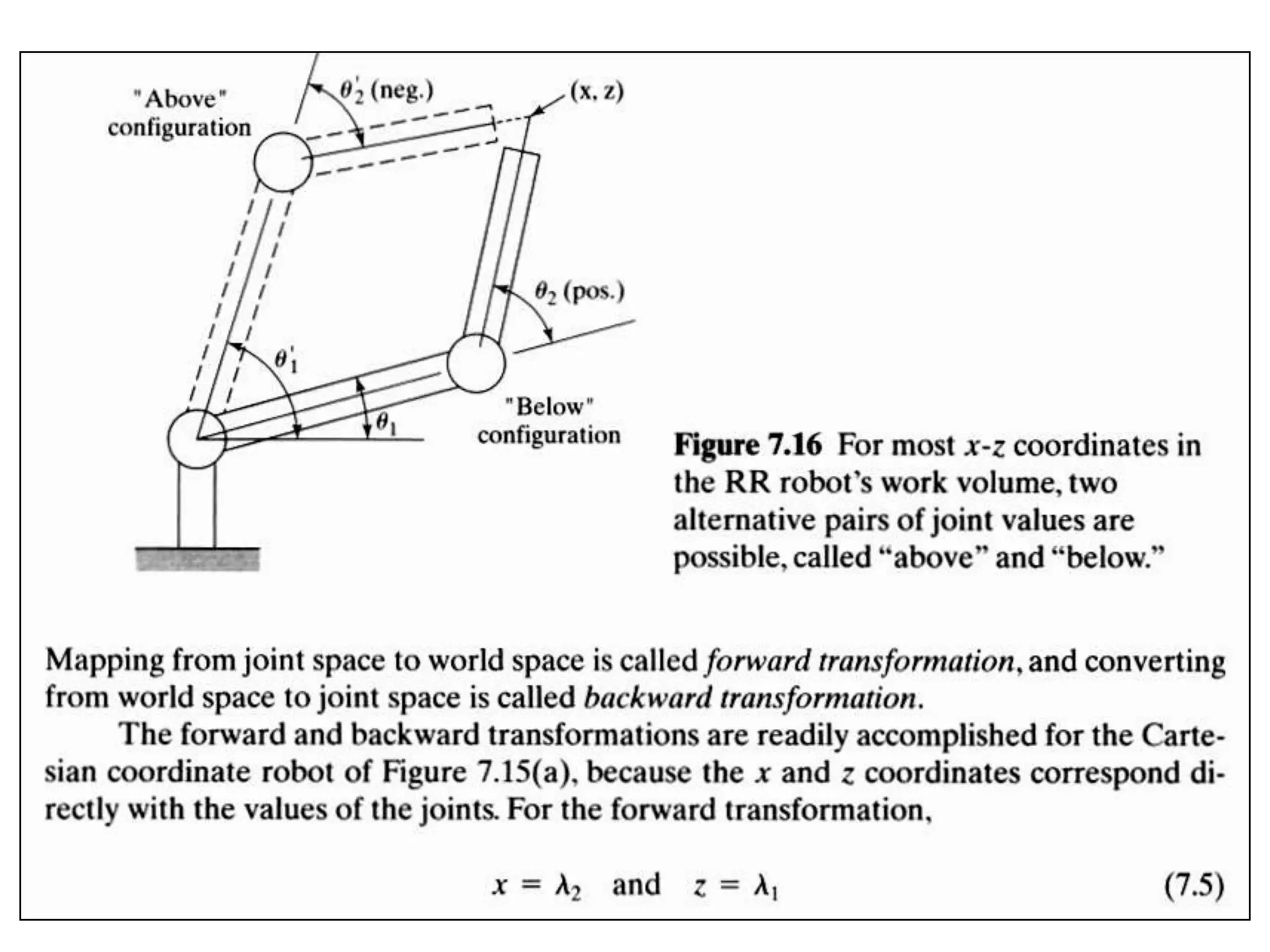

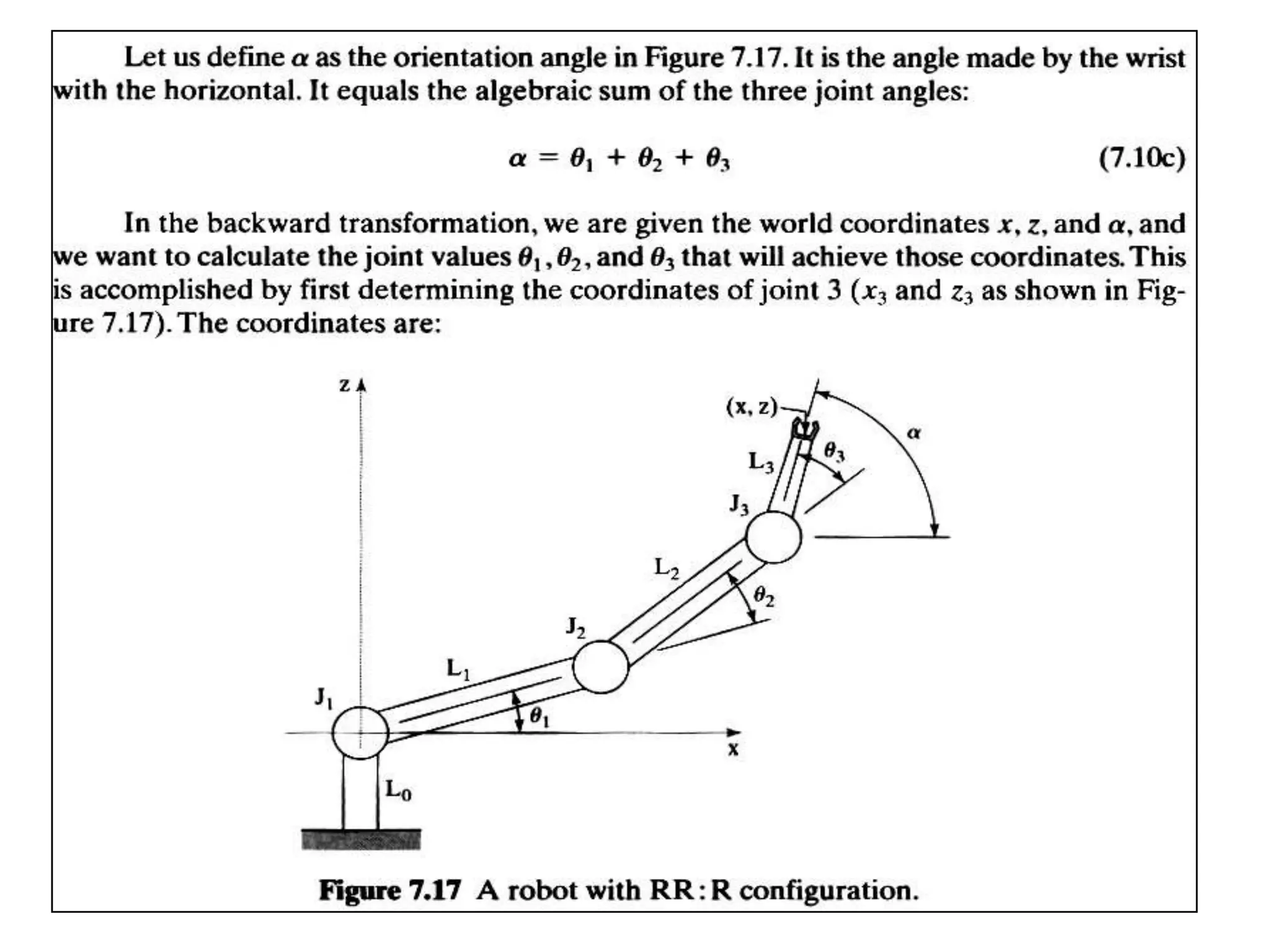

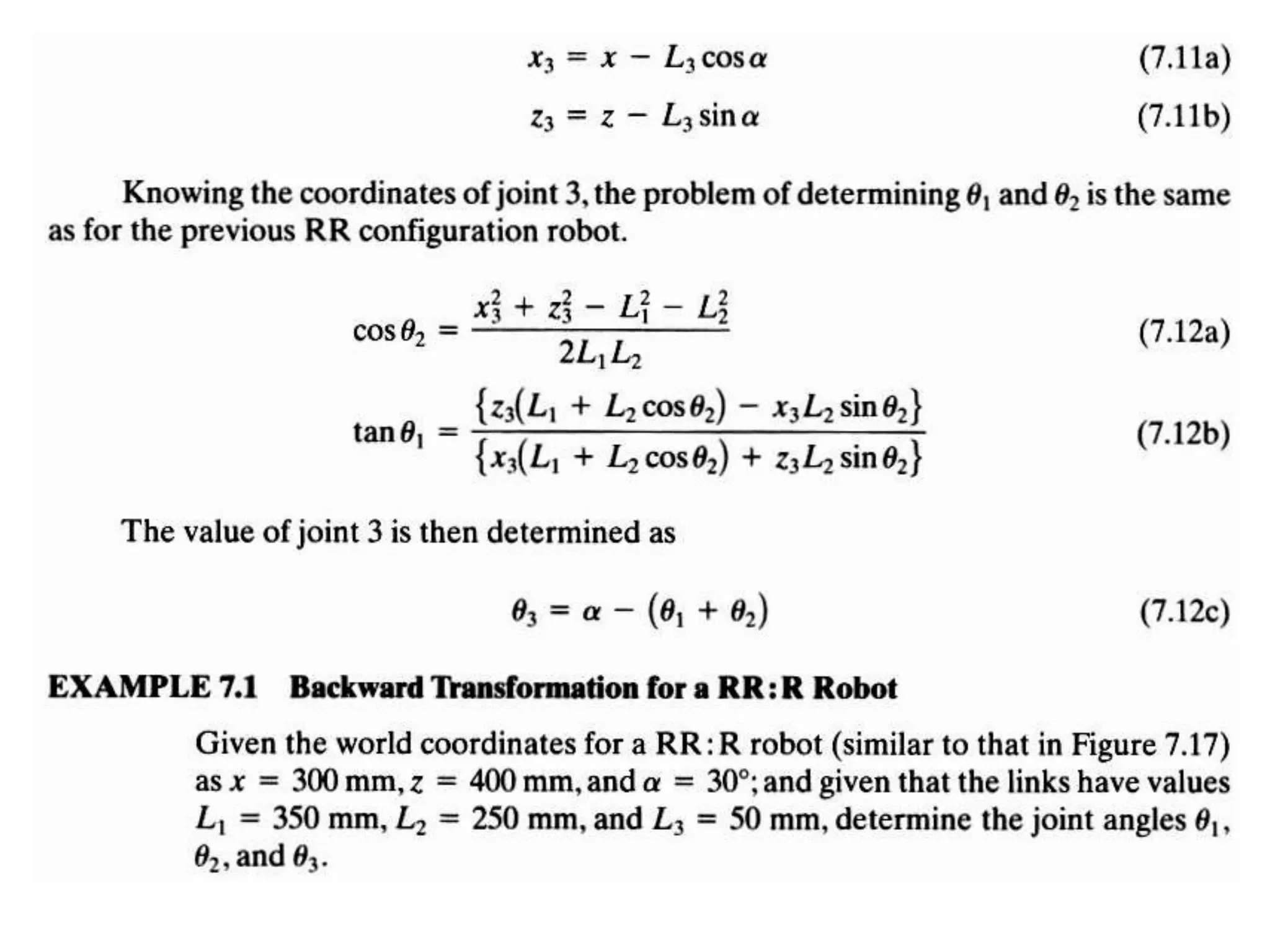

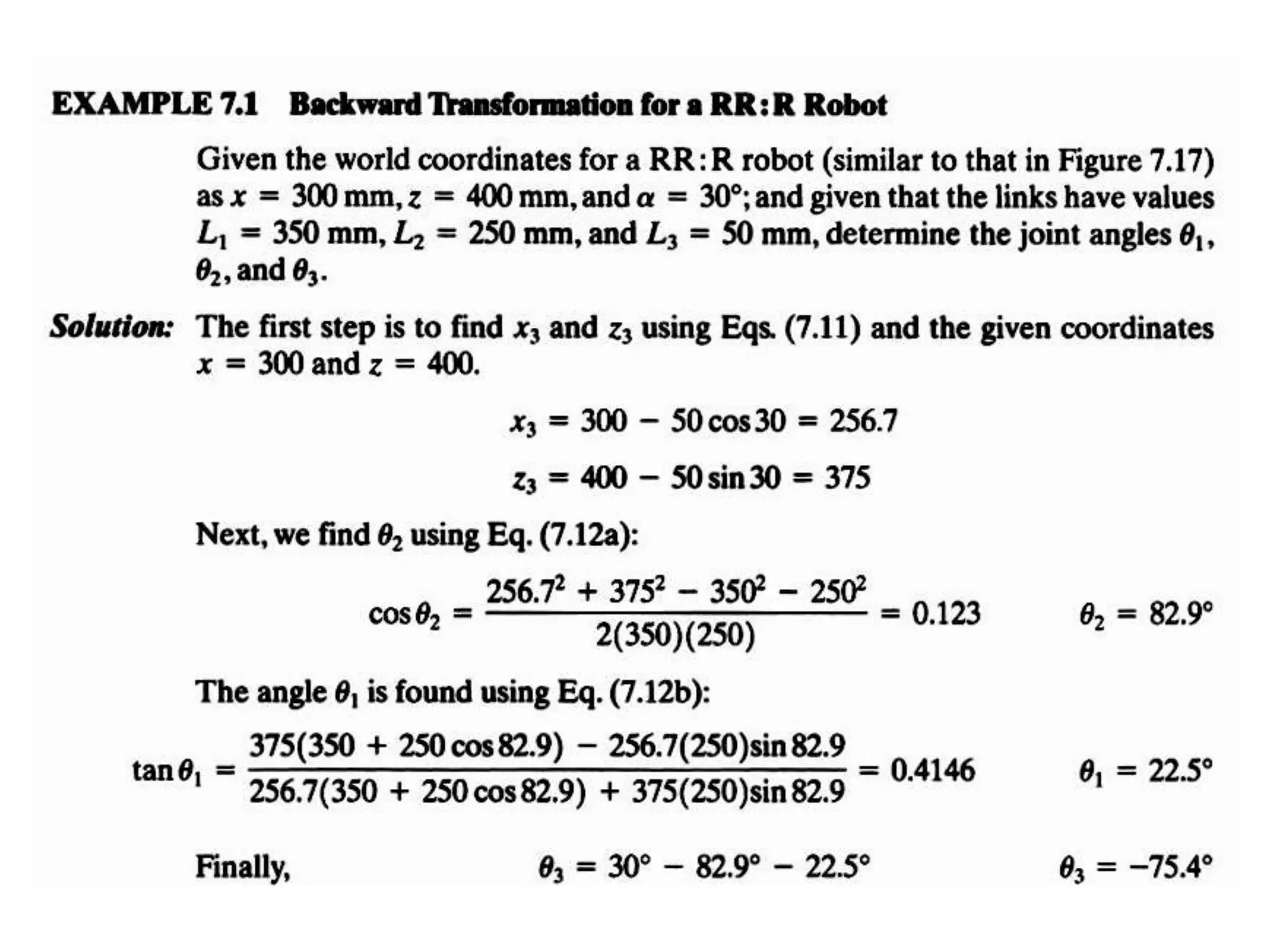

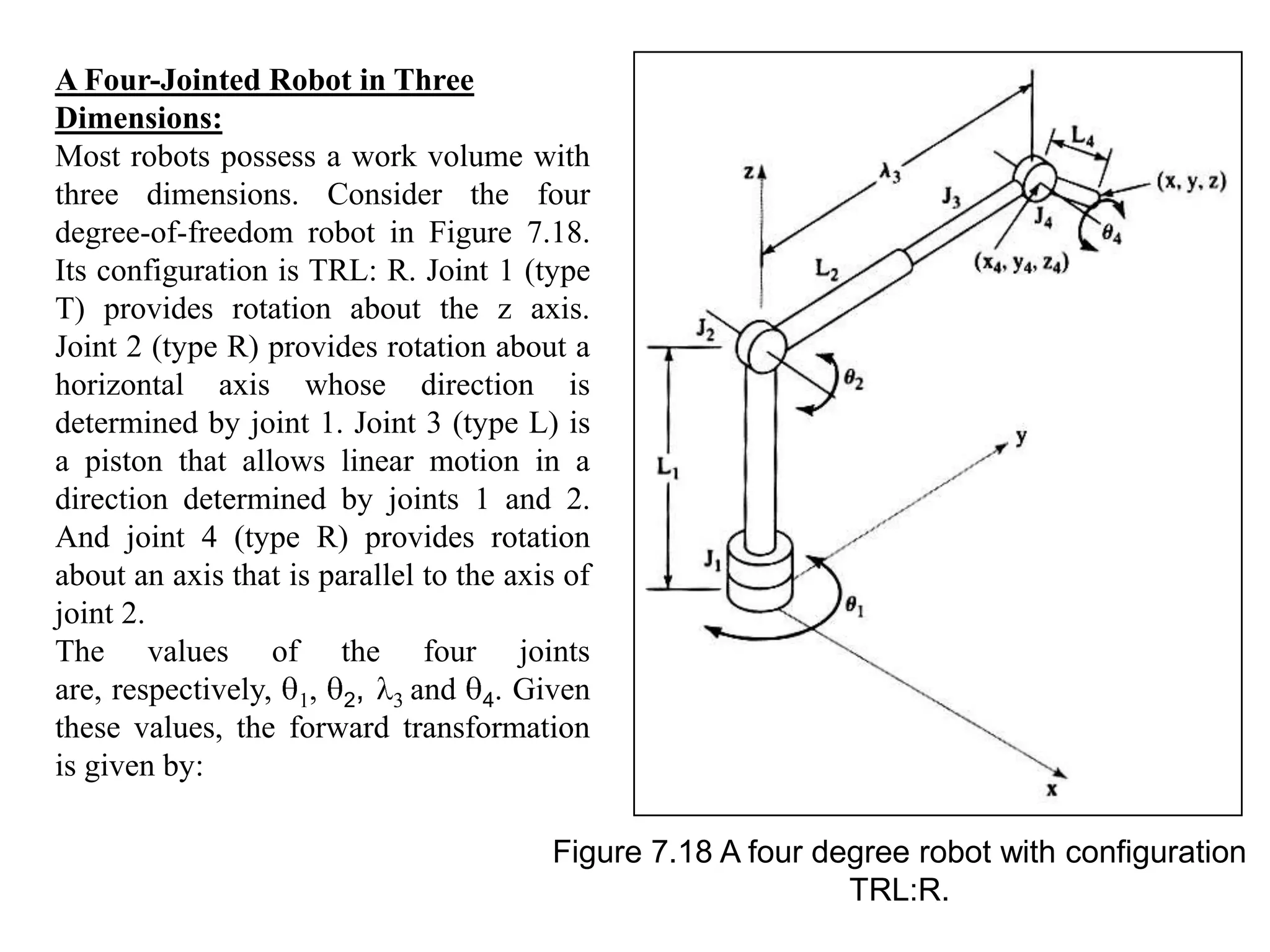

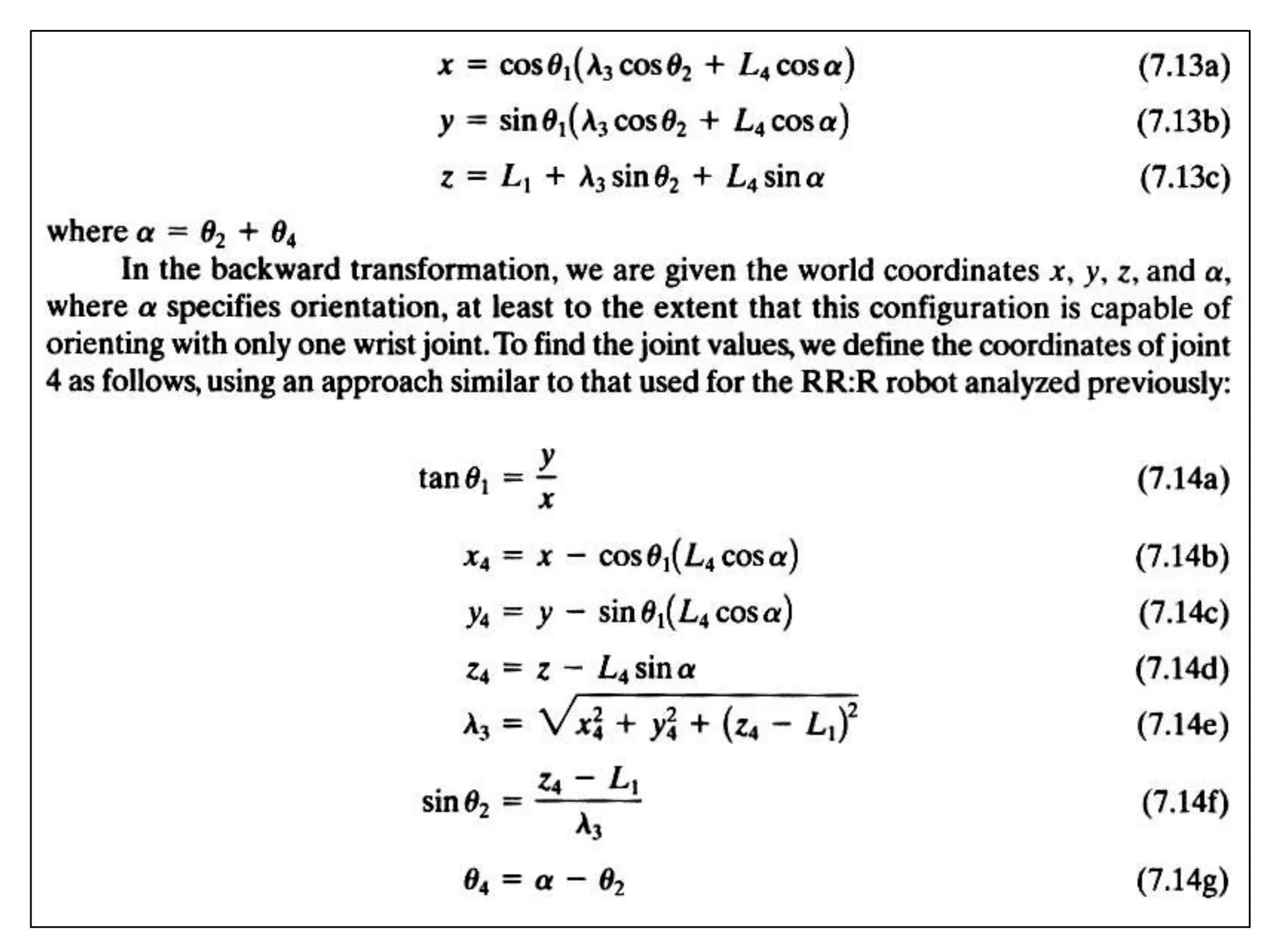

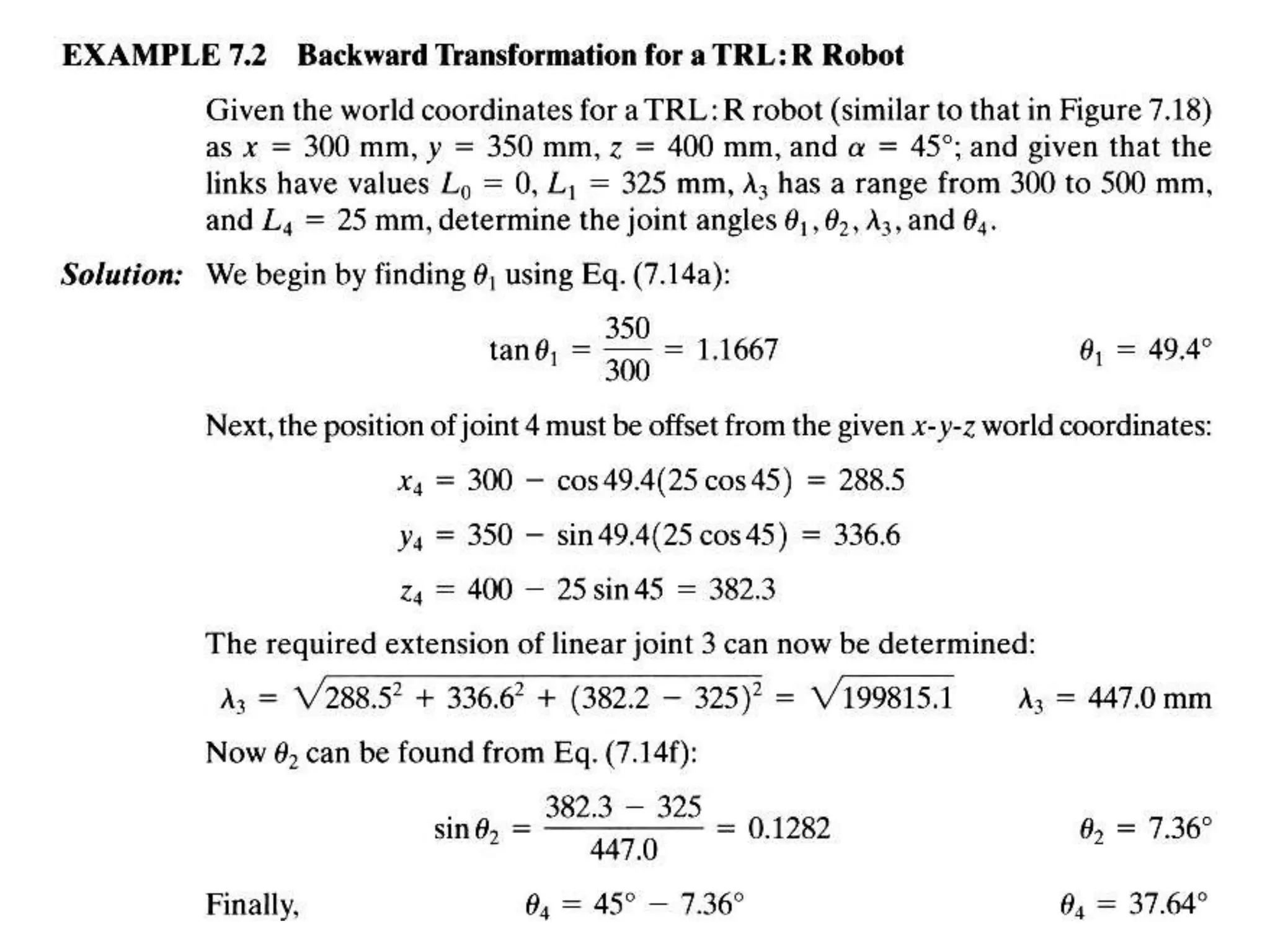

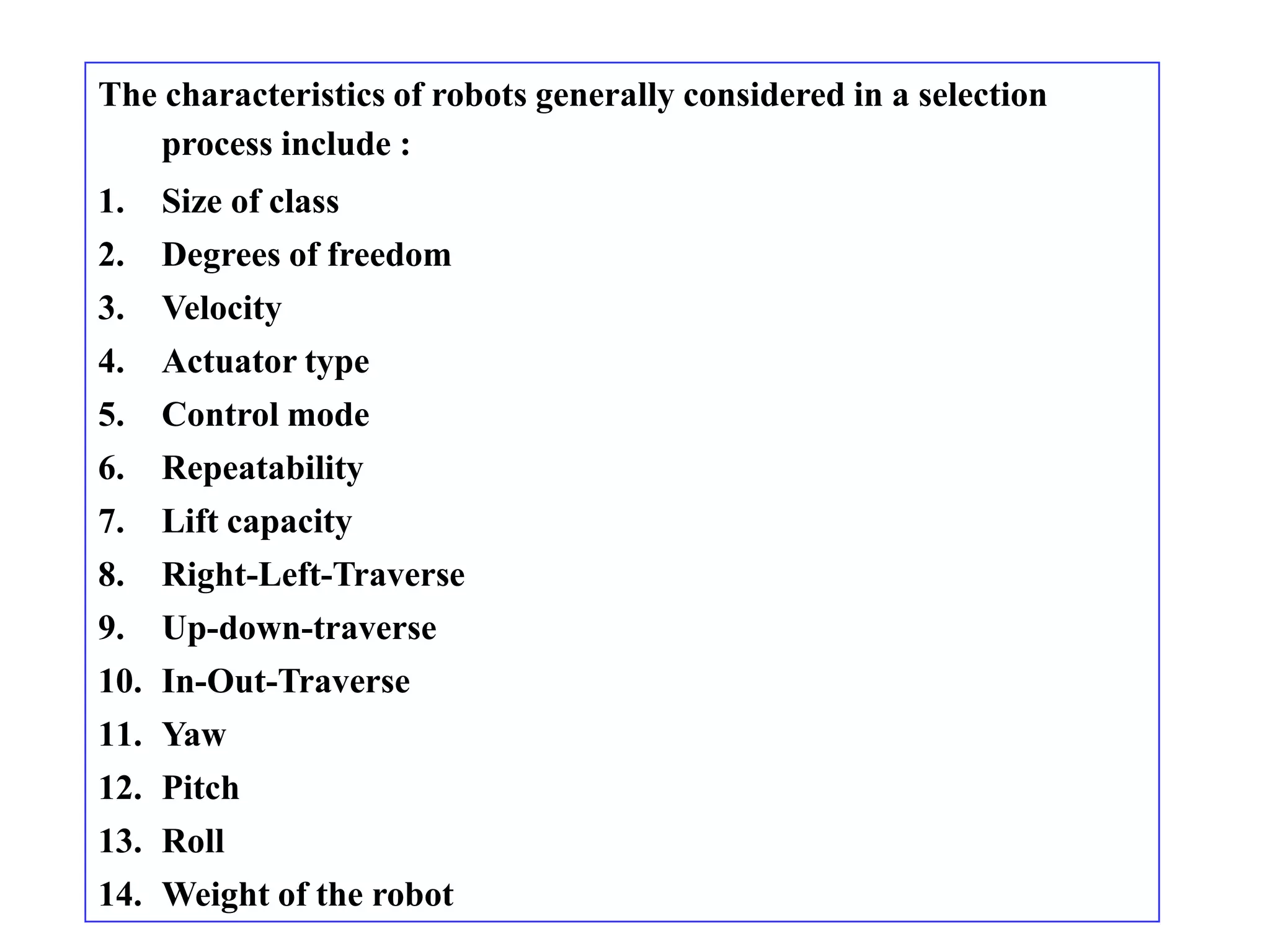

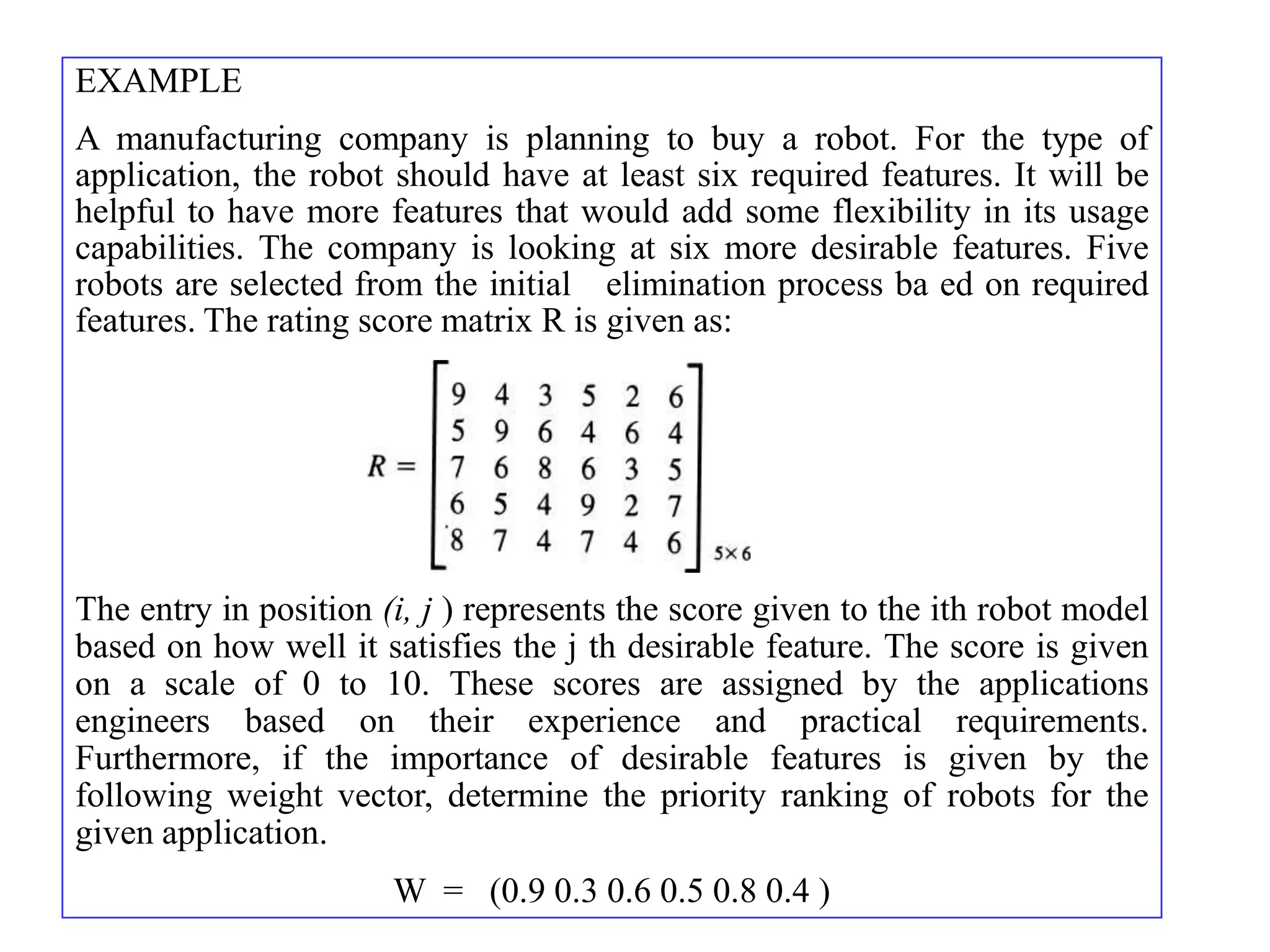

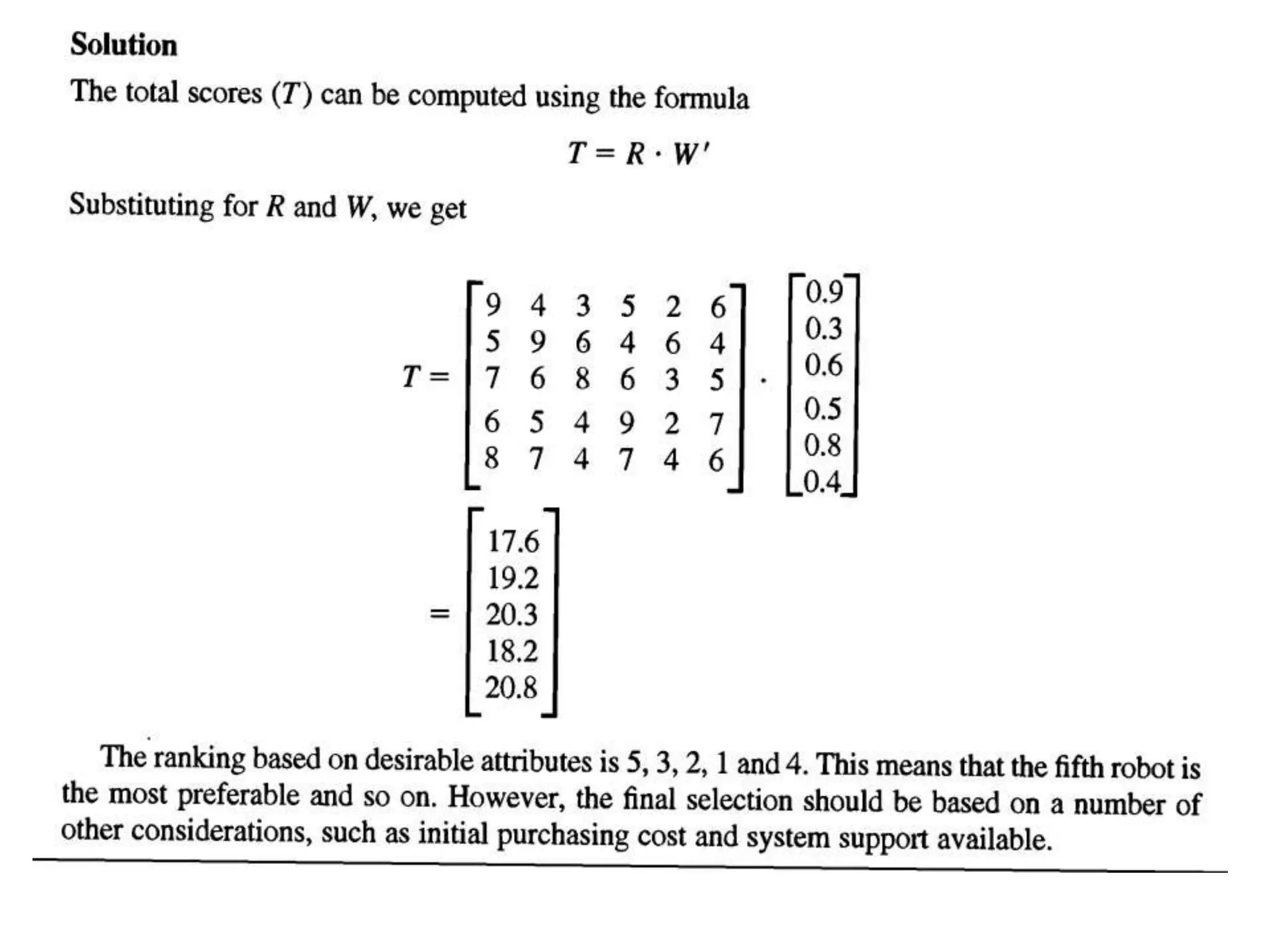

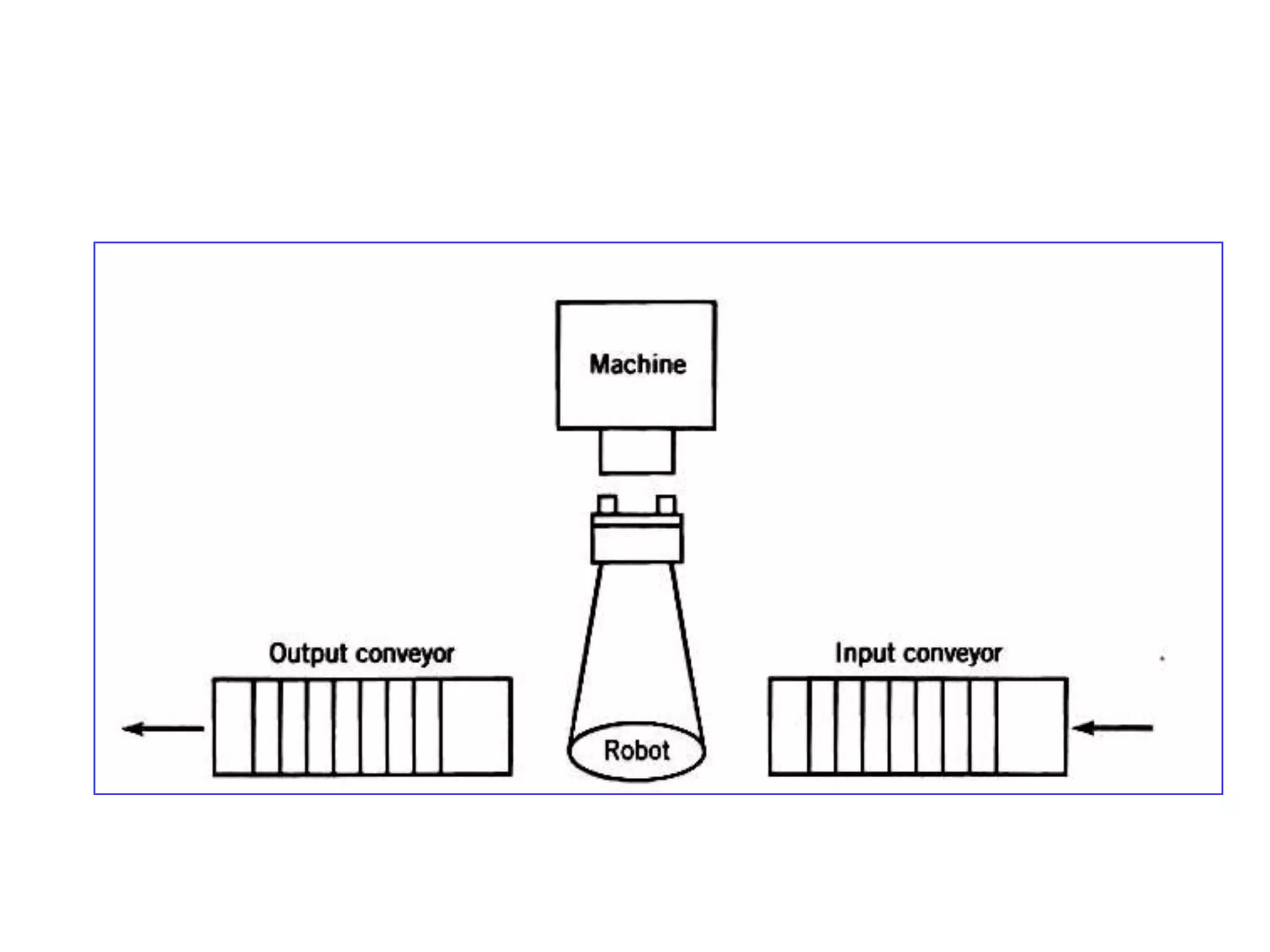

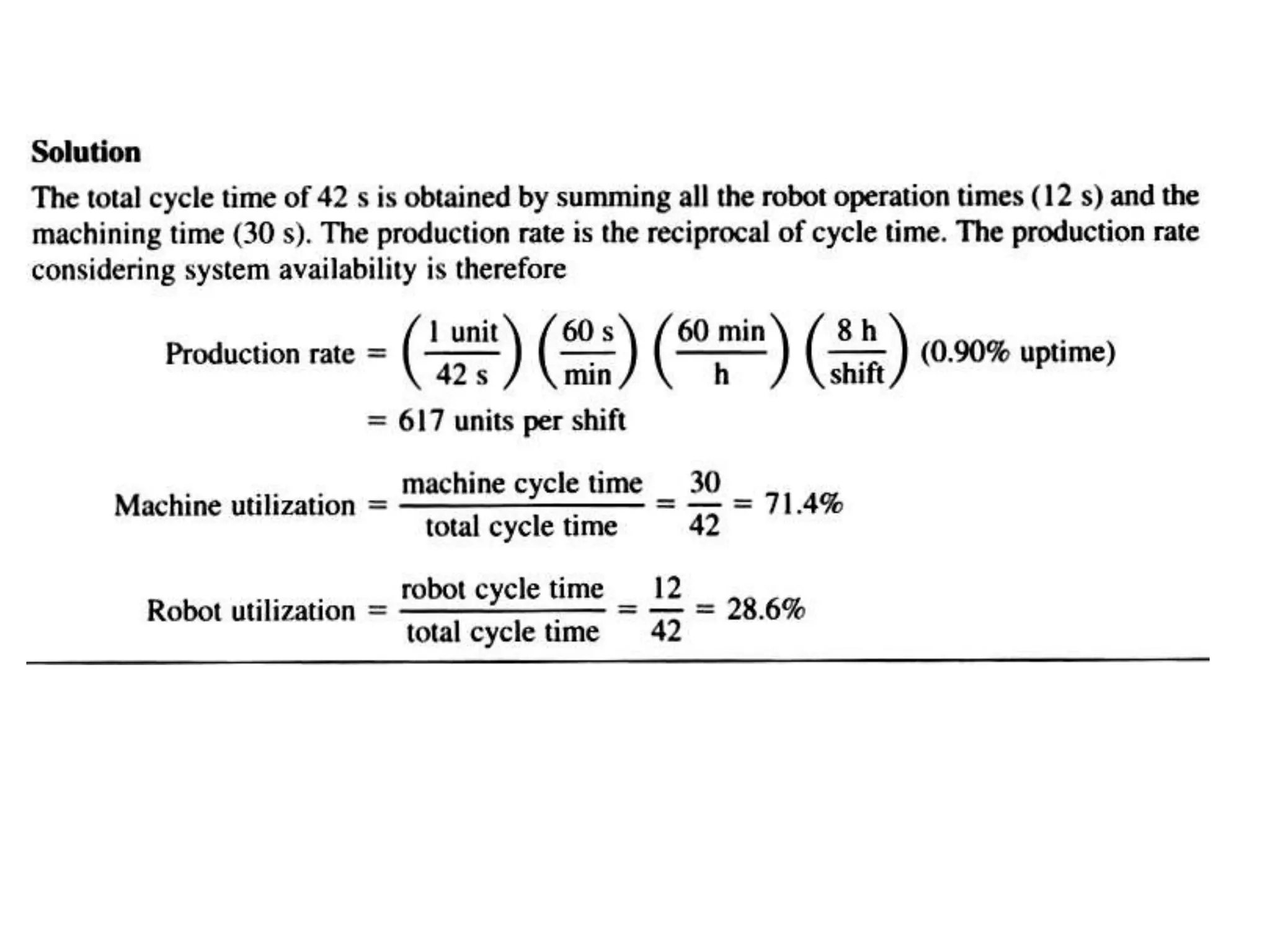

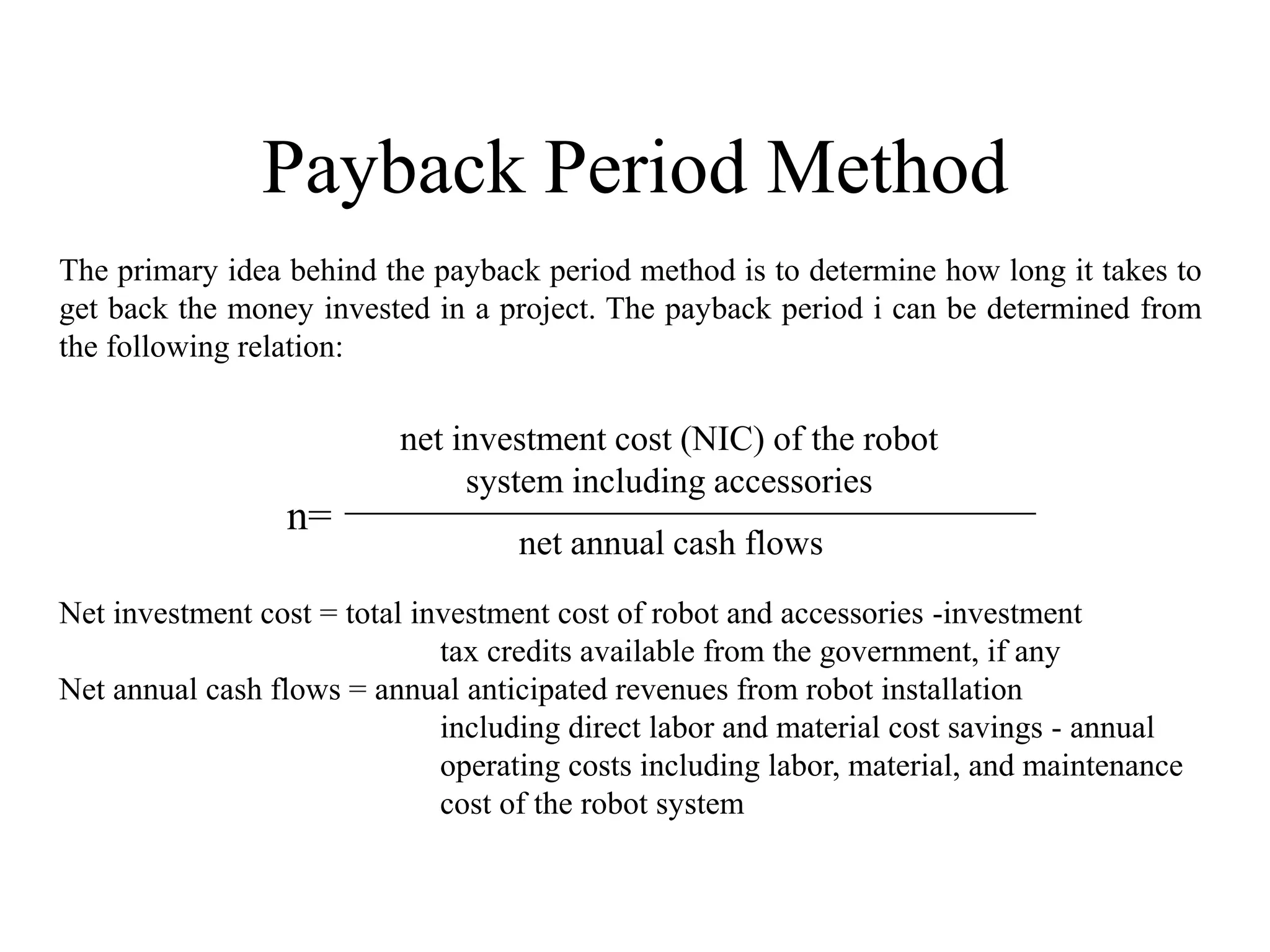

The document discusses industrial robots, including their basic components, types of joints, movement and precision, power sources, sensors, end effectors, and applications. An industrial robot generally consists of rigid links connected by joints to form an arm with an end effector or hand. It is controlled by a computer and can be programmed to perform automated tasks through variable motions. The document covers various robotic systems and their use in manufacturing.