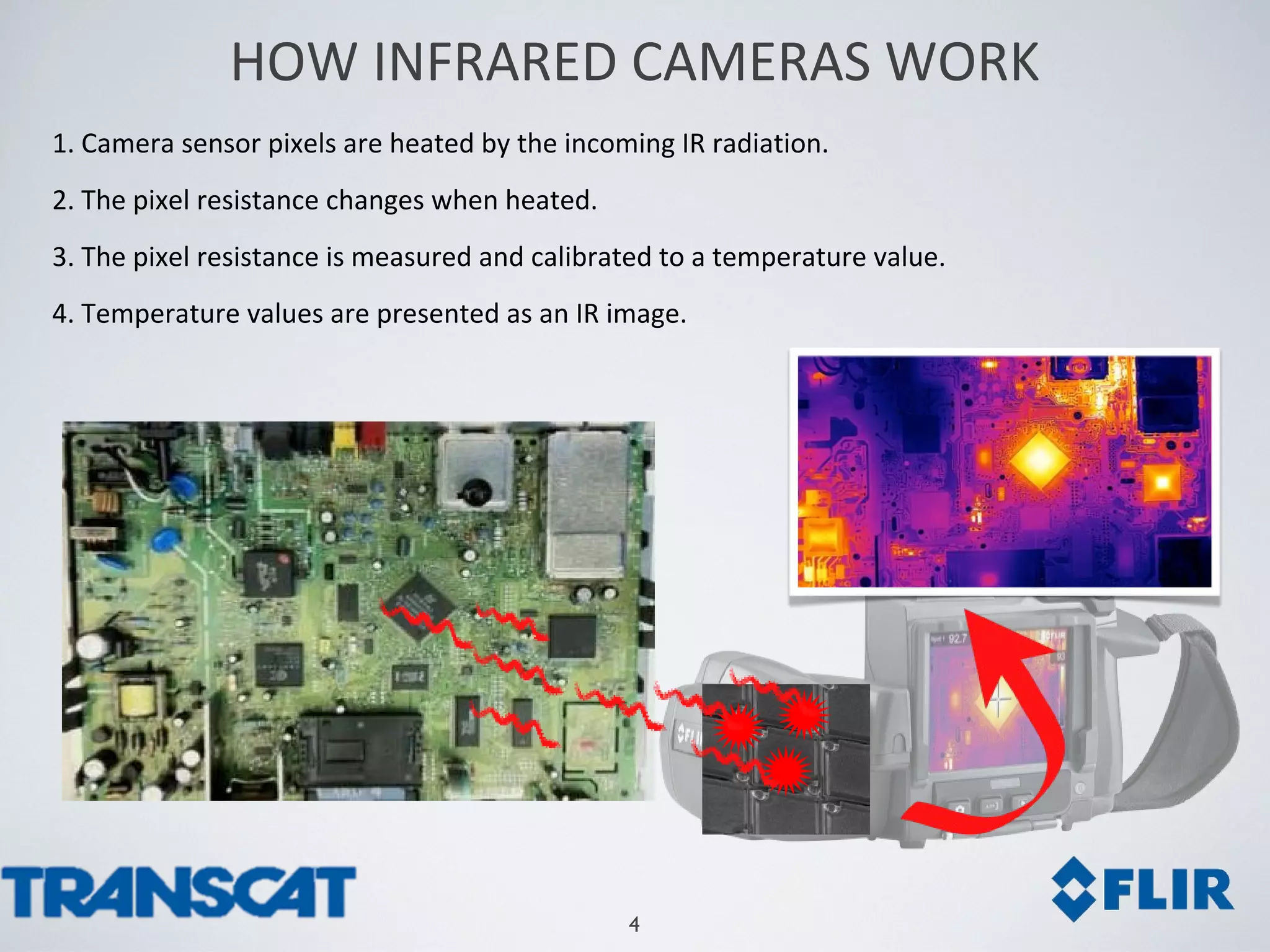

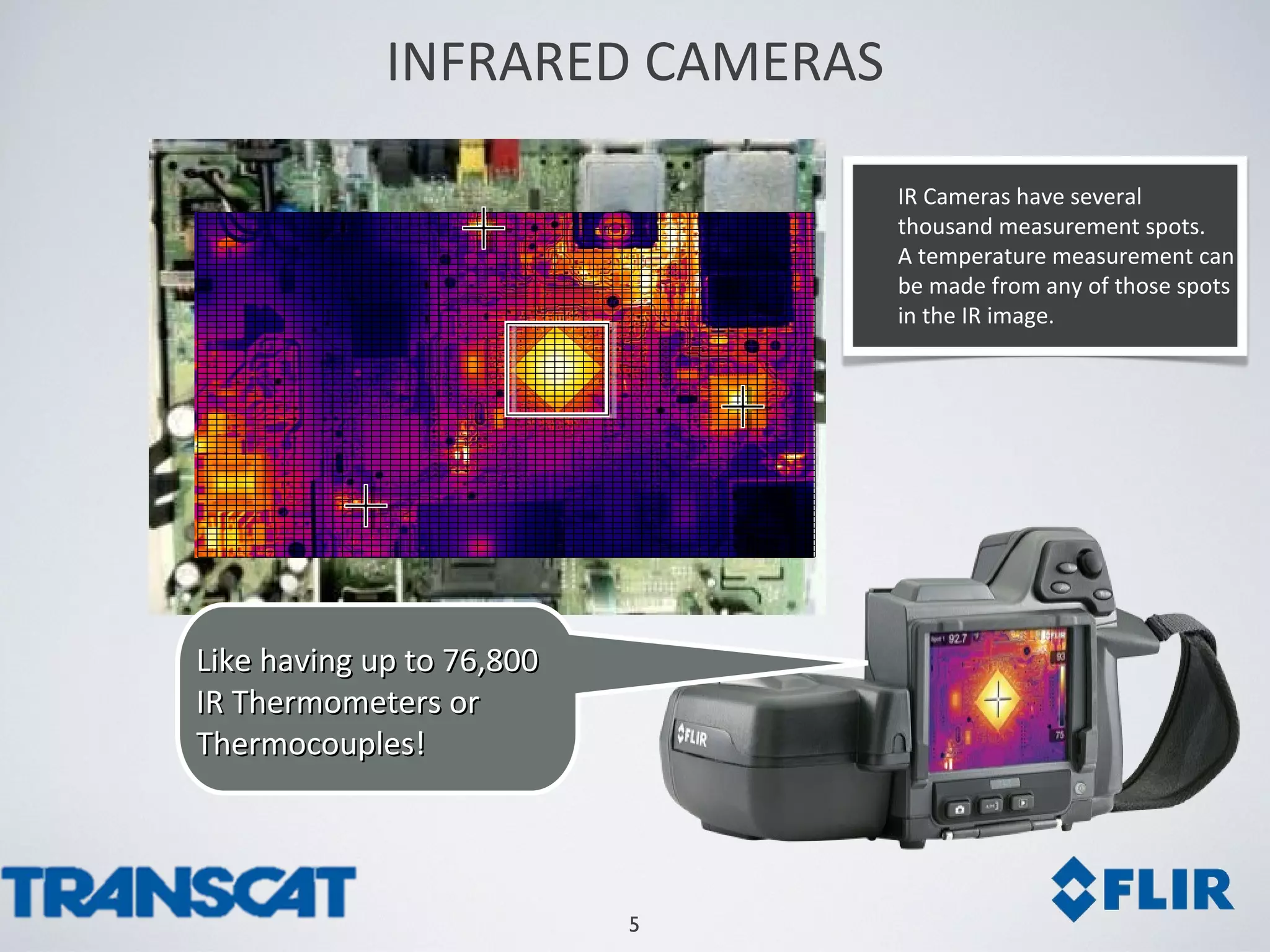

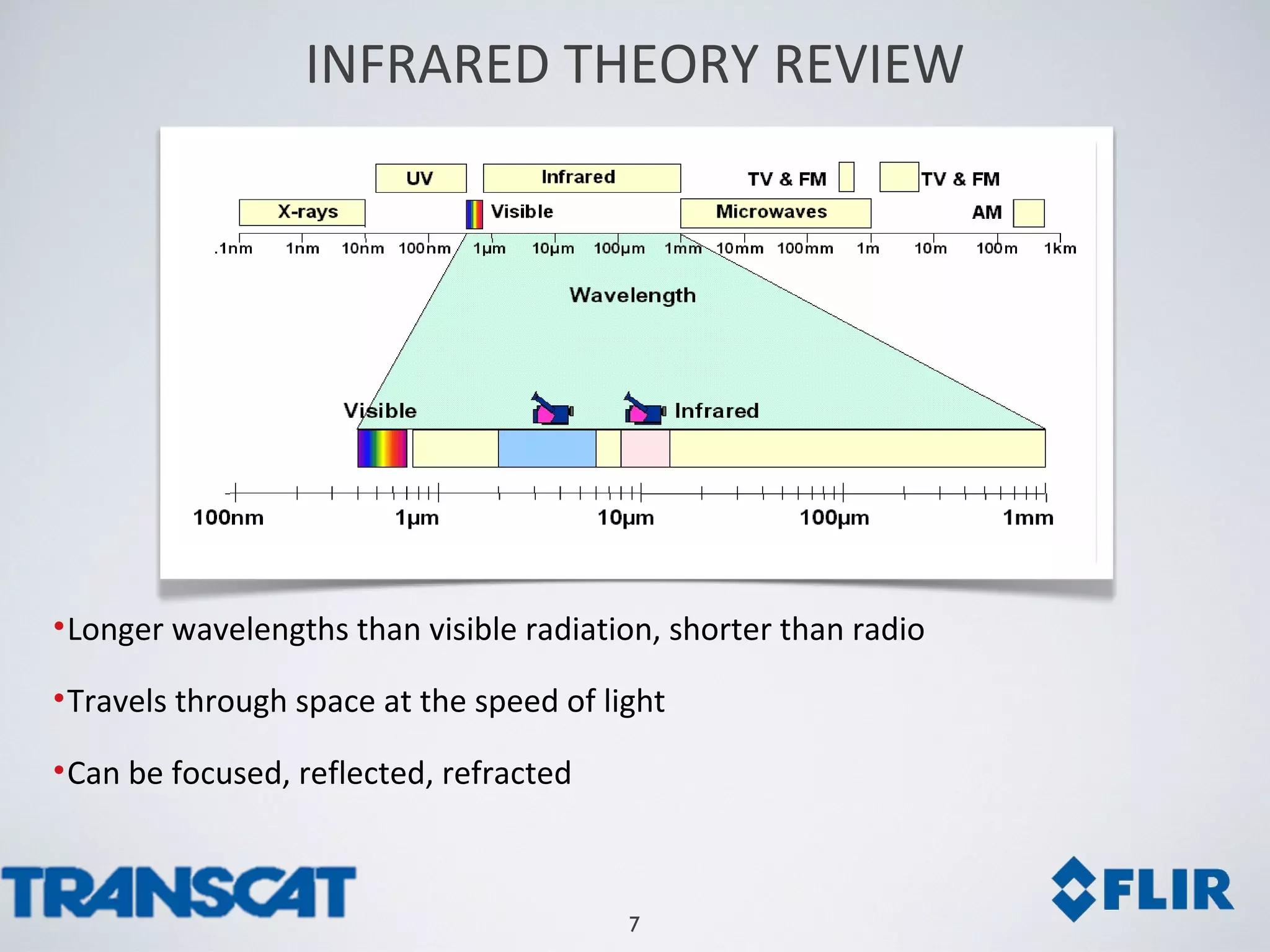

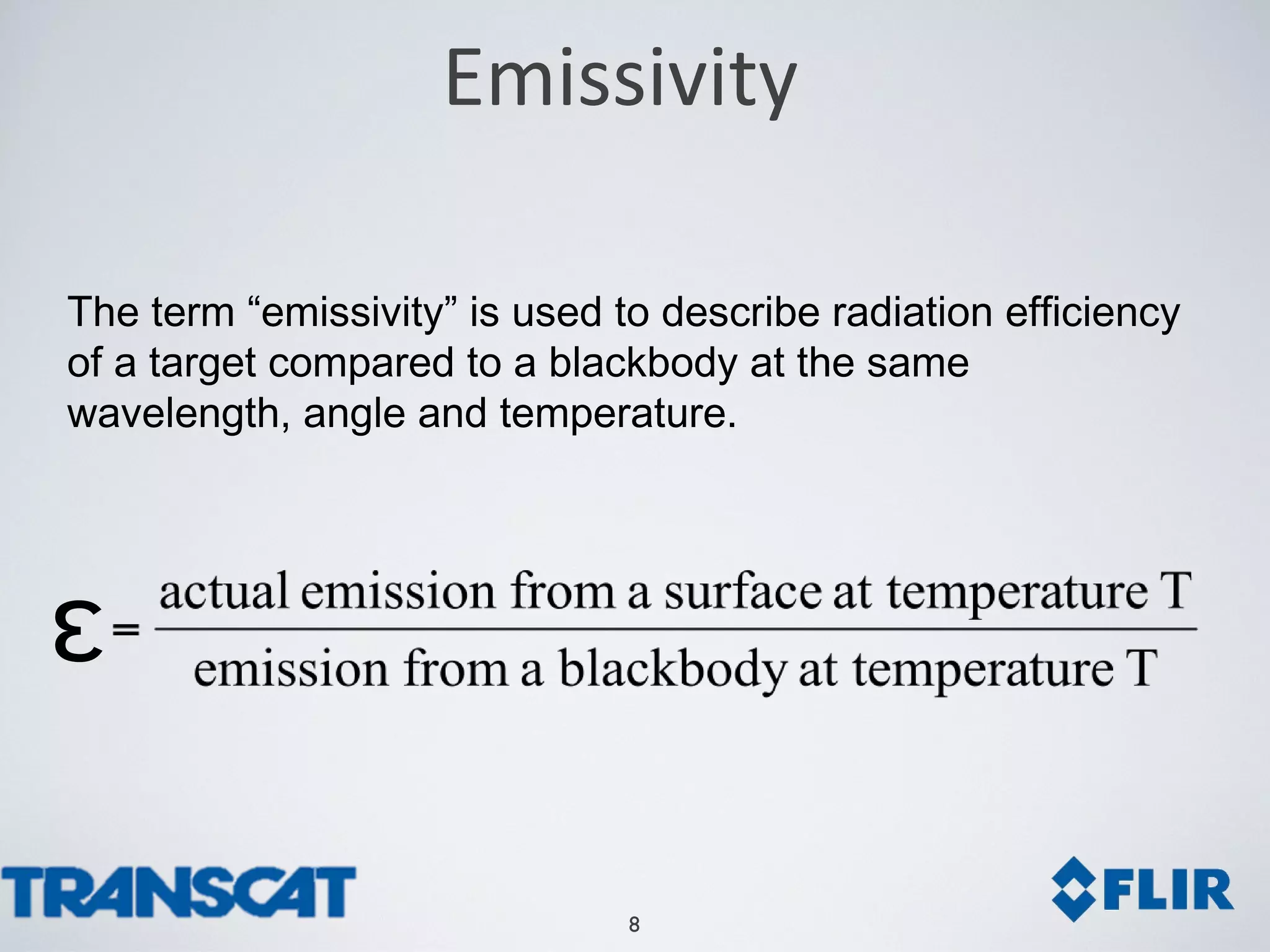

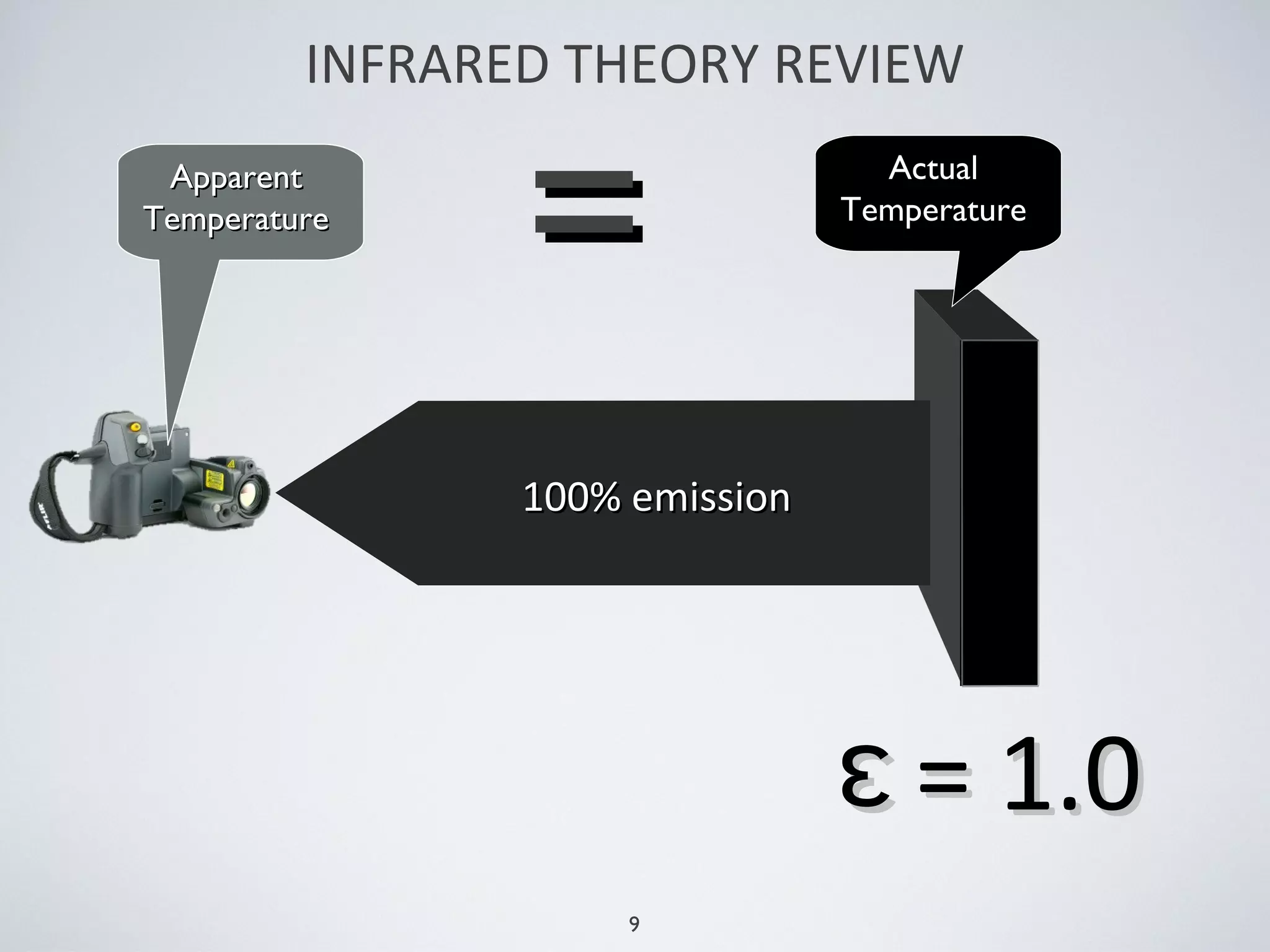

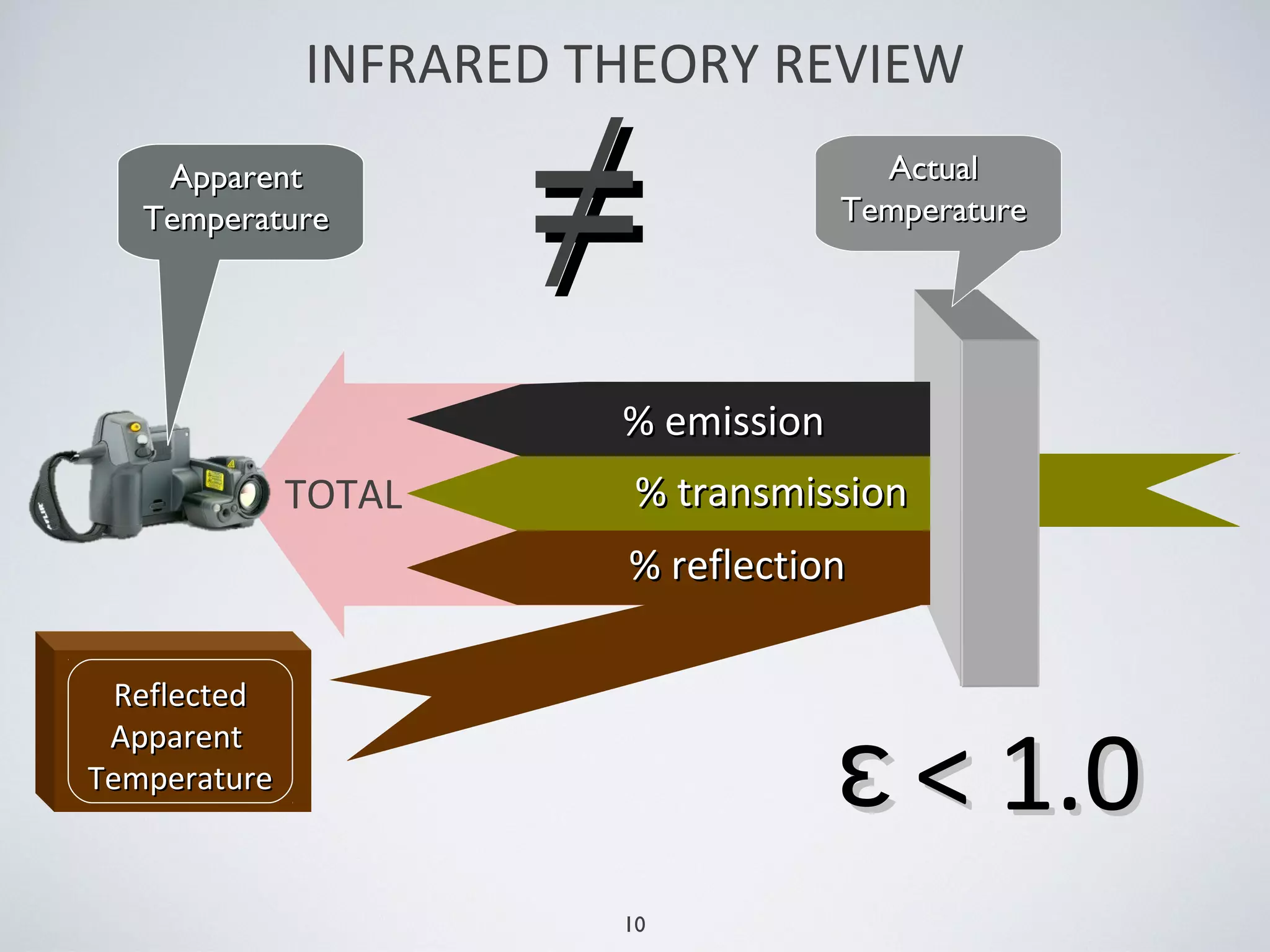

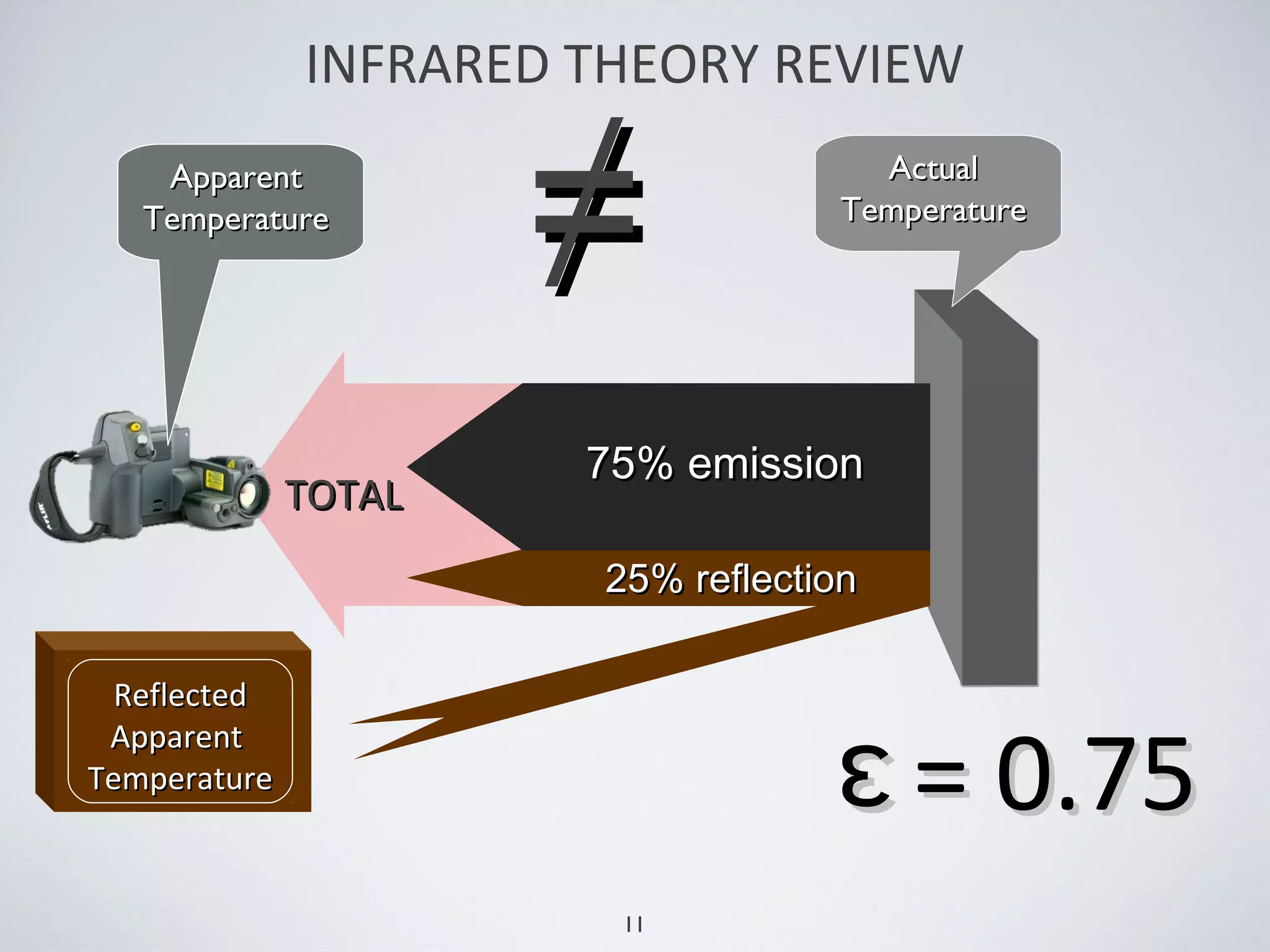

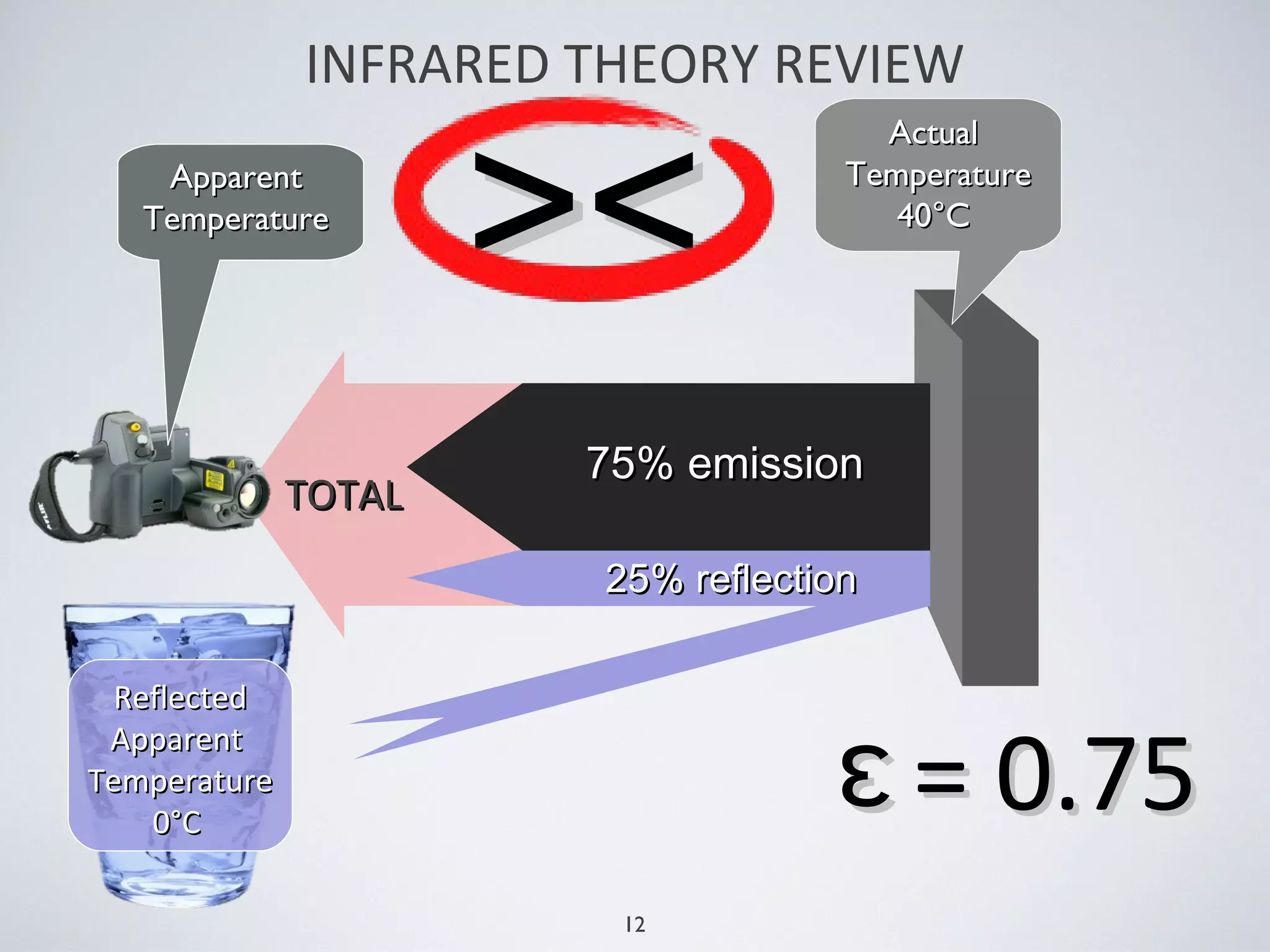

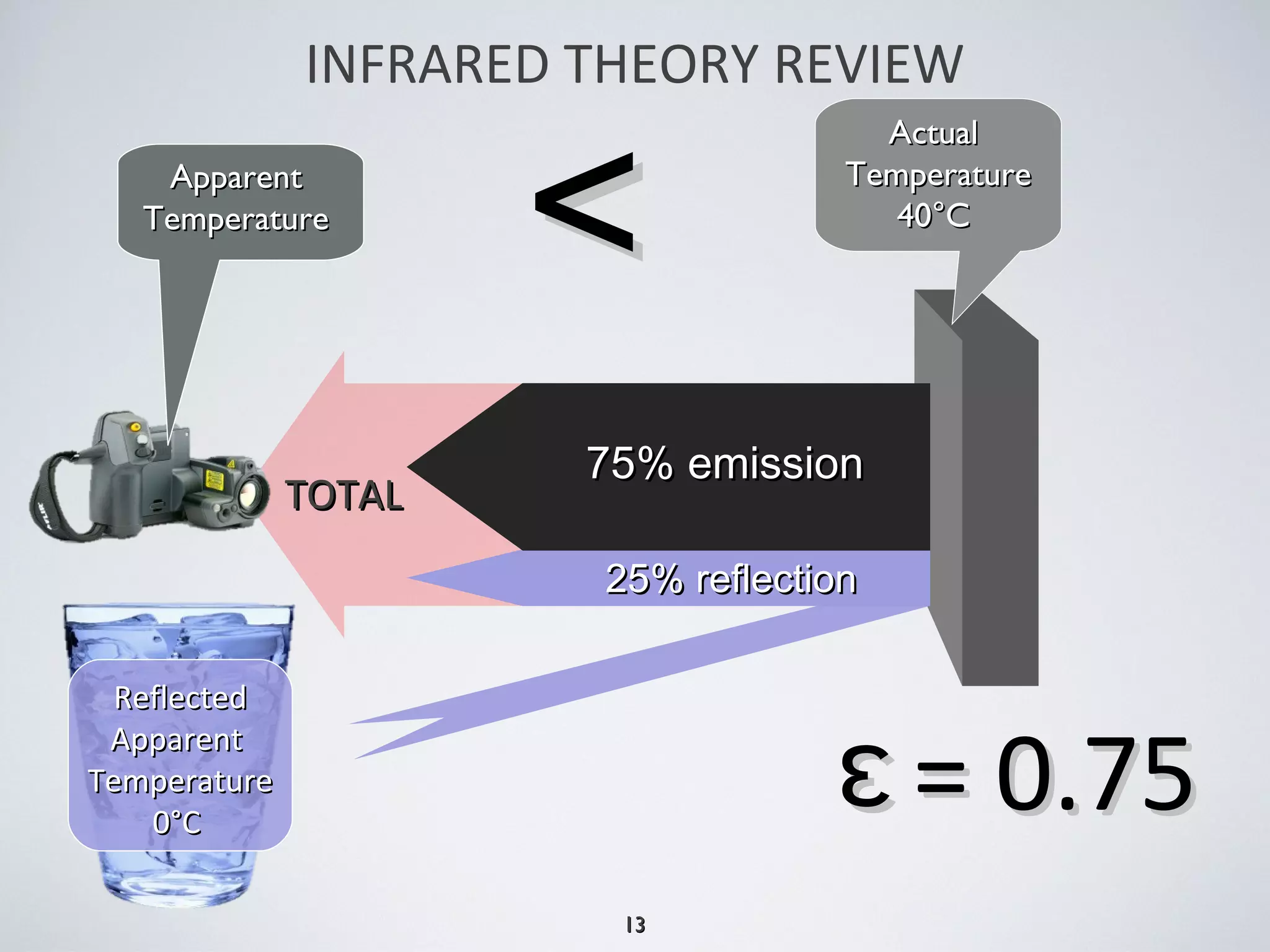

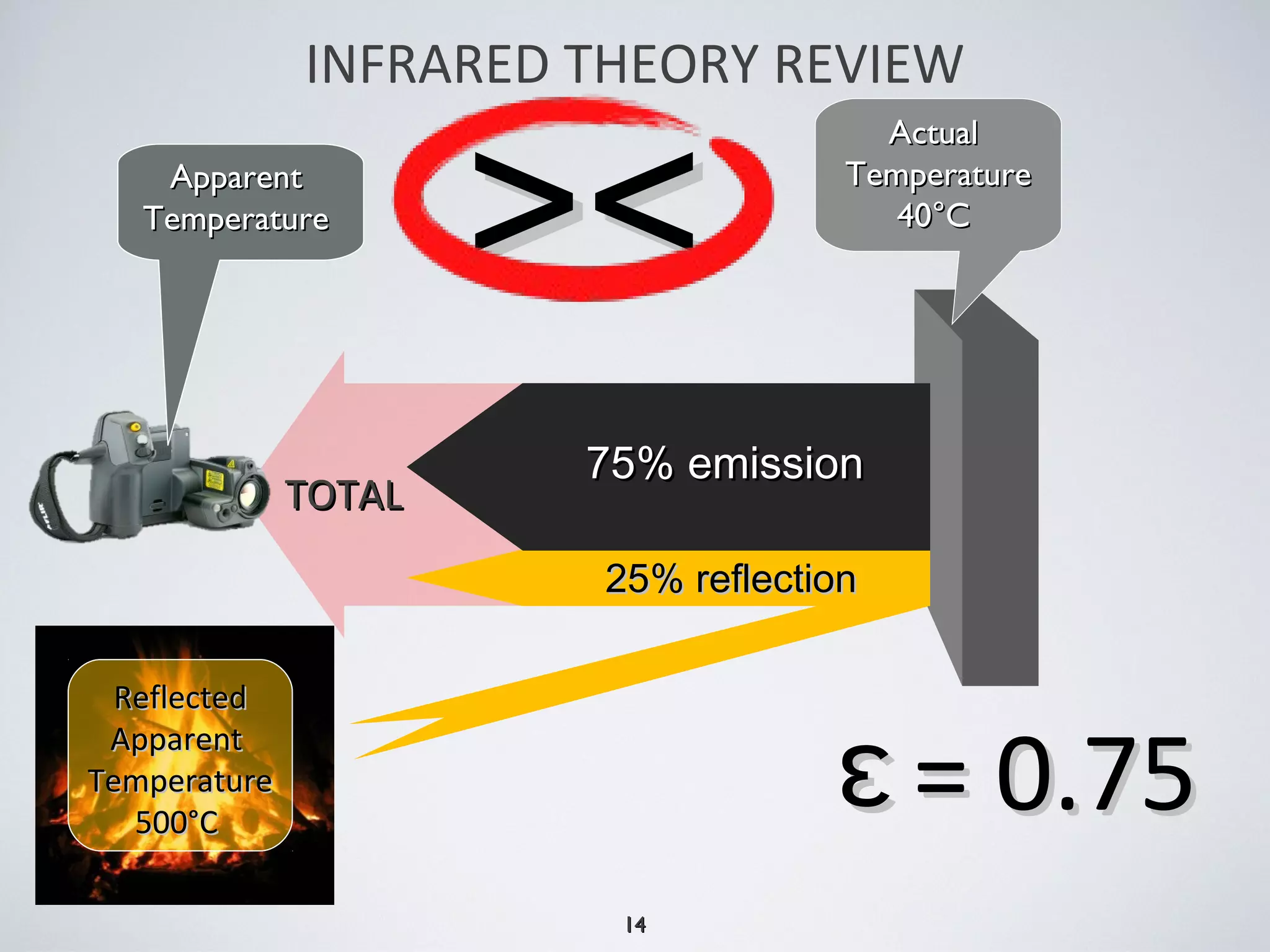

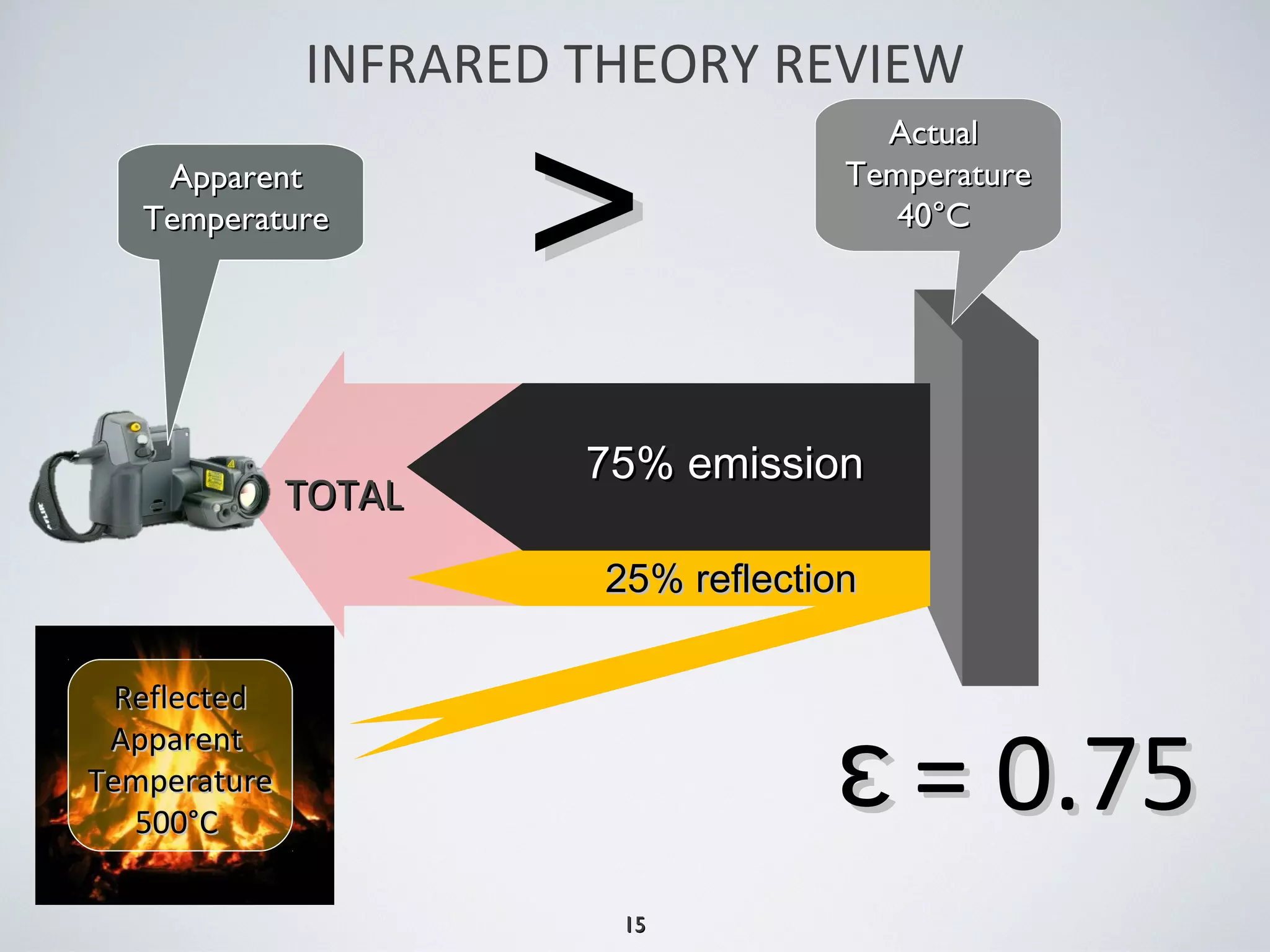

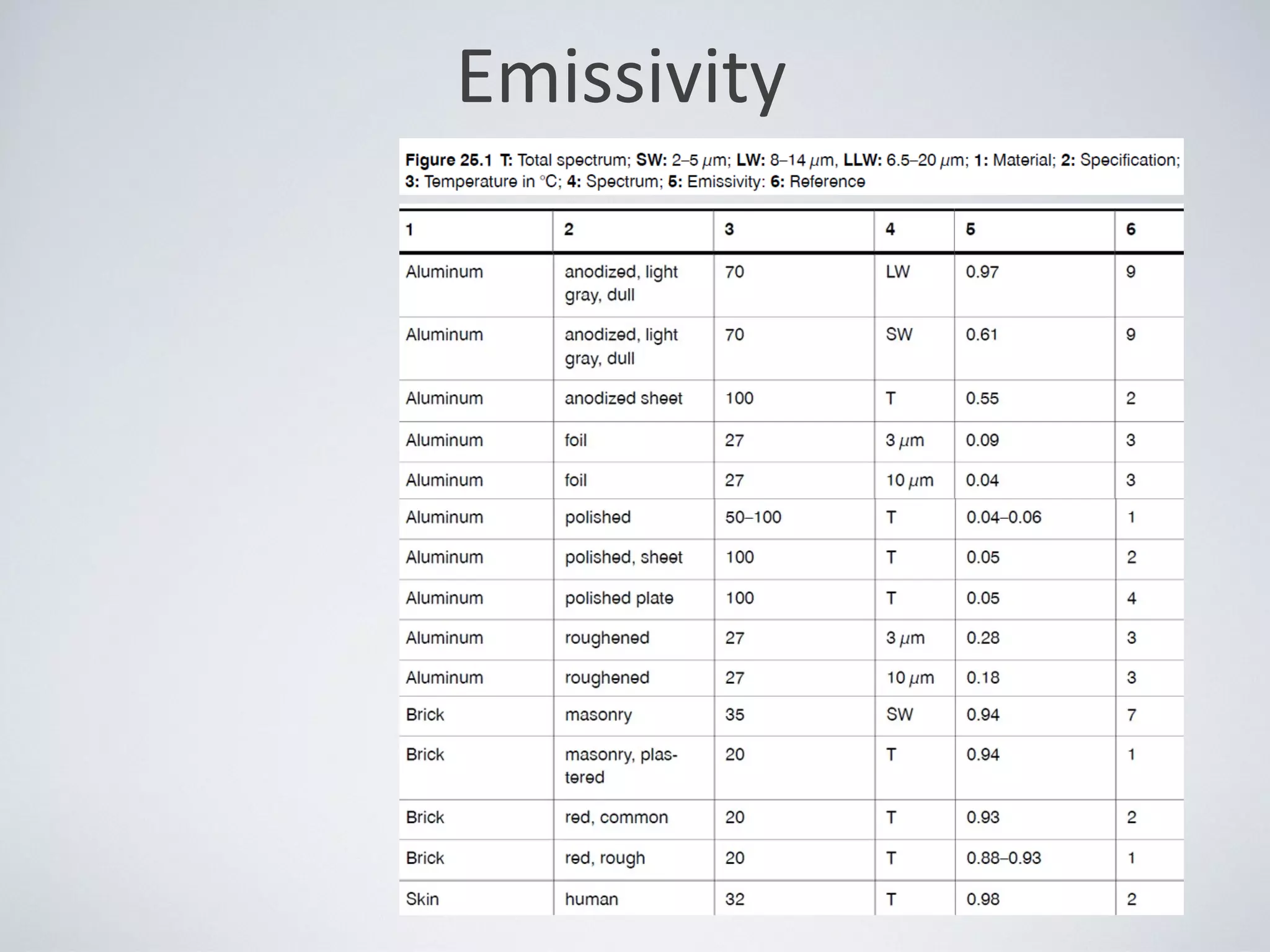

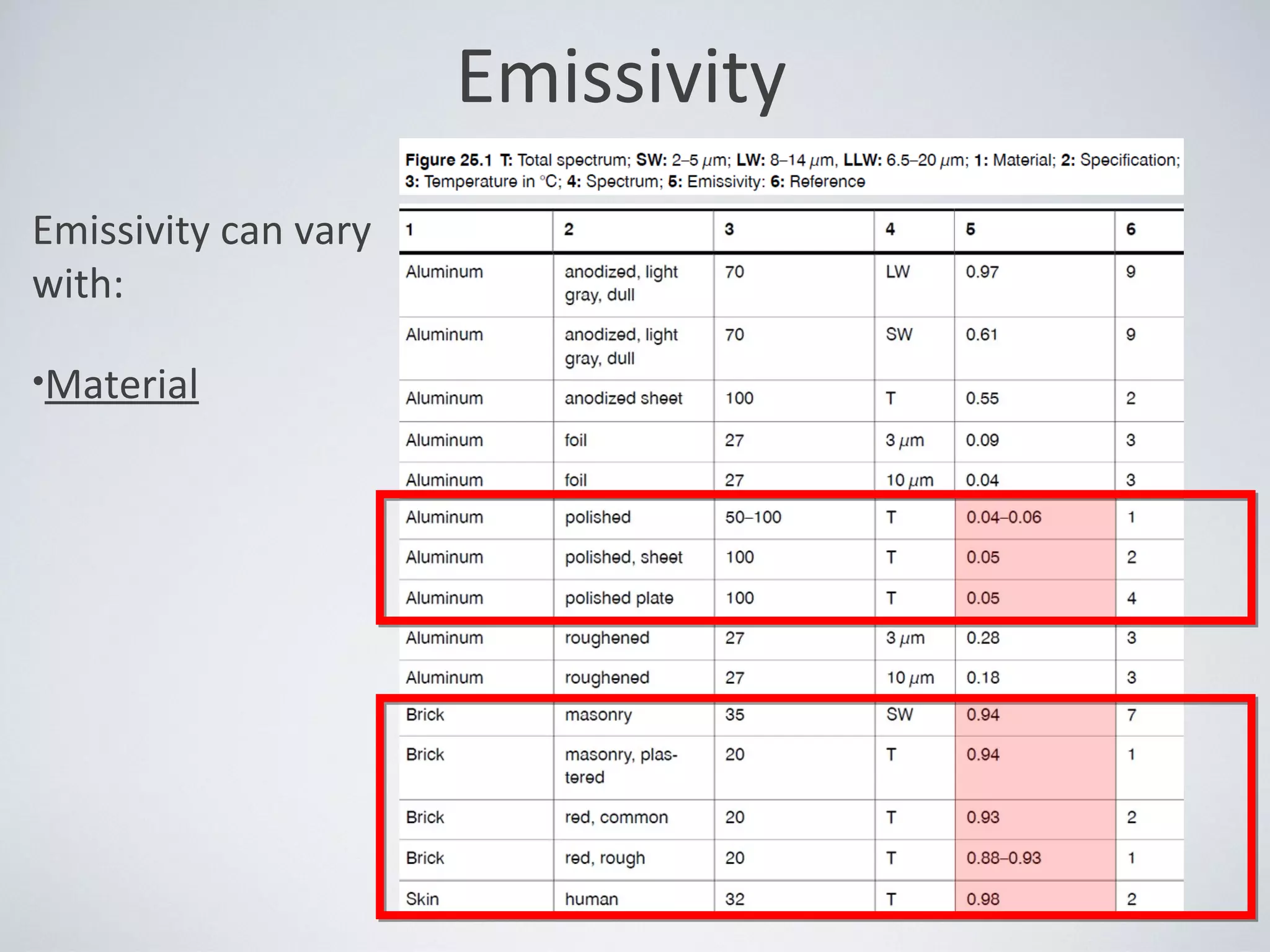

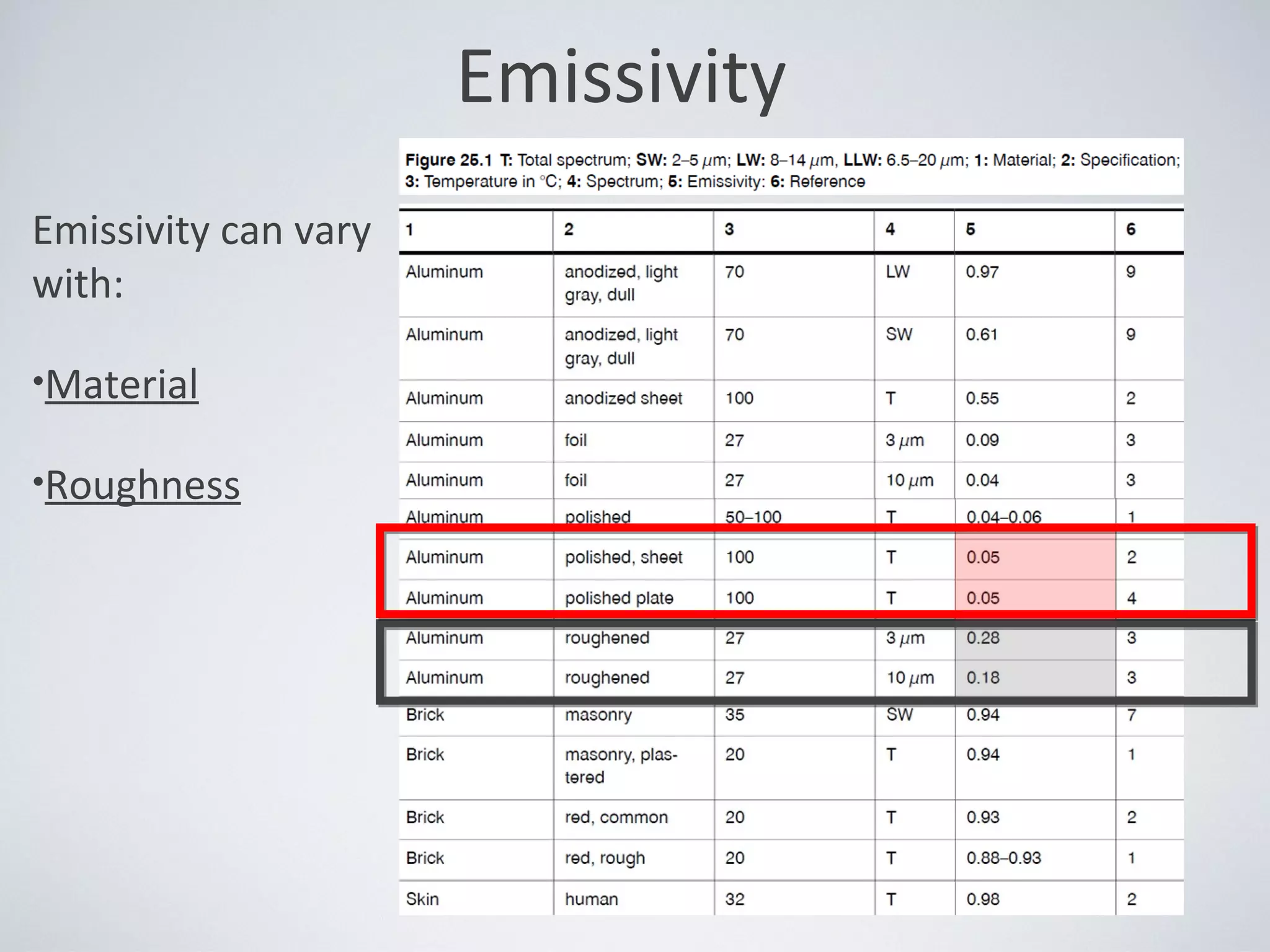

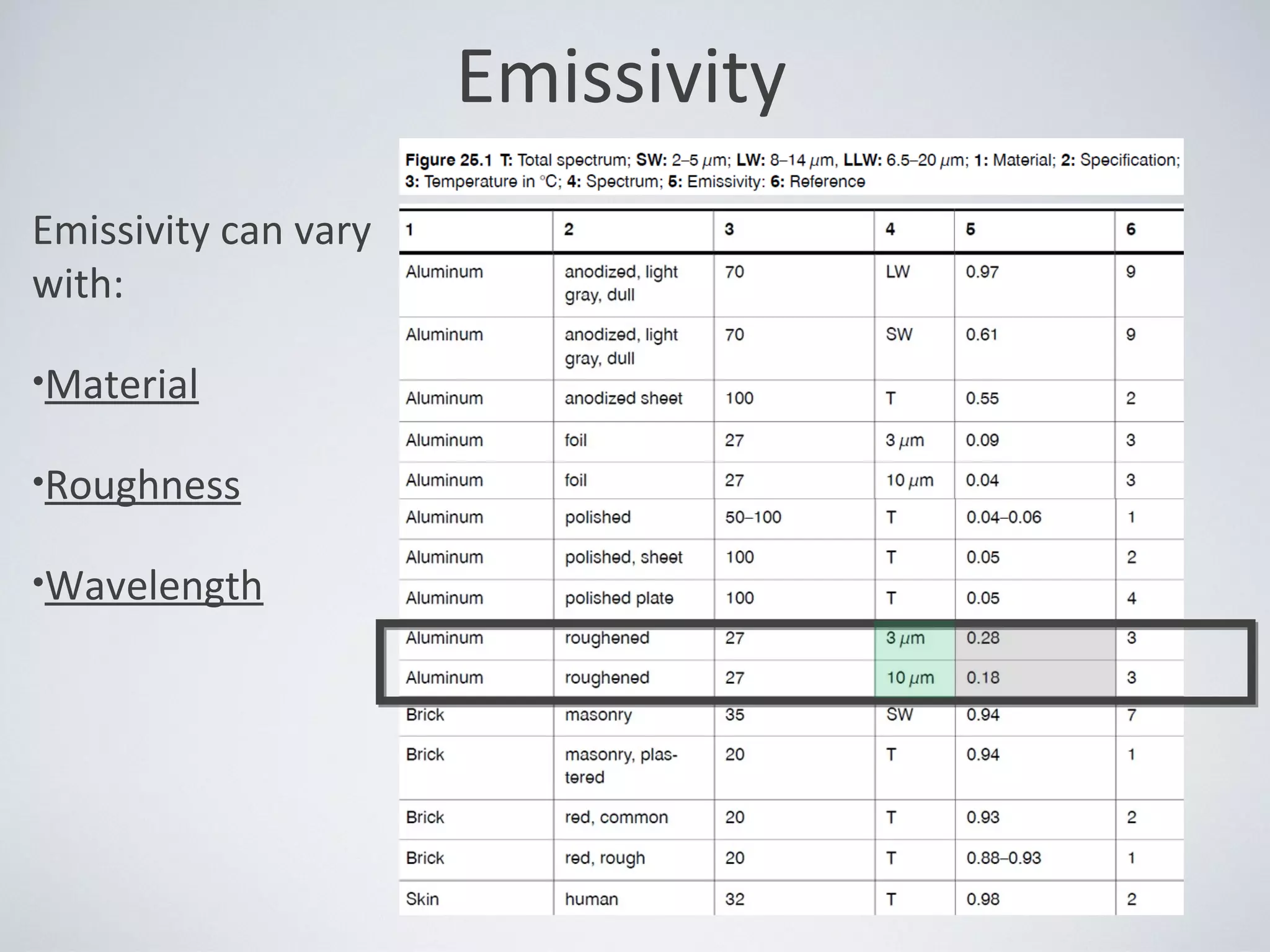

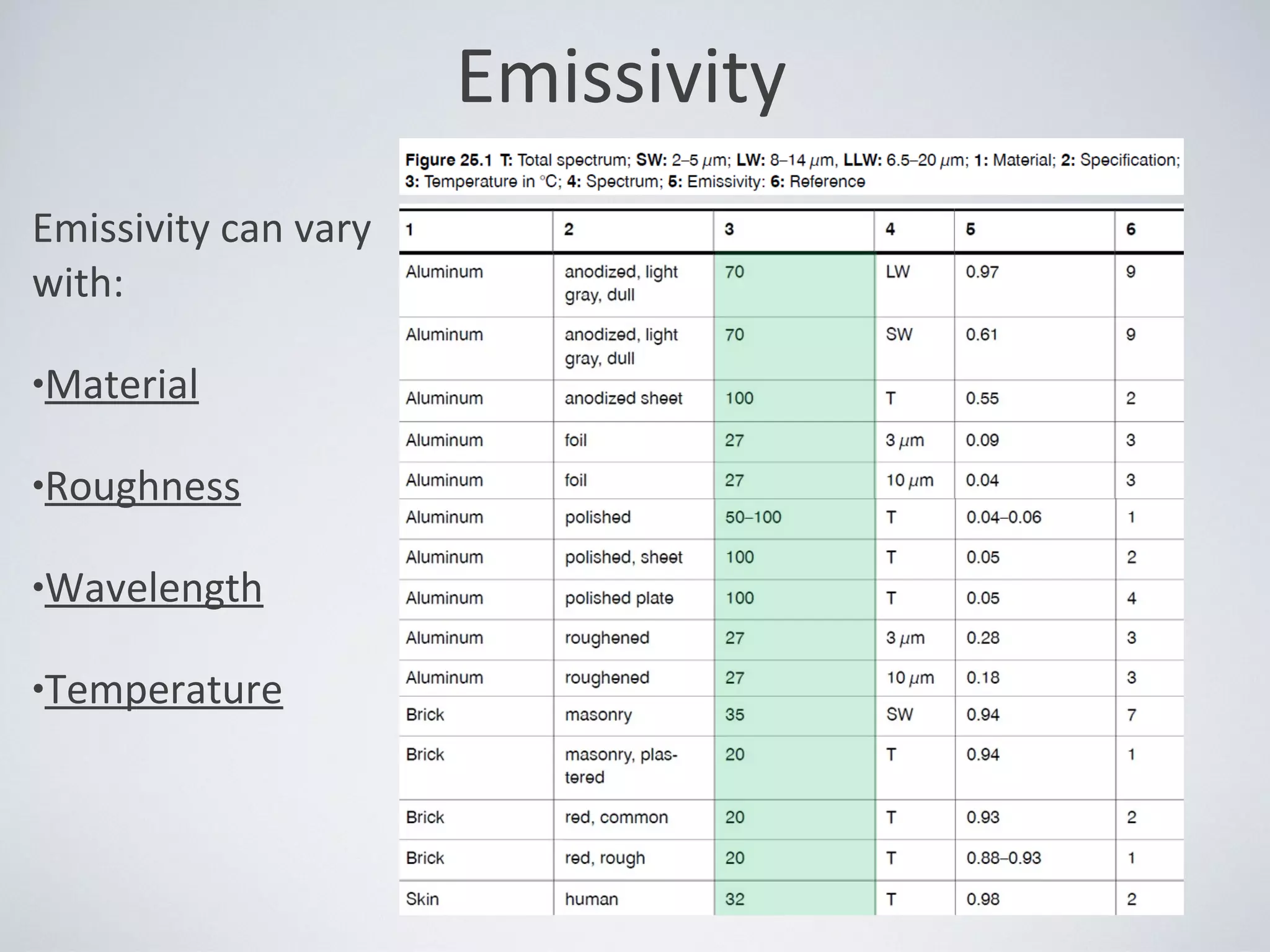

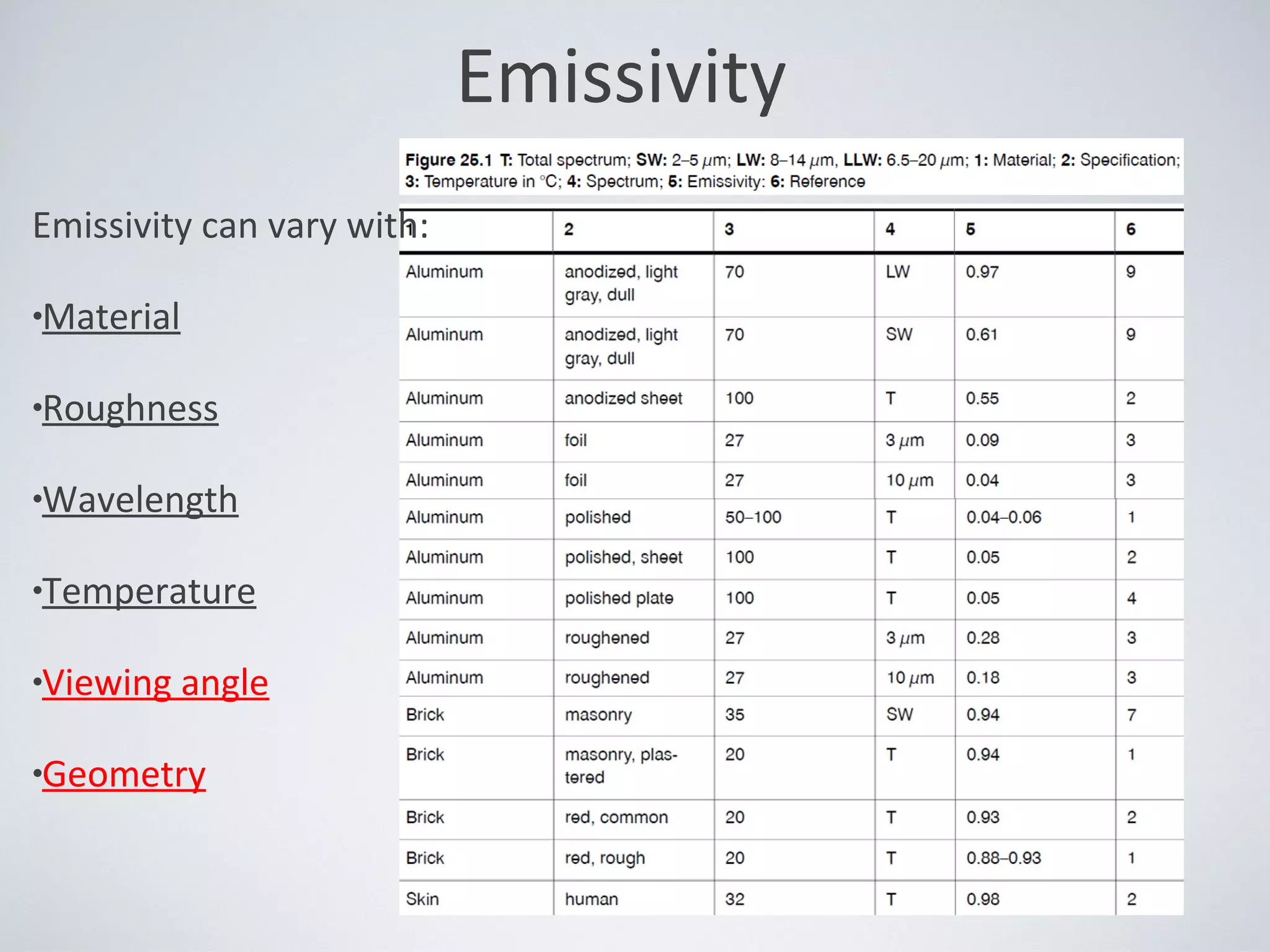

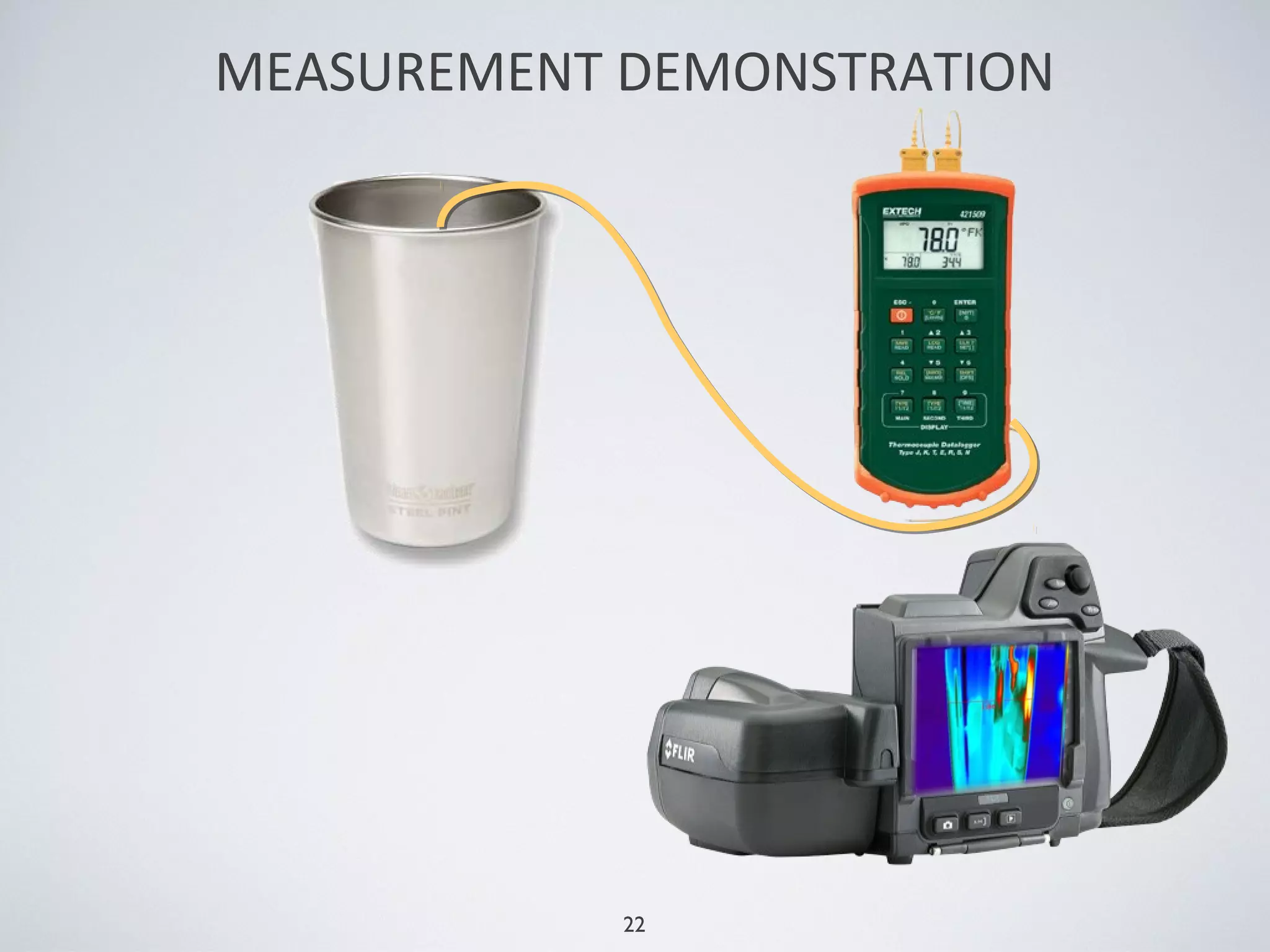

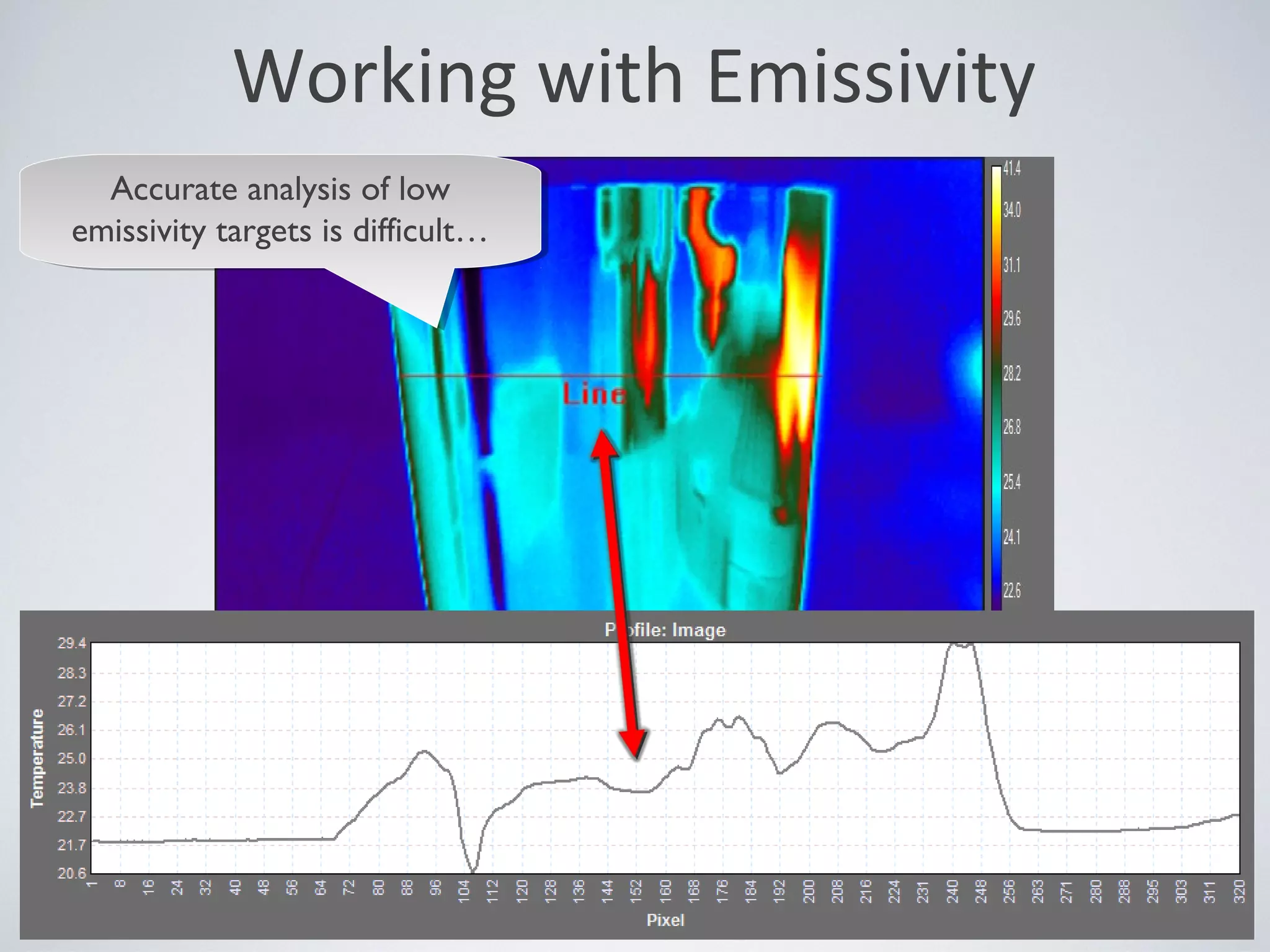

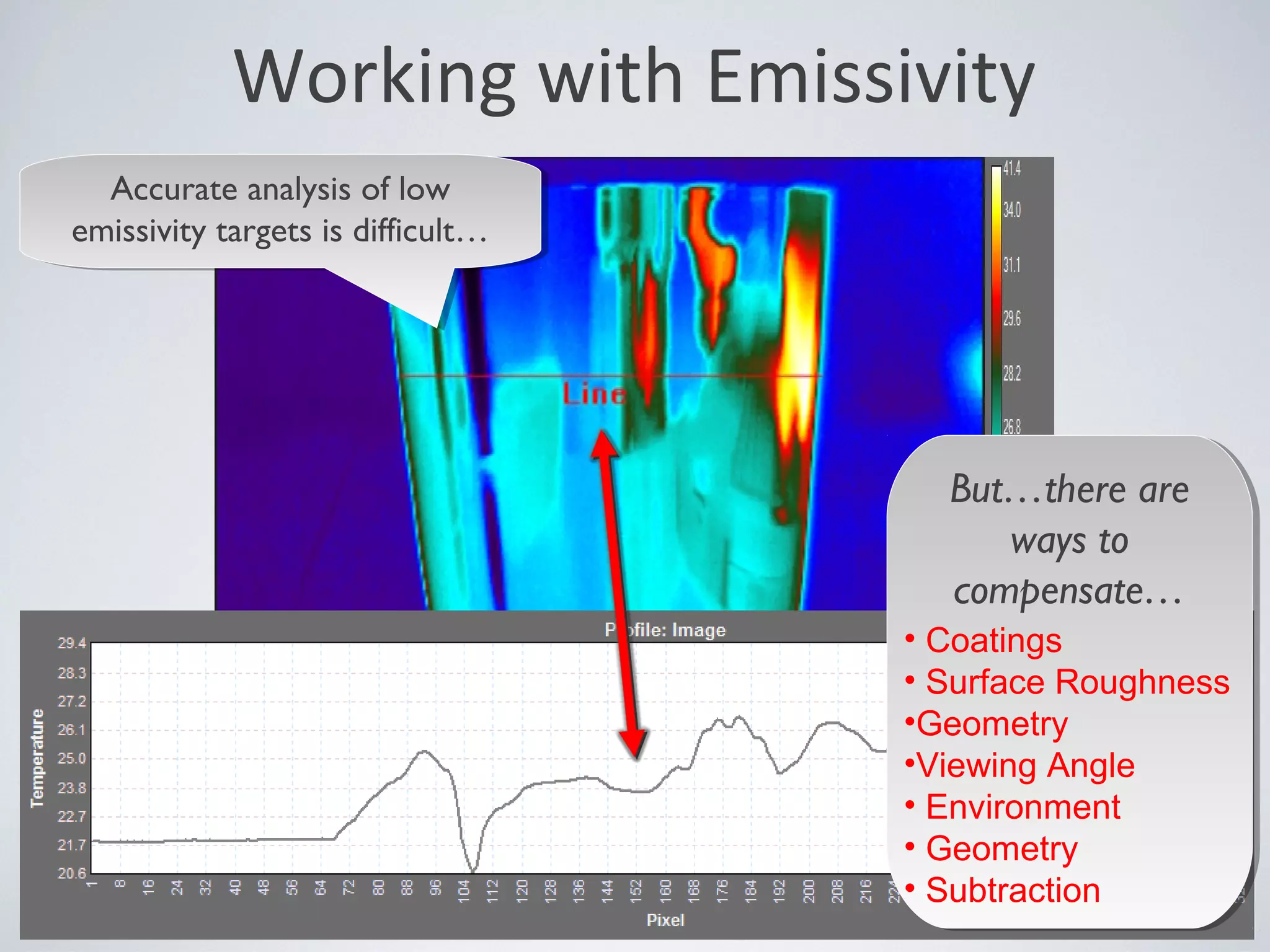

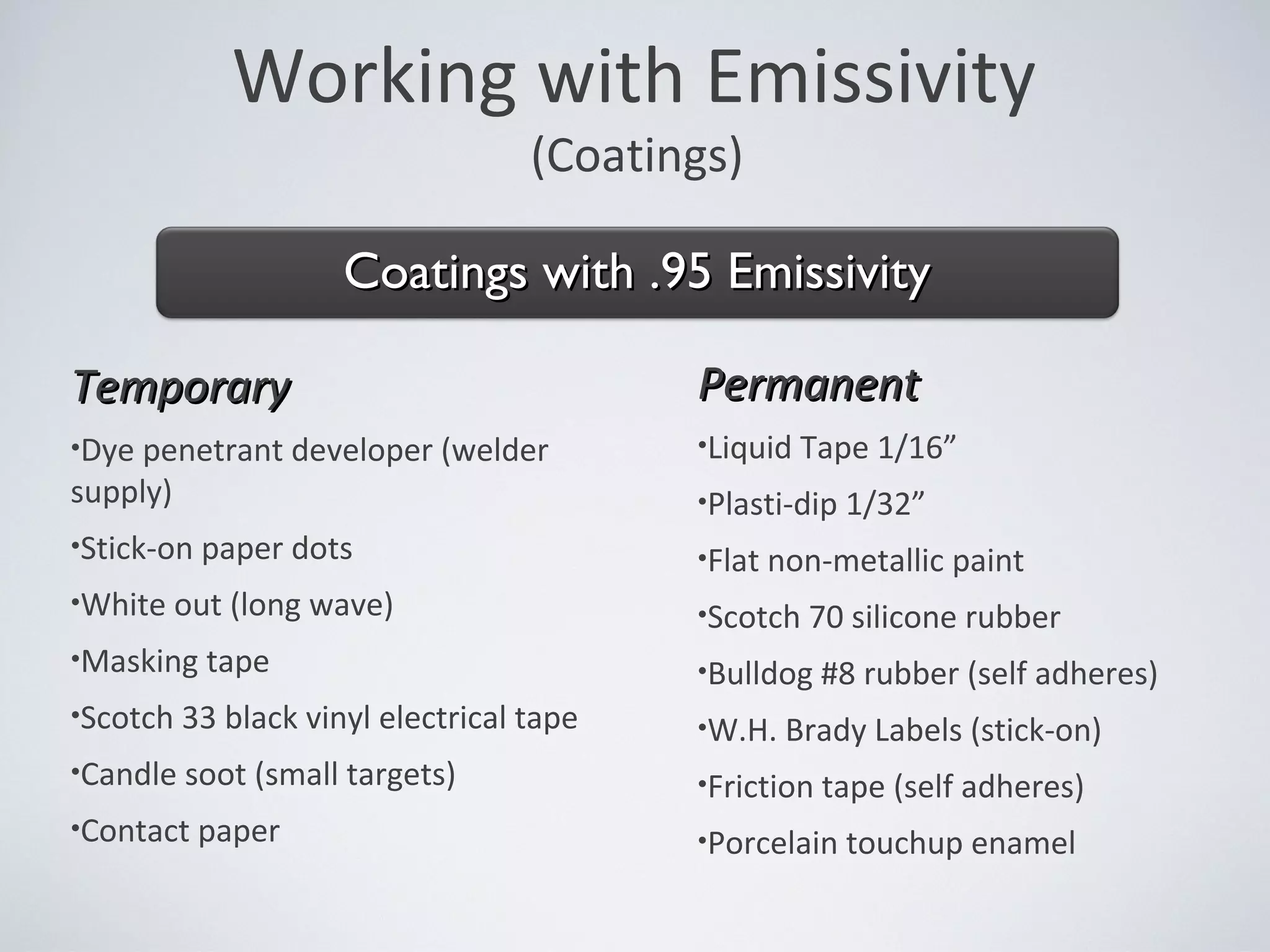

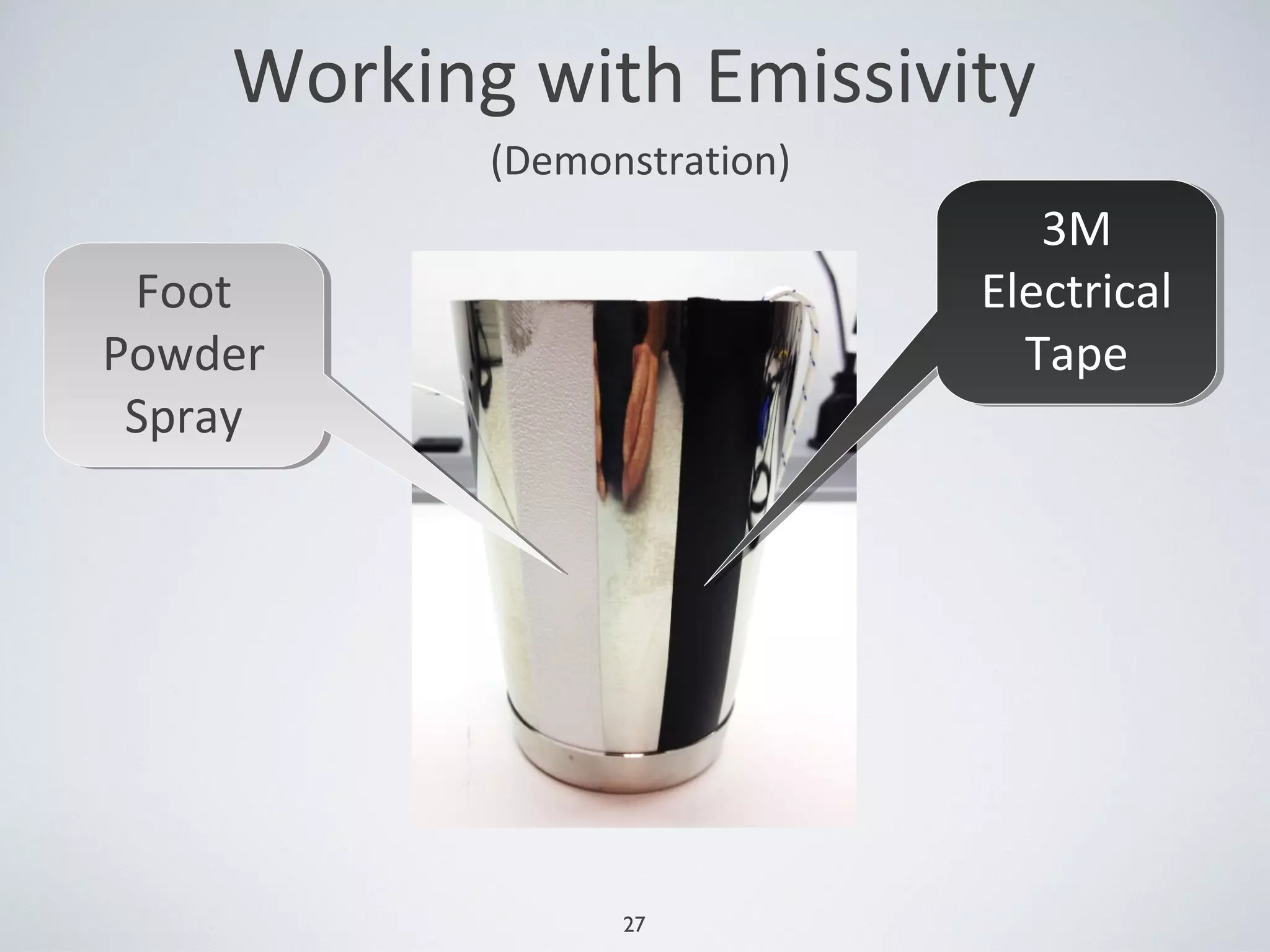

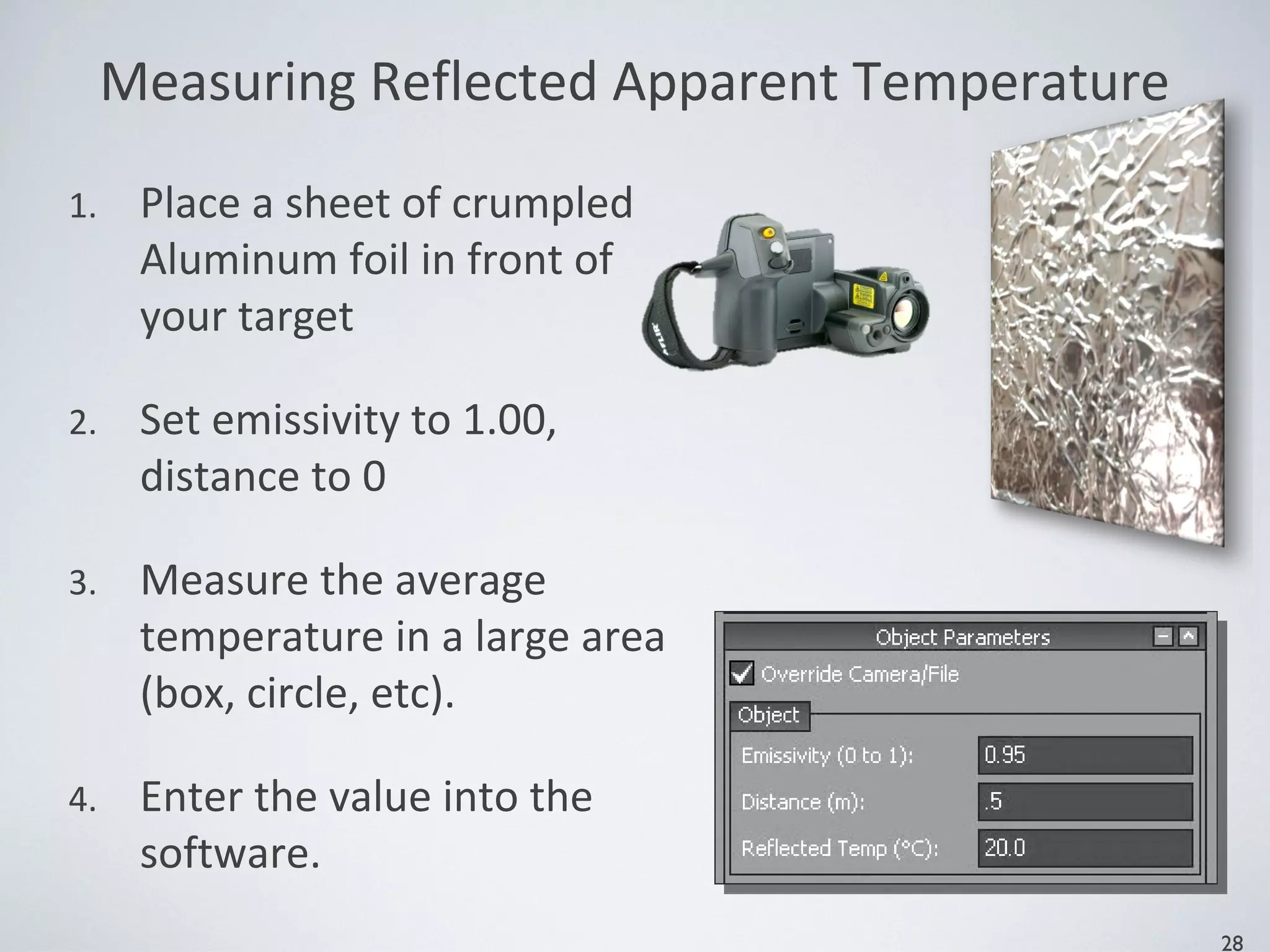

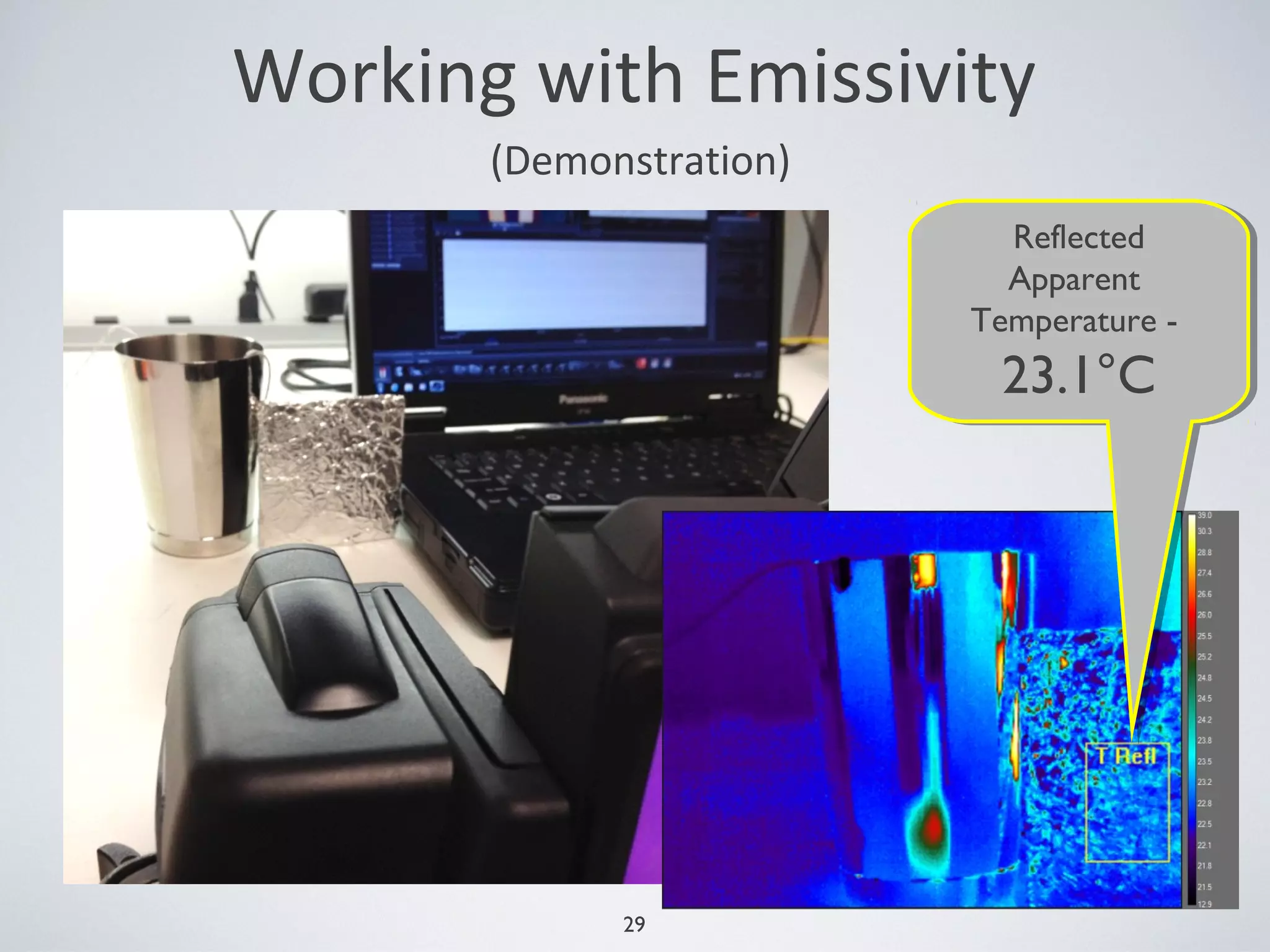

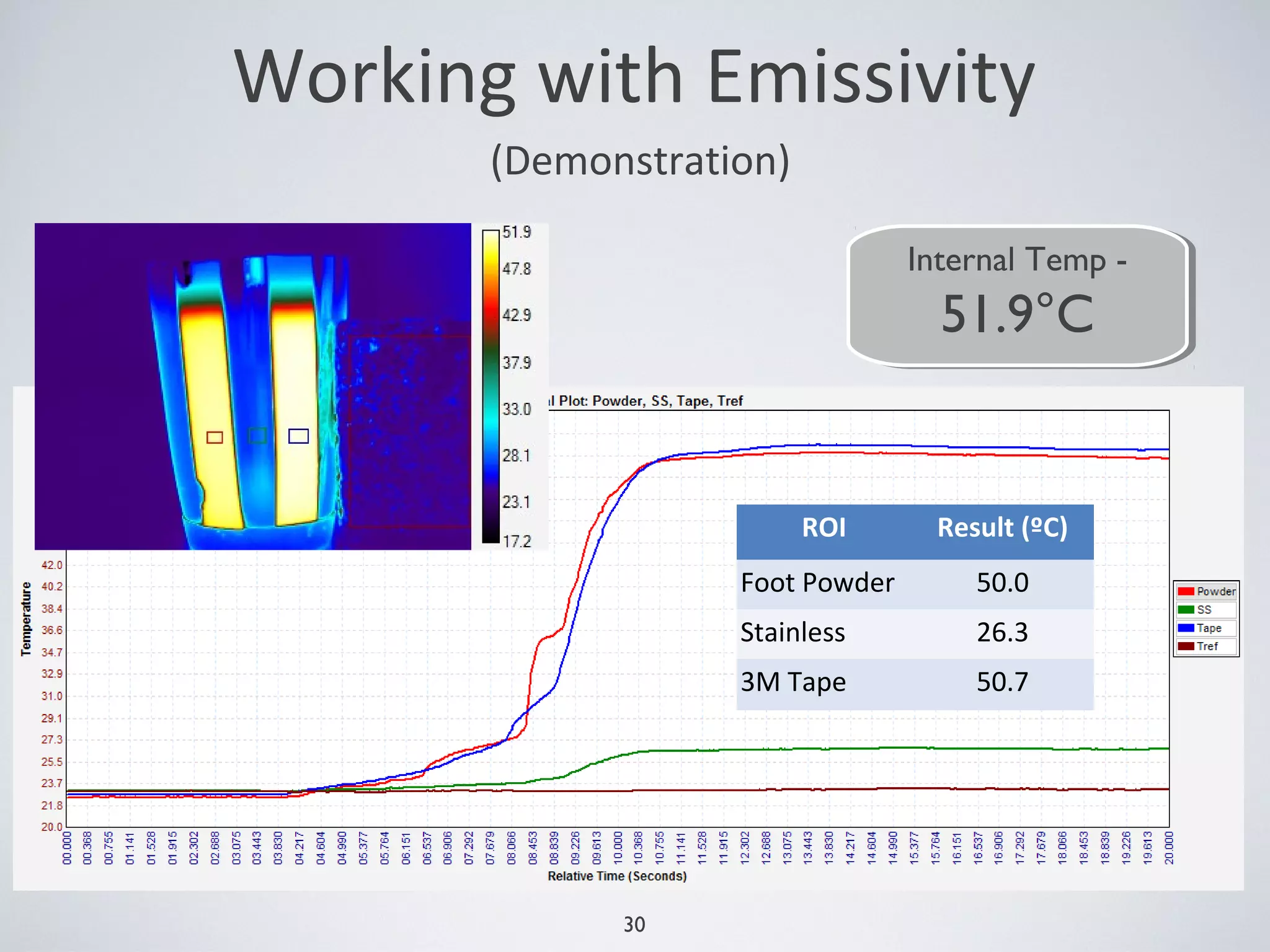

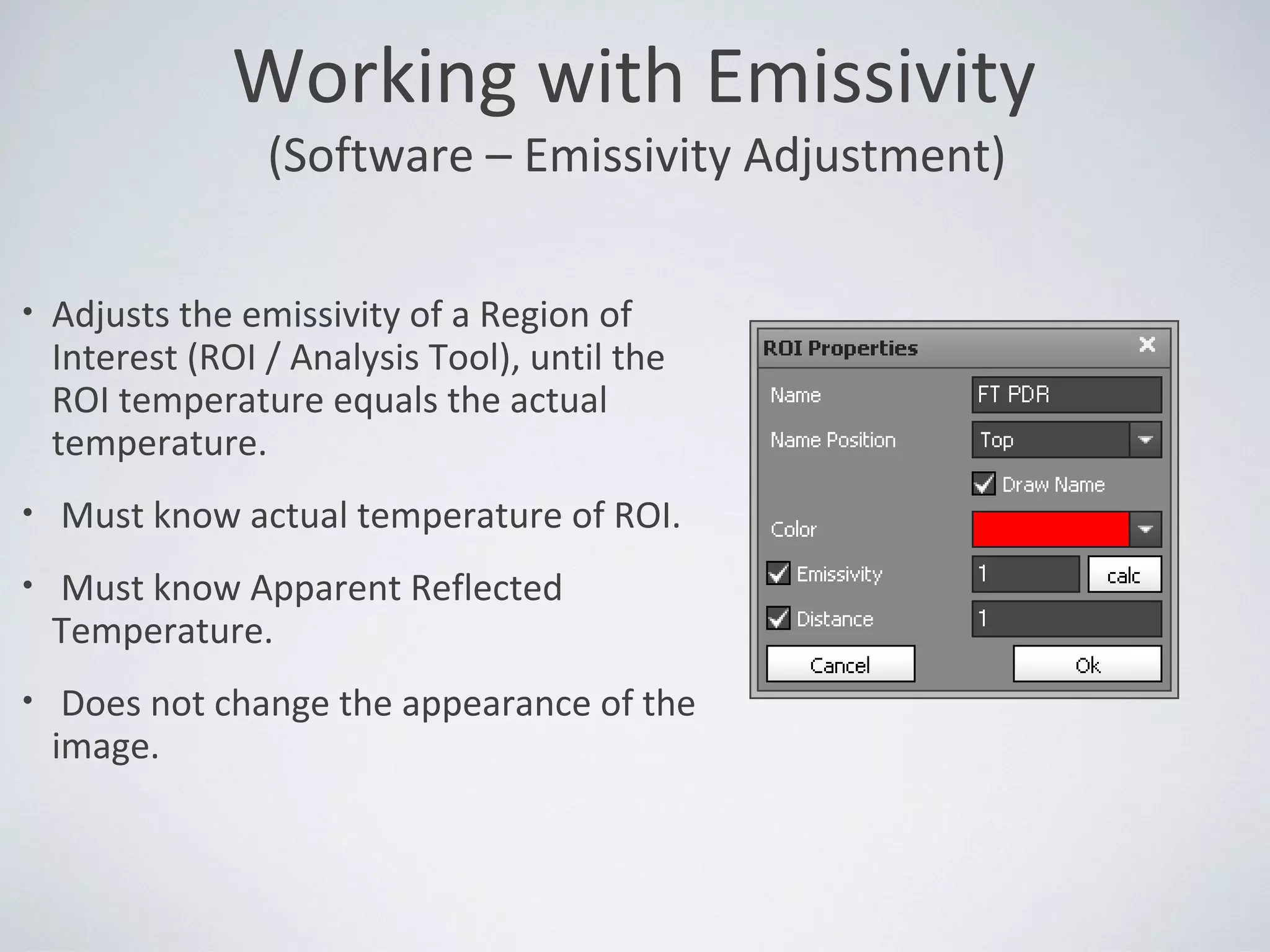

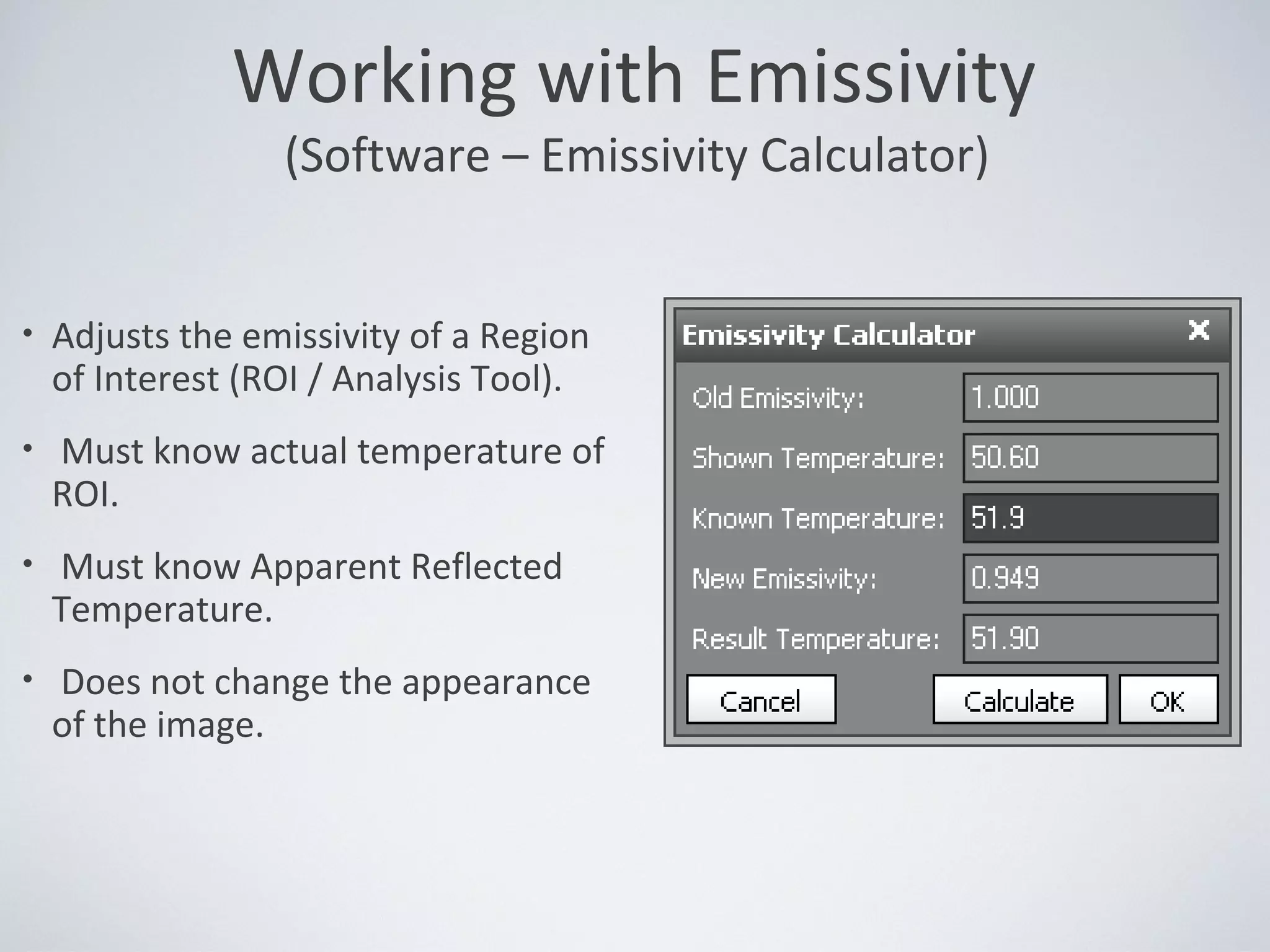

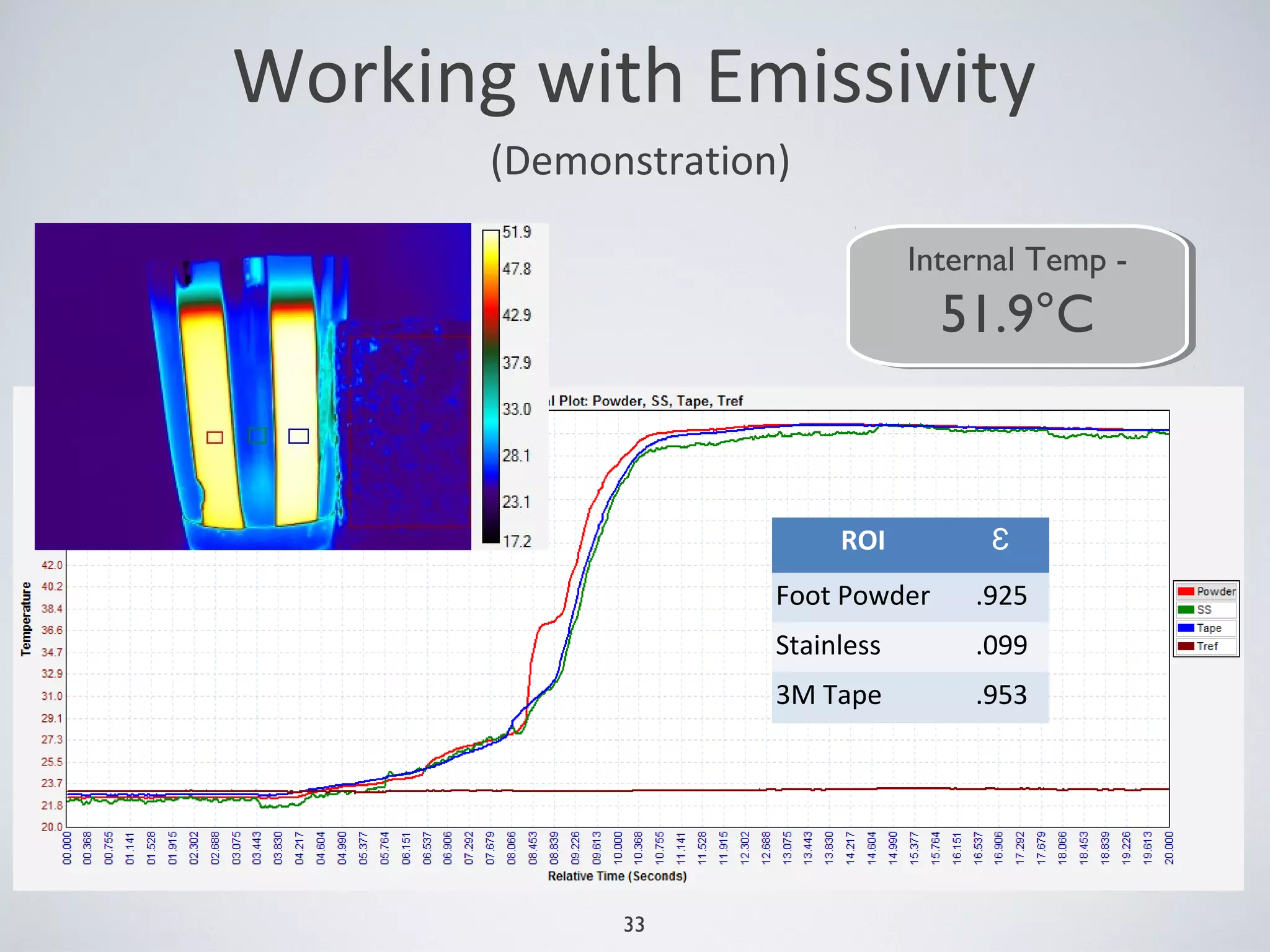

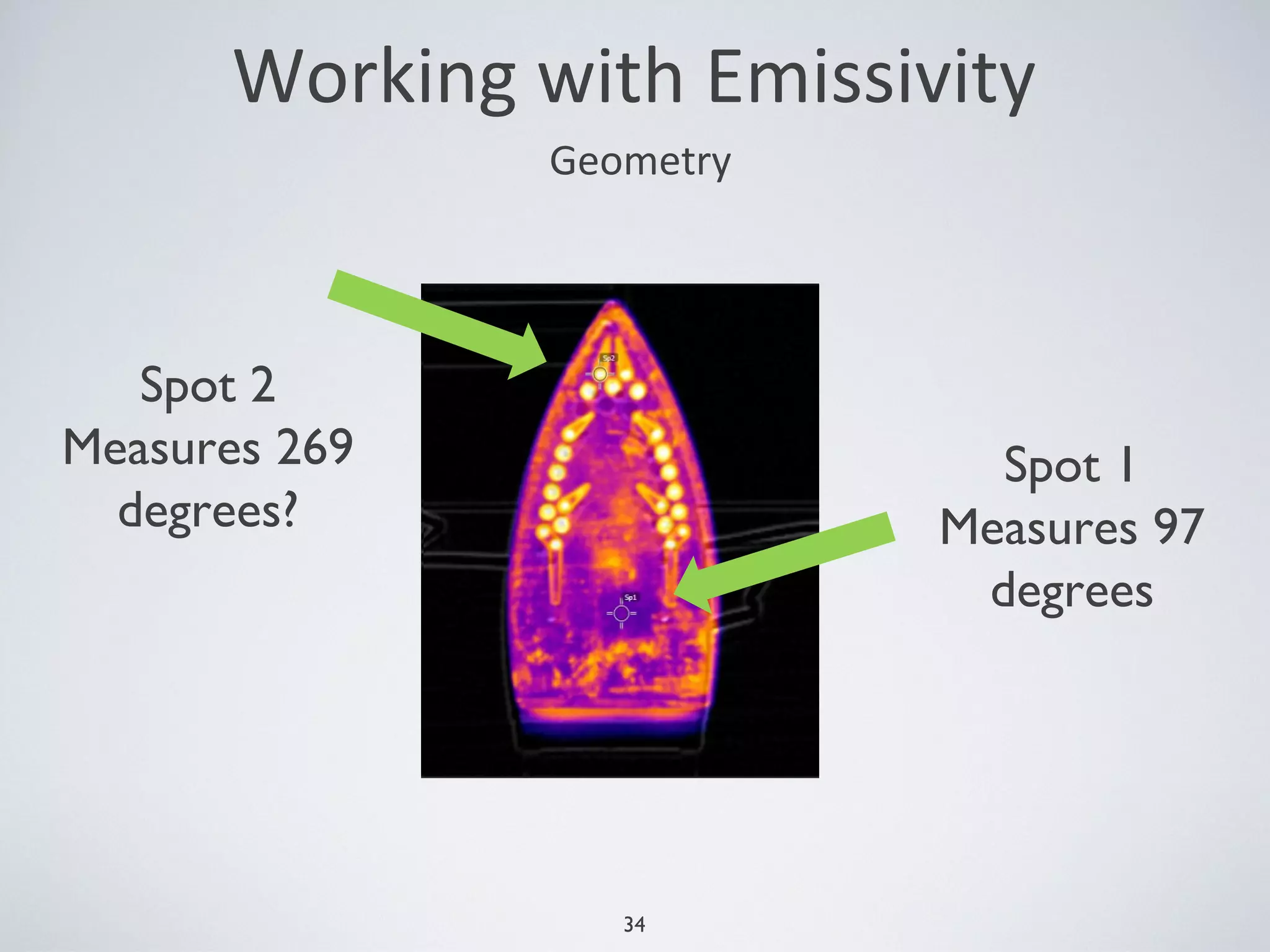

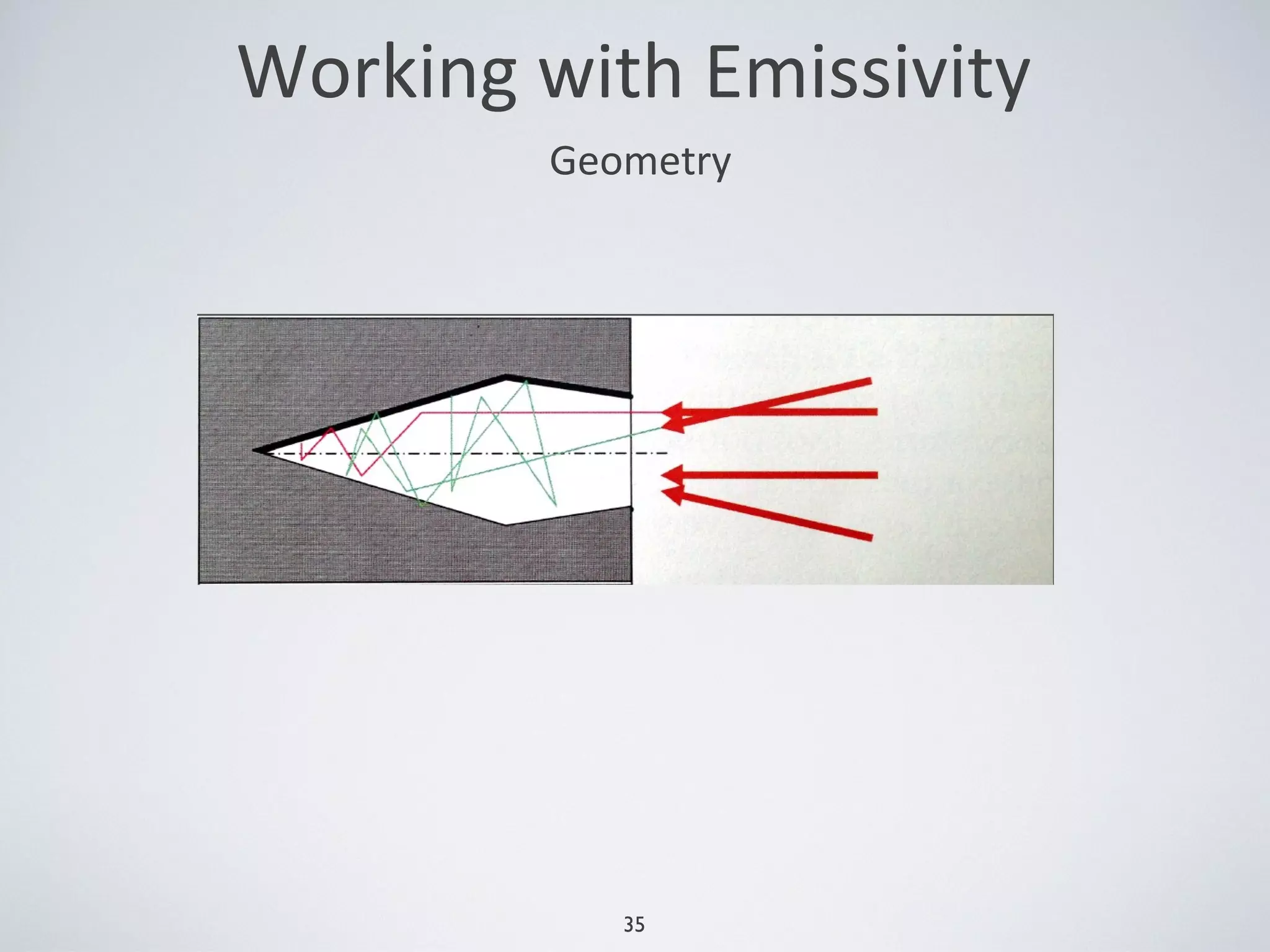

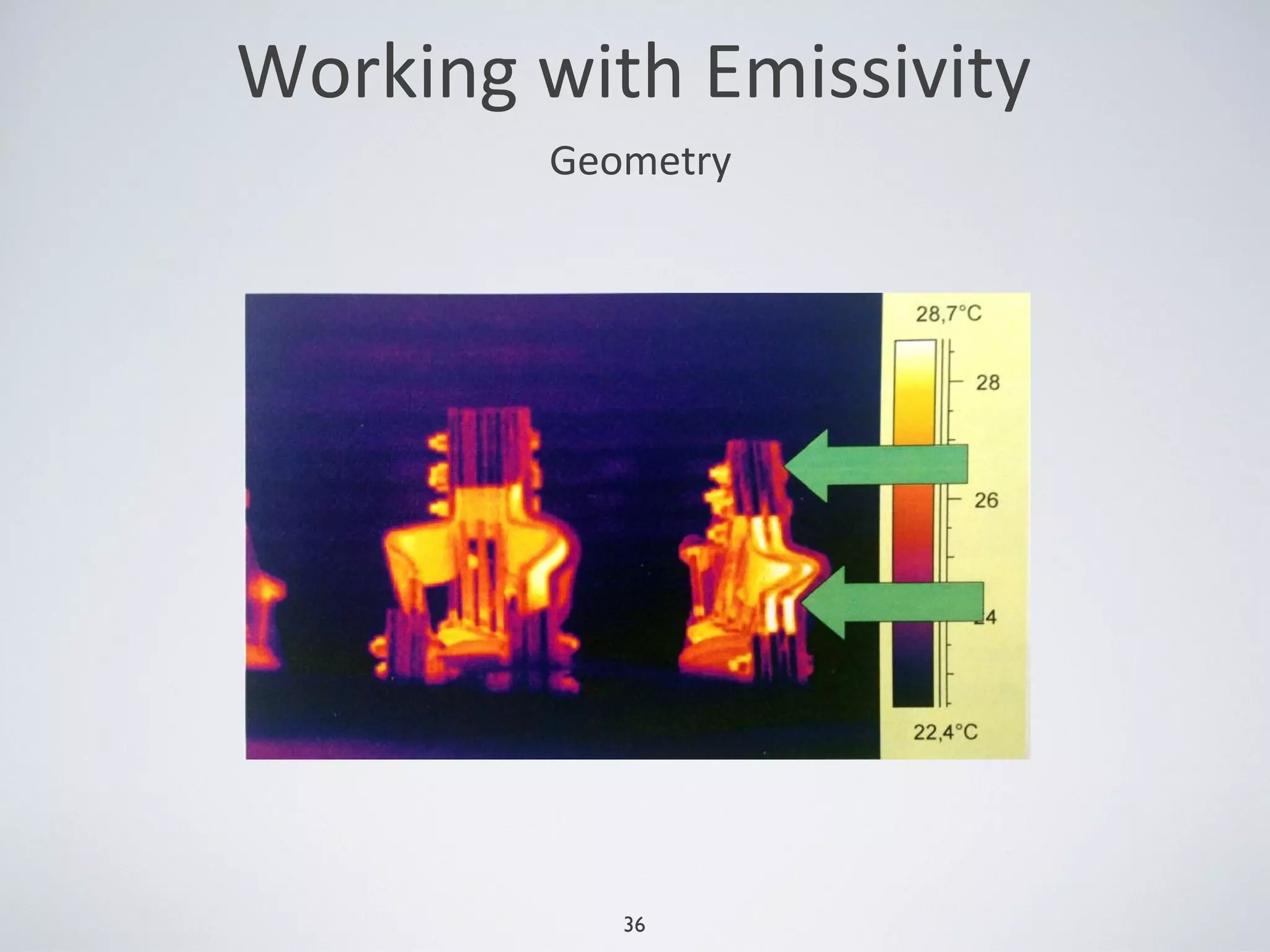

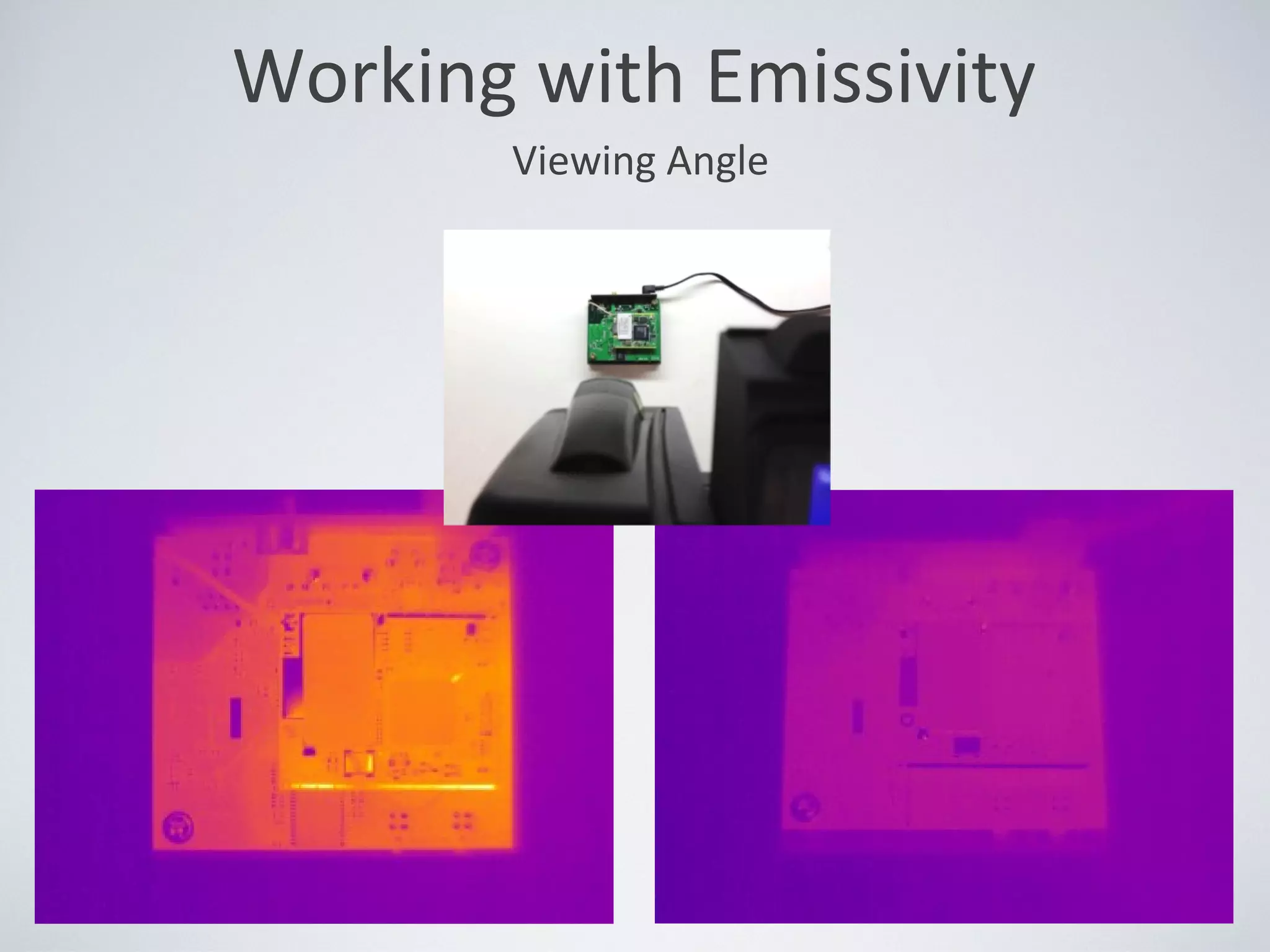

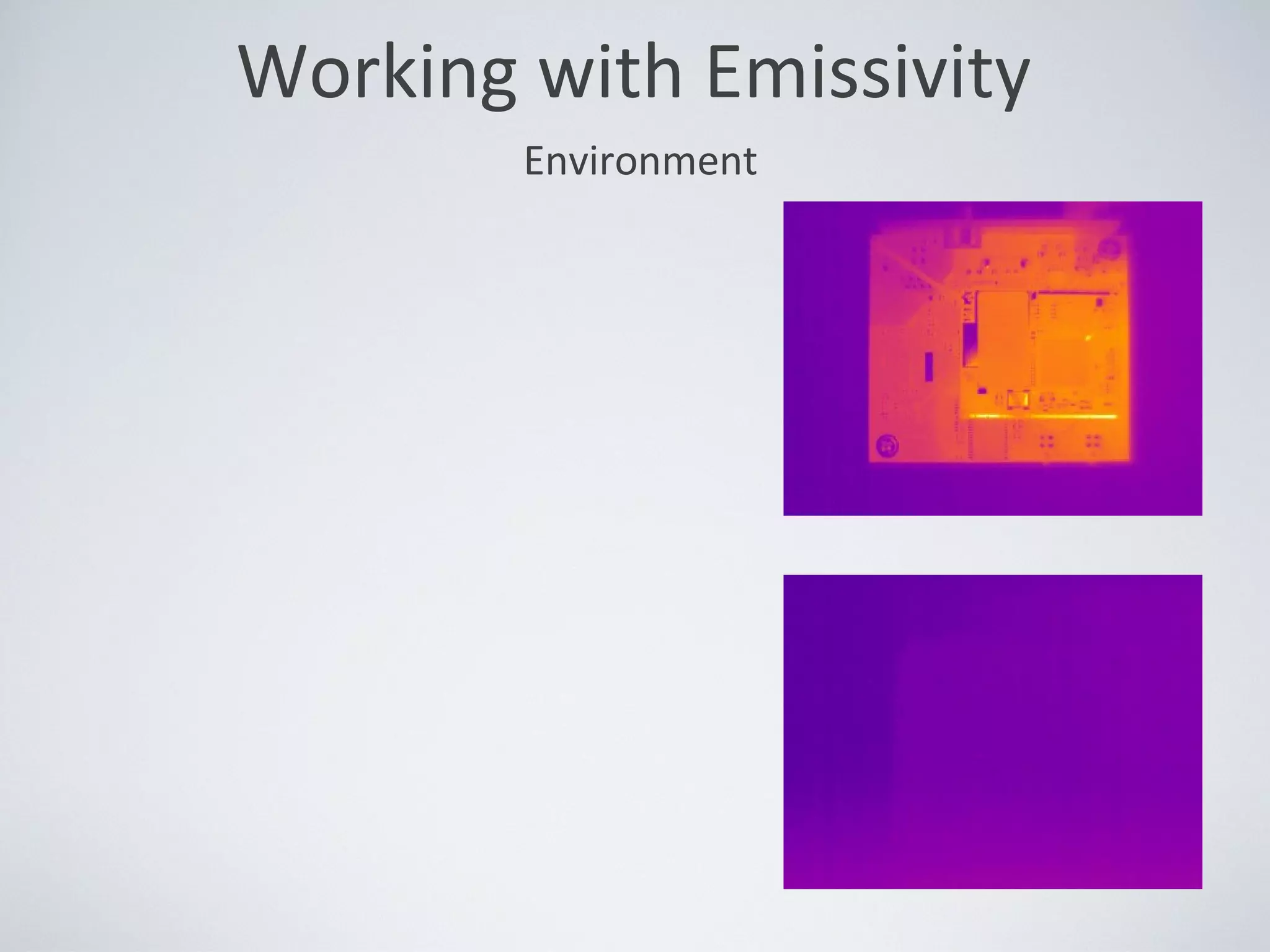

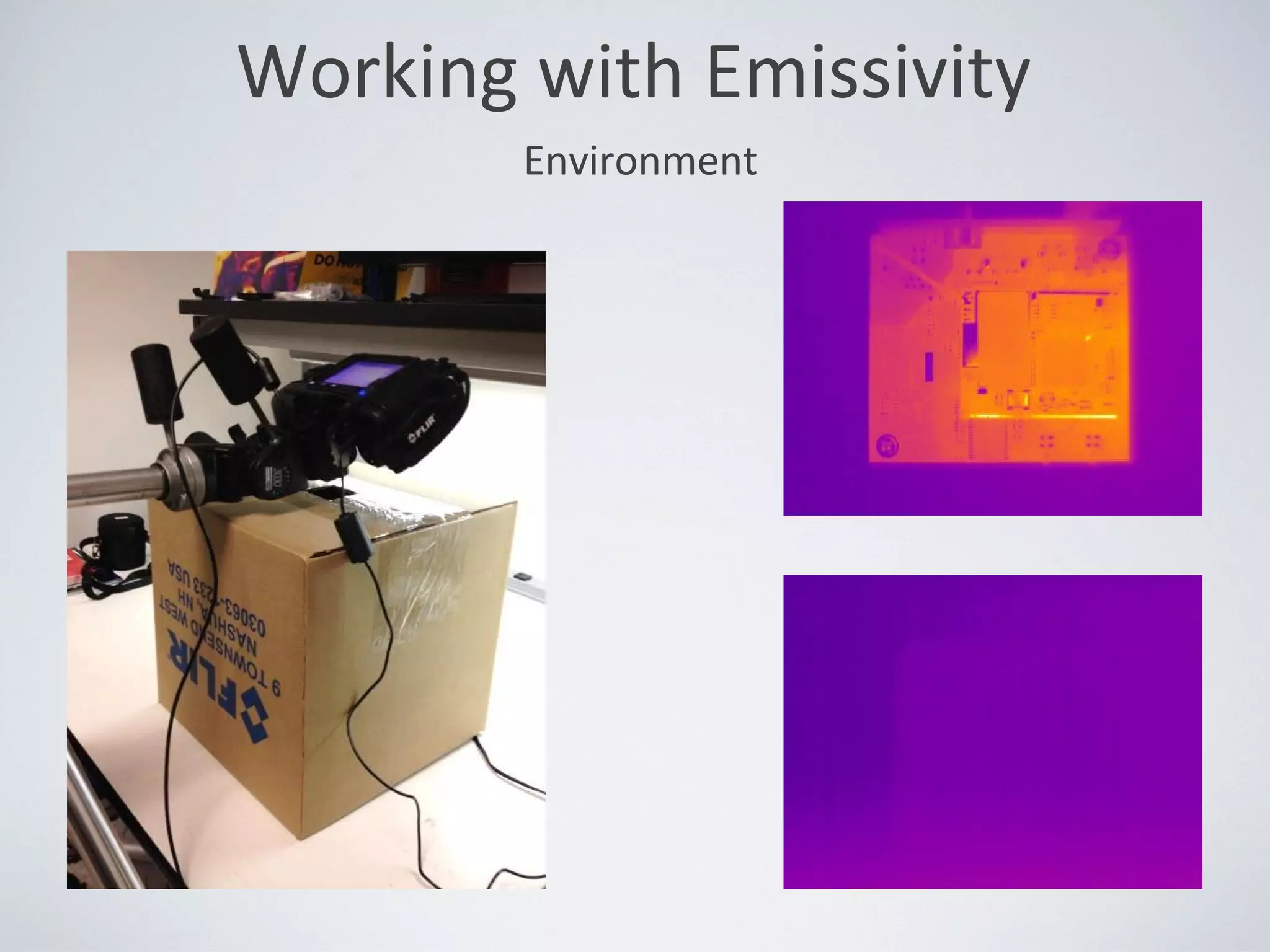

This document discusses infrared thermography and emissivity. It begins with an overview of infrared theory, including how infrared cameras measure temperature. Emissivity, the efficiency at which a surface emits infrared radiation compared to a blackbody, is then discussed in detail. Emissivity can vary based on material, roughness, wavelength, temperature, viewing angle, and geometry. The document demonstrates how to measure and account for emissivity through coatings, adjusting the reflected apparent temperature, and using emissivity calculators in camera software. It recommends infrared cameras for eliminating guesswork in thermal measurements and discusses factors to consider when selecting a camera.