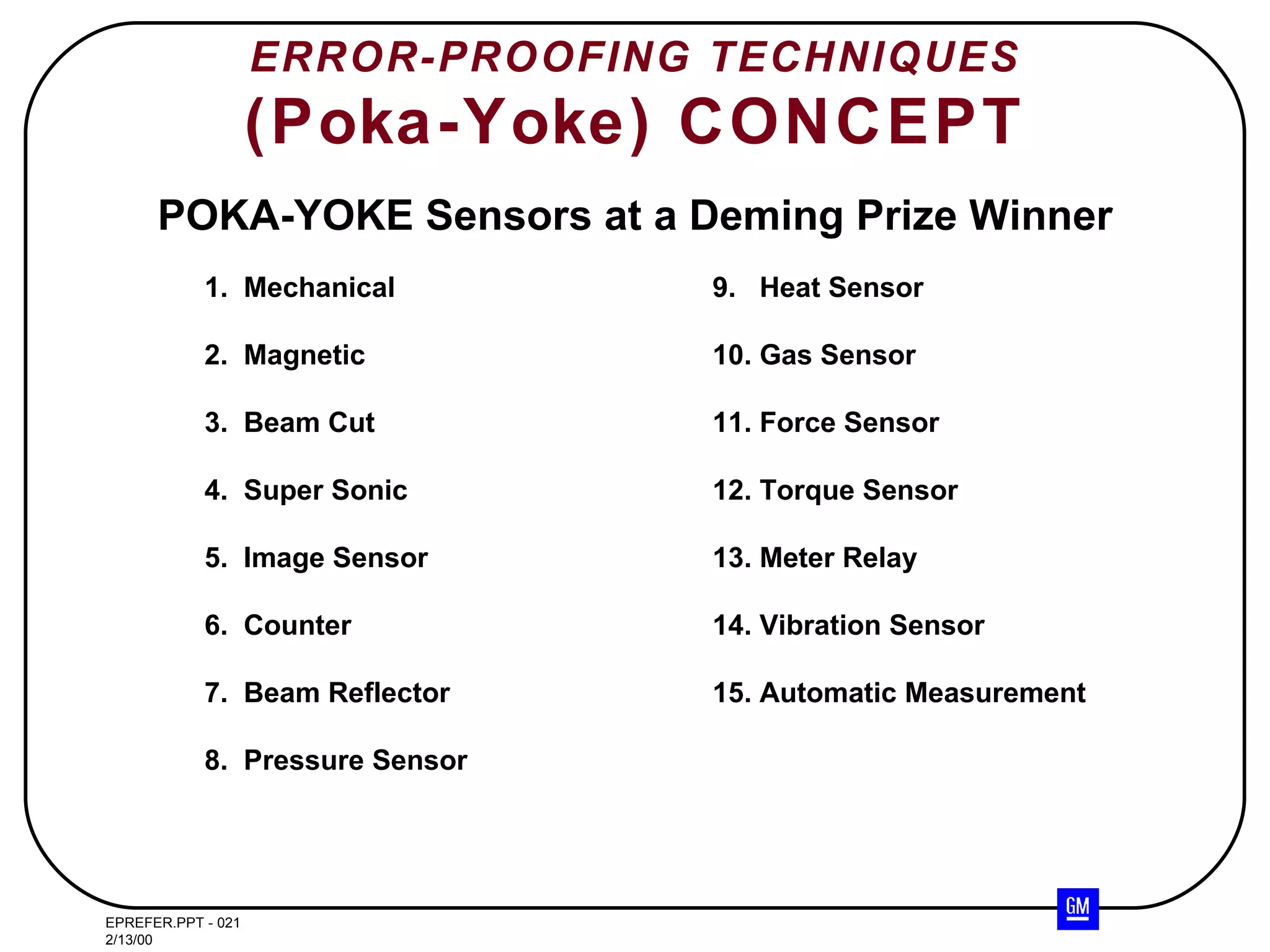

The document discusses various types of sensors used for error-proofing techniques (Poka-Yoke), including:

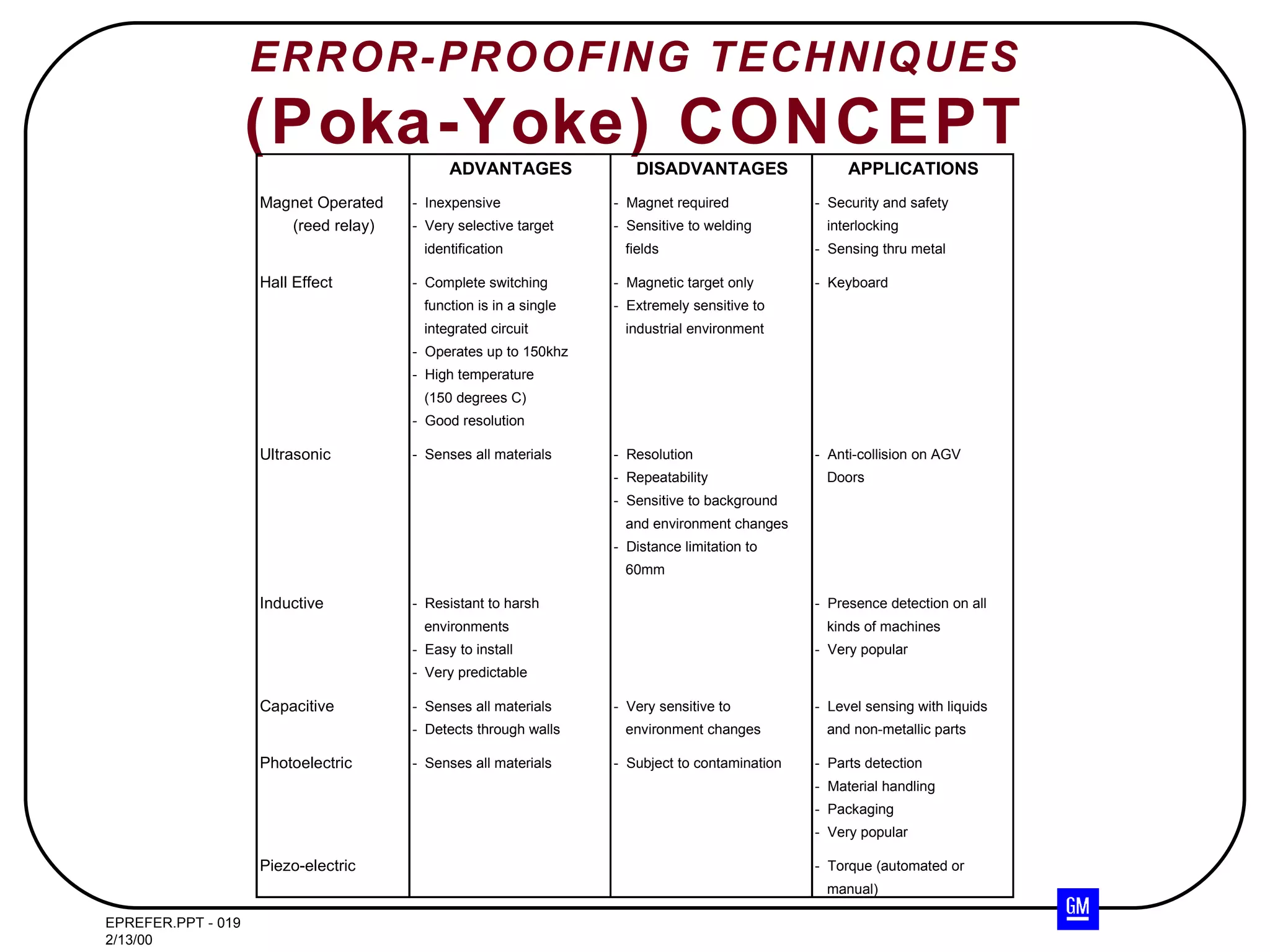

- Discrete and analog sensors

- Presence sensors that require physical contact or are non-contact

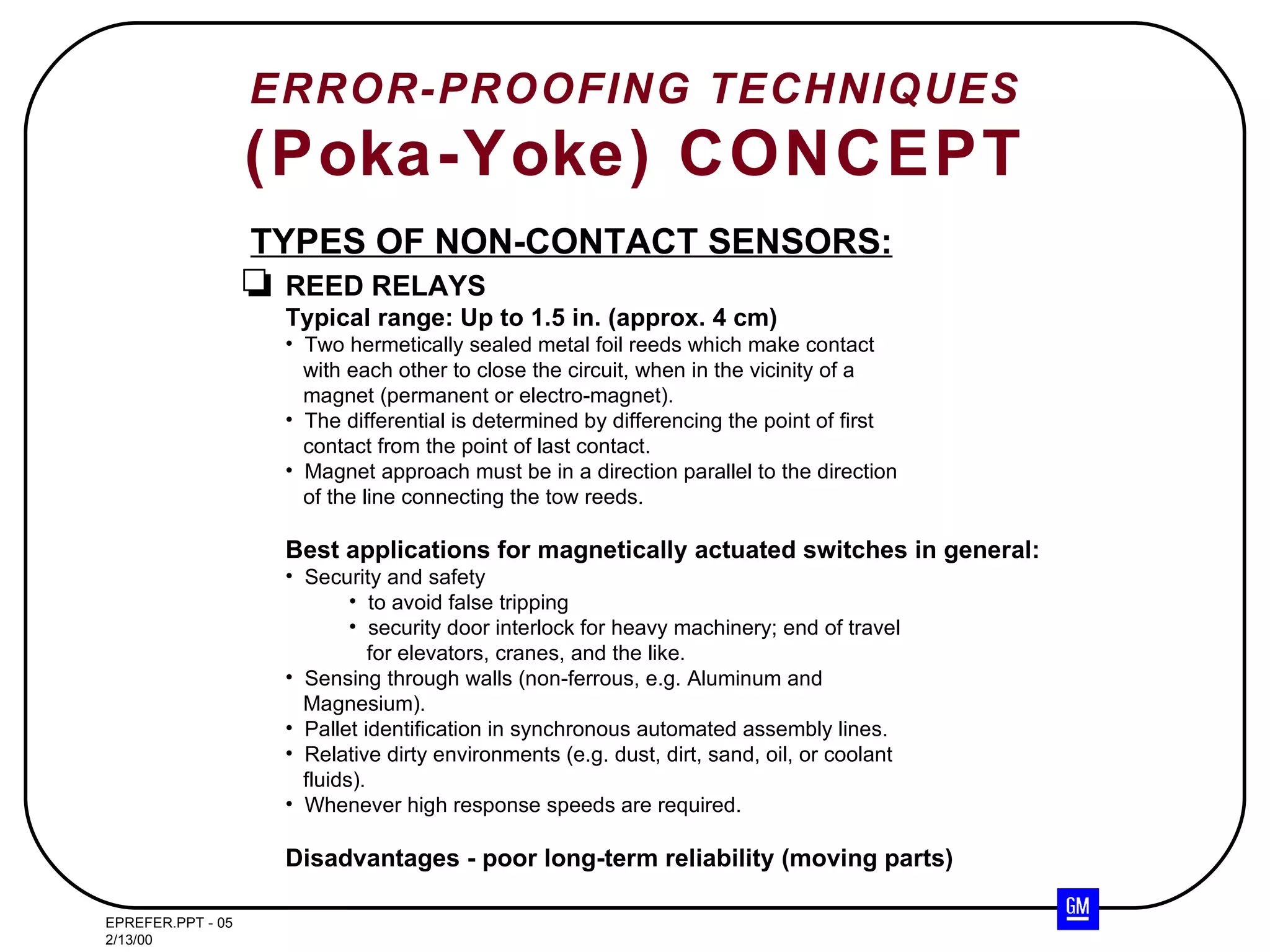

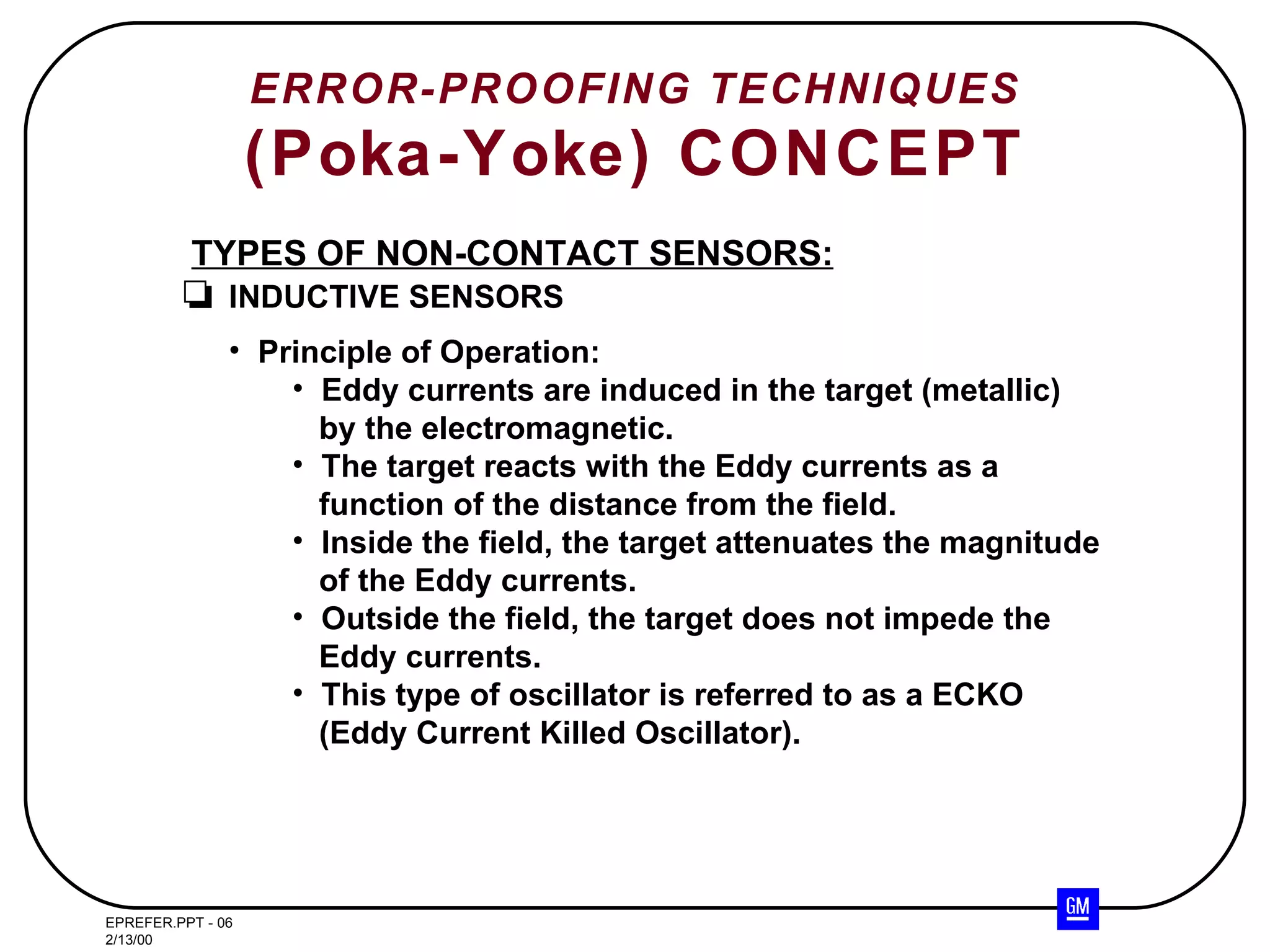

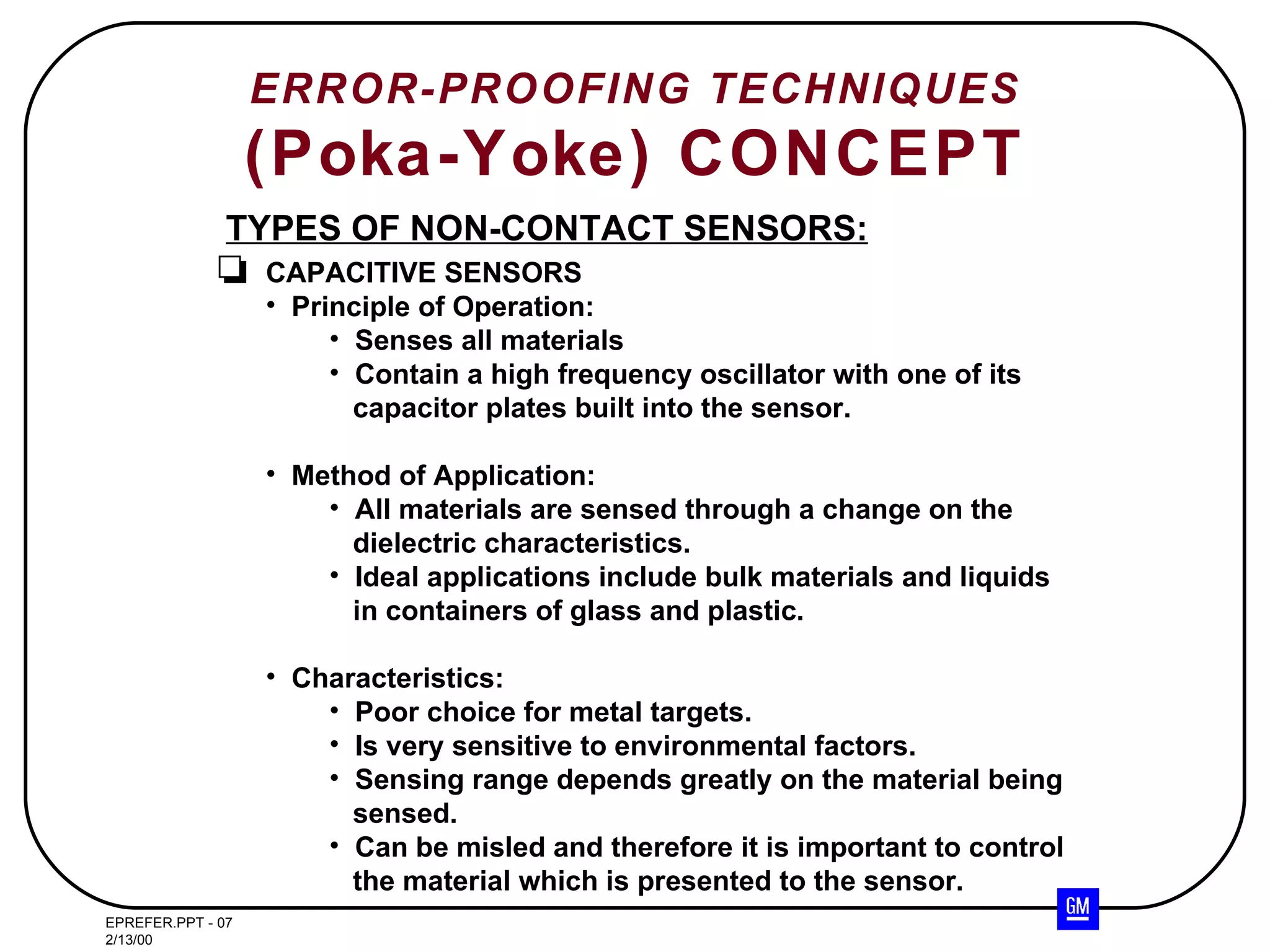

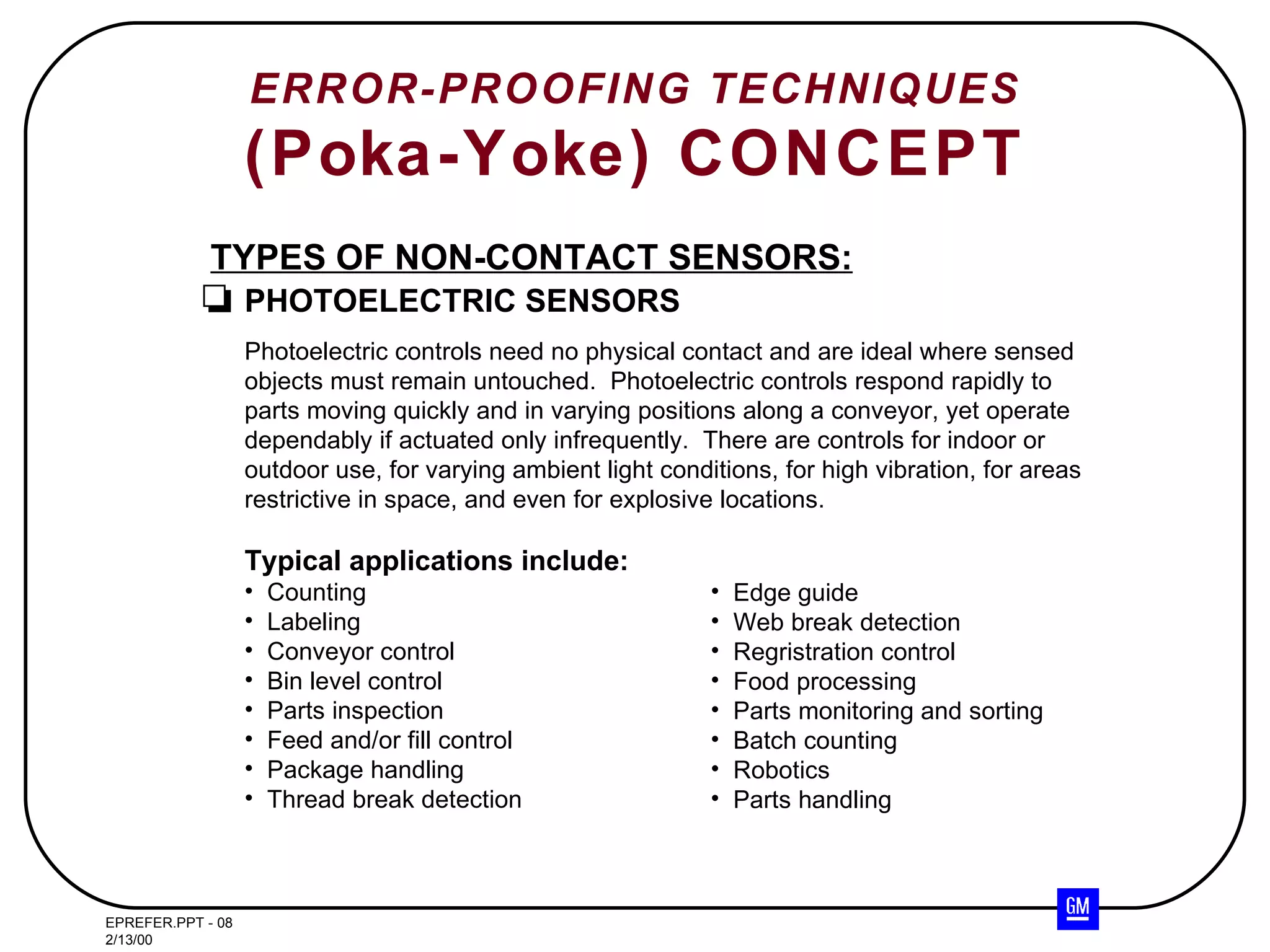

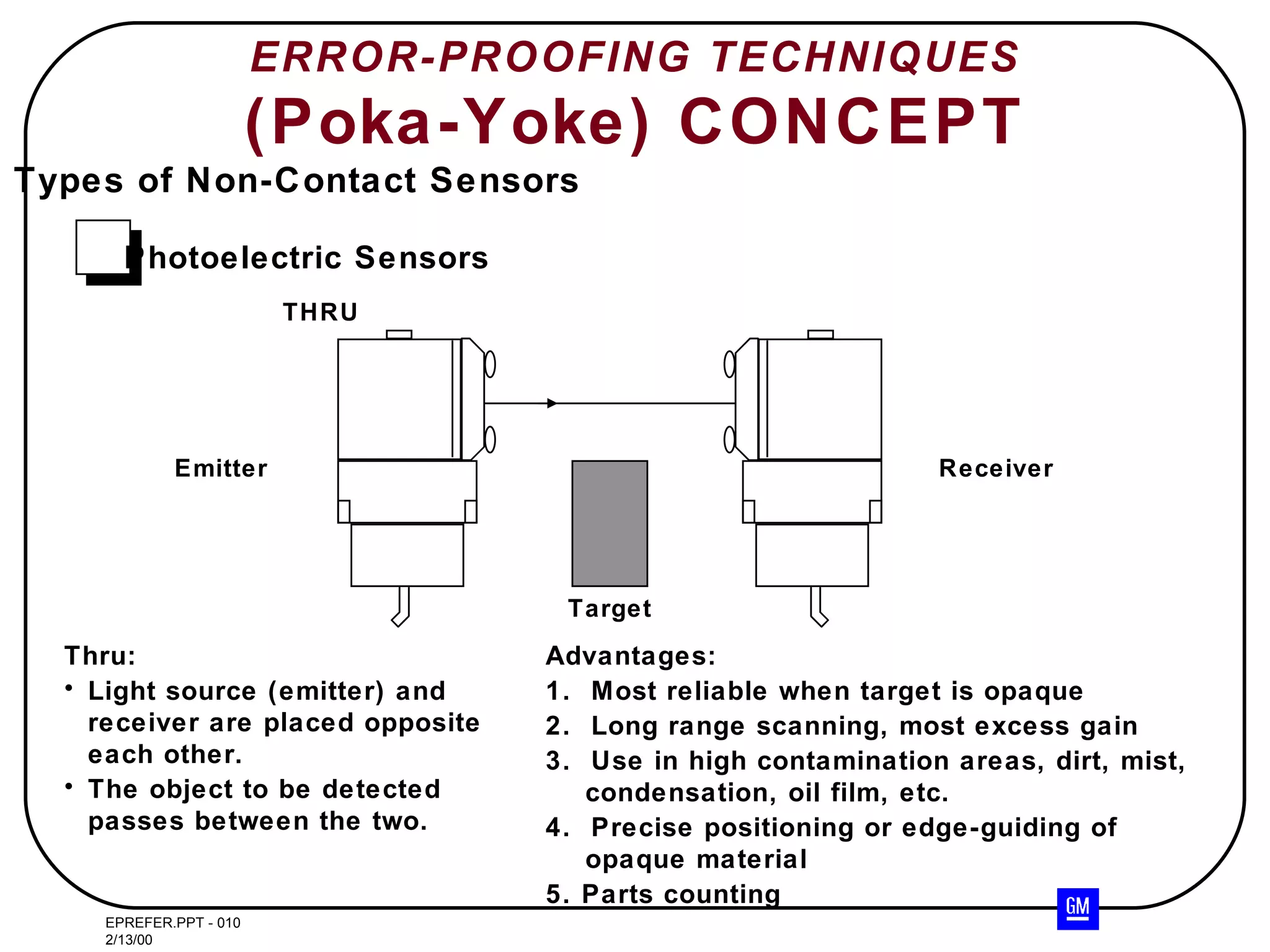

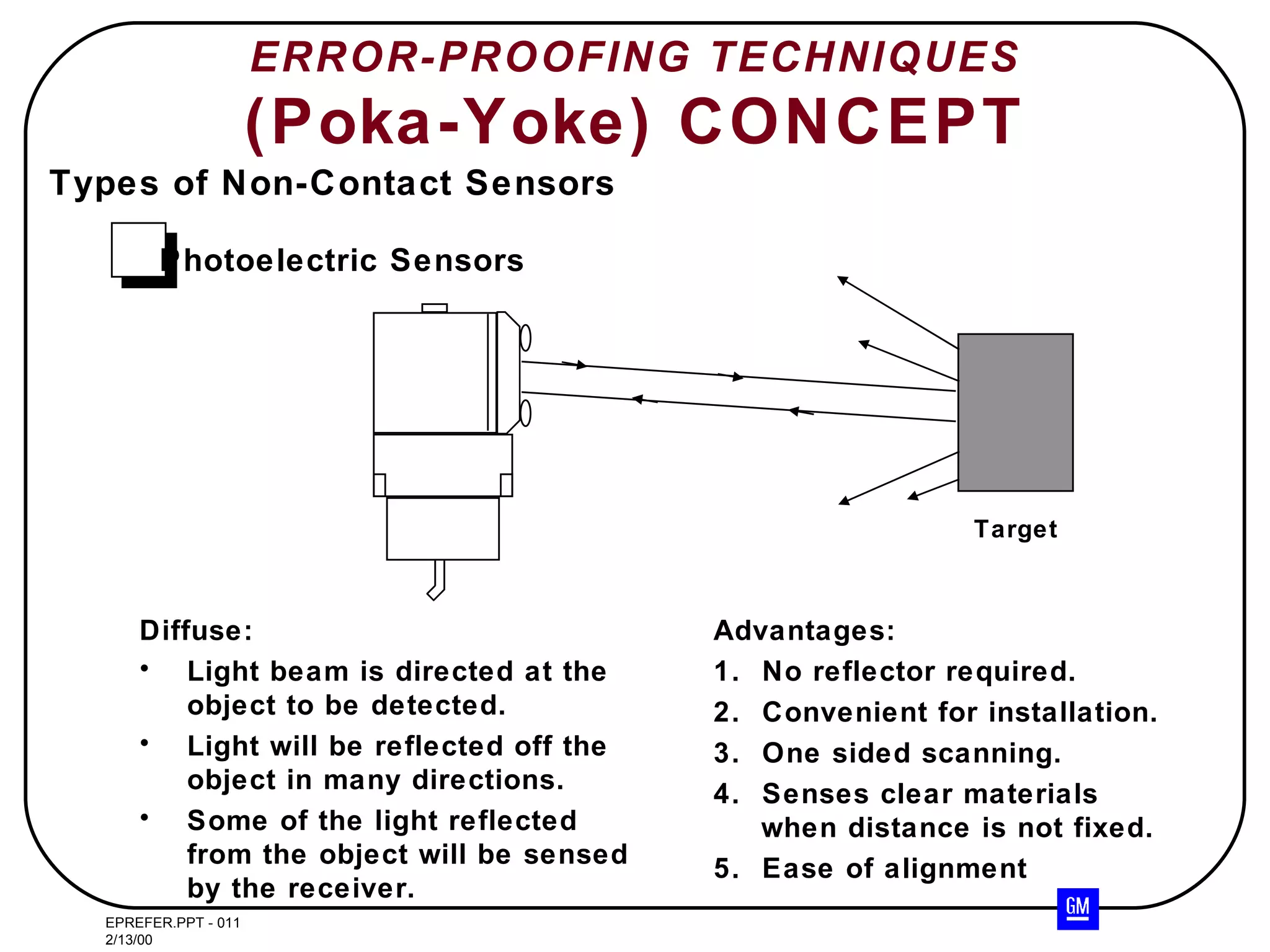

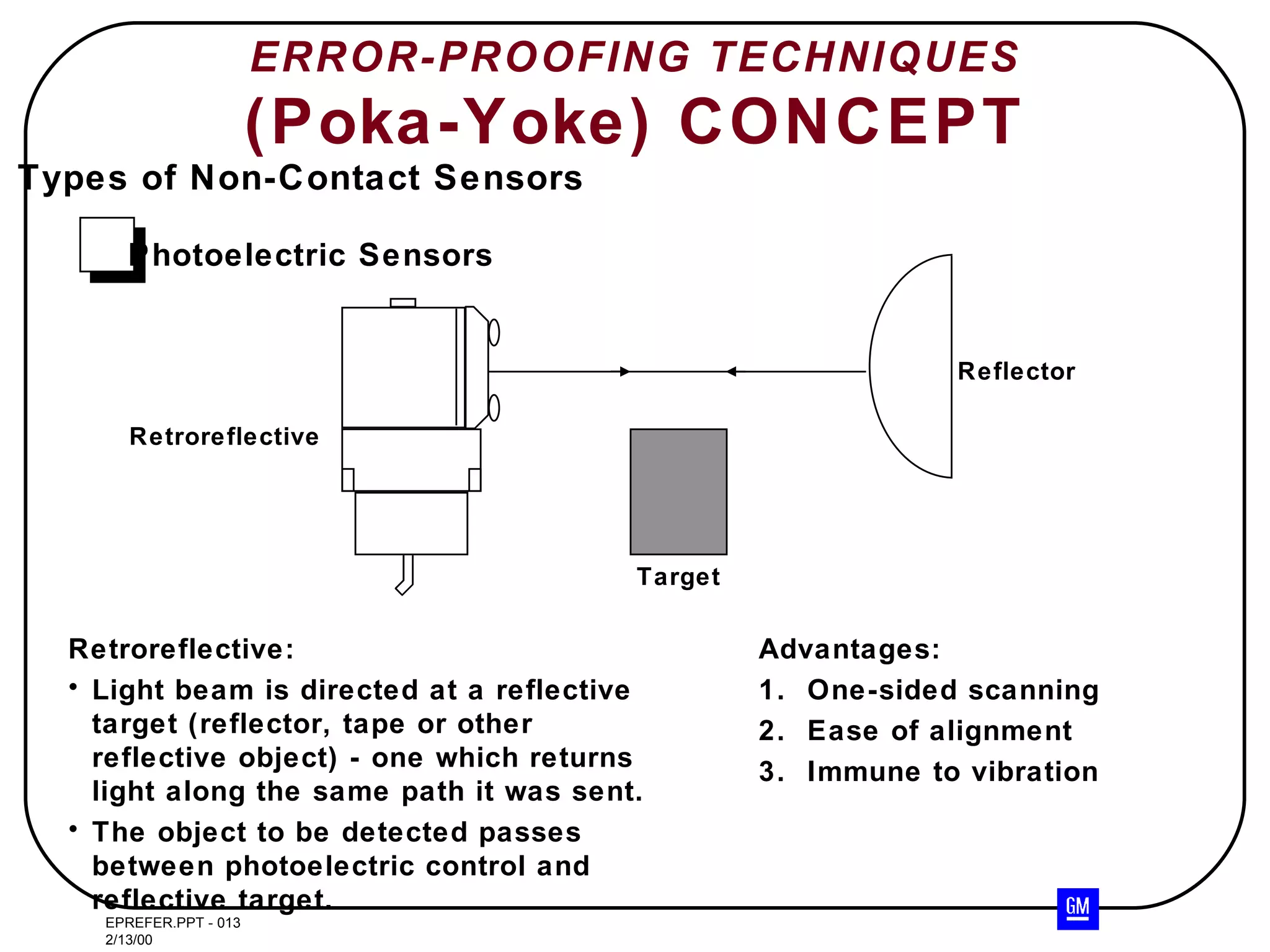

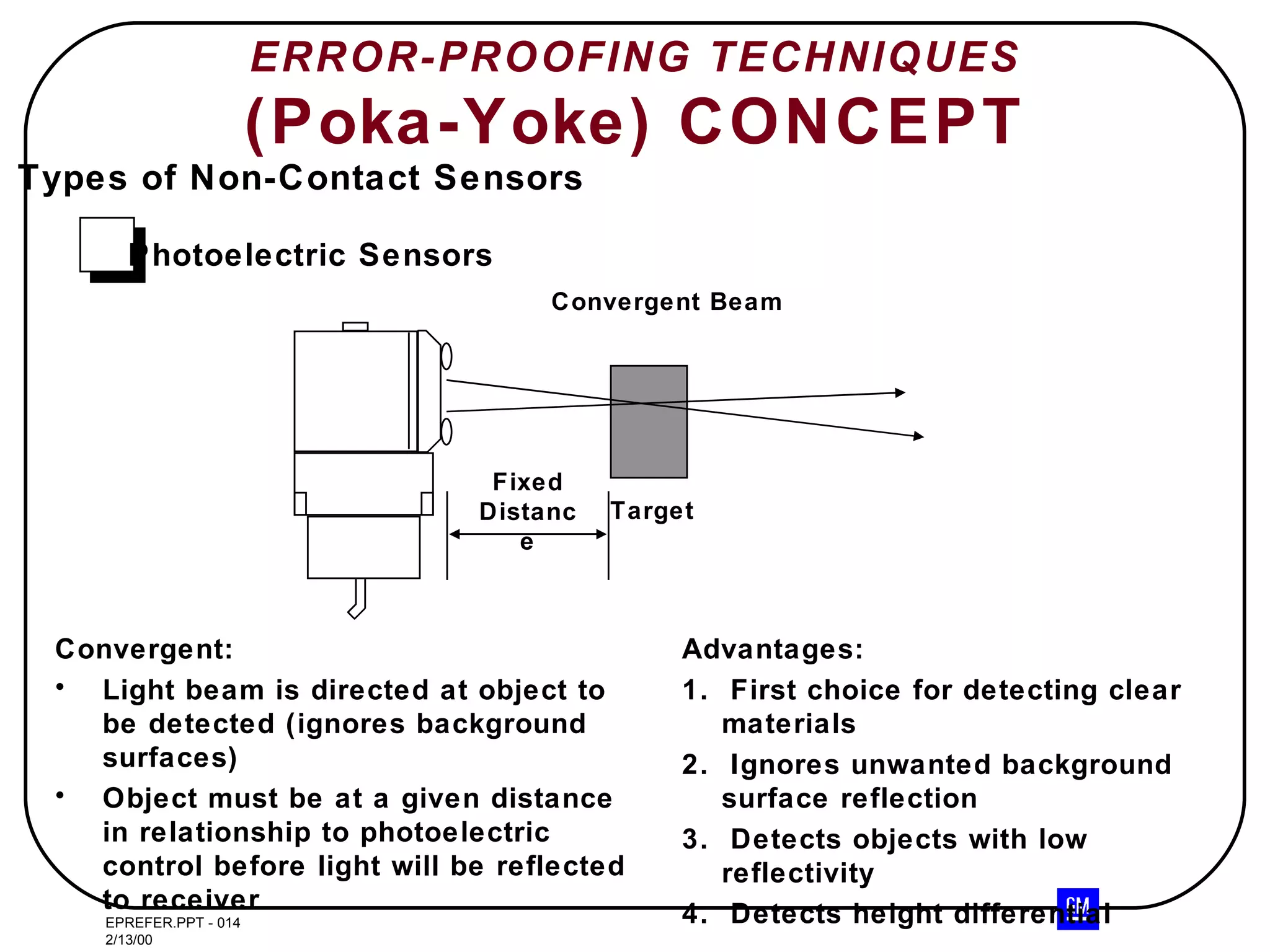

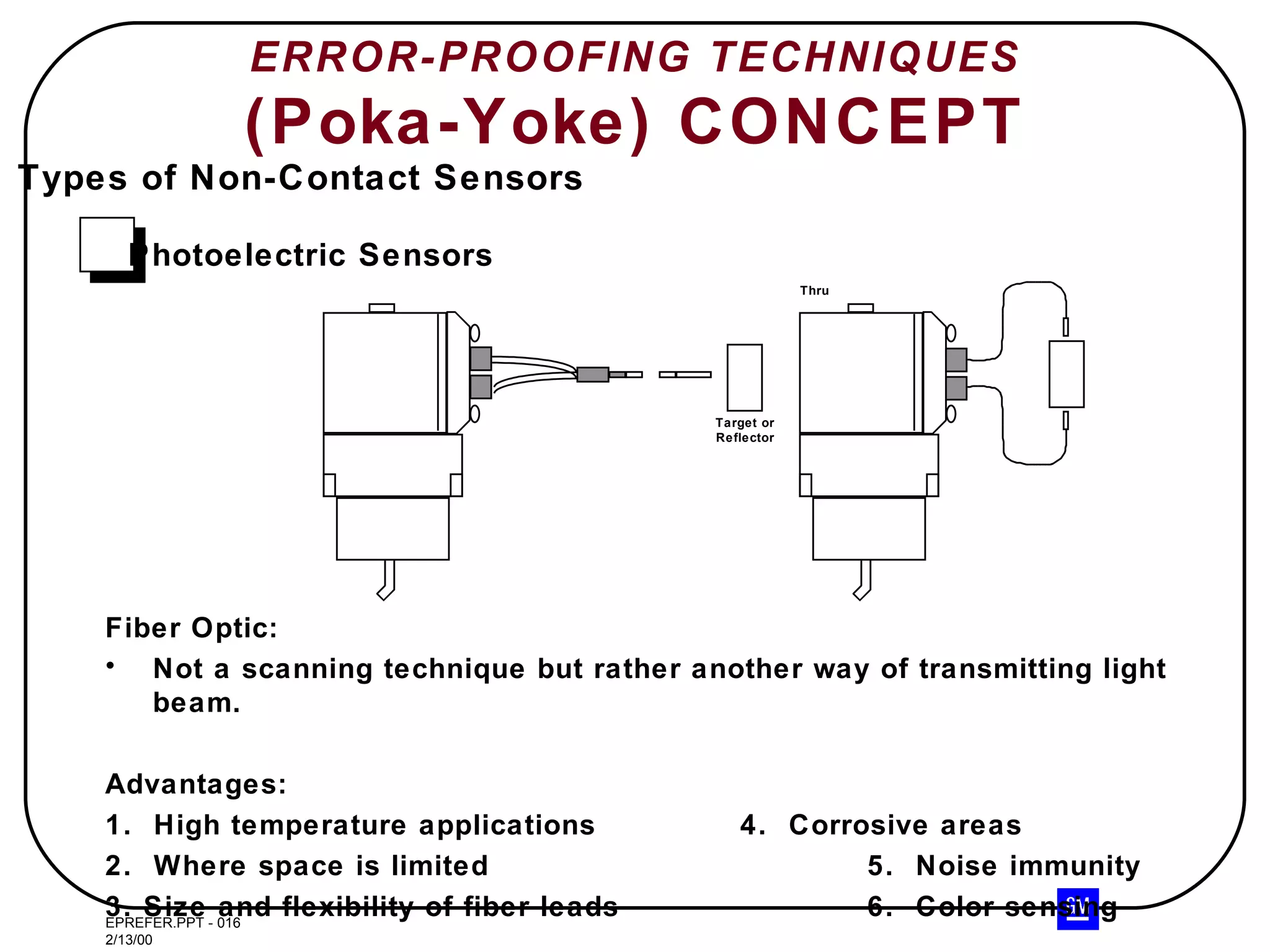

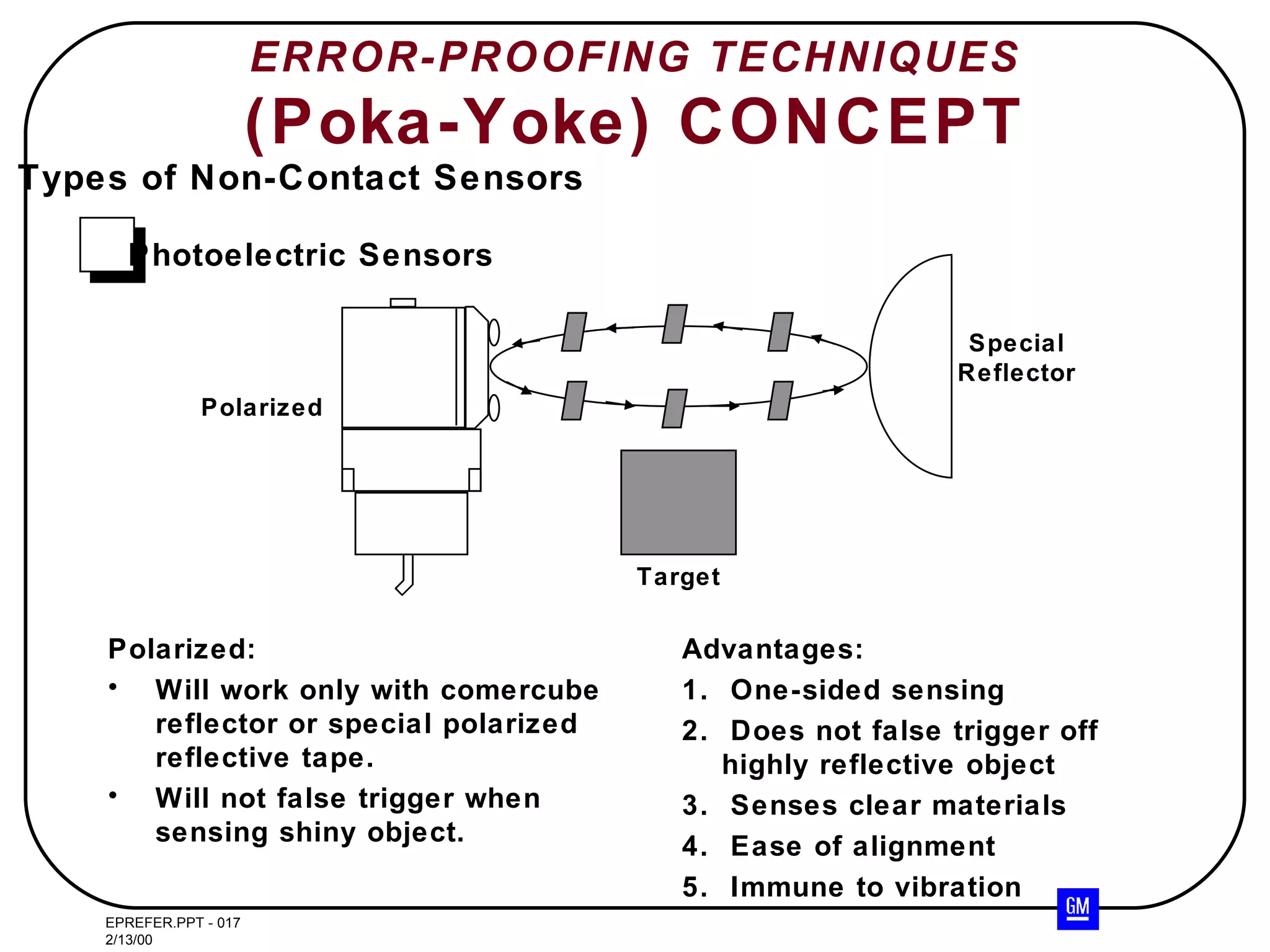

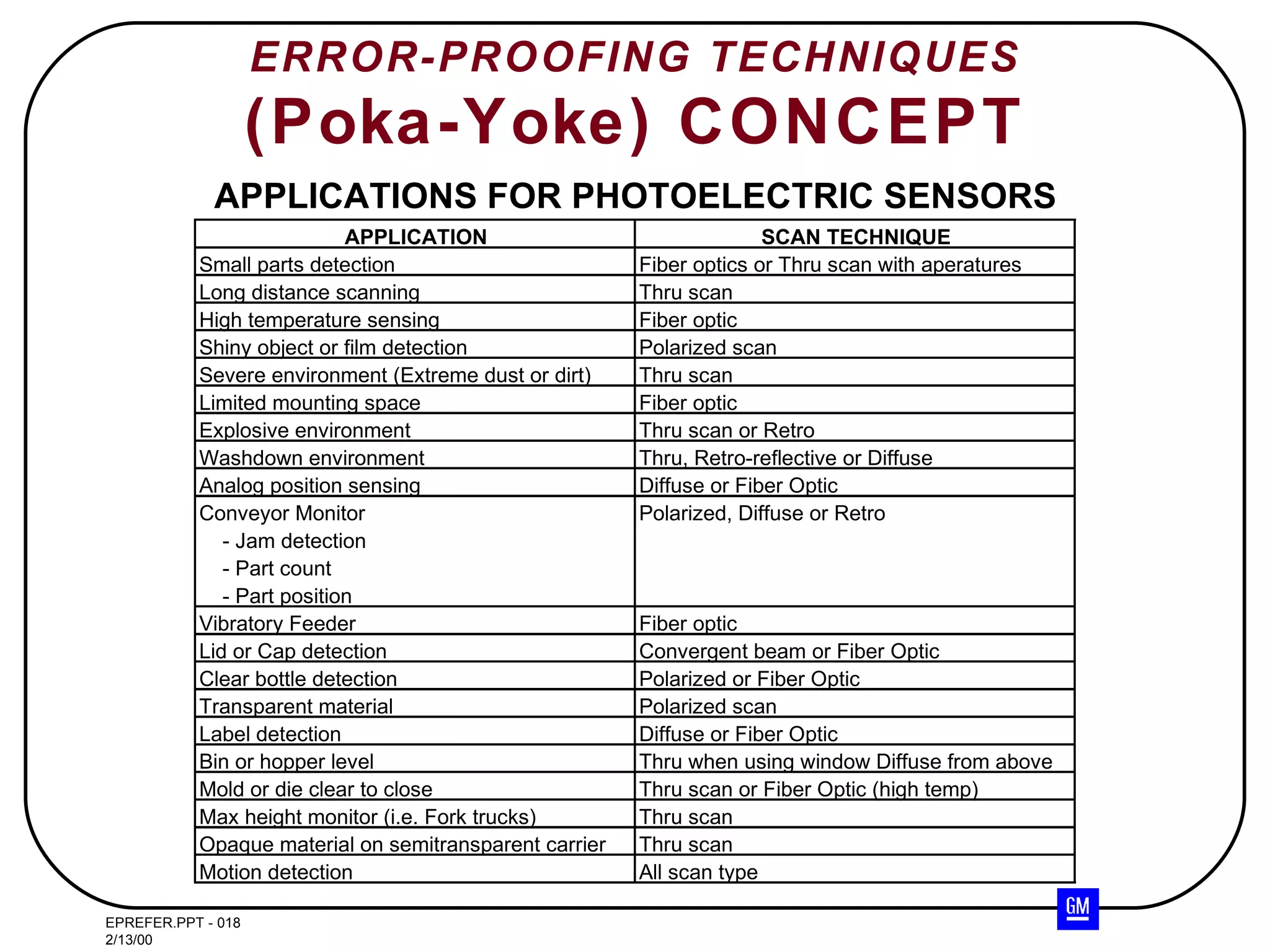

- Non-contact sensors like reed relays, inductive, capacitive, and photoelectric sensors

It provides details on the advantages and applications of these different sensor types.