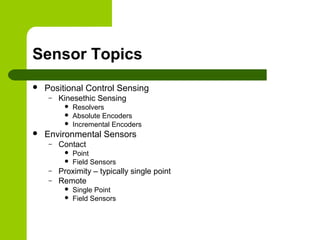

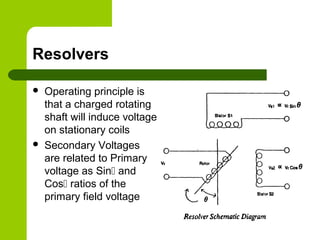

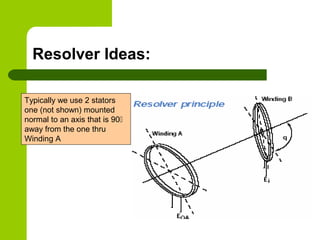

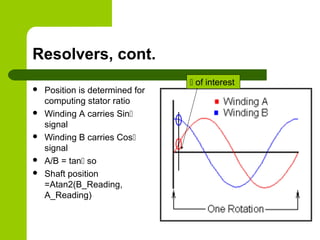

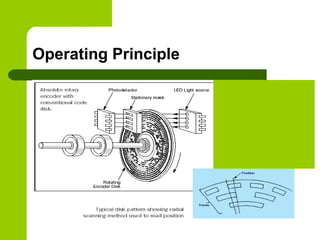

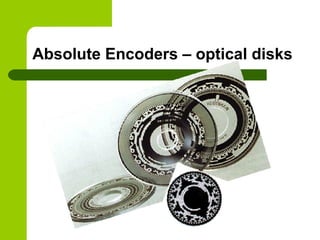

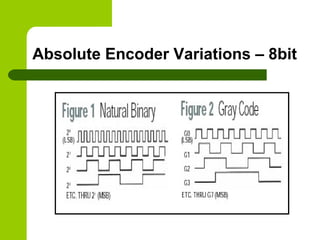

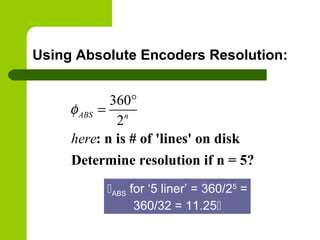

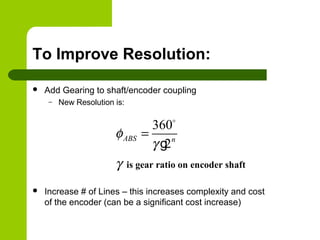

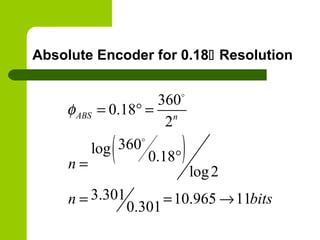

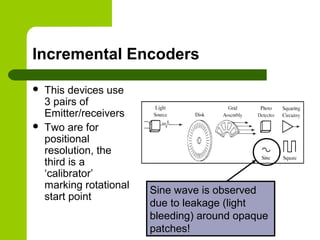

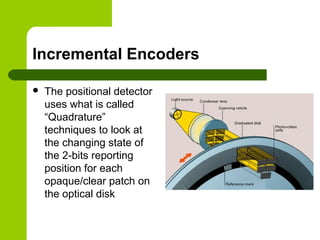

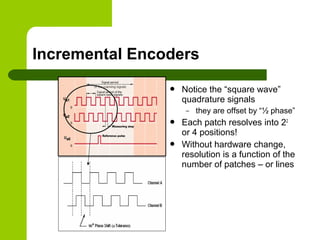

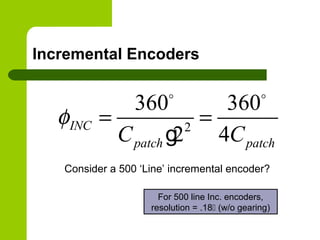

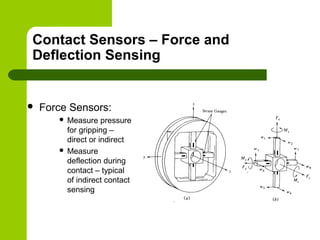

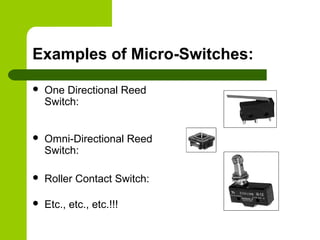

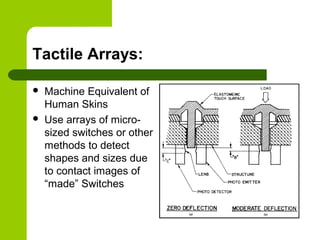

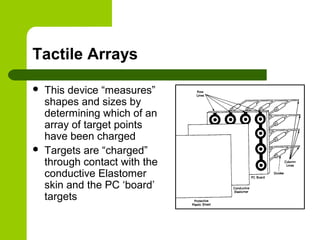

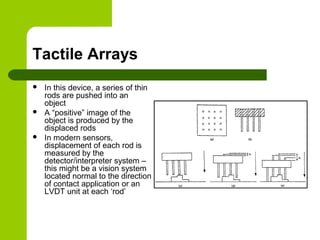

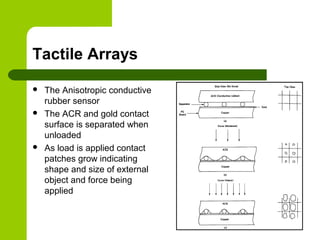

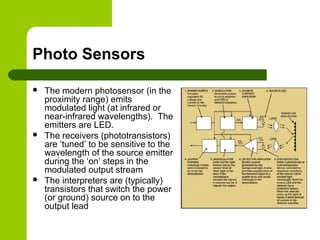

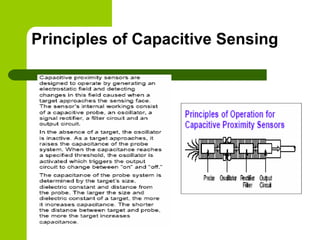

This document discusses various types of sensors used for robotics and control applications. It covers kinematic sensing technologies like resolvers, absolute encoders, and incremental encoders. It also discusses environmental sensors including contact sensors, tactile arrays, and proximity sensors. The key types of sensors are described in terms of their operating principles and how they provide positional or environmental feedback for robot control systems.