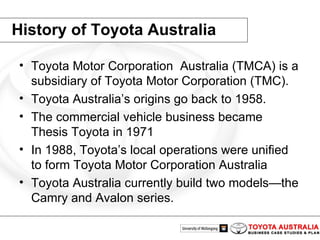

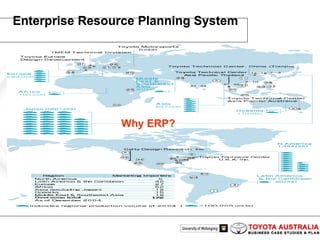

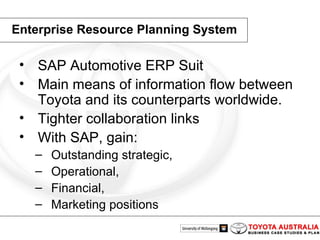

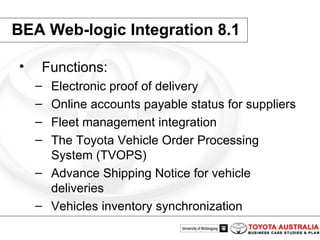

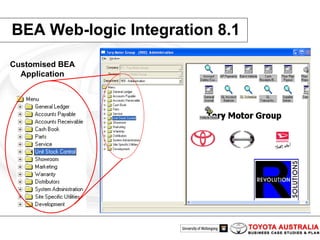

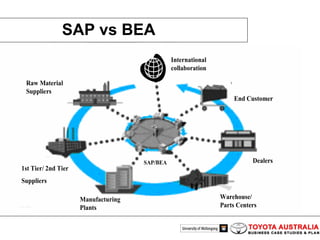

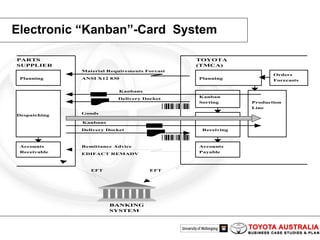

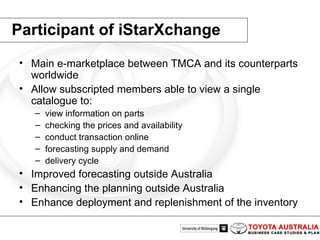

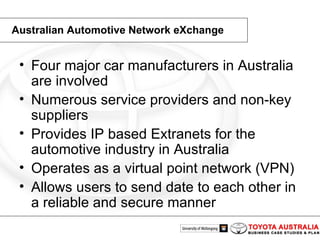

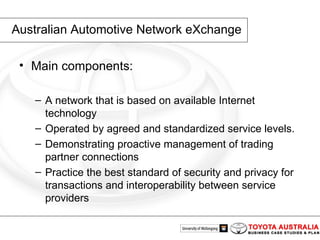

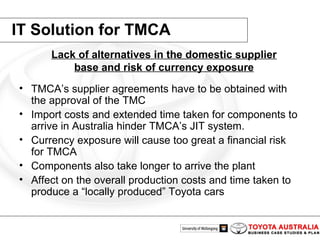

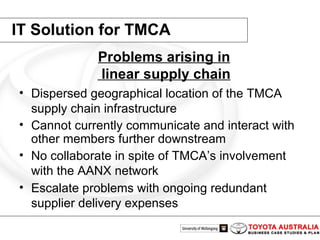

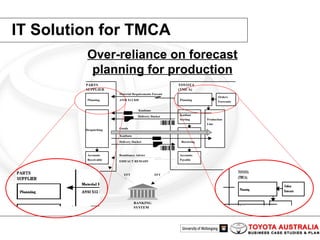

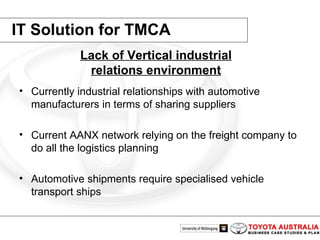

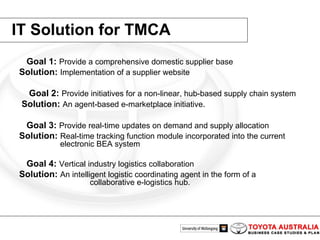

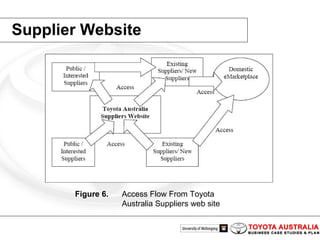

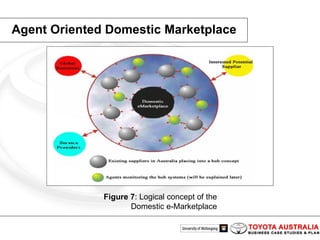

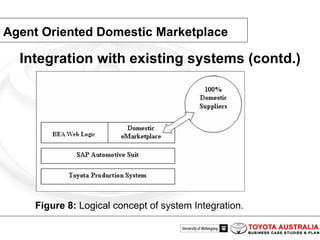

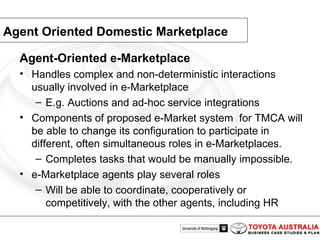

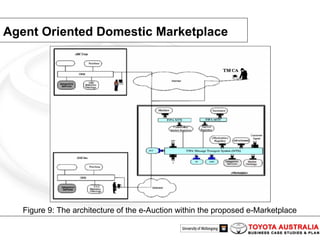

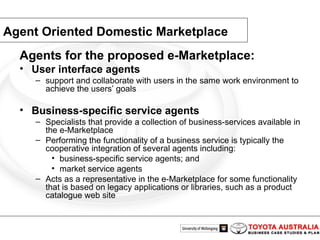

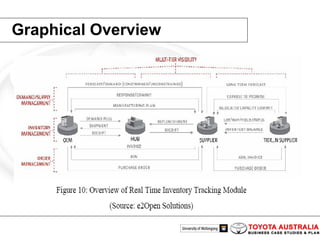

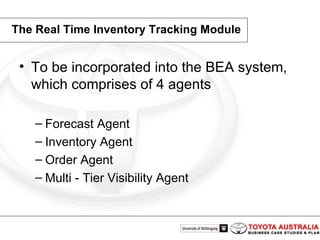

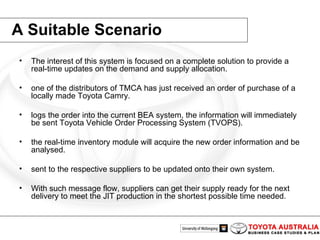

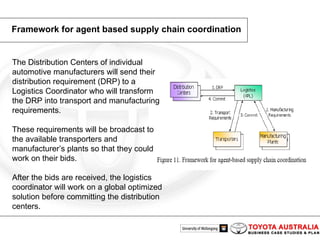

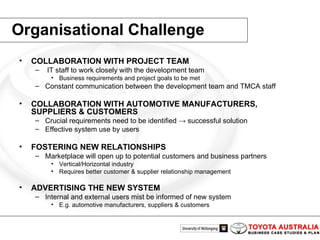

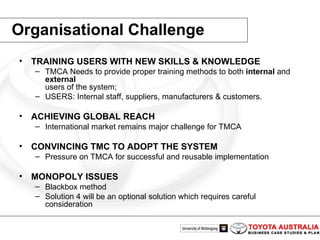

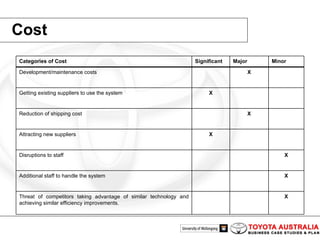

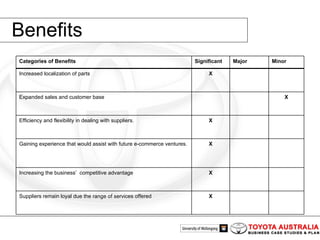

Toyota Australia, a subsidiary of Toyota Motor Corporation, has a rich history dating back to 1958 and currently ranks as the second-largest vehicle manufacturer in Australia, building models like the Camry and Avalon. The company faces challenges in supply chain management, particularly due to reliance on international imports for components, necessitating innovative IT solutions like an ERP system and an e-marketplace. Proposed solutions include establishing a comprehensive domestic supplier base and implementing agent-based e-marketplace initiatives to enhance supply chain coordination and efficiency.