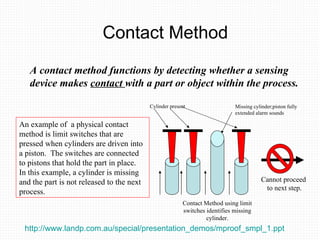

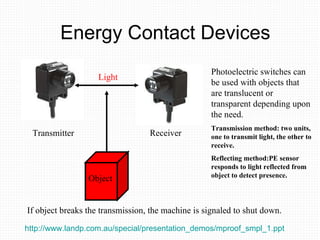

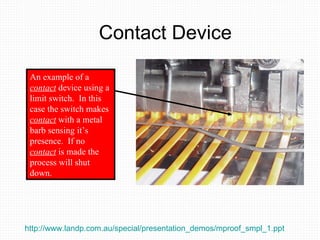

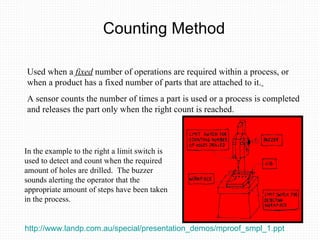

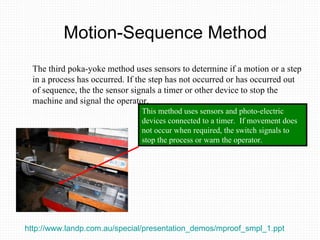

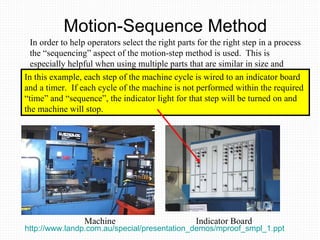

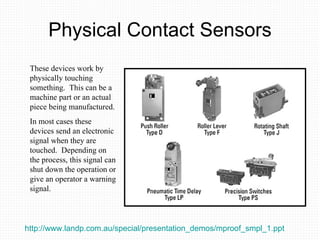

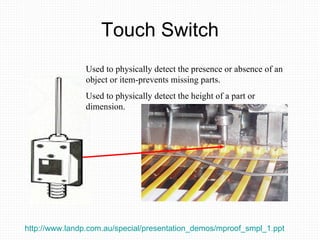

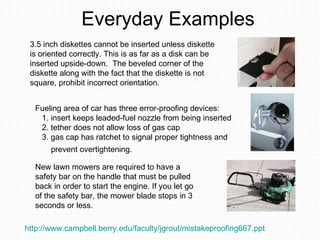

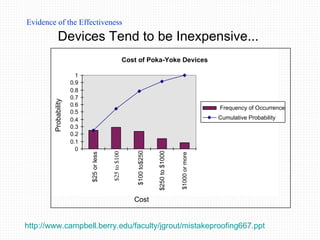

Poka-yoke, or mistake-proofing, aims to eliminate human errors in manufacturing processes through simple and inexpensive devices. There are three main poka-yoke methods: contact methods use sensors to detect proper physical contact between parts; counting methods ensure the correct number of process steps occur; and motion-sequence methods check that motions happen in the proper order. Examples show that simple devices like limit switches can detect missing parts or out-of-sequence steps, and cost little to implement while reaping large savings by reducing defects.

![… and Very Effective The “10:1, 100:1, even 1000:1” rates of return referred to by Bhote above are not unreasonable in practice. Dana corporation has reported a $500,000 savings resulting from a $6 device. (83,000:1) AT&T Power Systems (Lucent Technologies) reported net saving of $2545 per device (3300 devices) [Marchwinsky, 1997]. (25:1*) Weber Aircraft reports saving $350,000 during their first year of implementation of approximately 300 devices. (11:1*) *Assumes and average devise cost $100 http://www.campbell.berry.edu/faculty/jgrout/mistakeproofing667.ppt](https://image.slidesharecdn.com/pokeyoke-100605043431-phpapp01/85/Poka-yoke-7-320.jpg)