Different types of Sensors used in Mechatronics.ppt

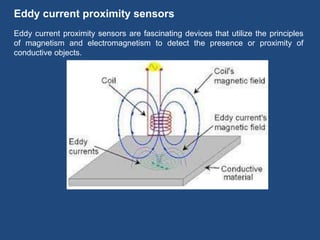

- 1. Eddy current proximity sensors Eddy current proximity sensors are fascinating devices that utilize the principles of magnetism and electromagnetism to detect the presence or proximity of conductive objects.

- 2. Working Principle: Coil and Oscillating Current: At the heart of the sensor lies a coil that transmits a high-frequency oscillating current. This generates a rapidly changing magnetic field around the coil. Eddy Current Induction: When a conductive object comes within the range of the magnetic field, eddy currents are induced within its material. These are circulating currents generated by the changing magnetic field, opposing the original field. Impedance Change: The presence of eddy currents alters the impedance (resistance to current flow) of the sensor coil. This change in impedance is detected and converted into an electrical signal. Output Signal: The electrical signal strength varies depending on the distance and type of conductive material. This information can be used to determine the presence, proximity, or even the type of object.

- 3. Characteristics: Non-contact detection: They can sense objects without any physical contact, making them ideal for harsh environments or delicate applications. Multi-material detection: They can detect various conductive materials, including metals, some plastics, and even fluids. High sensitivity: They can detect objects at very small distances, often down to sub-millimeter ranges. Temperature stability: They operate reliably even in extreme temperatures. Wear-resistant: They have no moving parts, making them durable and long-lasting.

- 4. Inductive Sensors: Inductive and capacitive sensors are two versatile and widely used proximity sensors that operate on different principles to detect the presence of objects. Inductive Sensors: Detection Method: Utilize a coil generating an oscillating magnetic field. When a conductive object enters the field, eddy currents are induced in the object, altering the coil's impedance and triggering an output signal. Material Sensitivity: Primarily detect ferrous metals (iron, steel), but some can also sense non-ferrous metals like aluminum and copper, although with reduced sensitivity. Detection Range: Typically range from a few millimetres to several centimetres, depending on the sensor design and target material. Advantages: Non-contact detection, robust against harsh environments, immune to moisture and humidity. Disadvantages: Limited to conductive materials, can be sensitive to nearby metal objects, higher cost compared to some capacitive sensors. Applications: Industrial automation (conveyor belts, object presence/absence), automotive (crankshaft/camshaft position), security systems (door/window sensors).

- 6. Capacitive Sensors: Detection Method: Create an electric field using a pair of electrodes. When an object with different dielectric properties enters the field, its capacitance changes, affecting the current flow and triggering an output signal. Material Sensitivity: Can detect a wider range of materials, including metal, plastic, liquids, and even some non-conductive materials. Detection Range: Usually similar to inductive sensors, but some high-resolution models can reach up to meters. Advantages: Versatile material detection, good immunity to environmental factors like dust and dirt, potentially lower cost than some inductive sensors. Disadvantages: May be prone to interference from moisture and humidity, sensitive to object size and shape, often require careful grounding. Applications: Level measurement in tanks, touchscreens, medical devices (blood flow, proximity detection), food and beverage industry (material detection, bottle filling).

- 8. Stroboscope: Function: A stroboscope is not actually a motion sensor itself, but rather a high- speed light source used to visualize motion. It emits pulses of light at a known frequency. When the light illuminates a moving object, the object appears to slow down or even freeze if the light pulse frequency matches the object's movement frequency. Applications: Stroboscopes are primarily used in industrial settings for: Analyzing machinery vibration: By adjusting the light pulse frequency, technicians can identify the specific vibration frequency of faulty bearings or other components. Inspecting high-speed processes: Observing manufacturing processes, printing presses, or even the operation of engines at slow motion can reveal defects or inefficiencies. Tuning instruments: By synchronizing the stroboscope frequency with the desired vibration frequency of an instrument, like a tuning fork, it can be finely tuned for accuracy.

- 9. Pyroelectric Sensor: Function: A pyroelectric sensor is a passive infrared (PIR) sensor that detects changes in temperature. They contain a pyroelectric material that generates a voltage difference when exposed to infrared radiation. Any object with a different temperature than the background environment will emit infrared radiation, which the sensor can detect. Applications: Pyroelectric sensors are widely used in: Security systems: Motion triggers alarms when someone enters a room by generating a change in temperature due to their body heat. Automatic lighting: Sensors activate lights when someone enters a room or hallway. Energy conservation: Thermostats can adjust heating or cooling based on occupancy detected by the sensor. Counting people: Sensors can track the number of people entering or leaving a space. Key Differences: Operating principle: Stroboscope uses light, while pyroelectric sensor uses temperature change. Purpose: Stroboscope visualizes motion, while pyroelectric sensor detects motion. Applications: Stroboscope mainly for industrial analysis, while pyroelectric sensor is versatile for security, automation, and more.

- 10. Acceleration sensors are fascinating devices that measure the rate of change in an object's velocity, or its acceleration. They find applications in various fields, from robotics and aviation to smartphones and fitness trackers. Here's a breakdown of three common types of acceleration sensors: Acceleration sensors Strain Gauge Accelerometer: Working Principle: This type uses thin metal wires (strain gauges) bonded to a flexible beam. When the object accelerates, the beam bends, stretching or compressing the wires and changing their resistance. This change in resistance is converted into an electrical signal proportional to the acceleration. Characteristics: Highly accurate and sensitive, making them suitable for demanding applications. Wide bandwidth capable of measuring both high and low frequencies. Relatively complex and expensive compared to other types. Susceptible to temperature changes and require calibration. Applications: Primarily used in aerospace, high-performance vehicles, and seismic monitoring due to their accuracy and wide bandwidth.

- 11. Piezoelectric Accelerometer: Working Principle: This type utilizes a piezoelectric material that generates a voltage when subjected to mechanical stress. As the object accelerates, the piezoelectric material experiences pressure or vibration, creating a voltage proportional to the acceleration. Characteristics: Compact and rugged, making them suitable for harsh environments. High-frequency response and good sensitivity. Relatively inexpensive compared to strain gauge accelerometers. May exhibit temperature sensitivity and require signal conditioning. Applications: Widely used in industrial automation, robotics, vibration monitoring, and consumer electronics like smartphones and gaming controllers.

- 12. LVDT Accelerometer (Linear Variable Differential Transformer): Working Principle: This type employs a transformer and a movable core linked to a spring-mass system. When the object accelerates, the mass displaces, changing the transformer's magnetic coupling and generating an electrical signal proportional to the displacement, which is then converted to acceleration. Characteristics: Robust and reliable, suitable for harsh environments. Excellent long-term stability and low maintenance requirements. Lower sensitivity and bandwidth compared to other types. Typically larger and more expensive than piezoelectric accelerometers. Applications: Often used in industrial settings like power plants, machinery monitoring, and structural integrity assessments due to their reliability and stability.

- 13. Pressure Sensors: Measure: Pressure exerted by a fluid (liquid or gas) on a surface. Applications: Widely used in various fields like pneumatics, hydraulics, medical devices, weather monitoring, and process control. Types: Many types exist, depending on the application and pressure range, such as piezoelectric, strain gauge, capacitive, optical, and resonant. Load Cells: Measure: Force applied to a specific point or area. This force can be generated by pressure (e.g., weight on a platform), tension (e.g., pulling on a cable), or compression (e.g., pushing down on a beam). Applications: Primarily used in weighing scales, industrial automation, robotics, construction, and material testing. Types: Similar to pressure sensors, various types exist depending on the design and force range, such as shear beam, S- beam, canister, tension/compression, and miniature cells.

- 14. Torque Measurement using Strain Gauges: Working Principle: Strain gauges are bonded to the shaft at specific angles. As torque is applied, the shaft twists, stretching or compressing the strain gauges. This change in shape alters the electrical resistance of the gauges. By measuring the resistance change, an electrical signal proportional to the torque is generated. Advantages: Highly accurate and sensitive, ideal for demanding applications. Wide measurement range, capable of handling both low and high torques. Non-contact measurement, no mechanical interference with the shaft. Relatively compact and versatile design. Disadvantages: More complex and expensive compared to torsion bars. Susceptible to temperature changes and require calibration. Installation and wiring can be more intricate.

- 15. Torque Measurement using Torsion Bar: Working Principle: A fixed and a rotating section of the shaft are connected by a flexible torsion bar. As torque is applied, the torsion bar twists, causing the rotating section to deflect from the fixed section. The angle of deflection is proportional to the applied torque. This deflection can be measured using various methods, such as optical encoders, potentiometers, or strain gauges attached to the torsion bar. Advantages: Simpler and more cost-effective design compared to strain gauge setups. Less susceptible to temperature changes and require less calibration. Robust and reliable, suitable for harsh environments. Disadvantages: Lower accuracy and sensitivity compared to high-precision strain gauge systems. Limited measurement range, may not be suitable for very high torques. Contact measurement requires careful alignment and potential friction losses.

- 16. Signal Conditioners: Ensuring Accurate Data in Mechatronics Systems Mechatronics systems integrate mechanical, electrical, and computer components, relying heavily on signals for control and feedback. However, raw sensor signals are often unreliable, noisy, and incompatible with downstream systems. Enter signal conditioners, the unsung heroes of mechatronics that refine and adjust these signals for accurate interpretation and efficient system operation. Here's a breakdown of the crucial roles played by different types of signal conditioners in mechatronics:

- 17. Isolators: Function: Break electrical ground between the sensor and the rest of the system, preventing ground loops and protecting sensitive electronics from overvoltage or electromagnetic interference (EMI). Need: Essential for protecting equipment and ensuring accurate data when dealing with high EMI environments, ground loops, or systems with different power domains. Filters: Function: Remove unwanted noise and distortions from the signal, such as power line hum, electromagnetic interference, and high-frequency noise from switching circuits. Need: Crucial for improving signal-to-noise ratio (SNR) and ensuring accurate data interpretation, especially in noisy environments or when dealing with weak signals.

- 18. Amplifiers: Function: Increase the amplitude (strength) of the signal to a level suitable for processing by downstream electronics. Need: Vital when dealing with weak sensor signals that need boosting before sending them to controllers or data acquisition systems. Fluid Amplifiers: Function: Utilize fluid pressure to manipulate and control fluid flow or pneumatic/hydraulic systems. They can amplify, switch, or modulate fluid signals. Need: Used in situations where electrical control is impractical or undesirable, such as in harsh environments or for high-power pneumatic/hydraulic applications. Optical Amplifiers: Function: Amplify optical signals (light) using techniques like stimulated emission. They can amplify analog or digital optical signals. Need: Primarily used in fiber optic communication systems when signal strength needs boosting over long distances with minimal loss.

- 19. Data Converters: Function: Convert signals between different formats, such as analog-to-digital (A/D) or digital-to-analog (D/A) conversion. Need: Essential for interfacing between analog sensors and digital controllers, enabling data processing and manipulation within the mechatronics system. Choosing the Right Signal Conditioner: Selecting the appropriate signal conditioner depends on several factors: Sensor type and output signal: Match the conditioner to the sensor's output format (e.g., voltage, current). Desired signal modification: Identify the need for isolation, filtering, amplification, or conversion. System requirements: Consider the desired gain, noise reduction, bandwidth, and accuracy. Cost and size constraints: Choose a cost-effective option that fits your specific needs and space limitations.