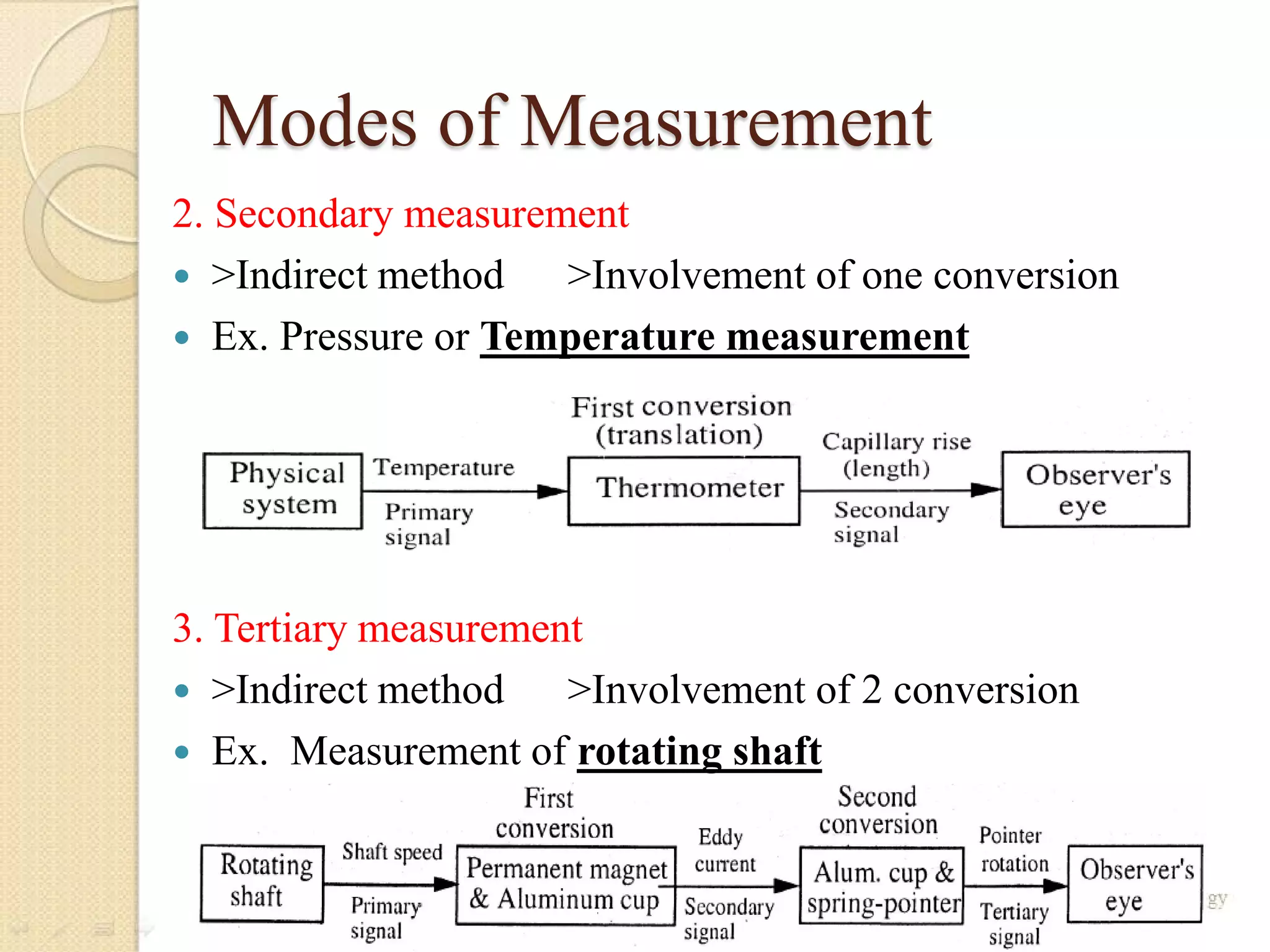

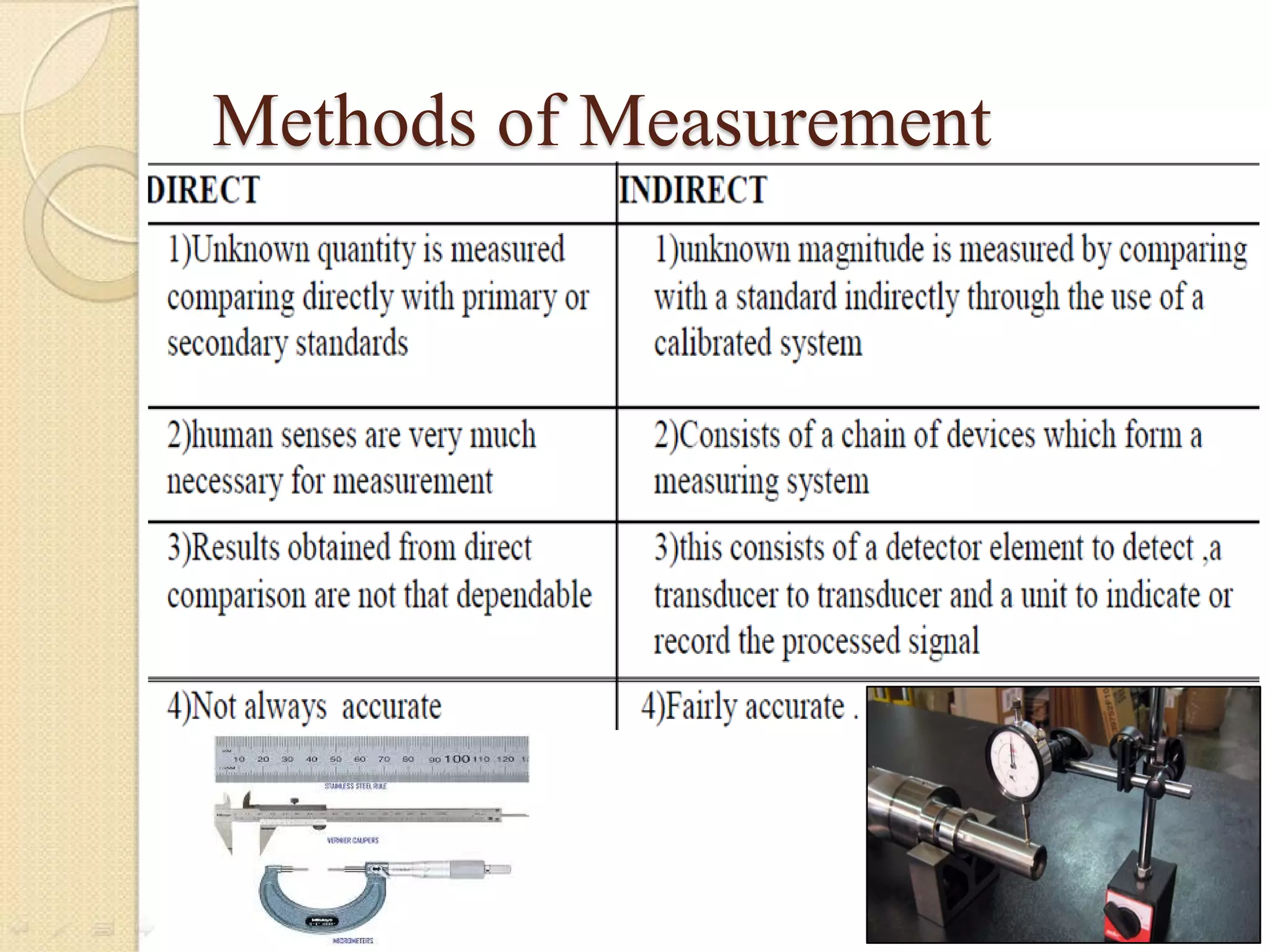

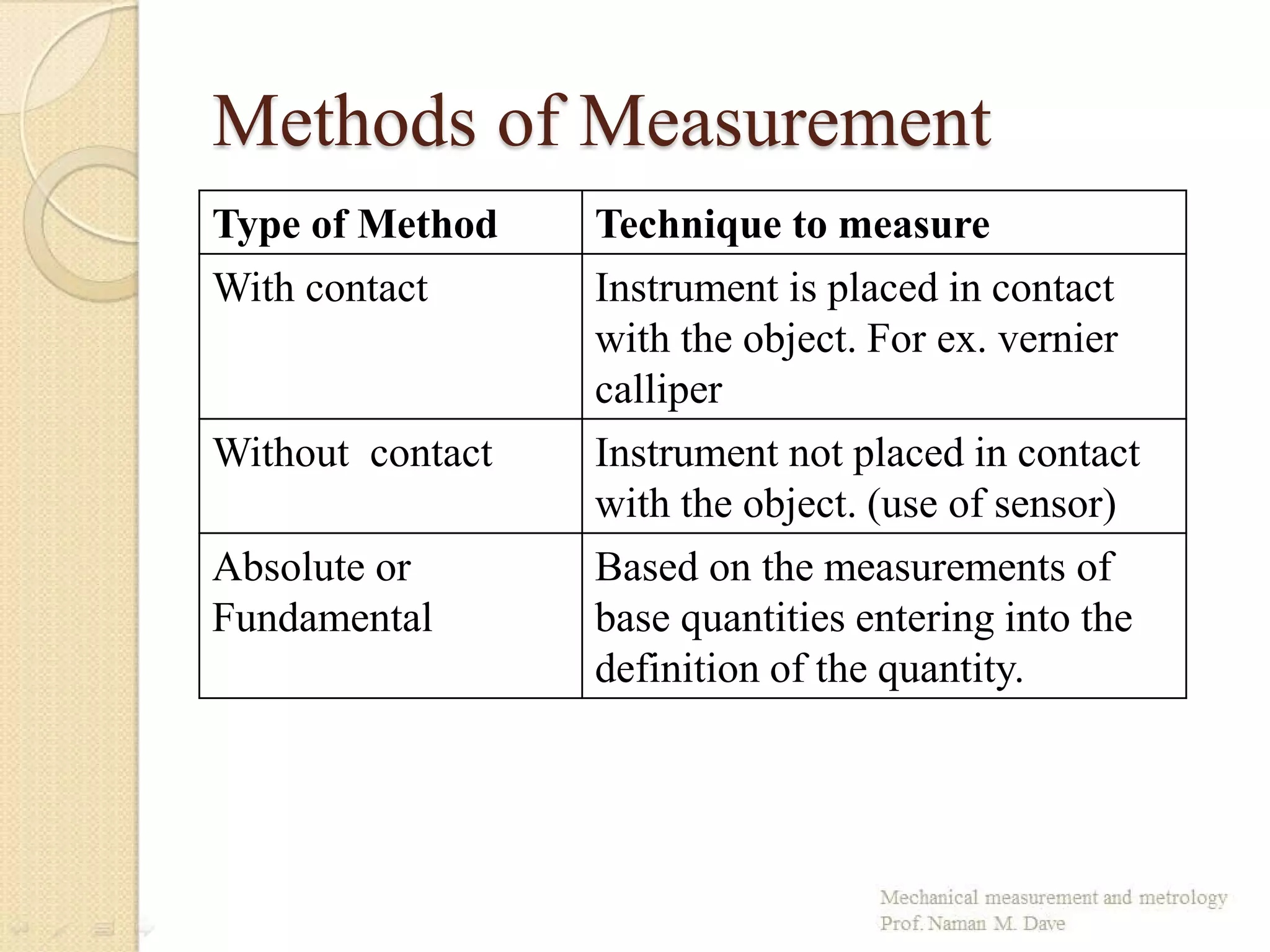

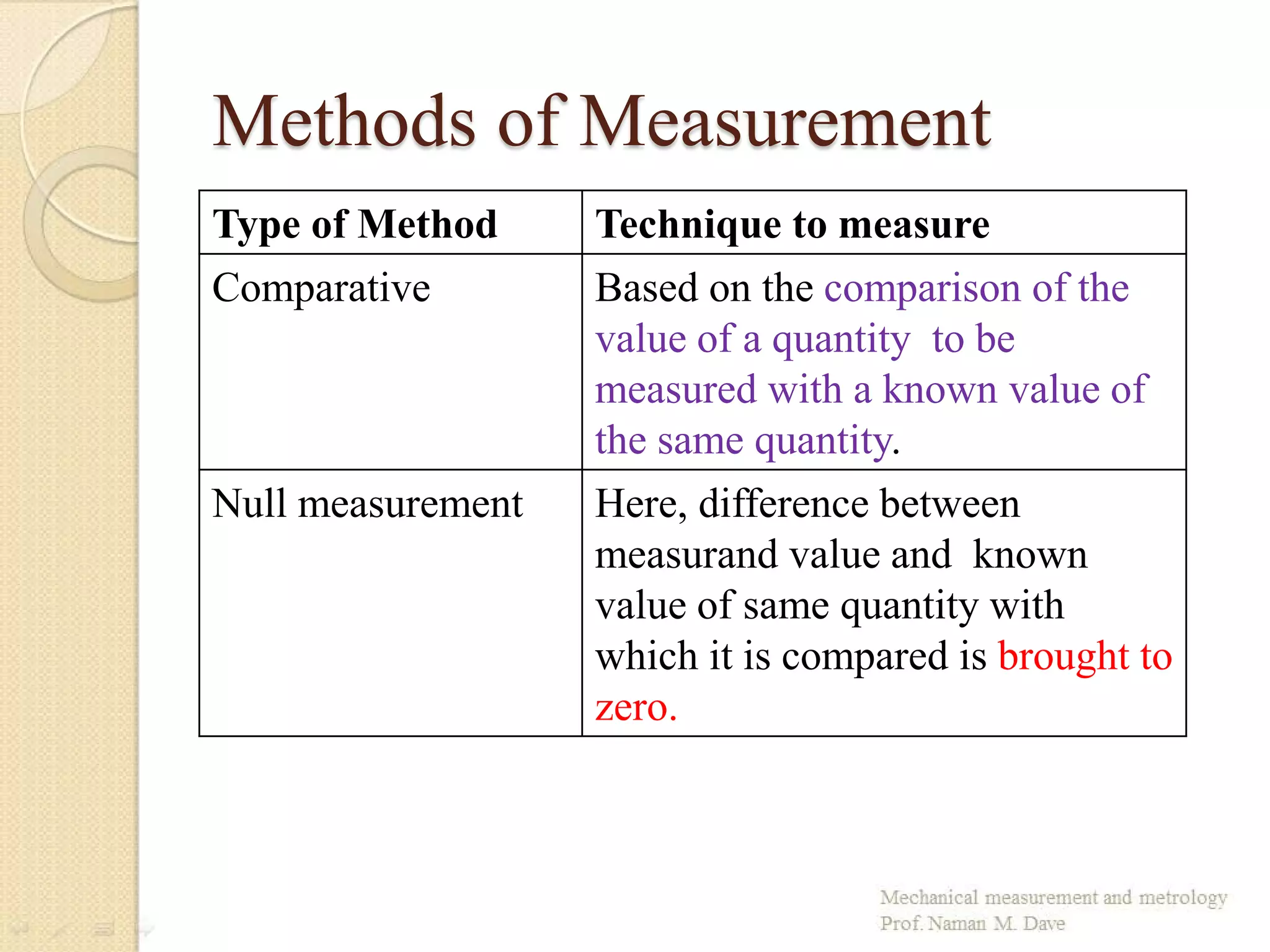

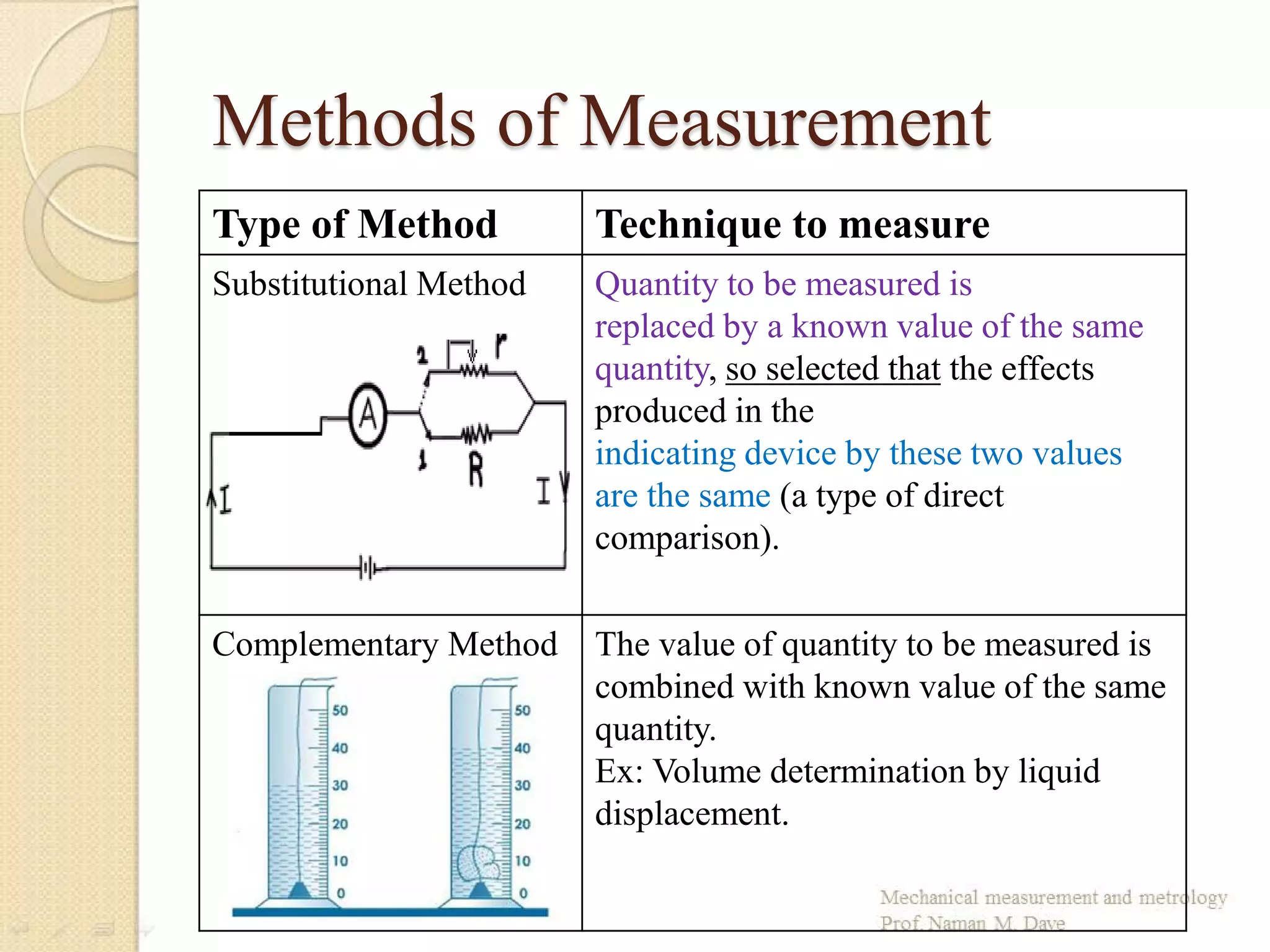

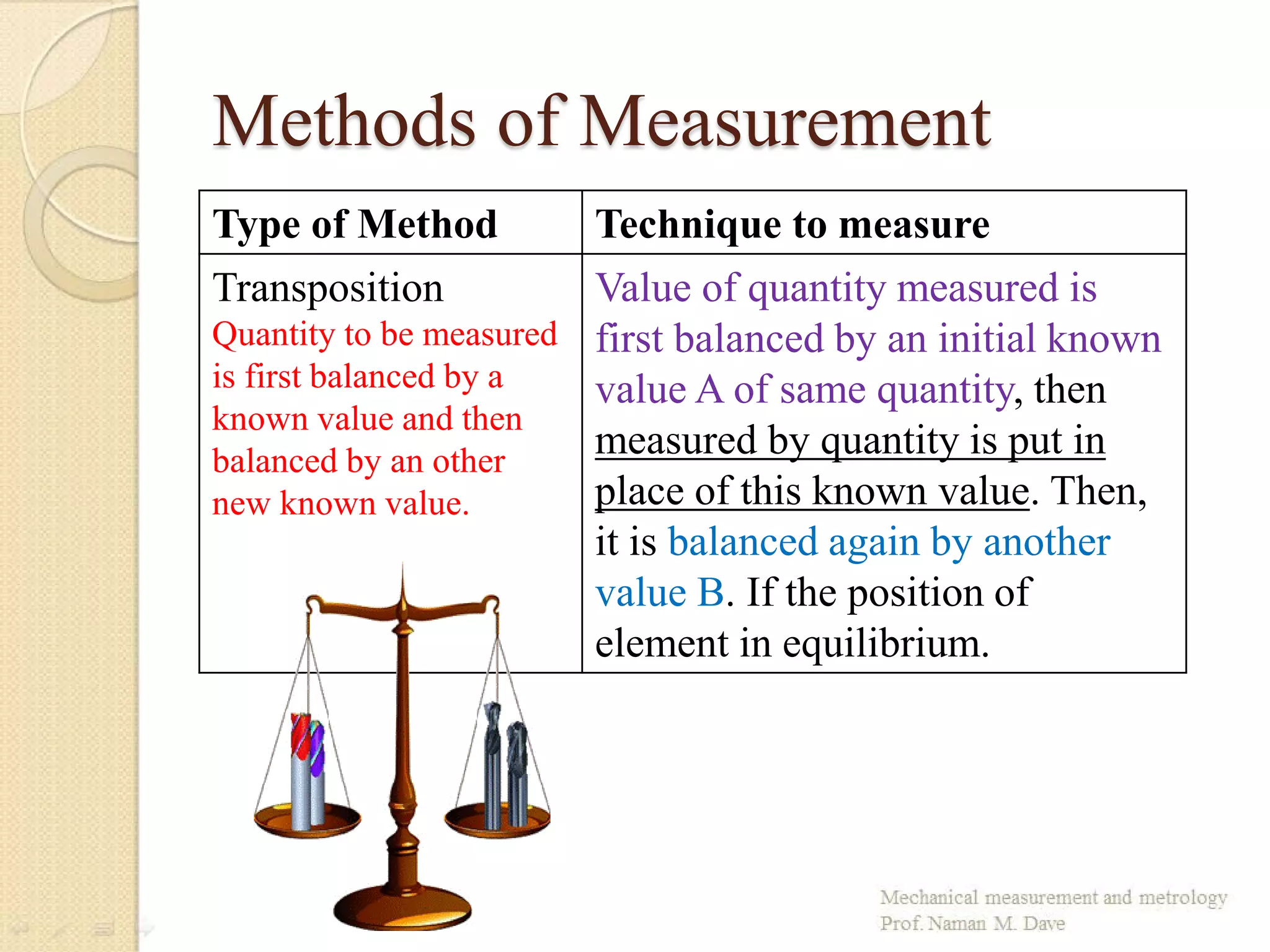

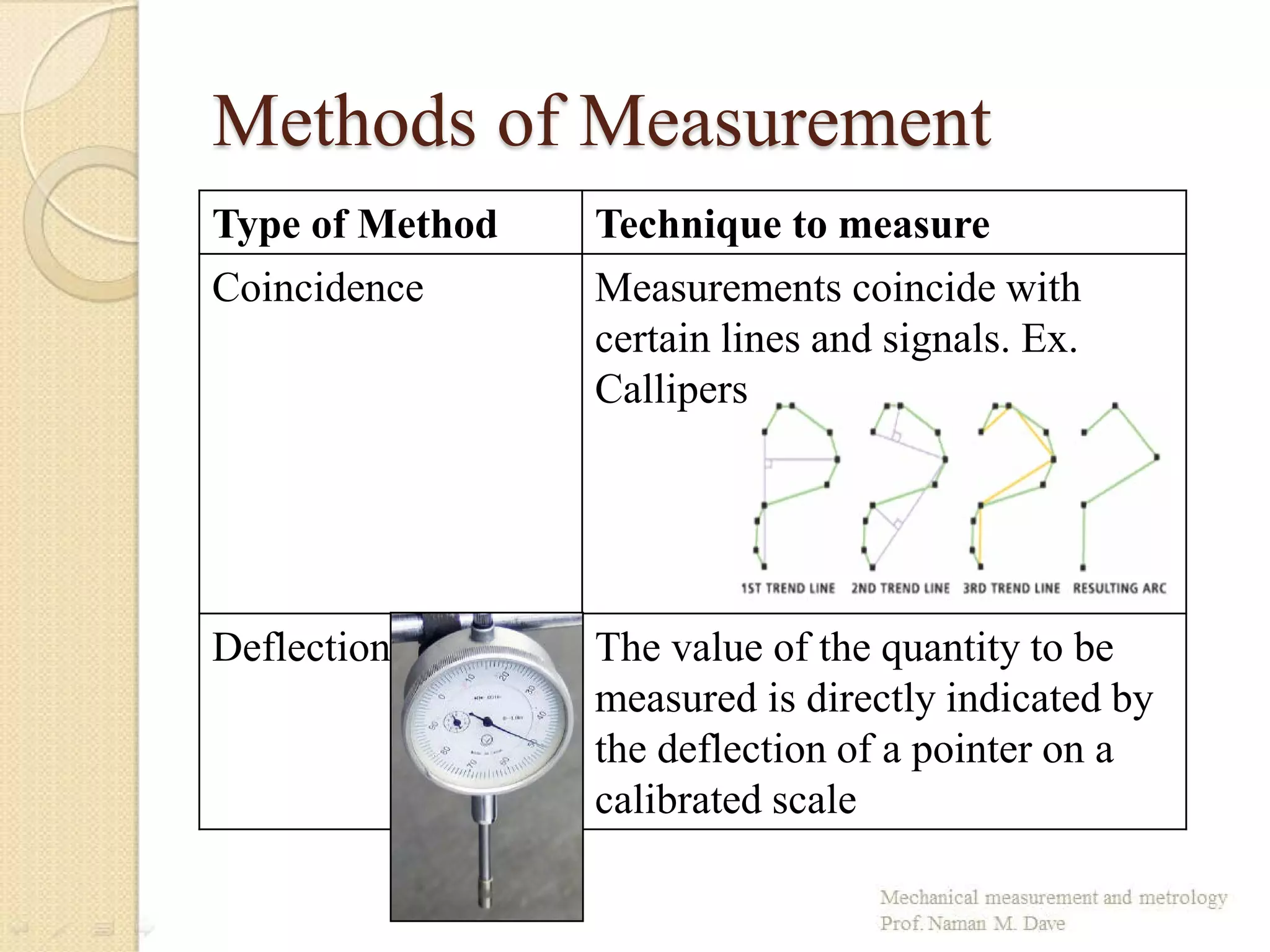

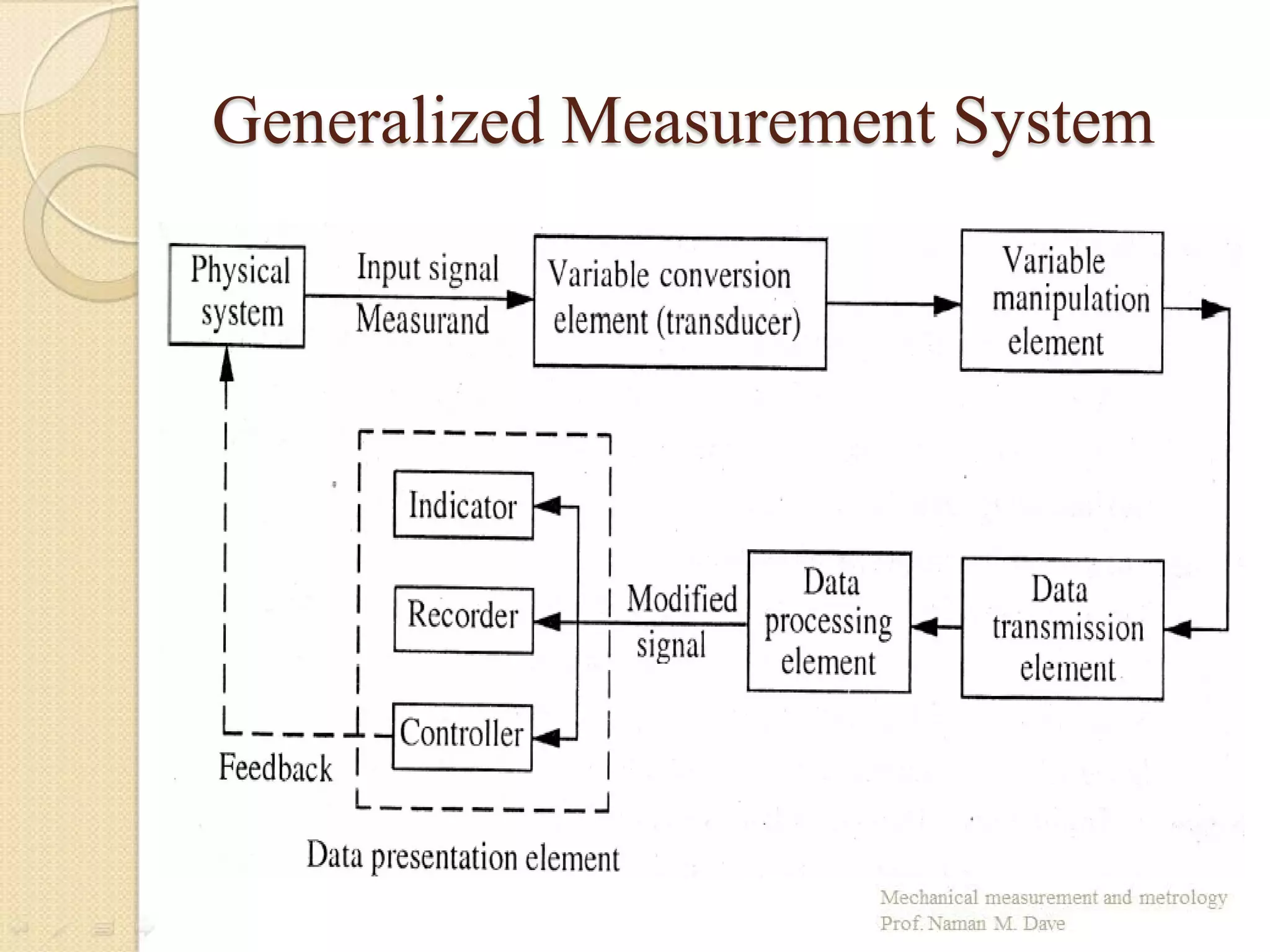

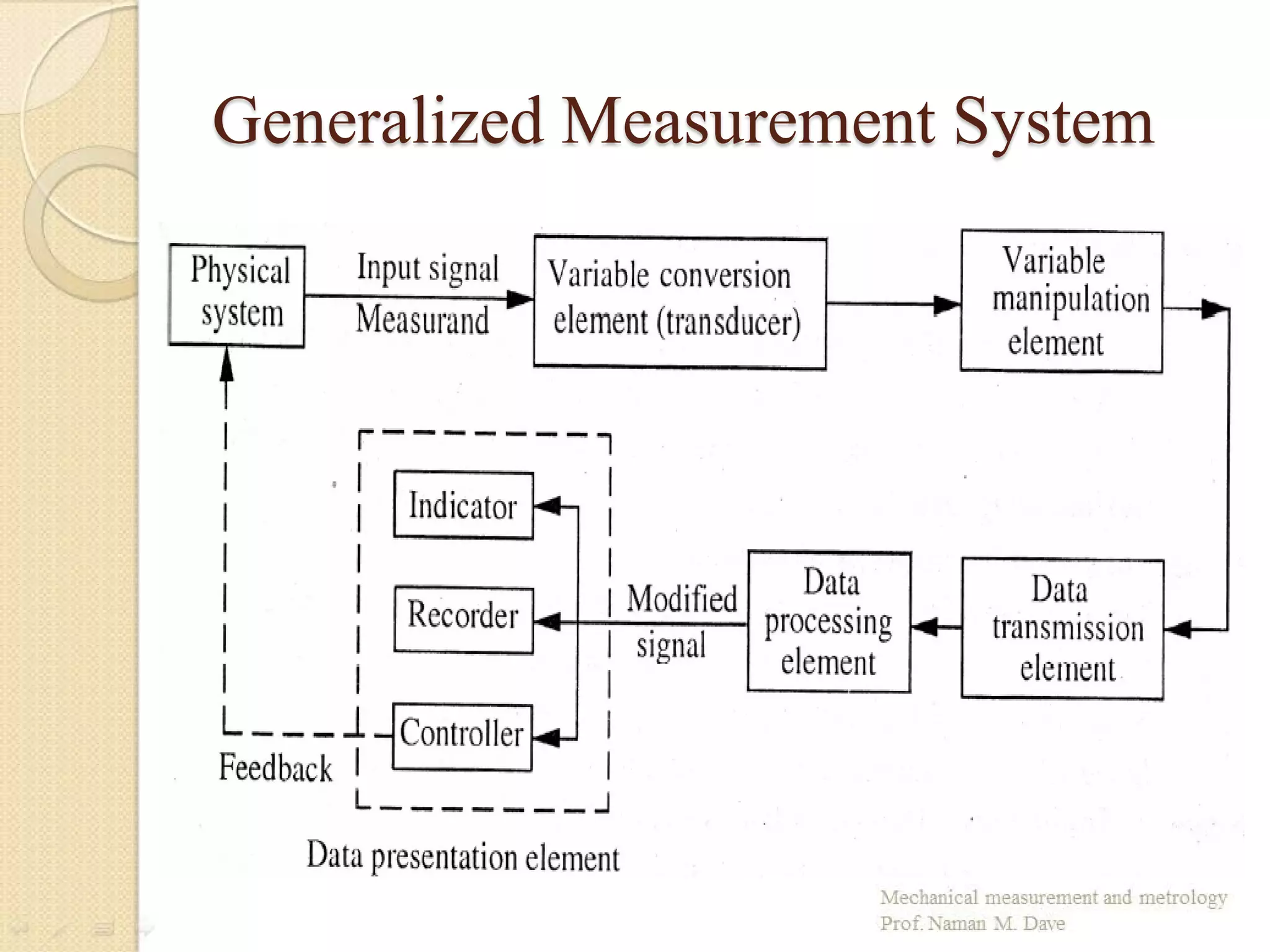

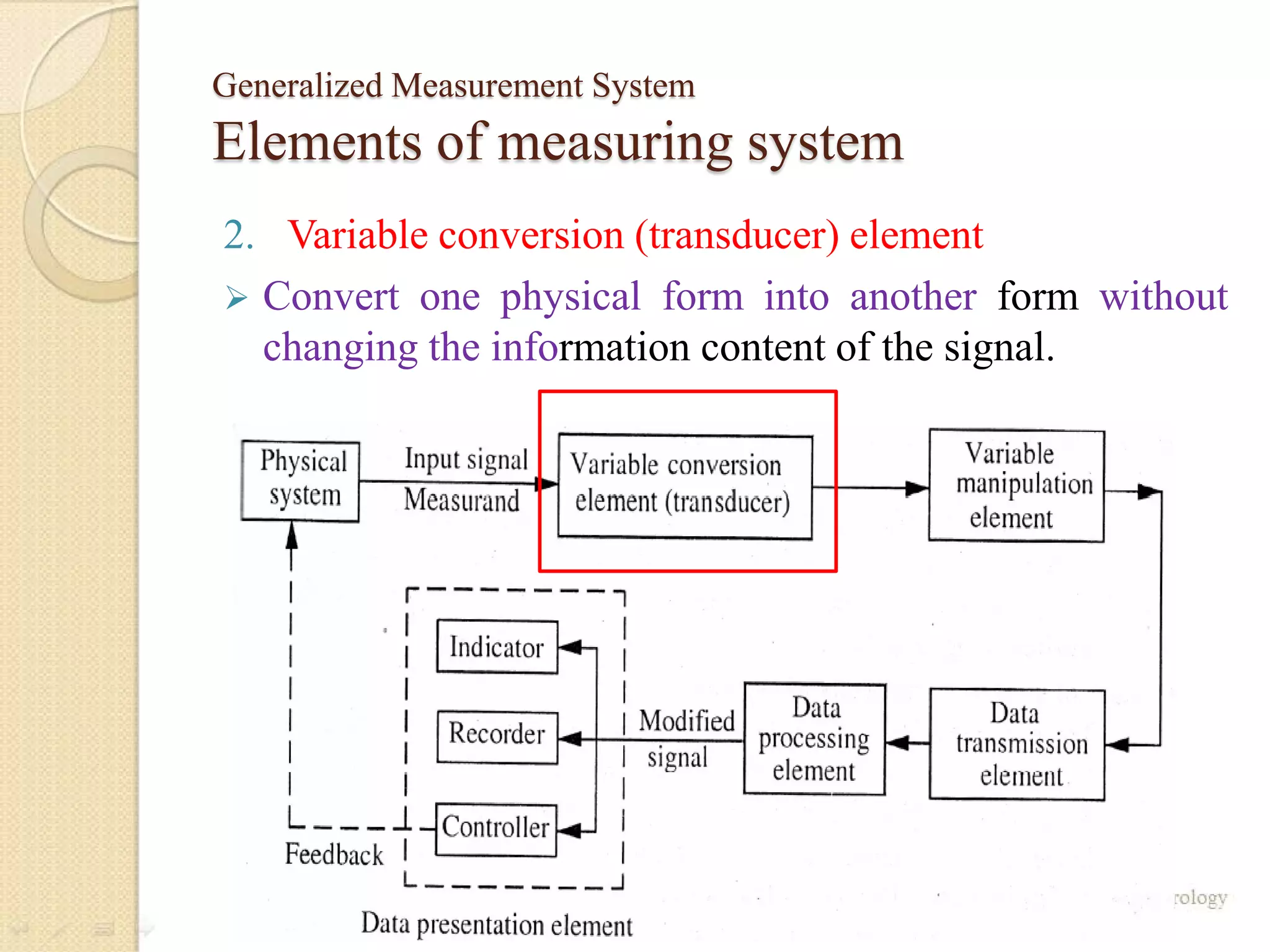

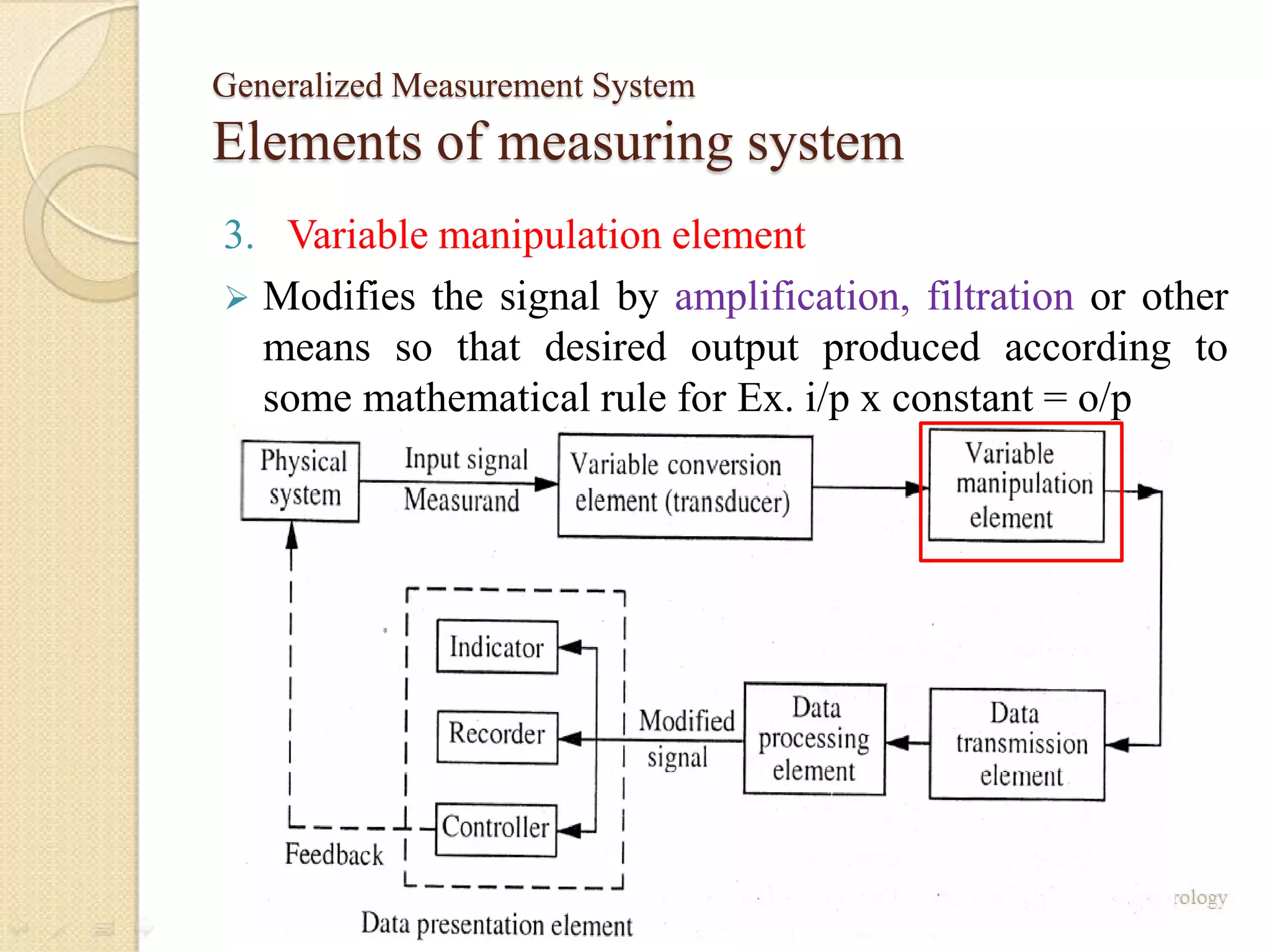

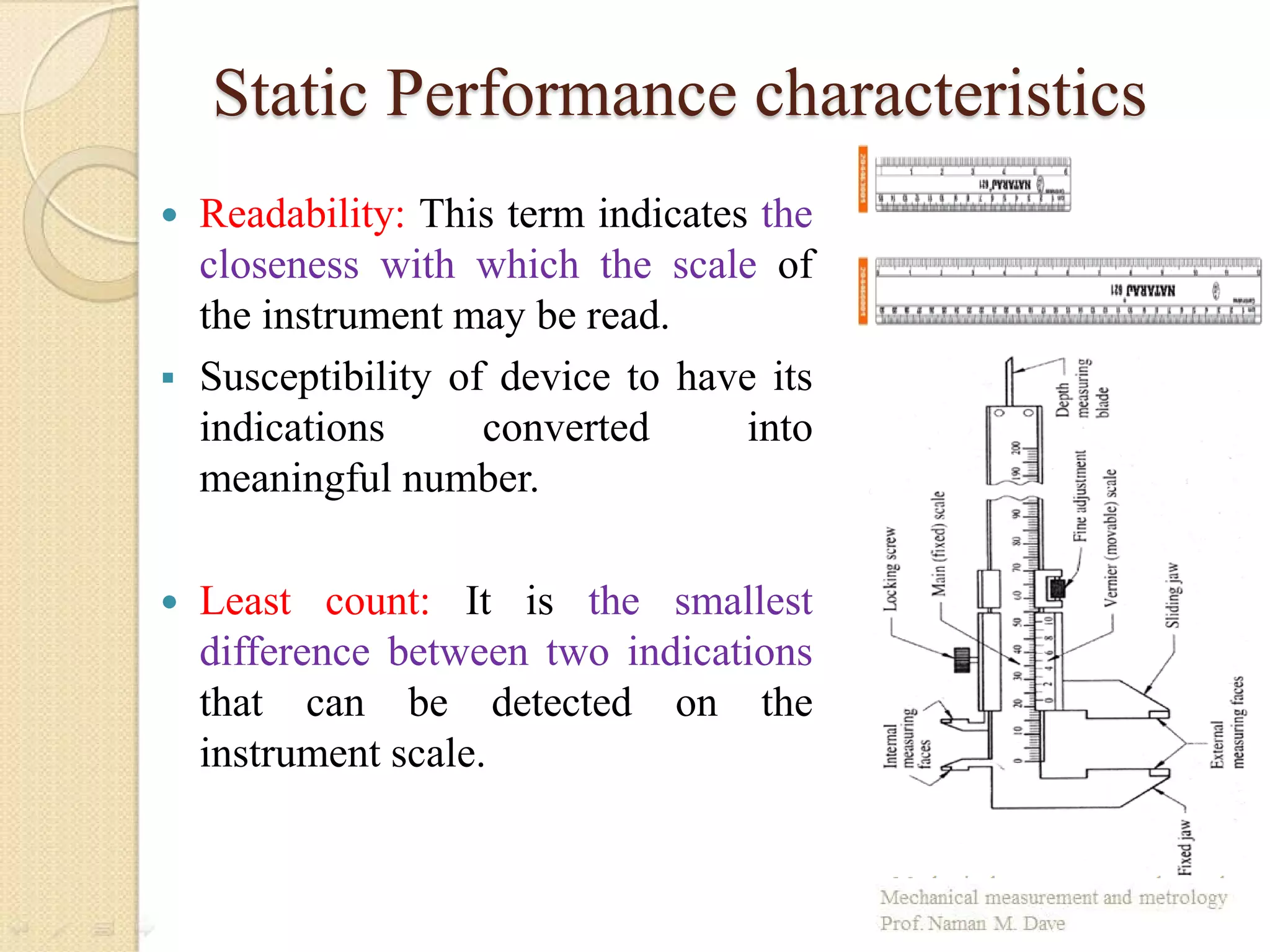

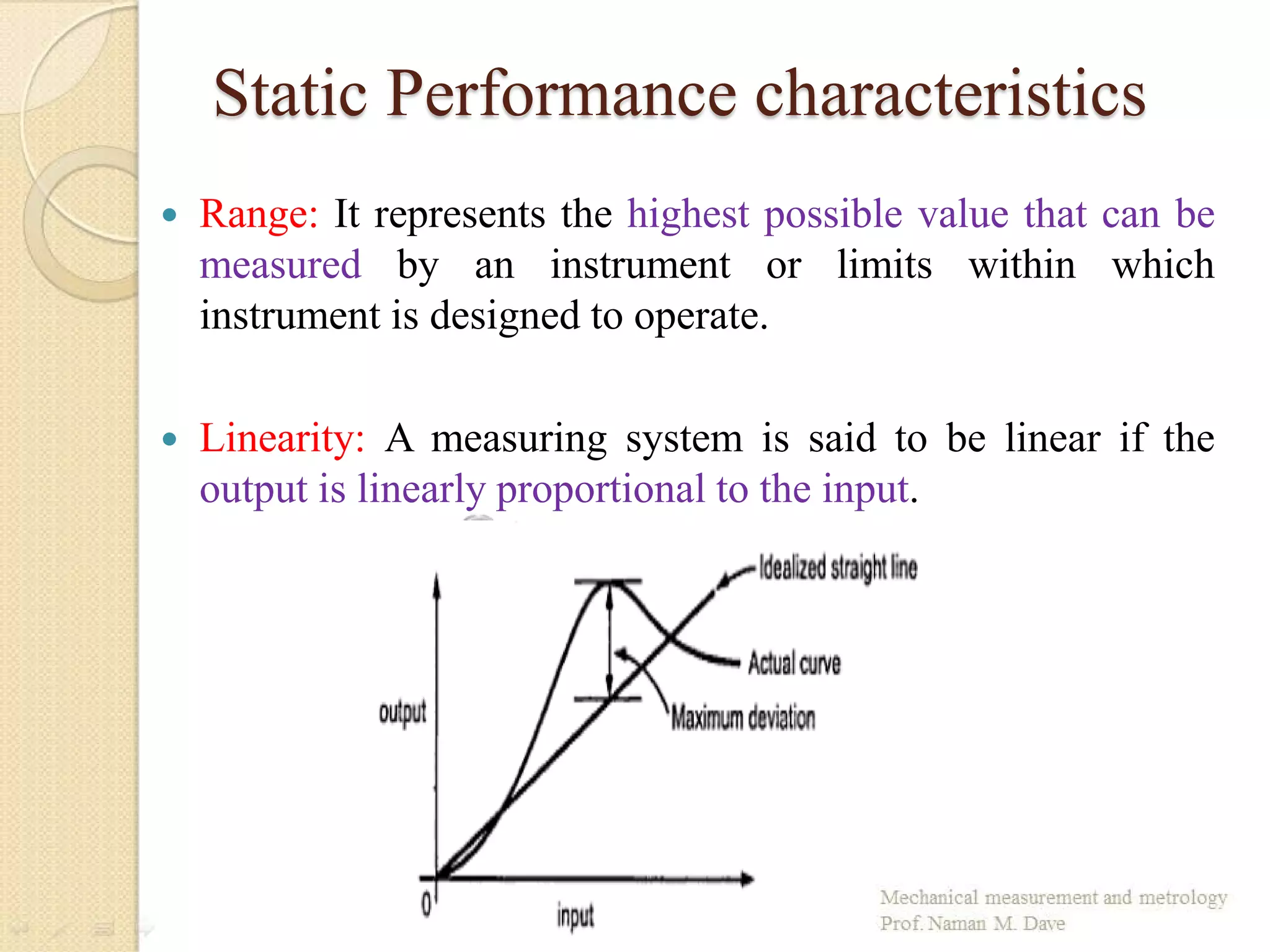

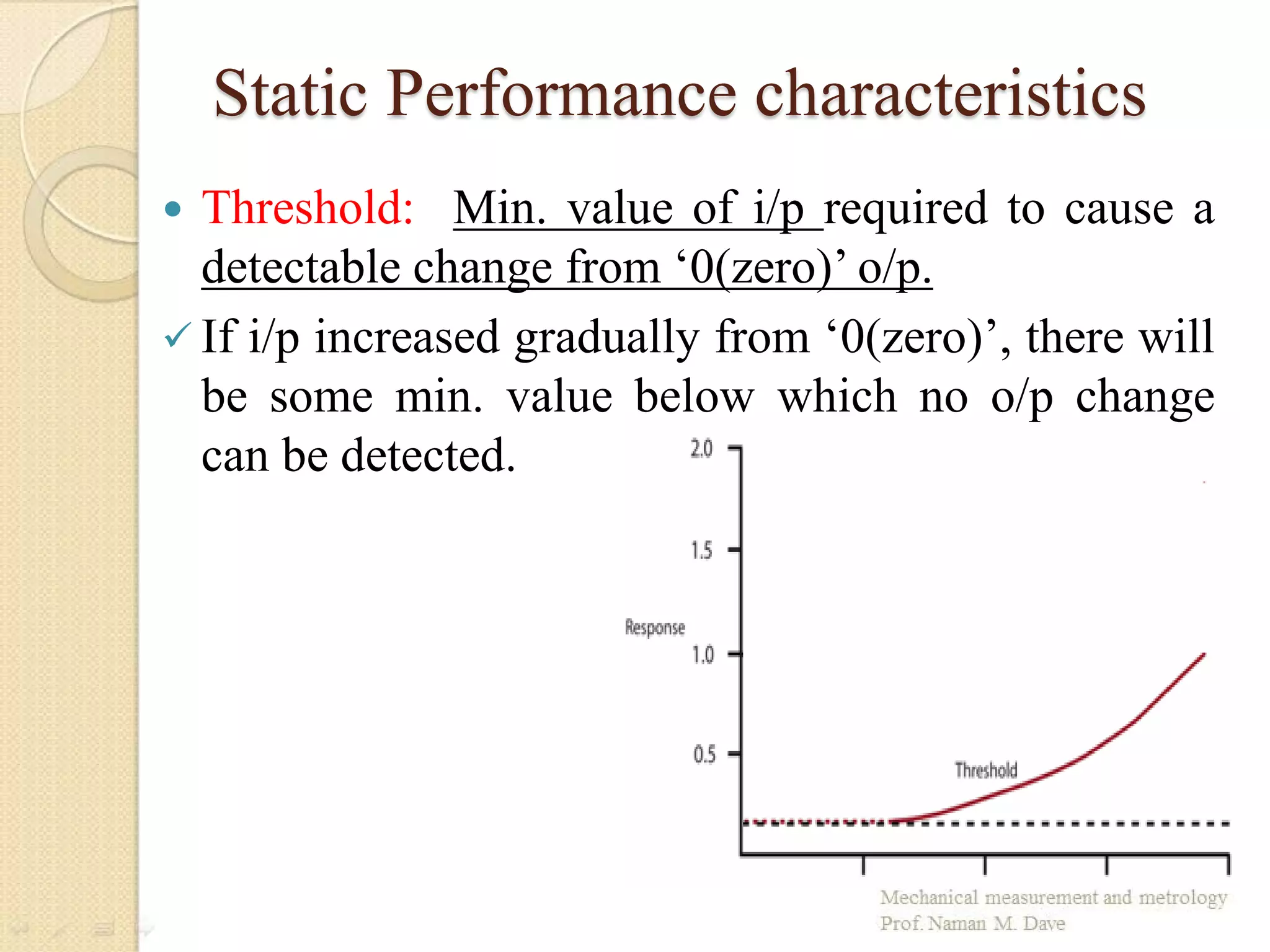

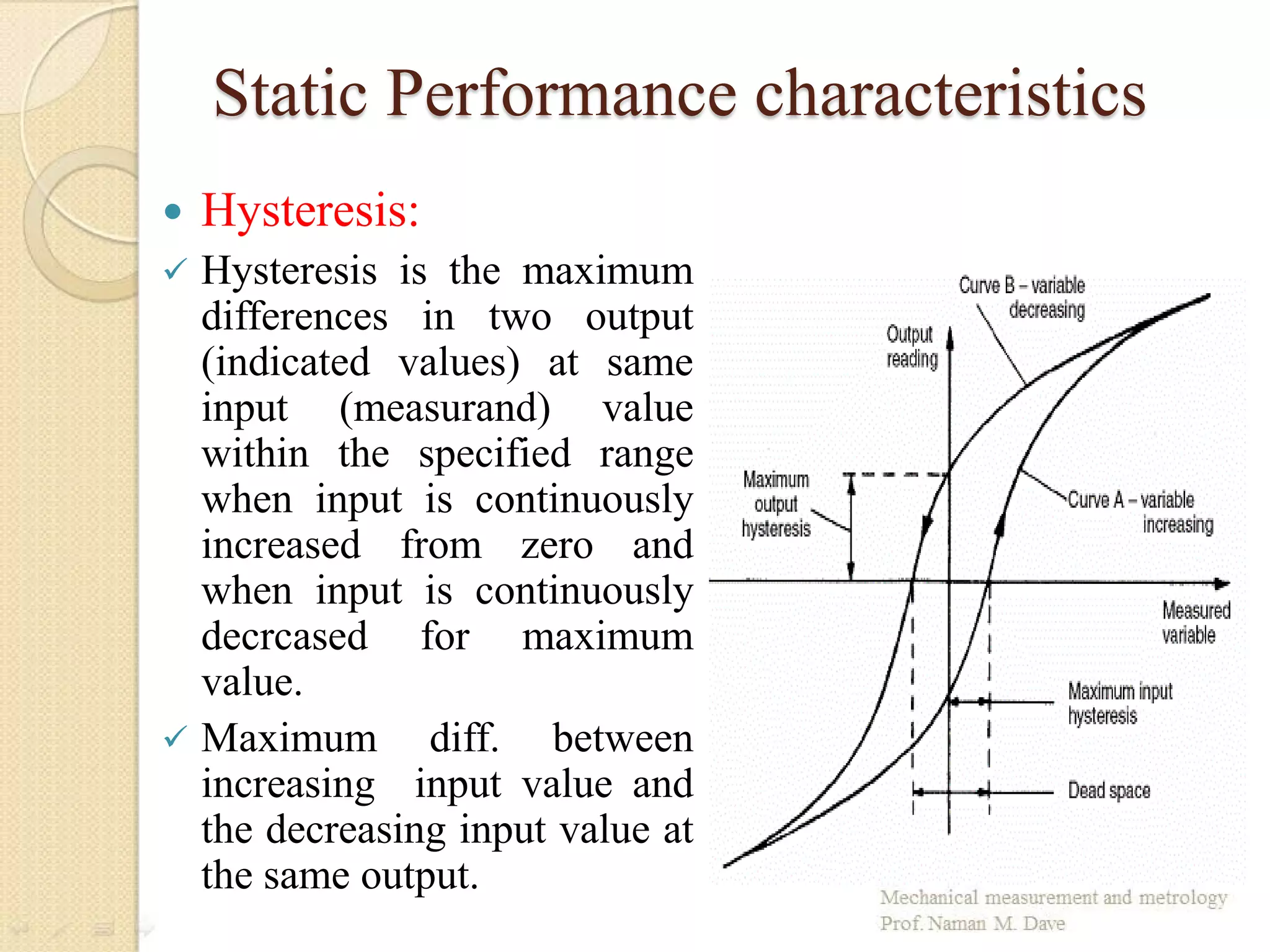

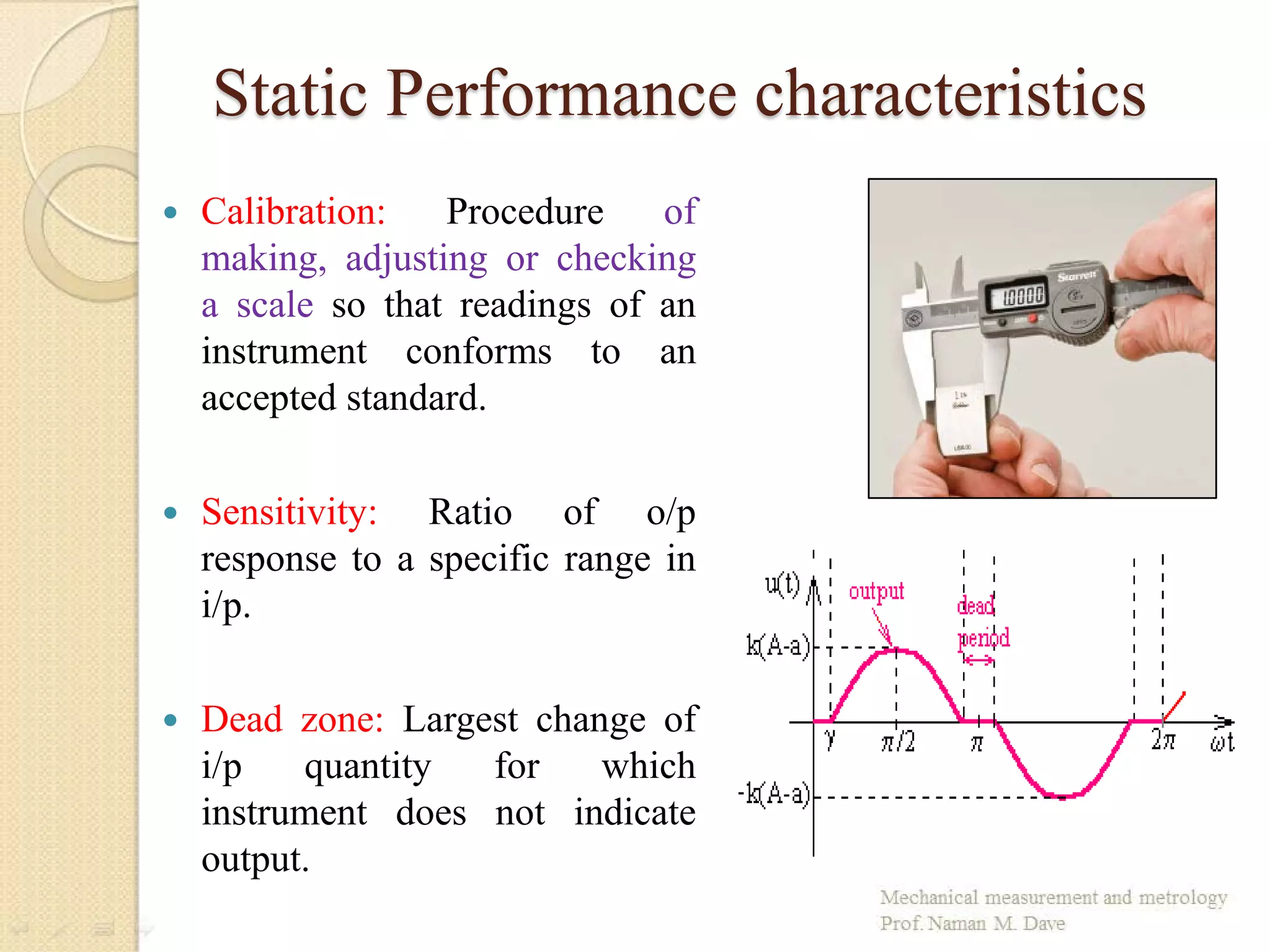

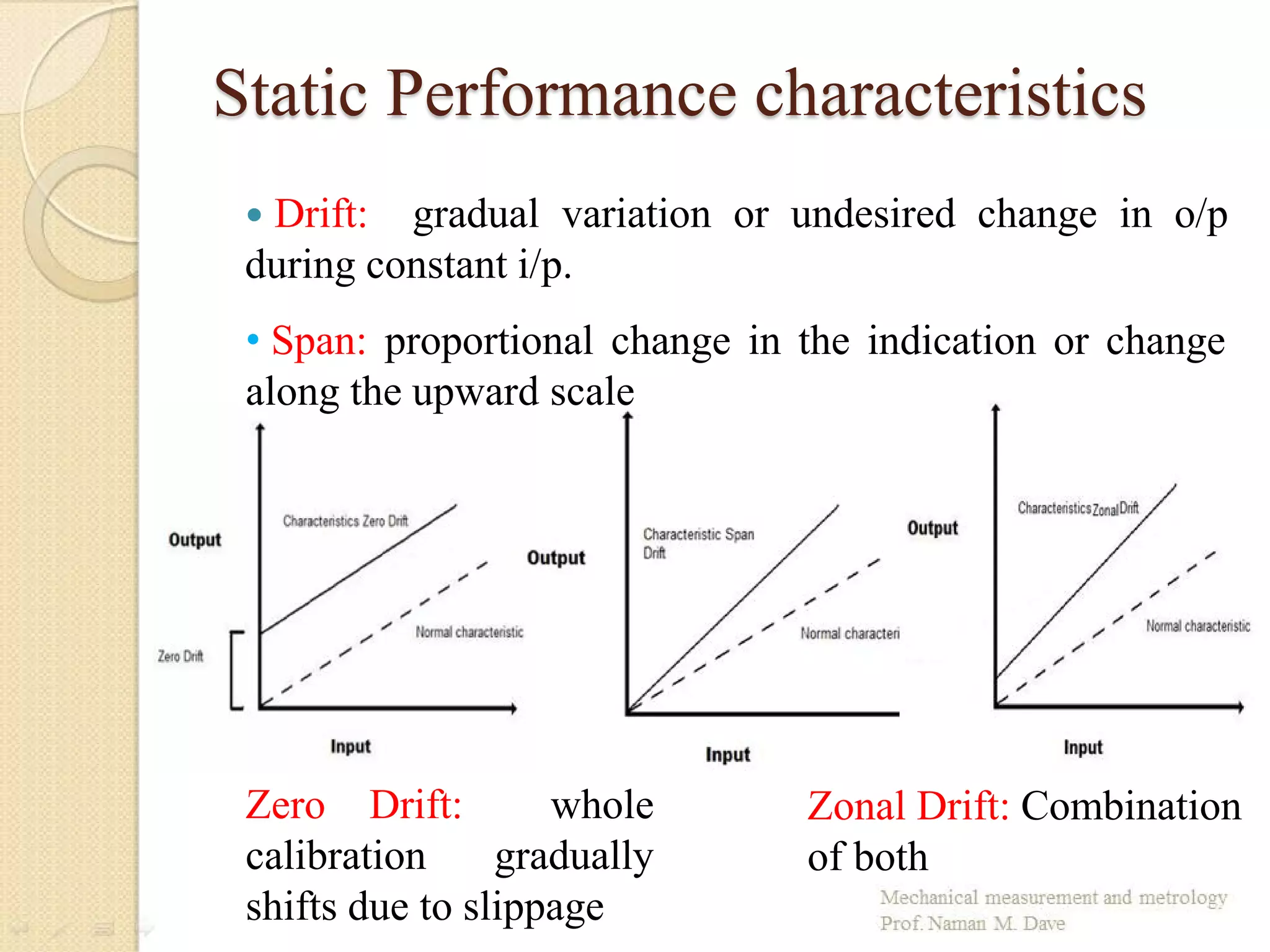

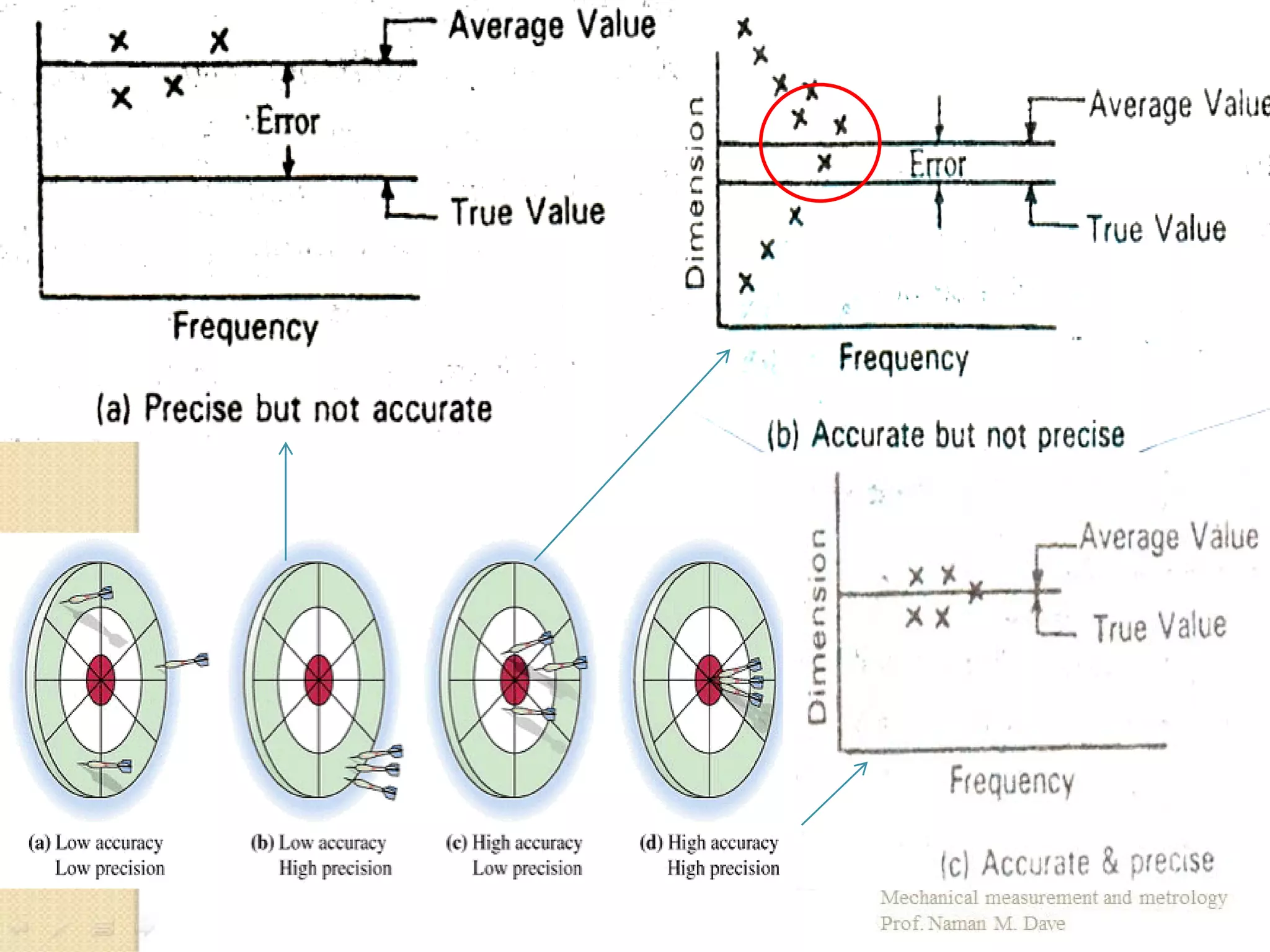

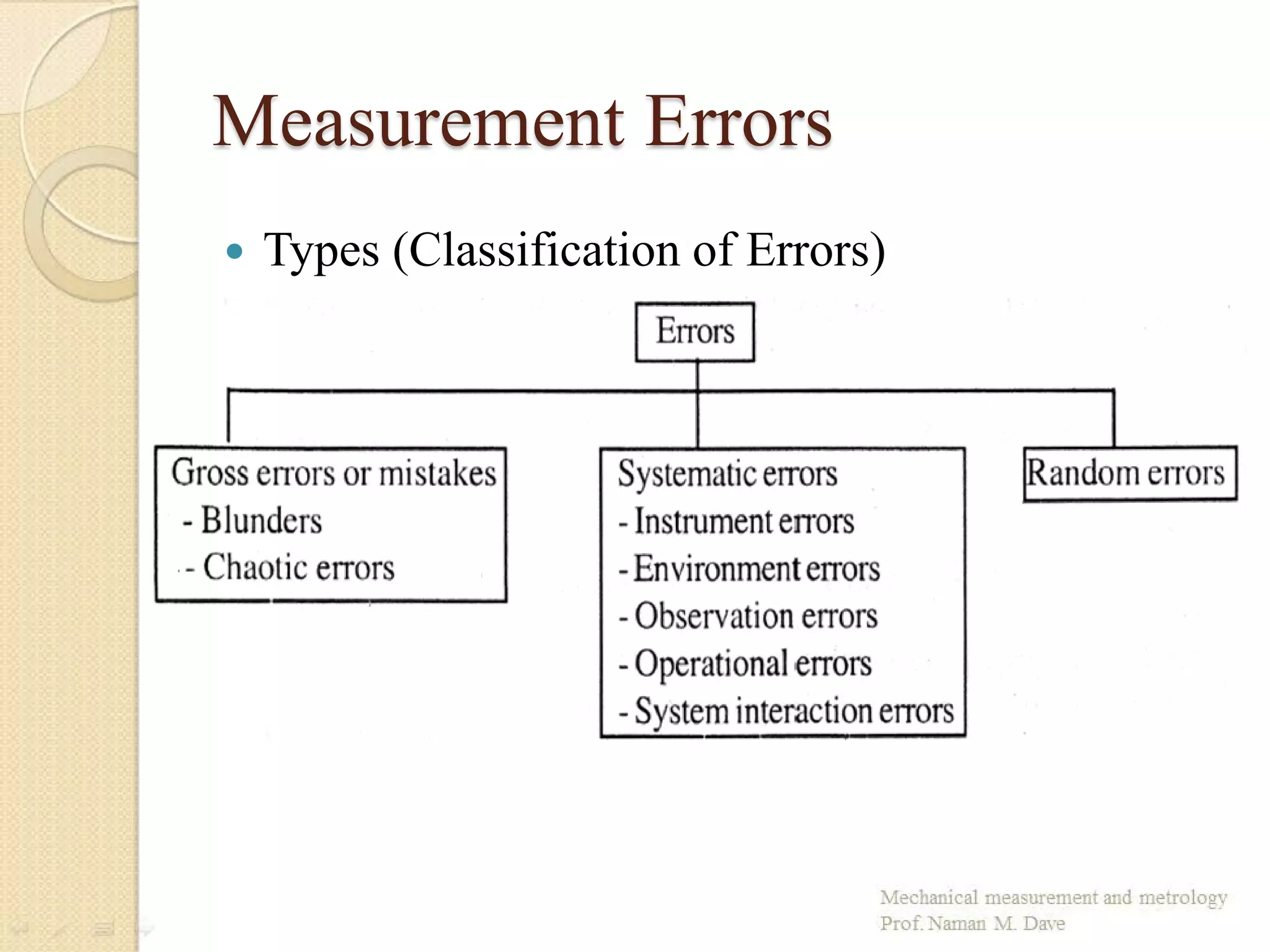

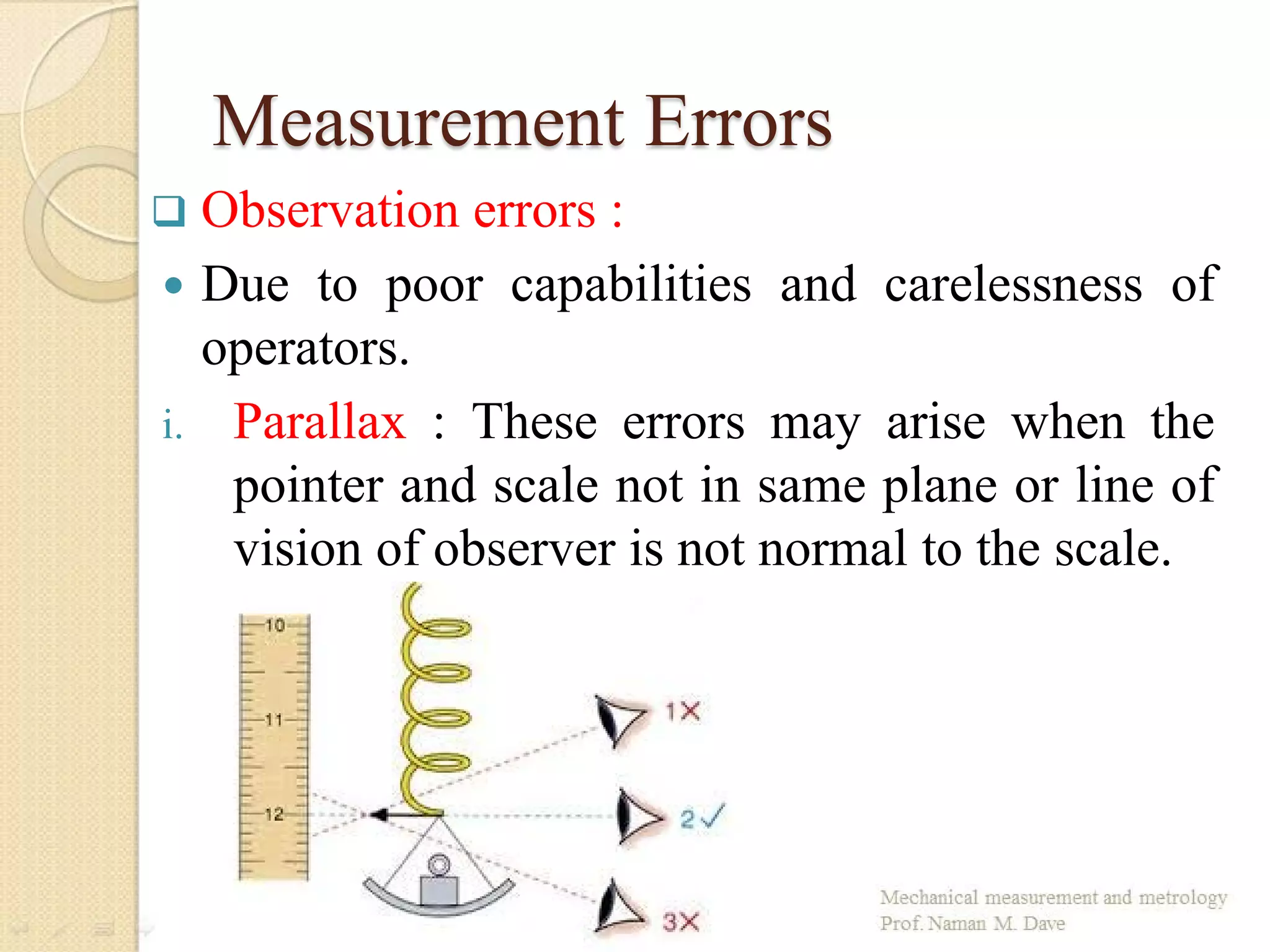

This document provides an overview of mechanical measurement and metrology, emphasizing the importance of accurate measurement in engineering. It discusses various modes, methods, and performance characteristics of measurement systems, including types of errors that can occur. Additionally, it outlines the objectives of metrology and the significance of maintaining measurement accuracy to ensure product quality and customer satisfaction.