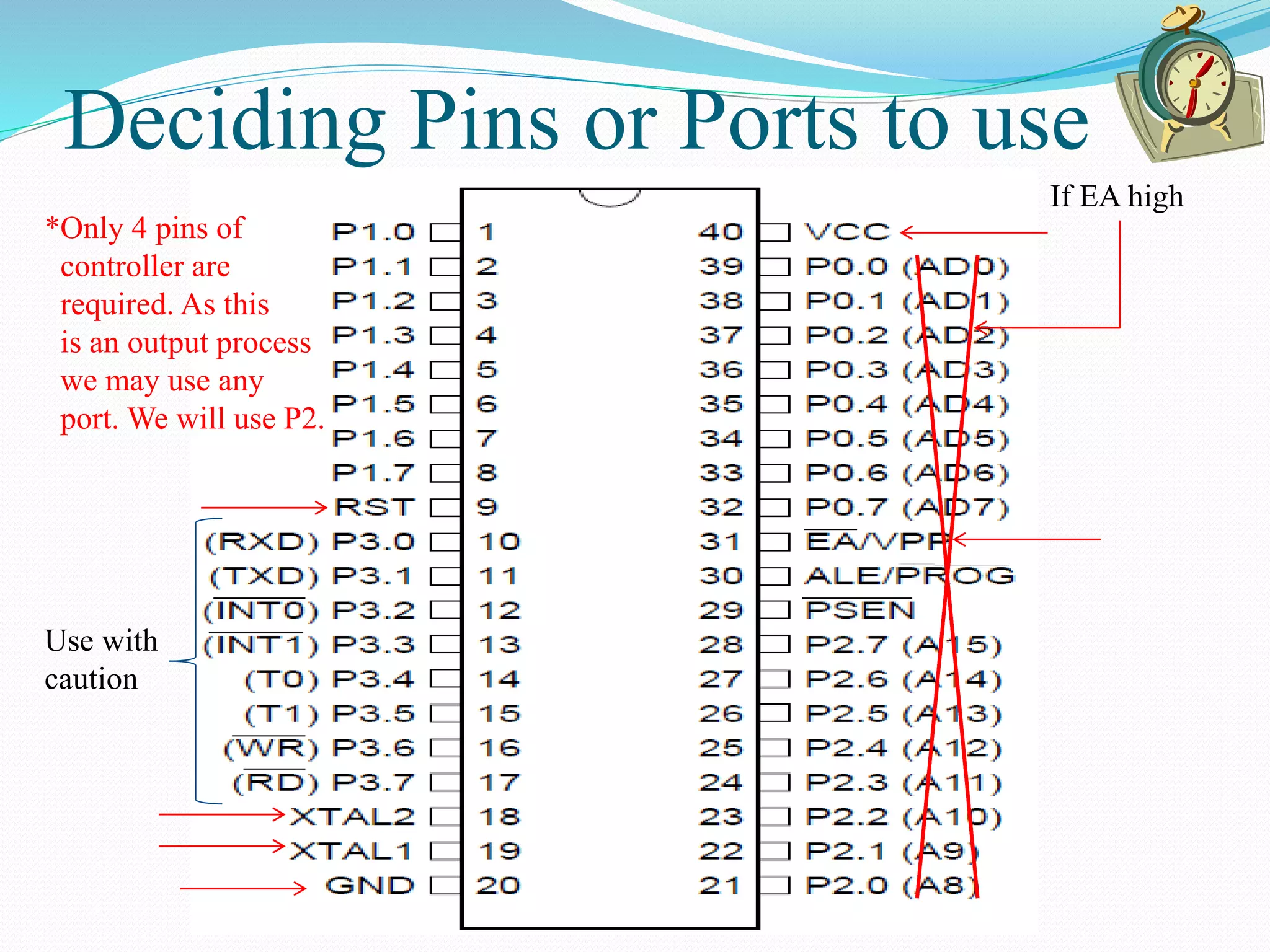

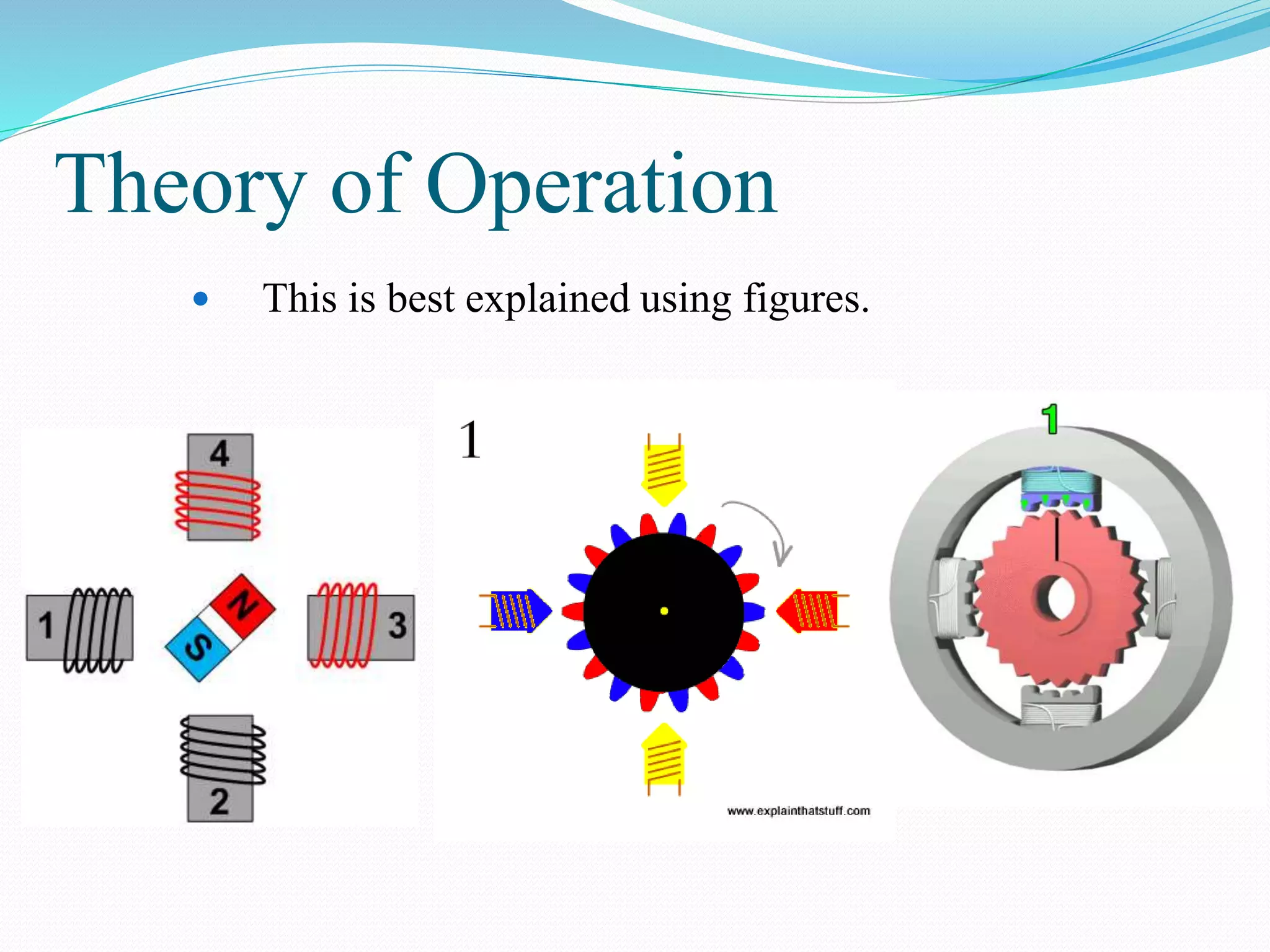

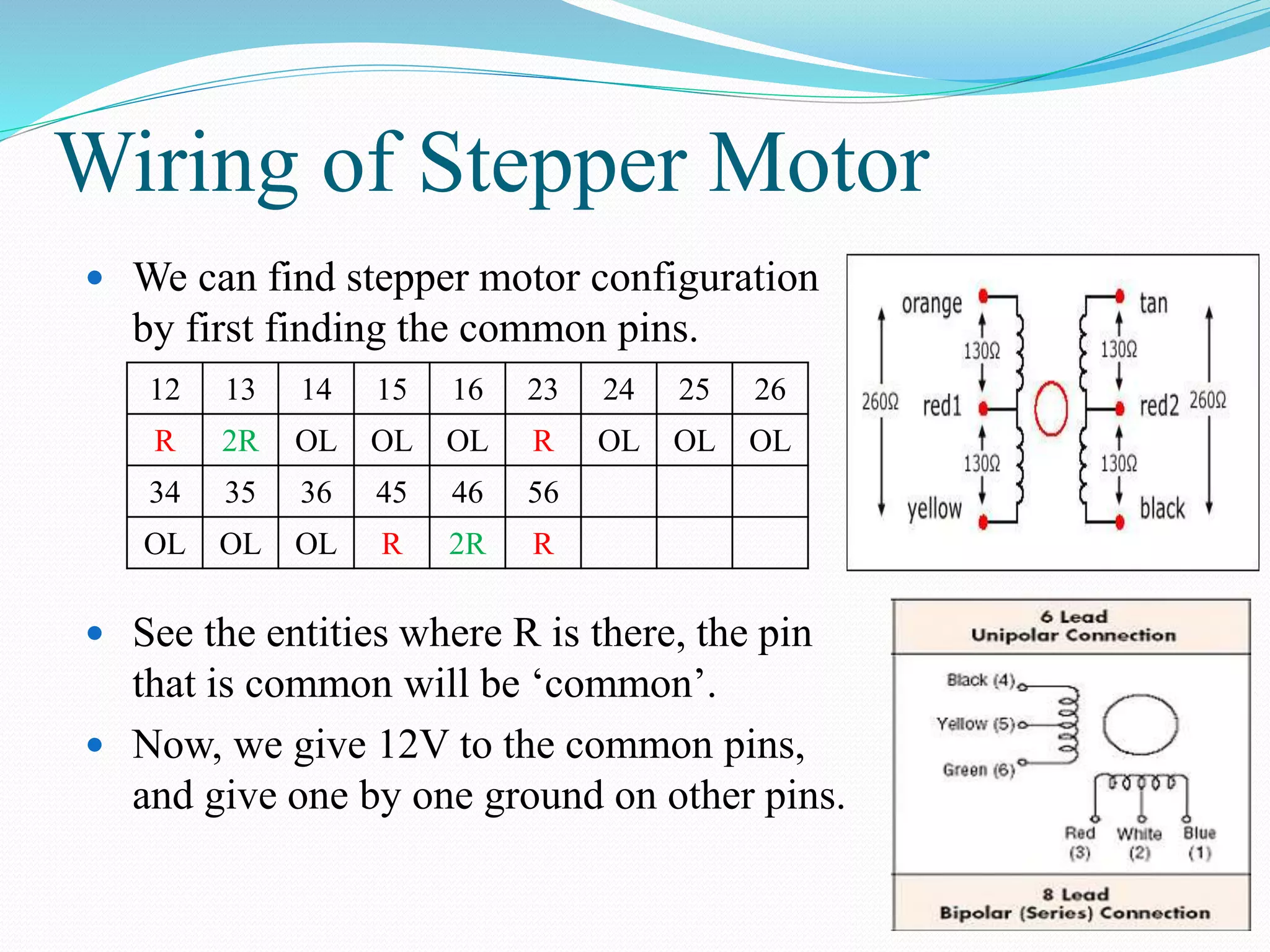

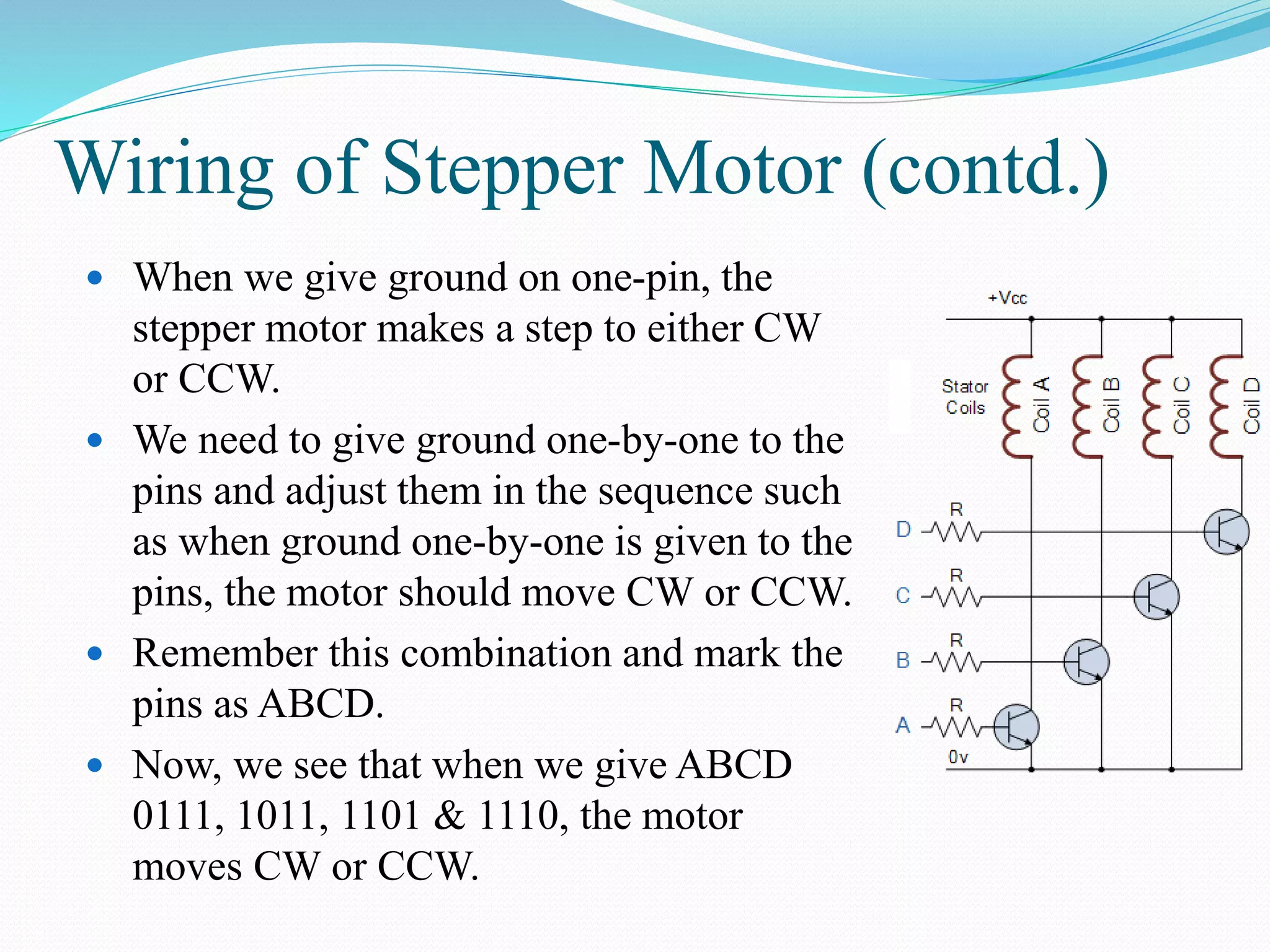

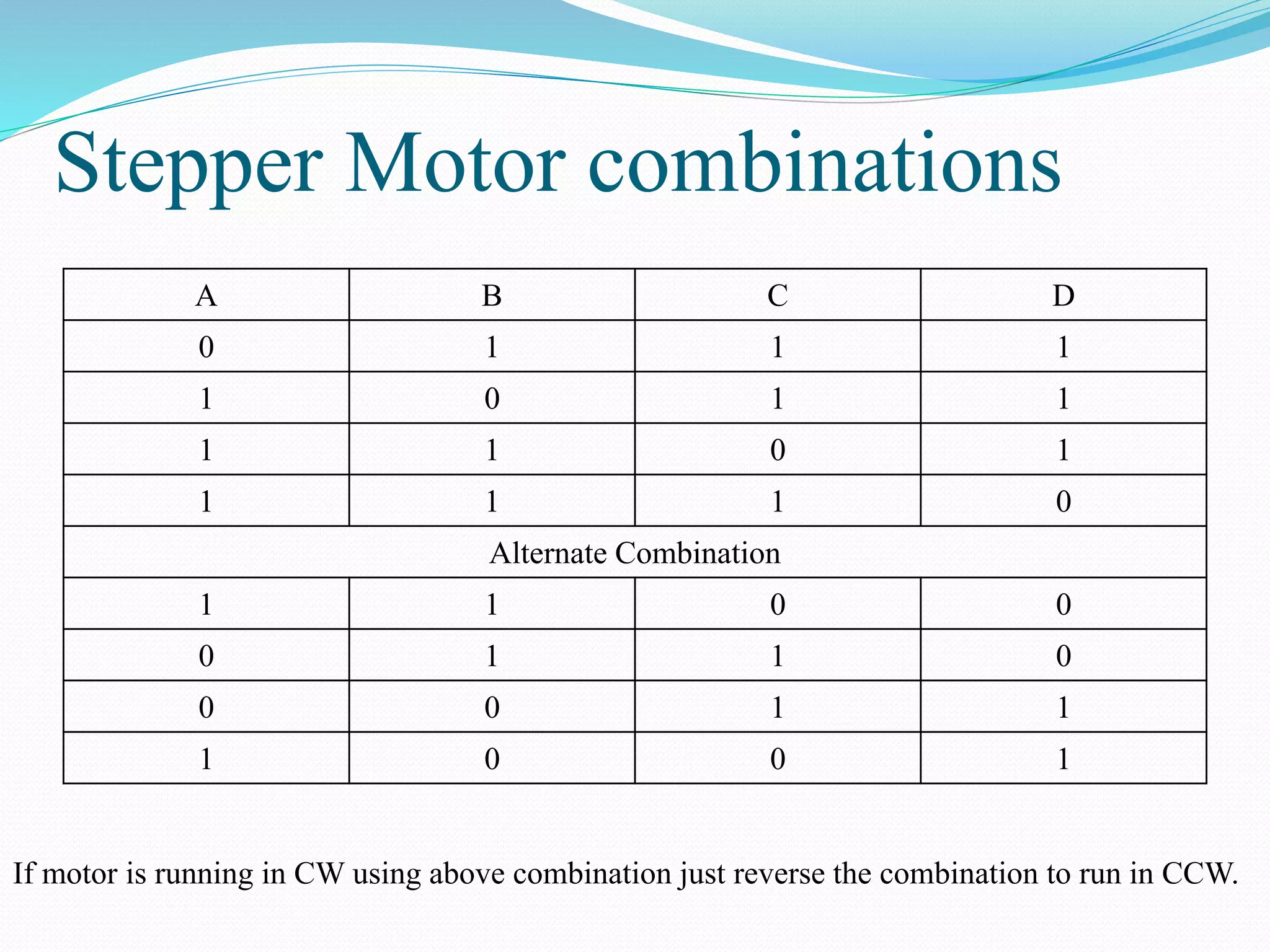

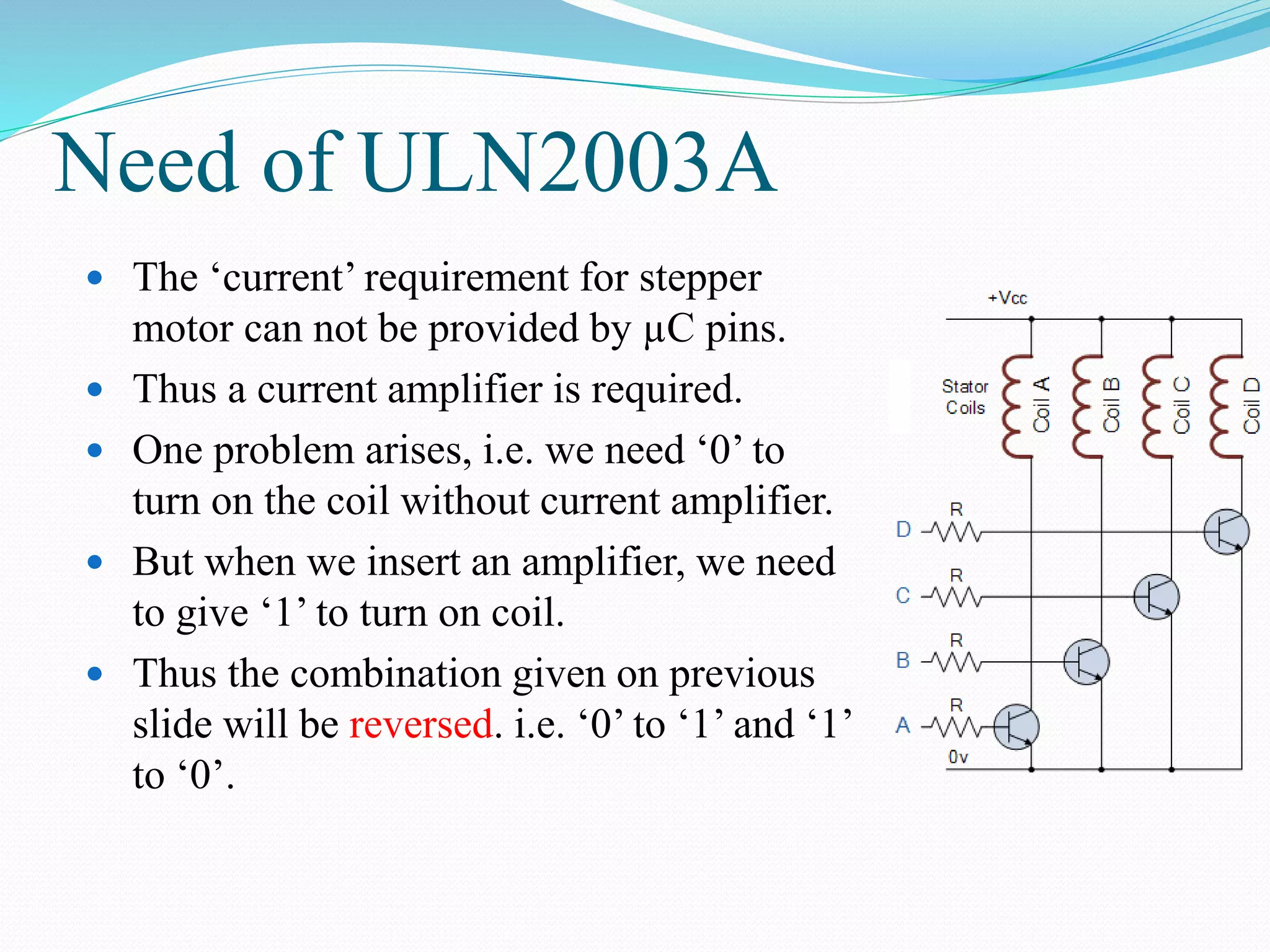

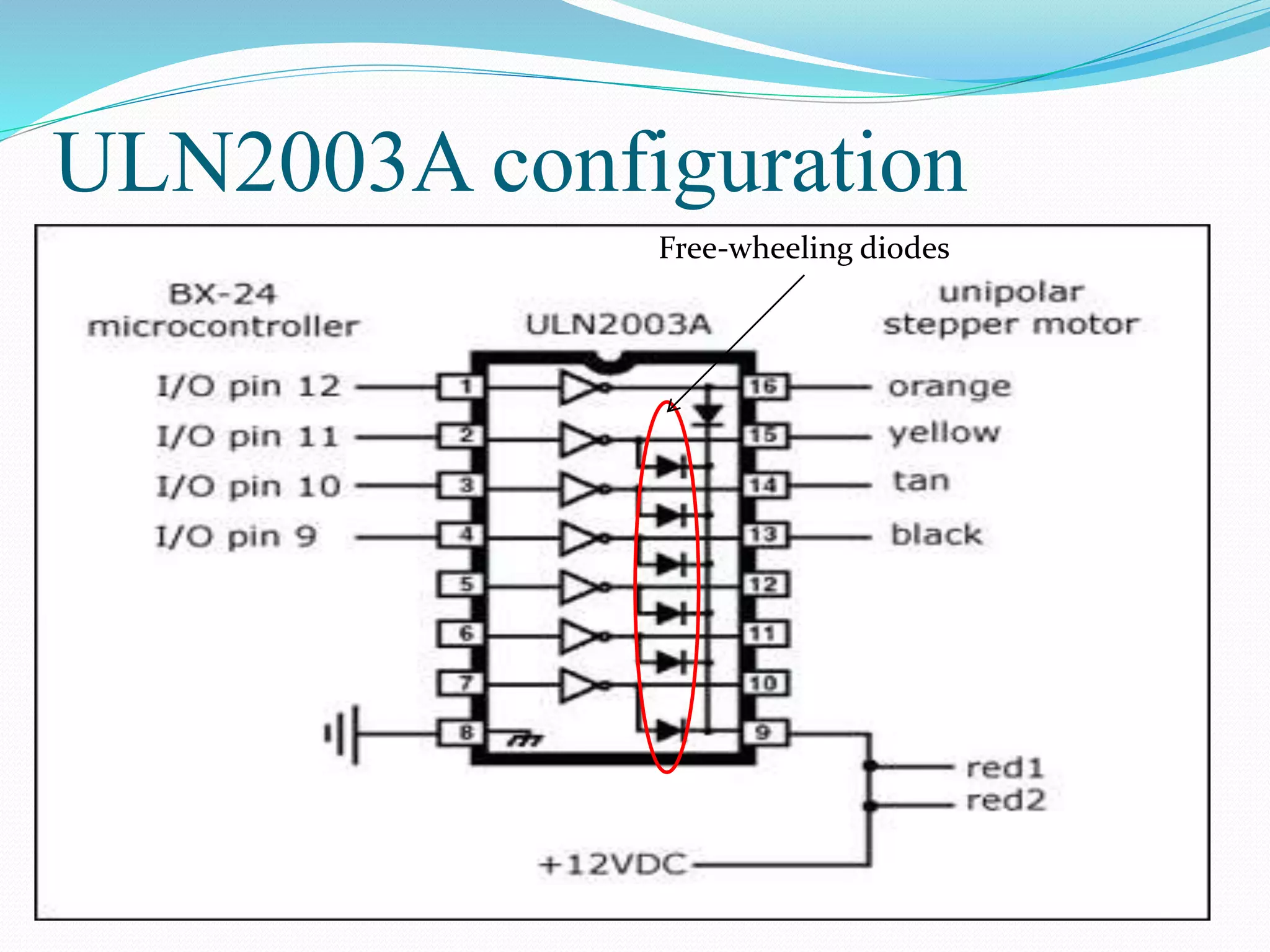

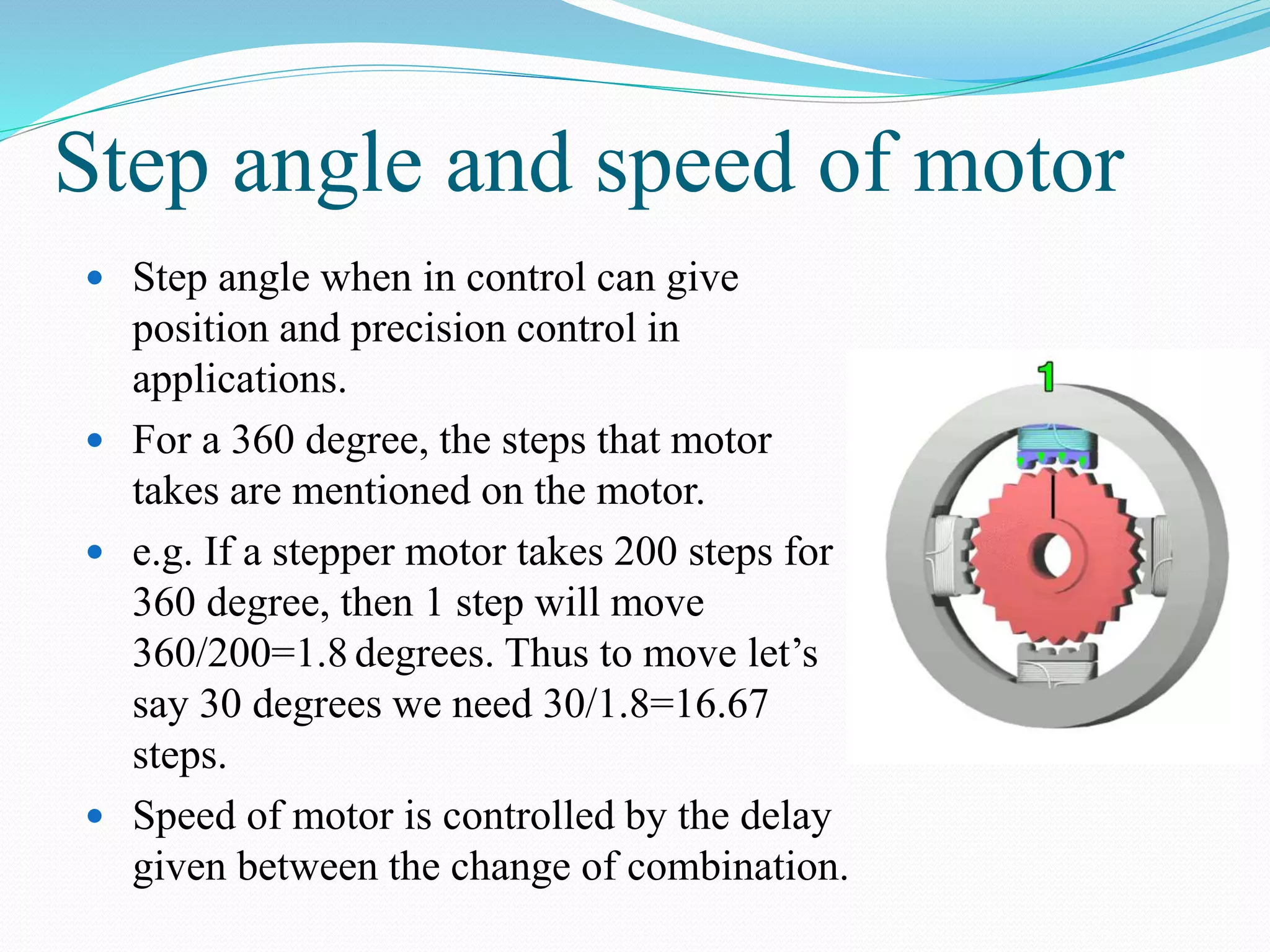

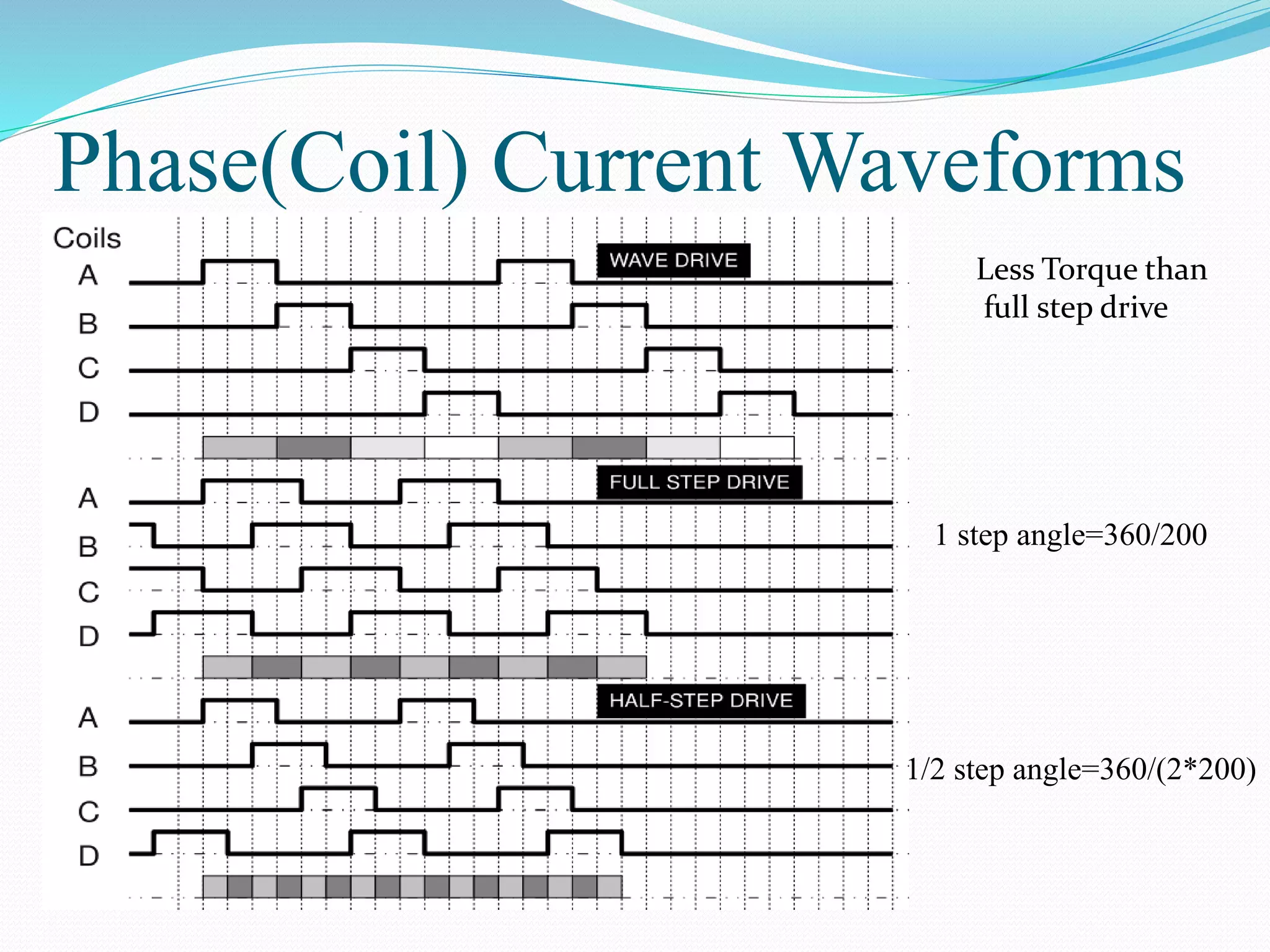

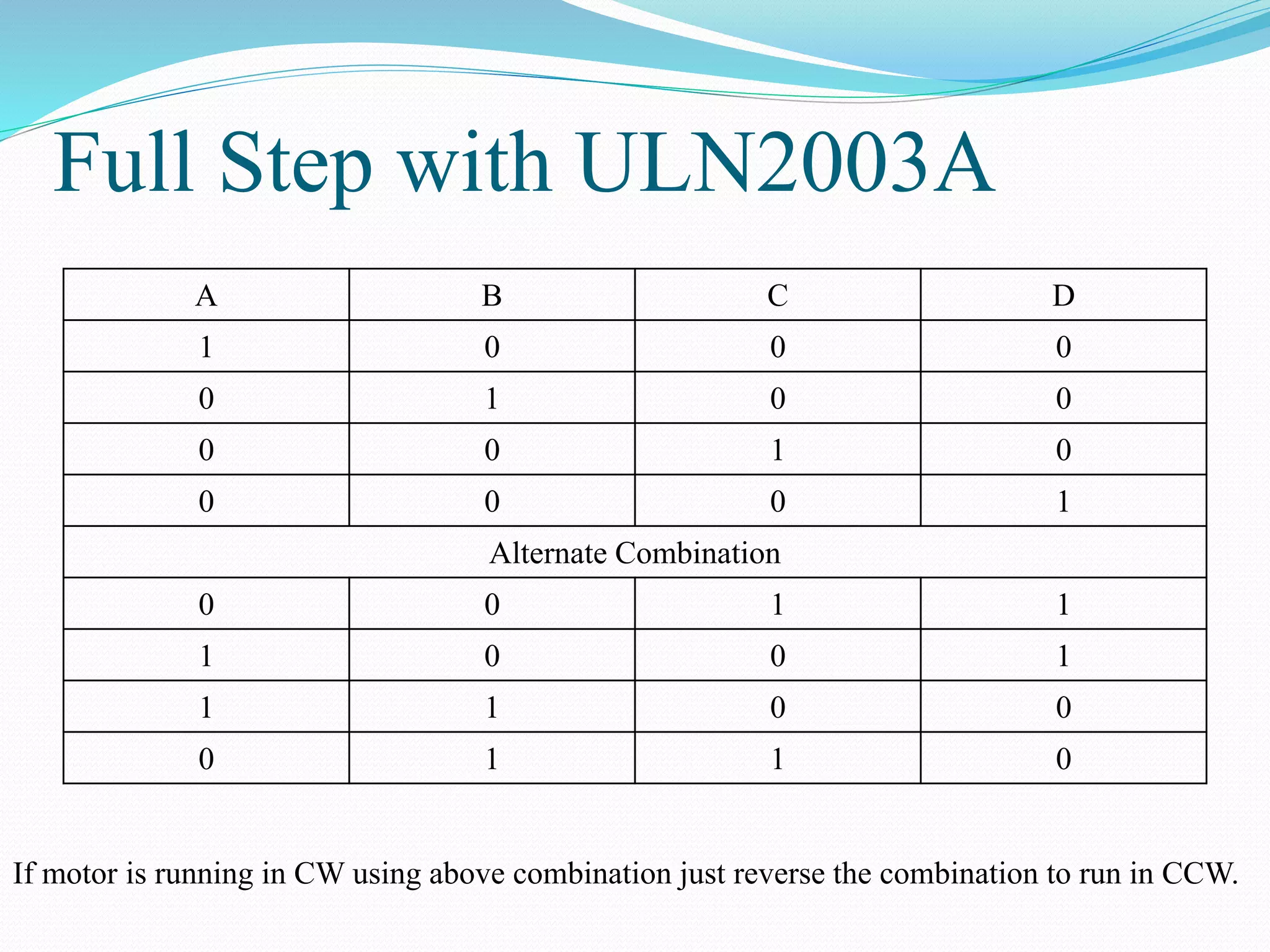

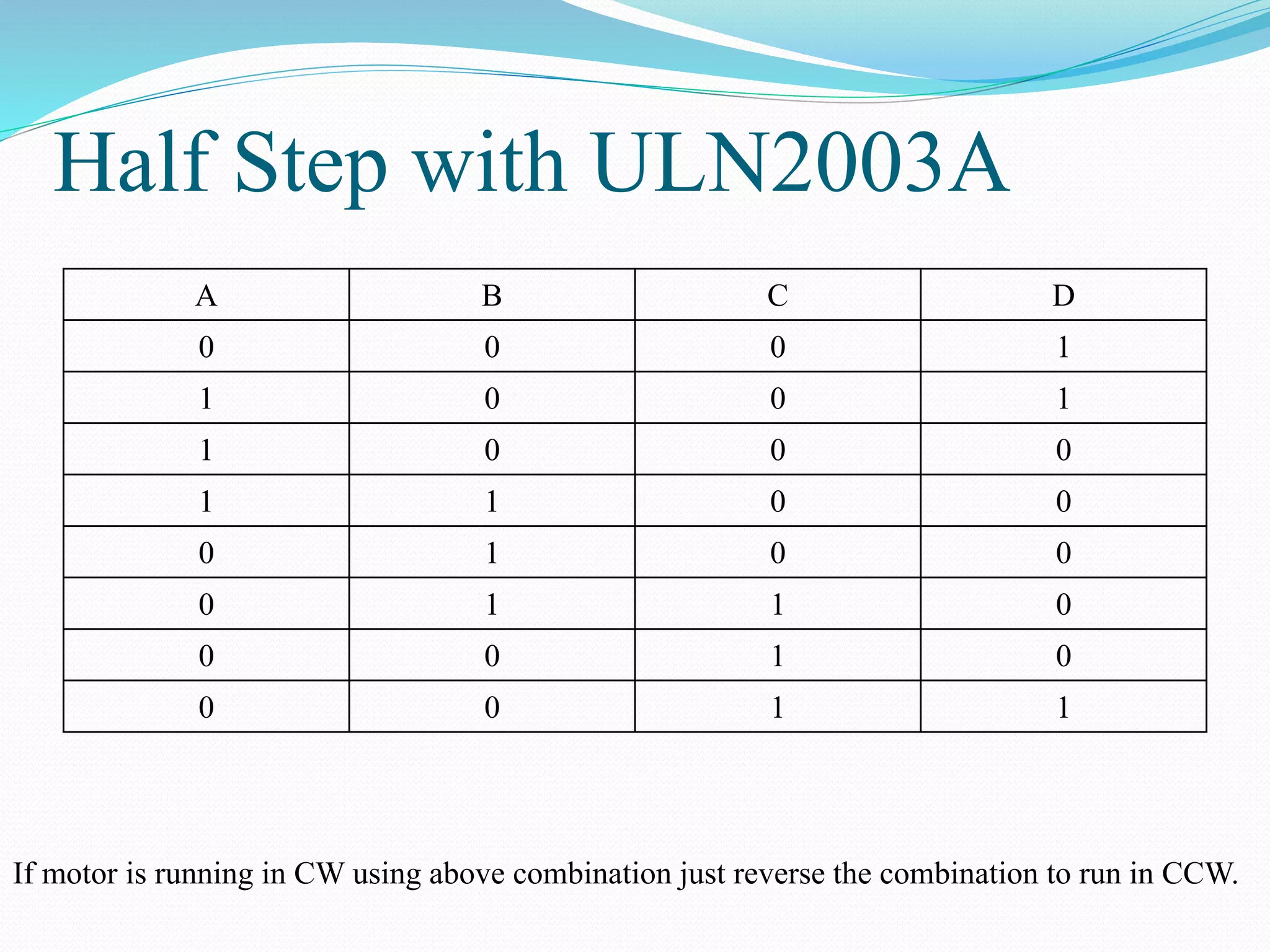

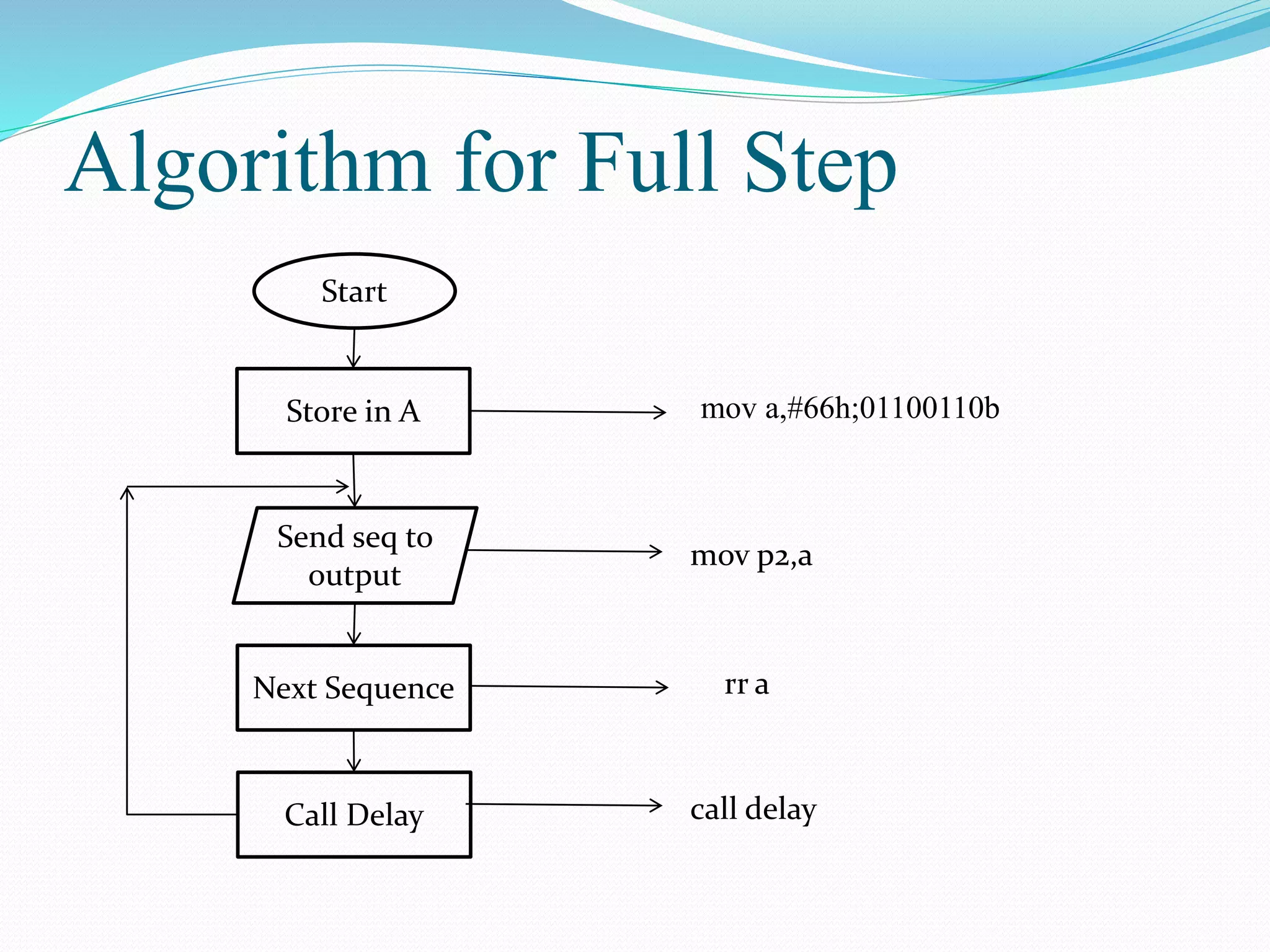

The document discusses driving a stepper motor using an 8051 microcontroller. It describes the objectives which are to learn about stepper motors, how to wire one, and interface it with an 8051. It explains that a ULN2003 chip is needed to provide sufficient current from the microcontroller pins to drive the motor. The document outlines how to determine the winding configuration, provides examples of full and half step sequences to rotate the motor clockwise and counterclockwise, and presents the algorithm to implement full stepping. It also discusses step angle and speed control.