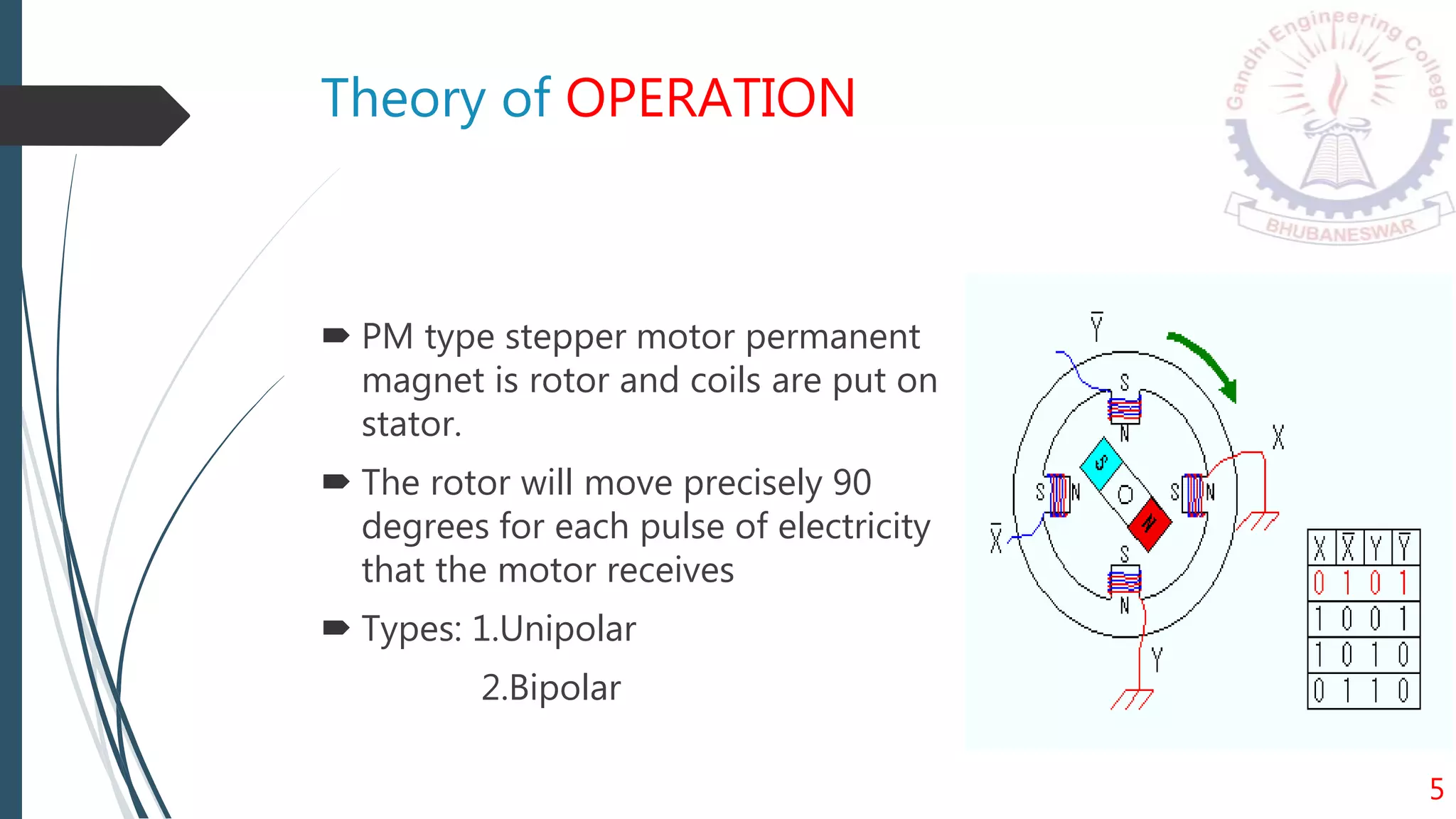

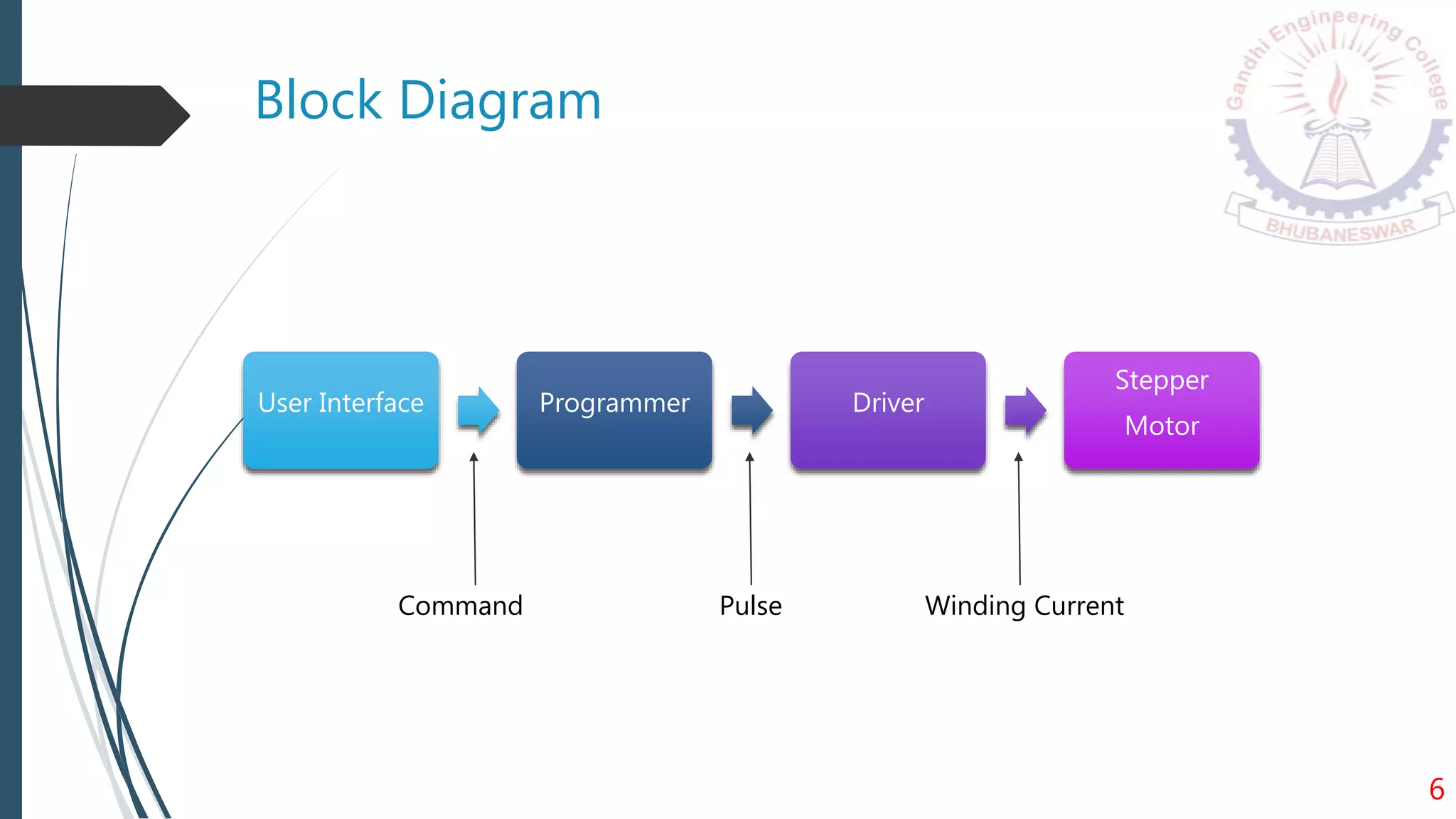

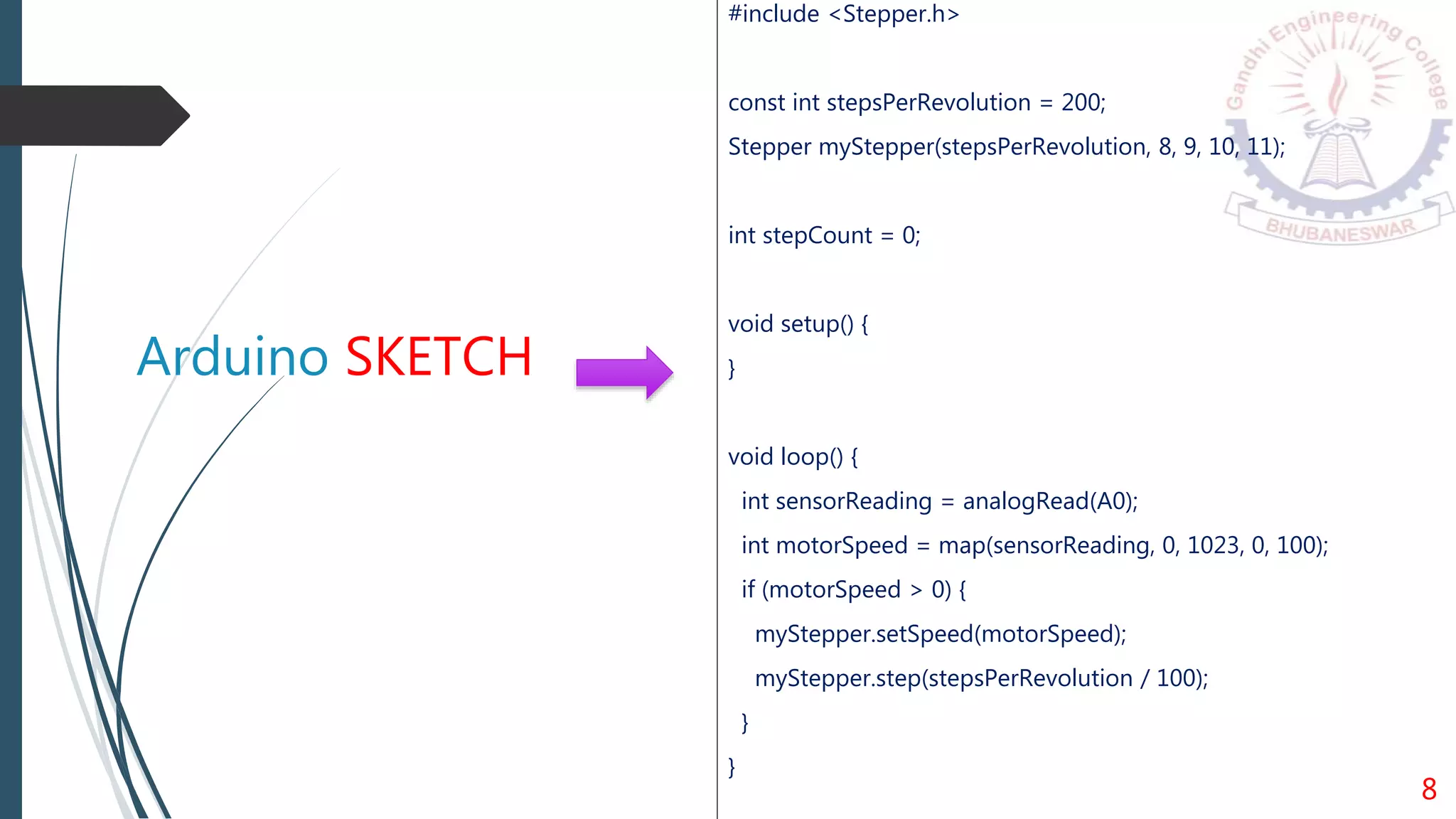

This document outlines a project to control stepper motor speed using an Arduino Uno R3, detailing its components, theory of operation, and advantages. It includes essential information such as the Arduino specifications, a stepper motor's functionality, an Arduino sketch for implementation, and an estimated cost for the parts required. The conclusion states the popularity and versatility of stepper motors in digital control applications like robotics.