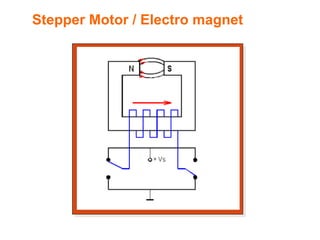

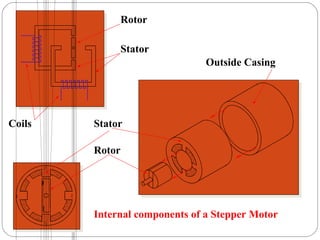

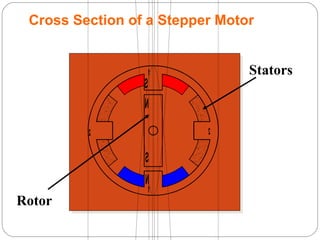

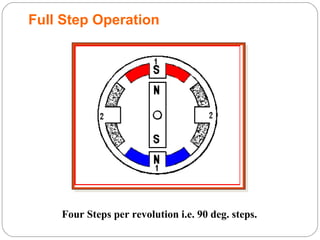

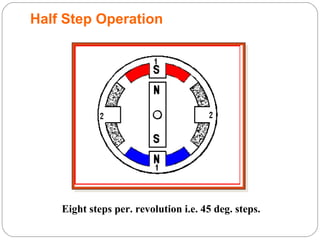

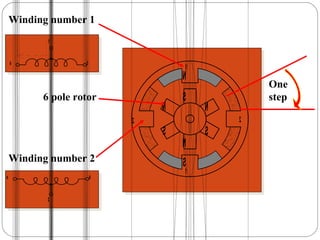

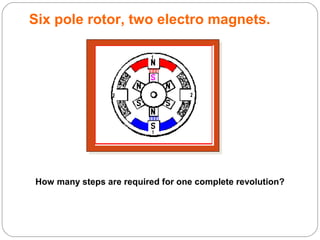

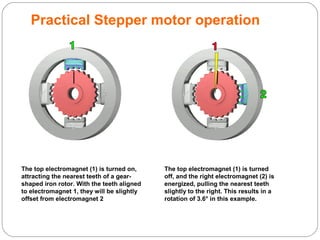

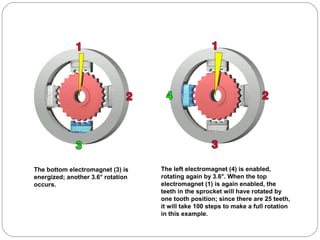

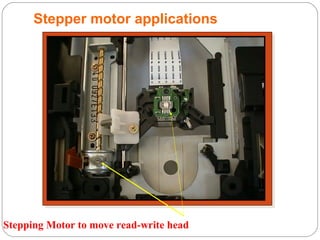

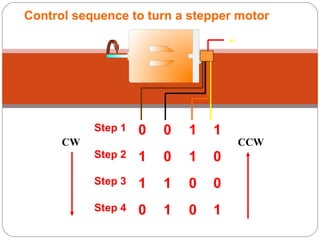

This document discusses stepper motors. It provides details on the internal components and operation of stepper motors including the stator, rotor, and coils. It explains how stepper motors operate through full step and half step modes to precisely control rotational position. Examples of applications that use stepper motors are also listed such as printers, CNC machines, and disk drives.