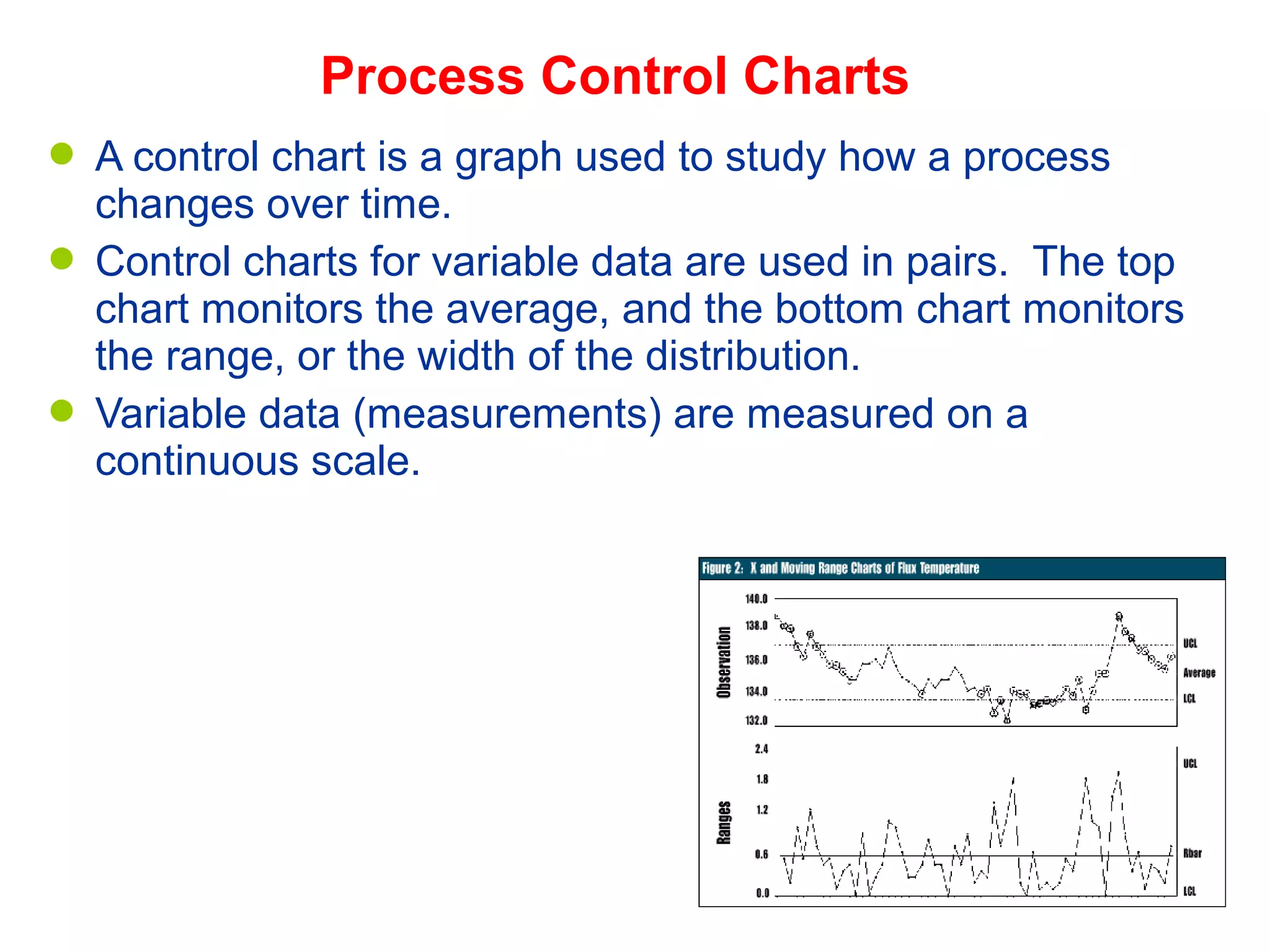

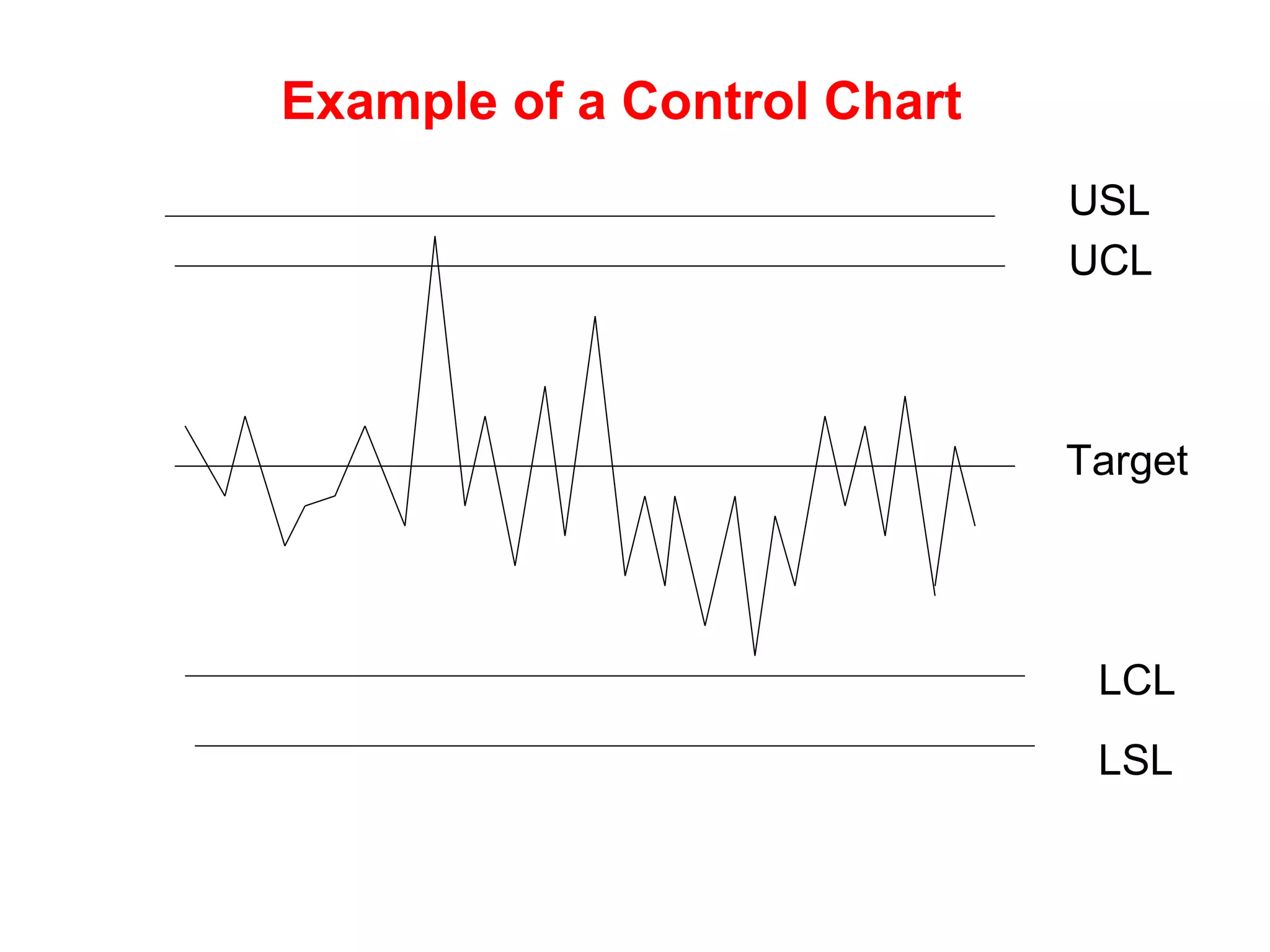

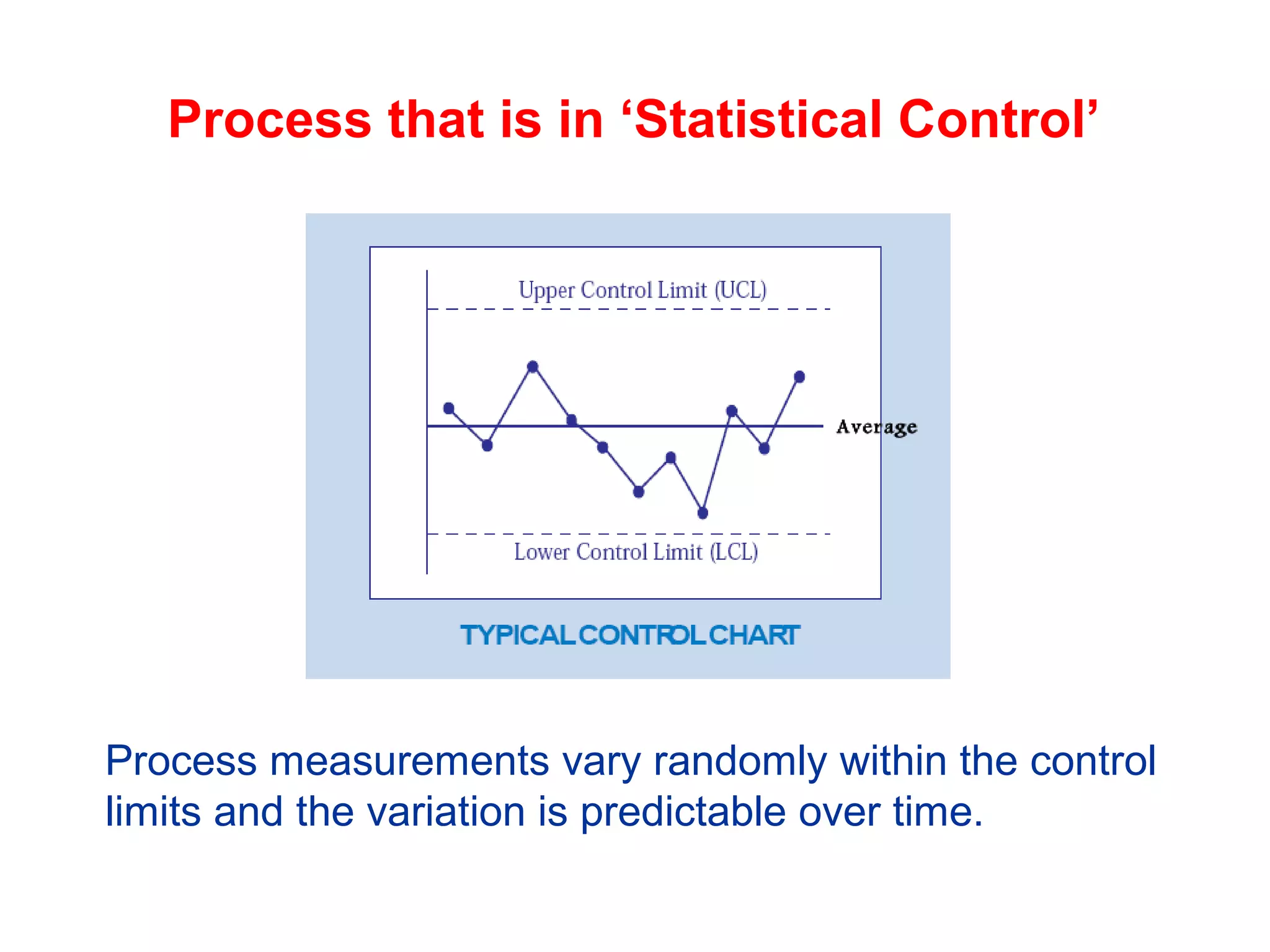

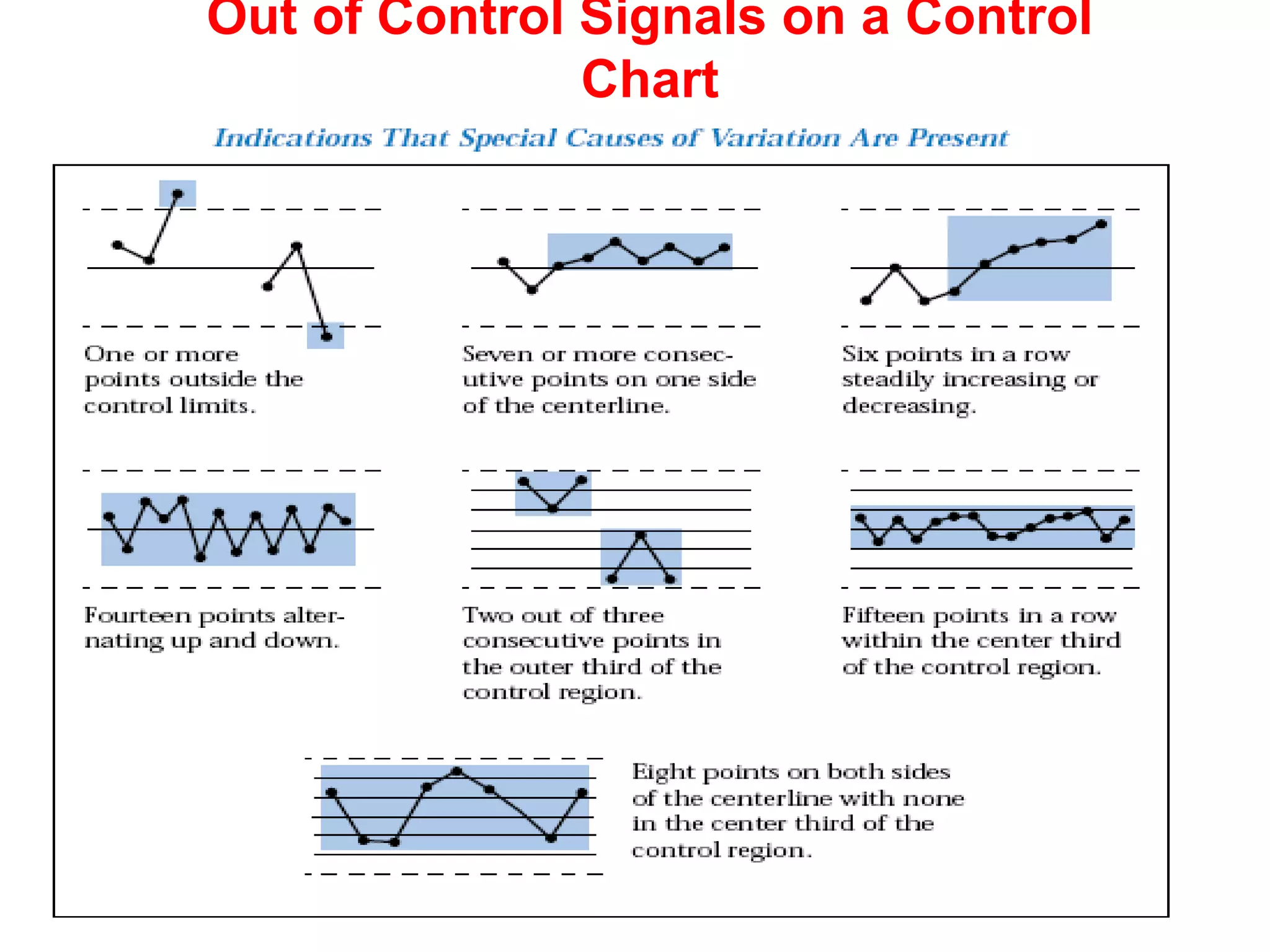

This document provides an overview of statistical process control (SPC). SPC uses statistical techniques to monitor processes and detect changes, helping to prevent defects and drive continuous improvement. It aims to identify problems in production as early as possible through analysis of process capability. Control charts are a key tool in SPC, monitoring the average and variation of a process over time through control limits. Being in statistical control means a process's measurements vary randomly within control limits in a predictable way. Patterns outside the limits indicate the process is out of control due to assignable causes that need correction. Benefits of SPC and control charts include reduced scrap, preventing unnecessary adjustments, and providing diagnostic information.