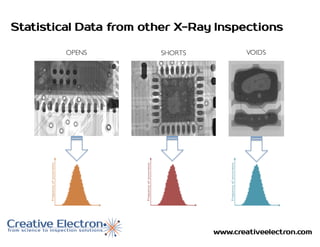

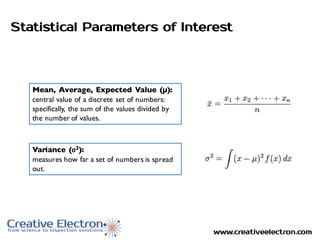

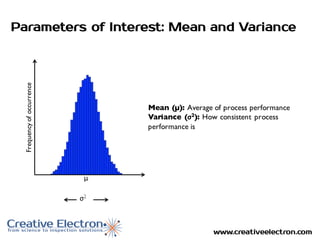

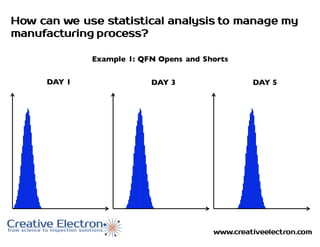

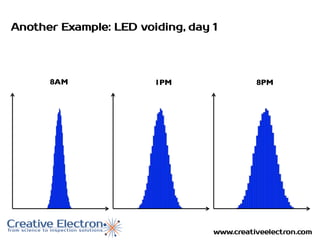

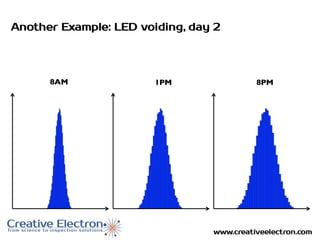

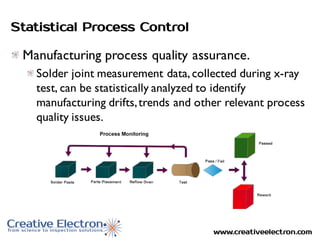

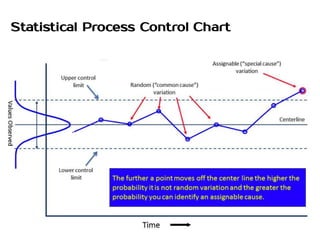

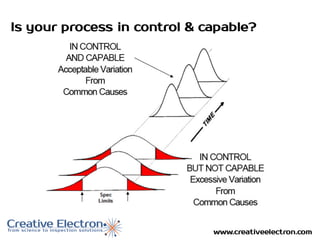

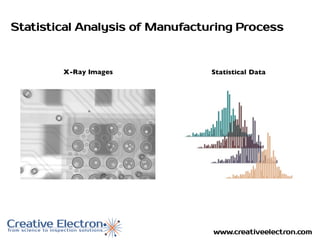

The document discusses the importance of statistical process control in manufacturing for quality assurance, particularly through the analysis of x-ray inspection data on solder joint measurements. It highlights how statistical parameters like mean and variance can help in identifying and managing manufacturing process issues, such as defects and consistency. The key takeaway is the integration of x-ray inspection systems into manufacturing to ensure quality control and process validation.

![www.creativeelectron.com

Statistical Data from BGA Inspection

Void [%]Frequencyofoccurrence

20%

Histogram](https://image.slidesharecdn.com/6-statistical-process-control-151002202513-lva1-app6892/85/Statistical-Process-Control-for-SMT-Electronic-Manufacturing-6-320.jpg)

![www.creativeelectron.com

Statistical Data from BGA Inspection

Void [%]Frequencyofoccurrence

10%

Histogram](https://image.slidesharecdn.com/6-statistical-process-control-151002202513-lva1-app6892/85/Statistical-Process-Control-for-SMT-Electronic-Manufacturing-7-320.jpg)

![www.creativeelectron.com

Statistical Data from BGA Inspection

Void [%]Frequencyofoccurrence

20%

Histogram](https://image.slidesharecdn.com/6-statistical-process-control-151002202513-lva1-app6892/85/Statistical-Process-Control-for-SMT-Electronic-Manufacturing-8-320.jpg)

![www.creativeelectron.com

Statistical Data from BGA Inspection

Void [%]

Frequencyofoccurrence

Histogram

Void [%]

Frequencyofoccurrence](https://image.slidesharecdn.com/6-statistical-process-control-151002202513-lva1-app6892/85/Statistical-Process-Control-for-SMT-Electronic-Manufacturing-9-320.jpg)