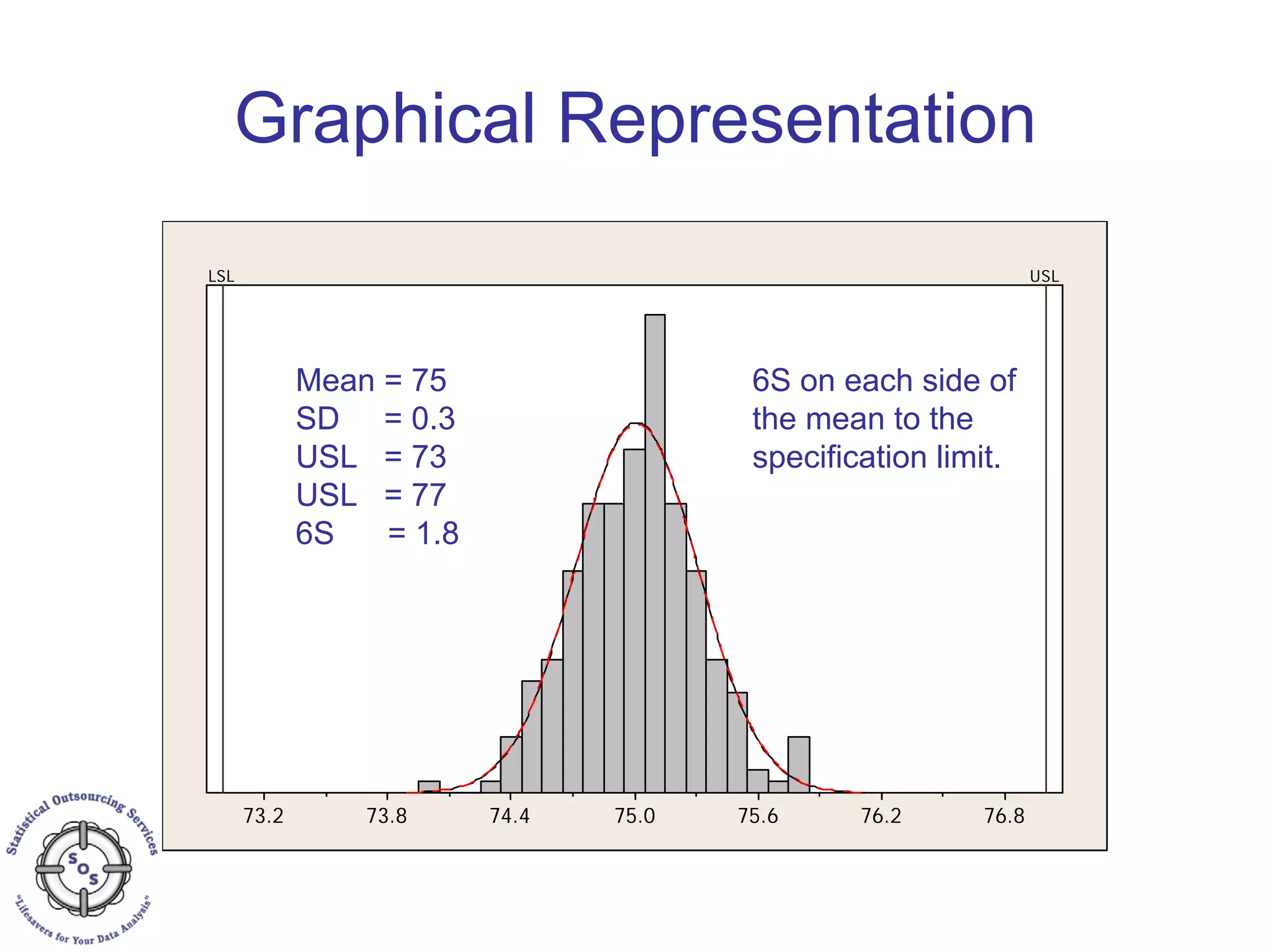

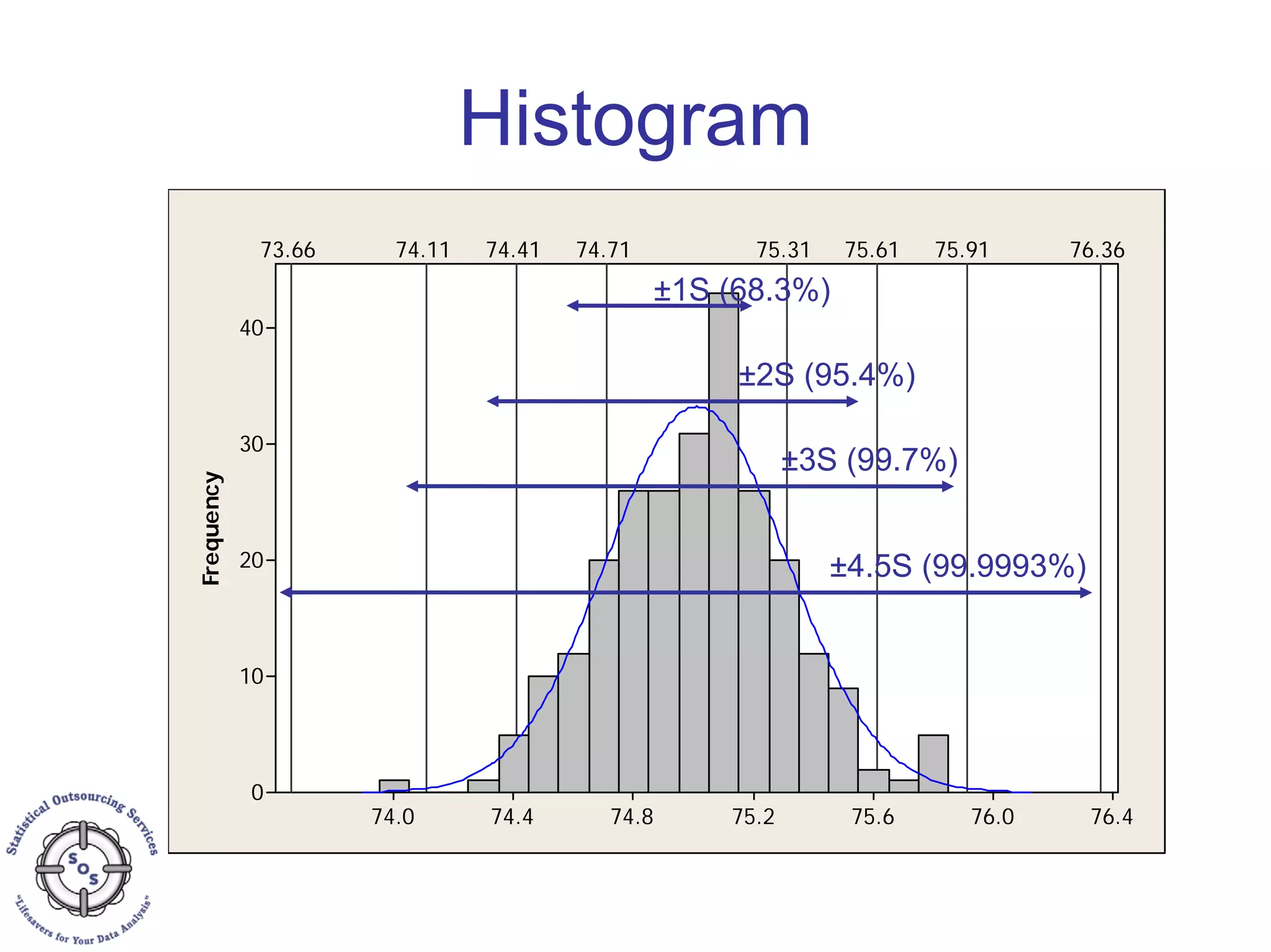

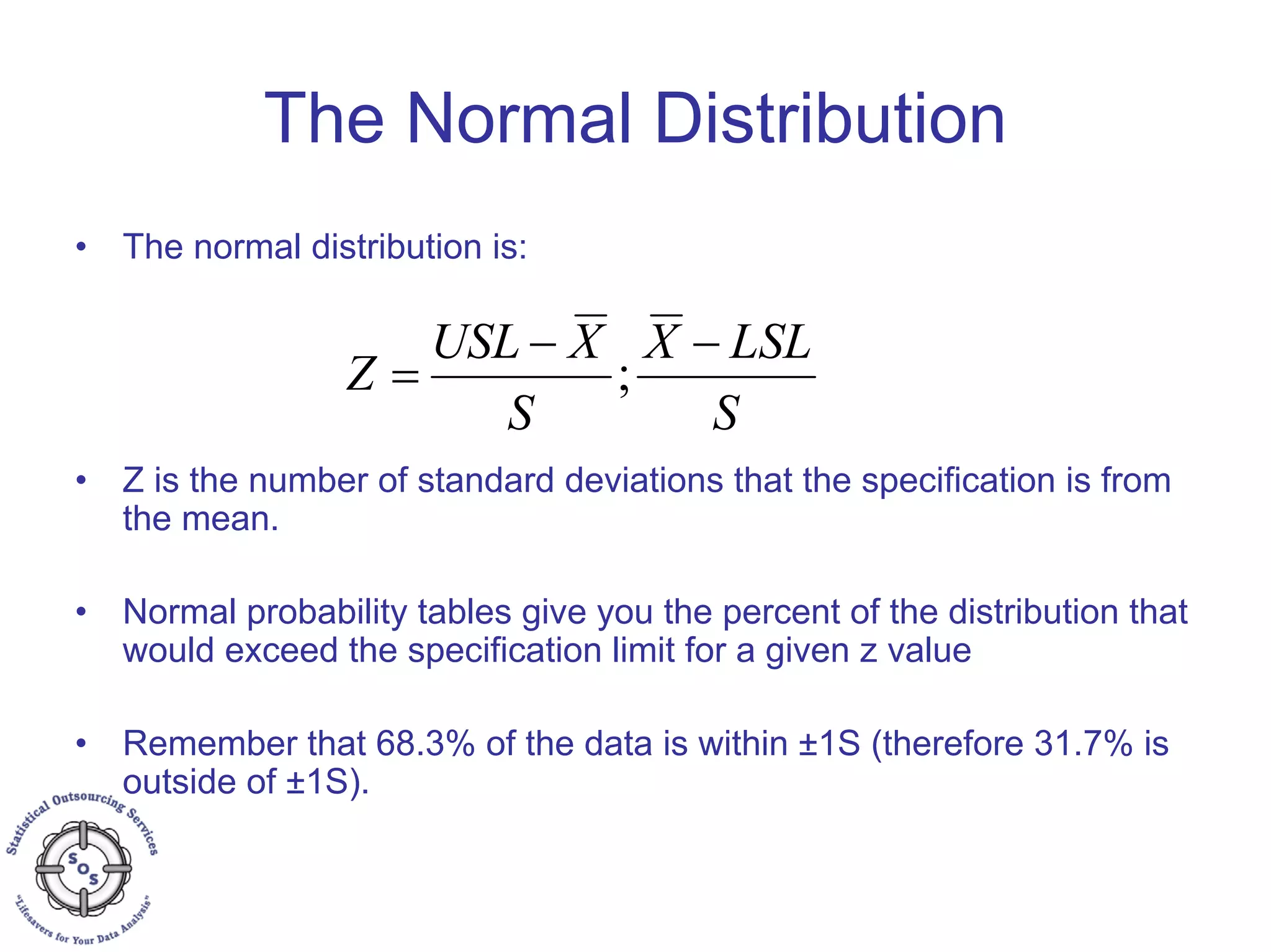

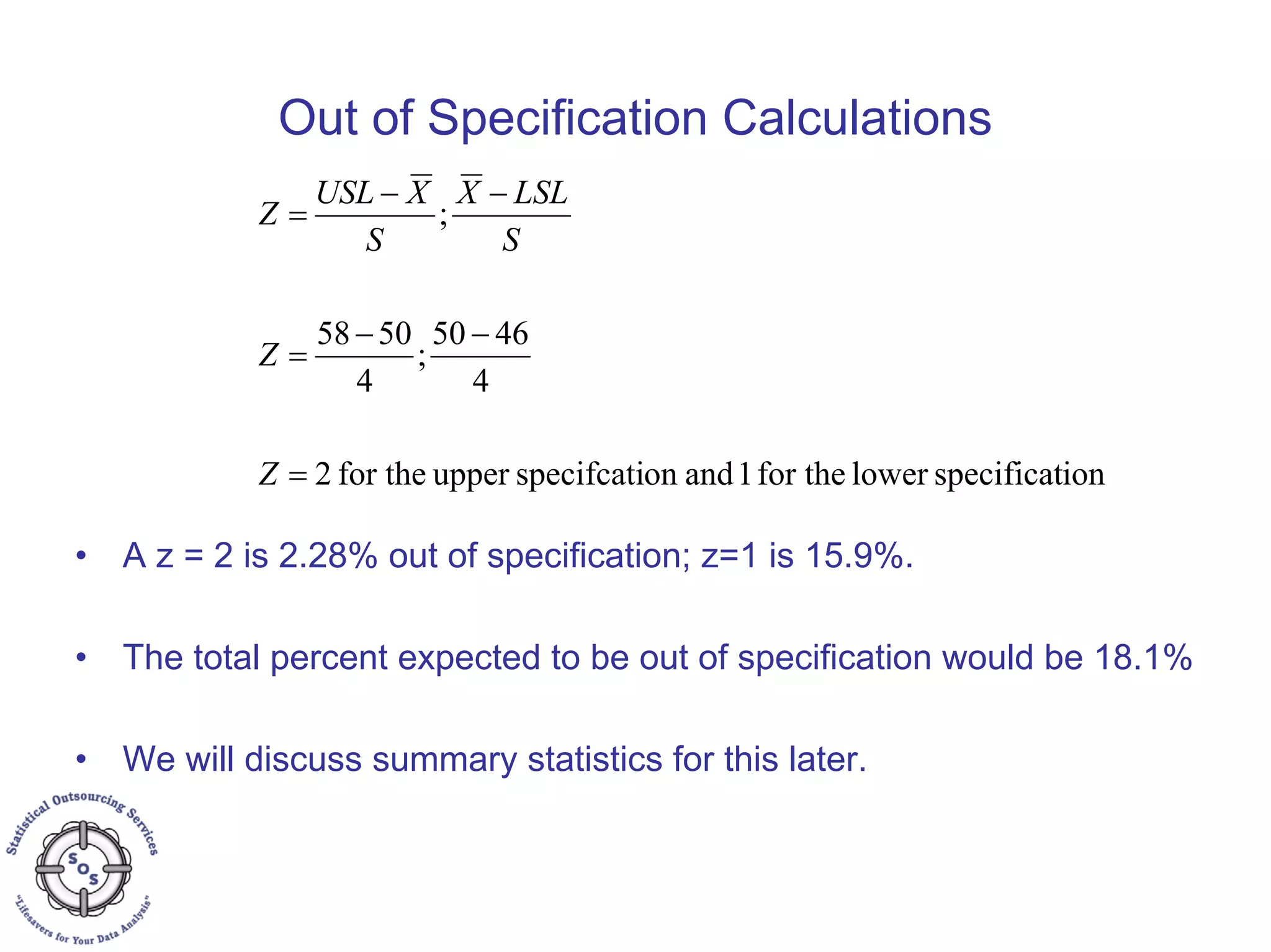

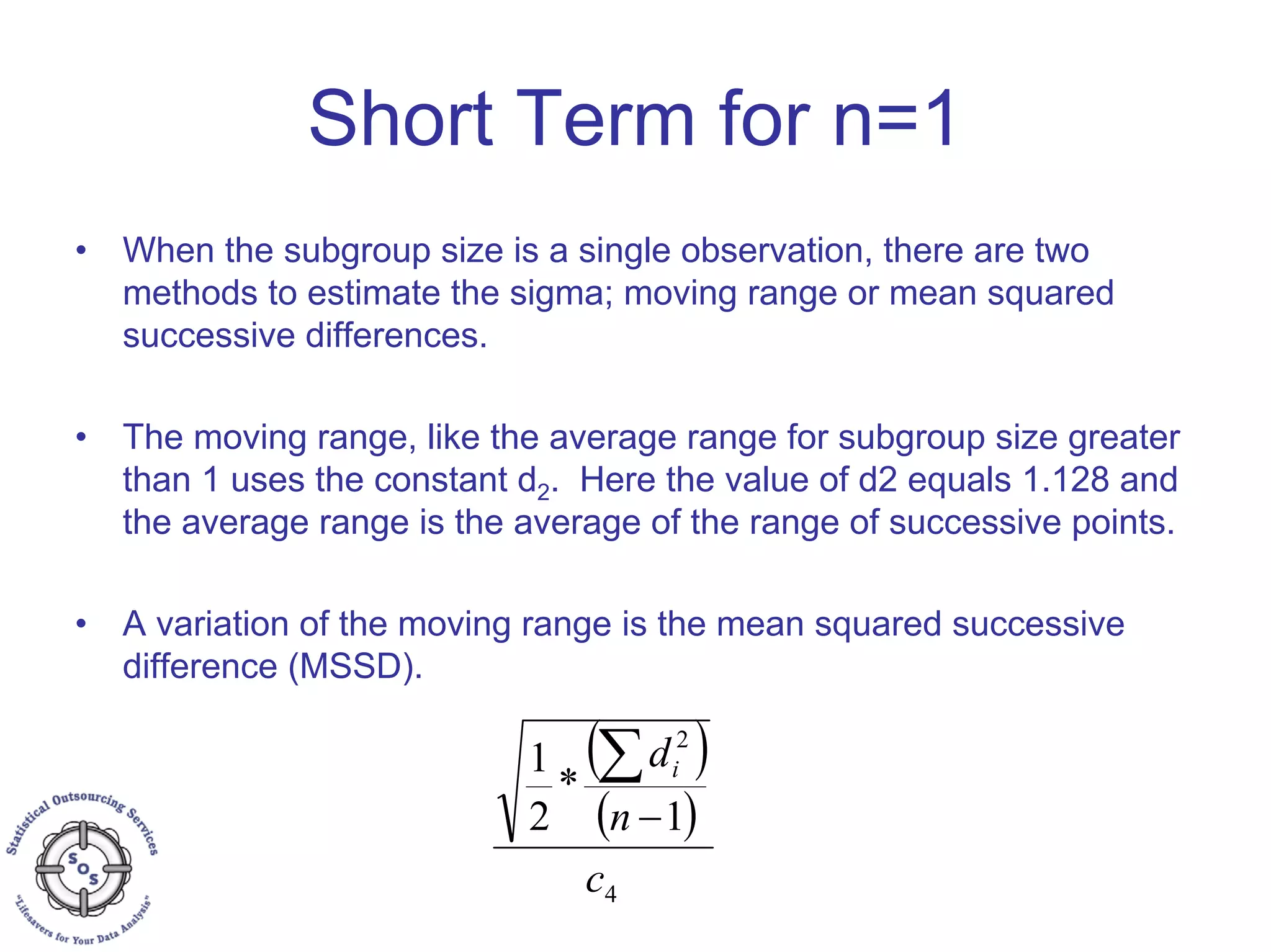

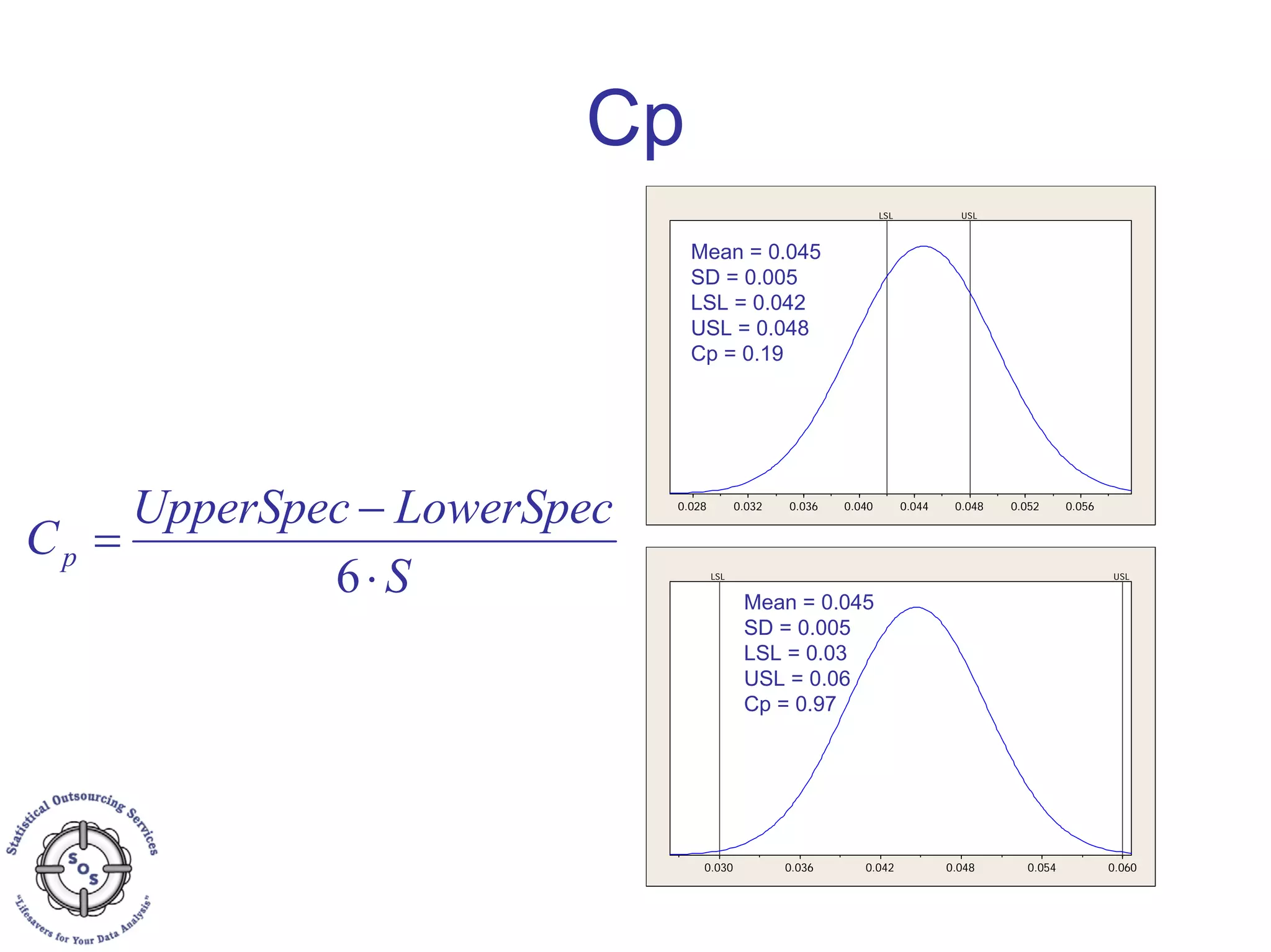

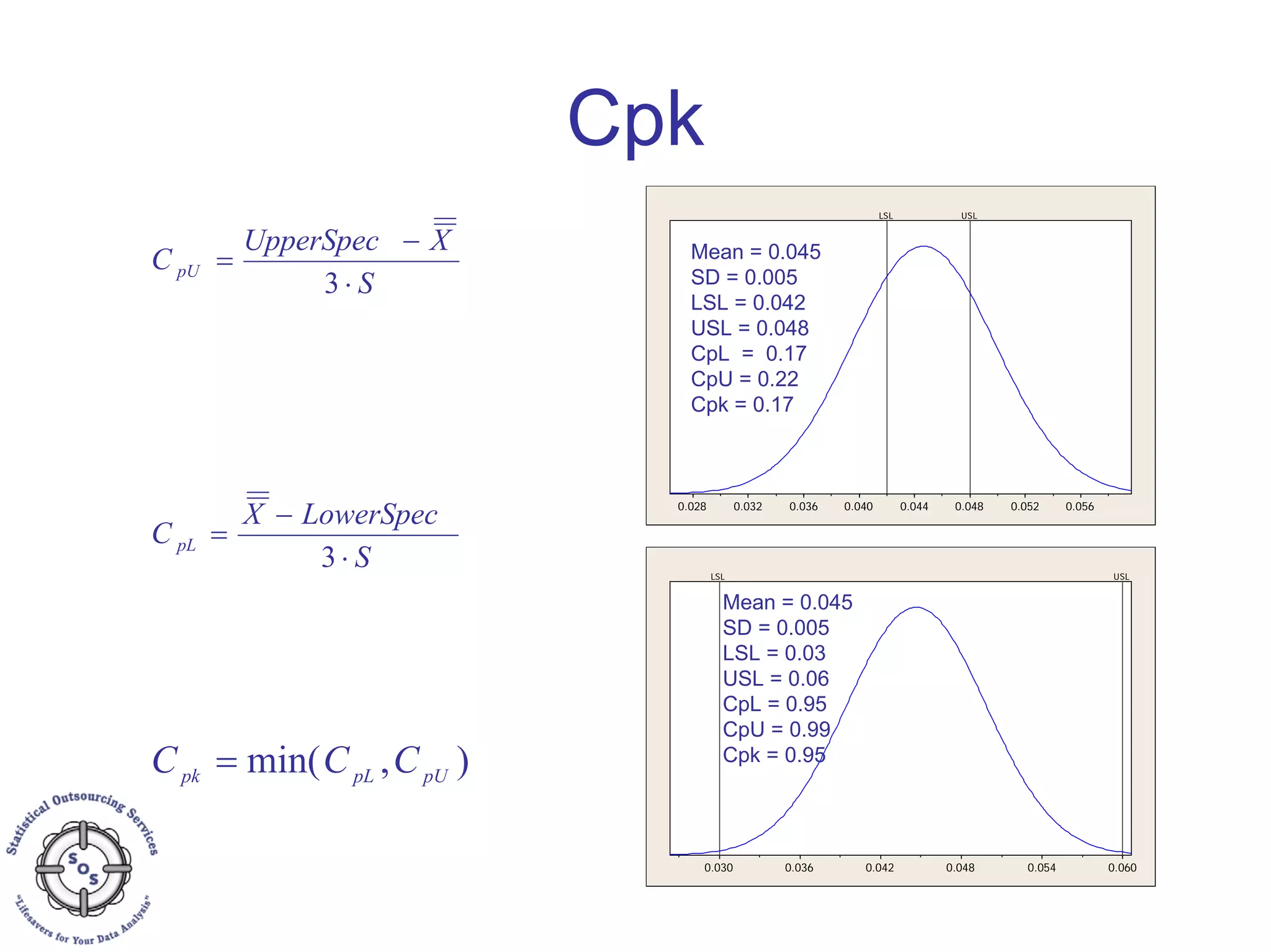

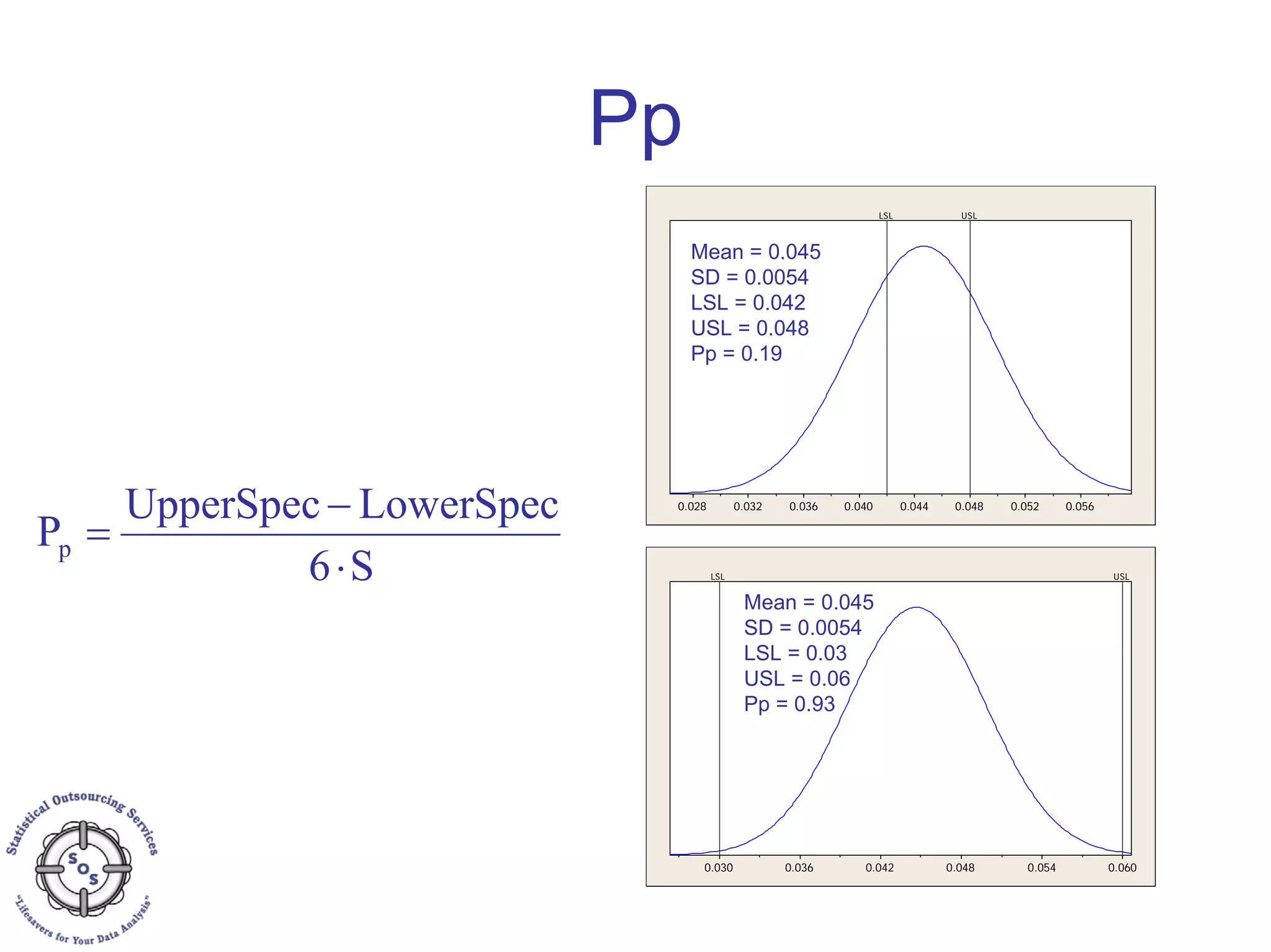

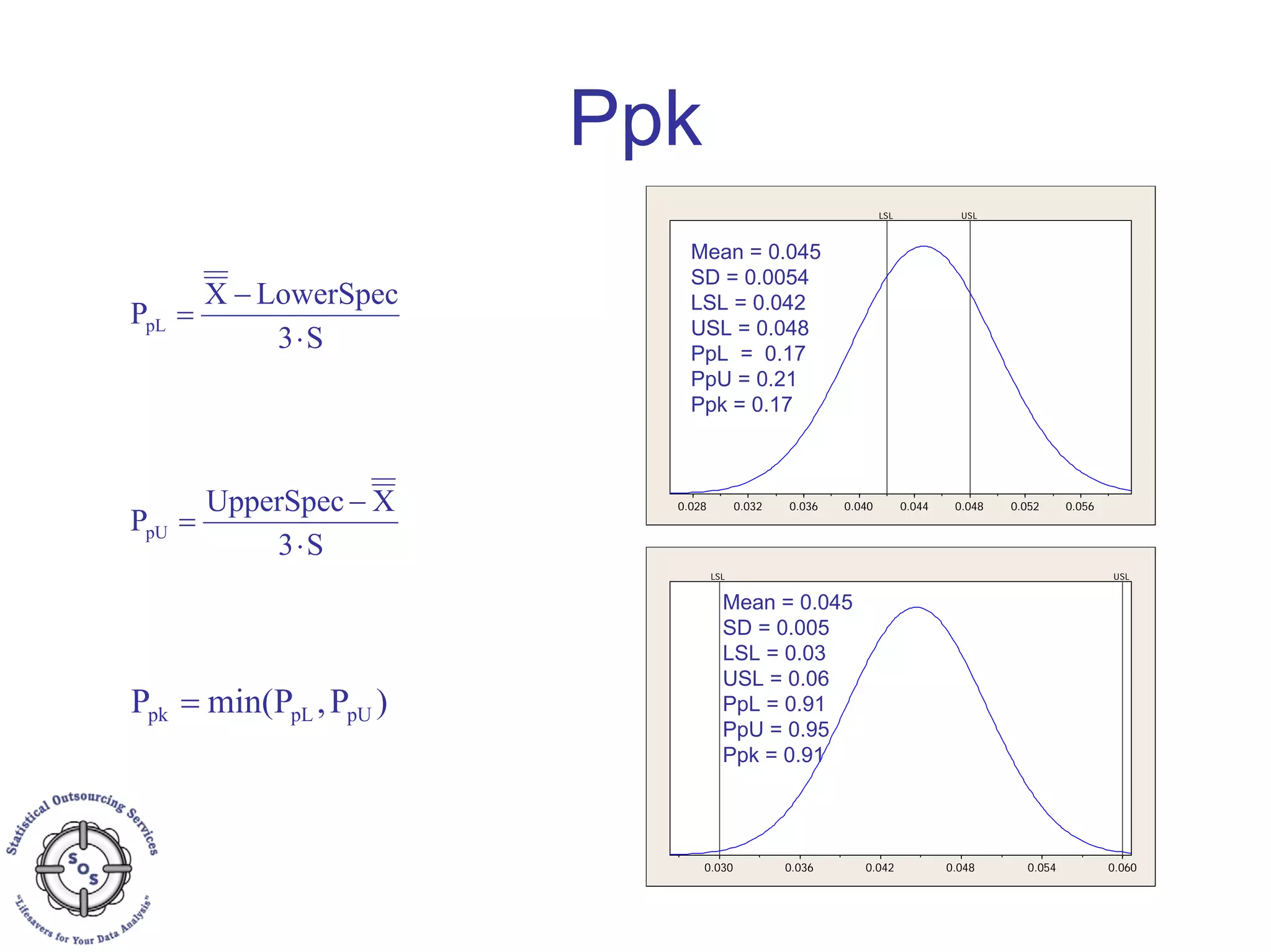

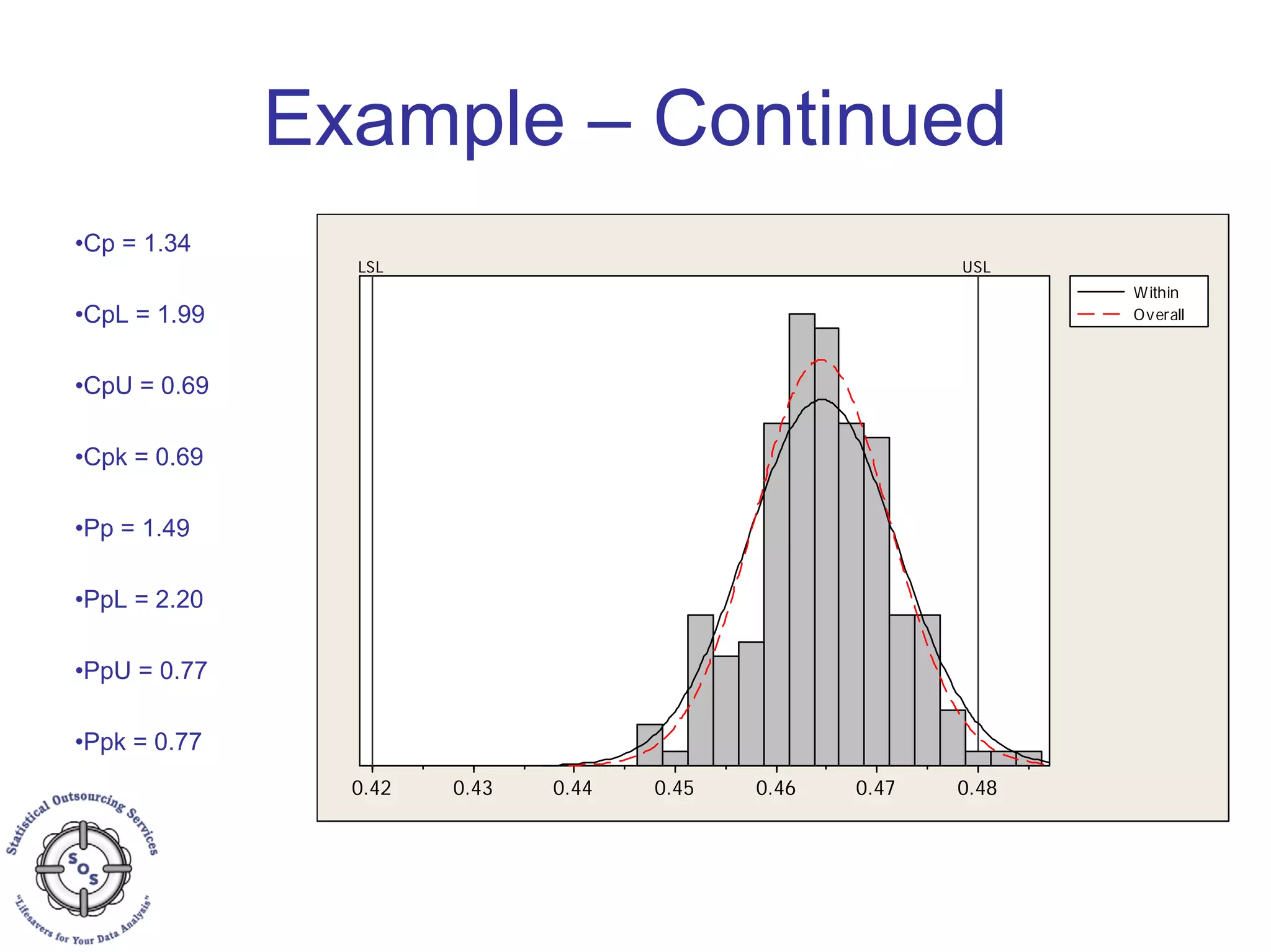

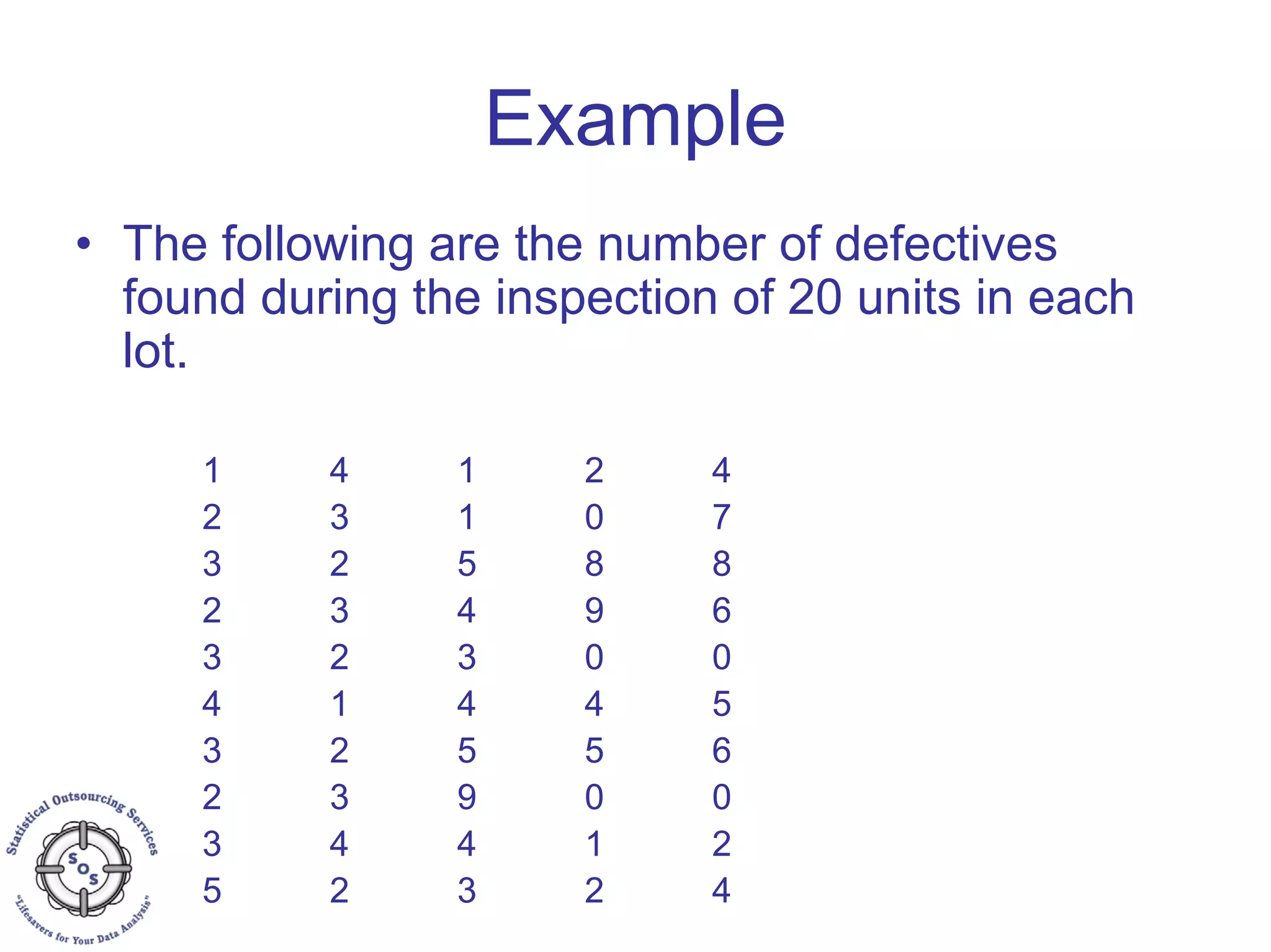

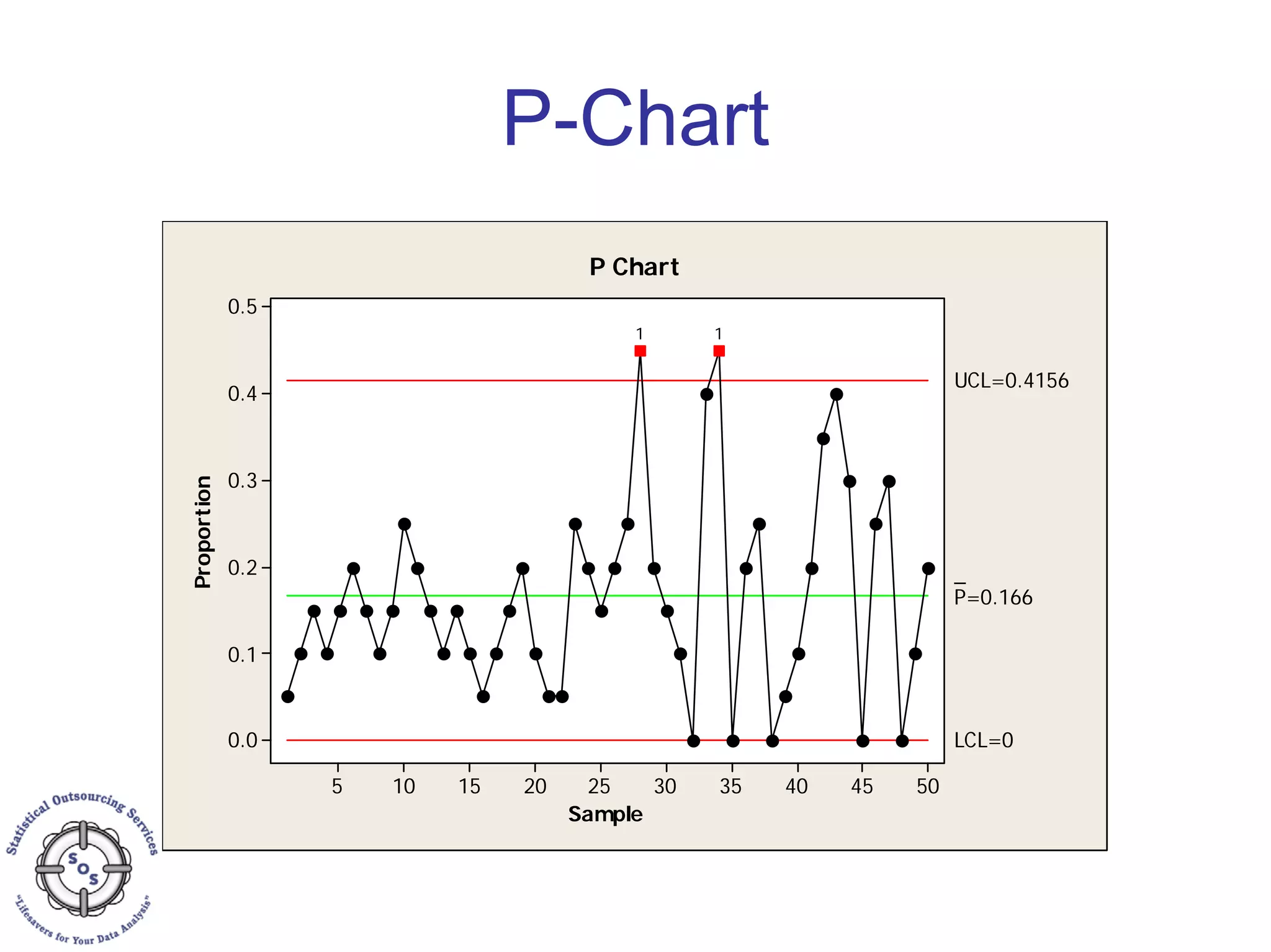

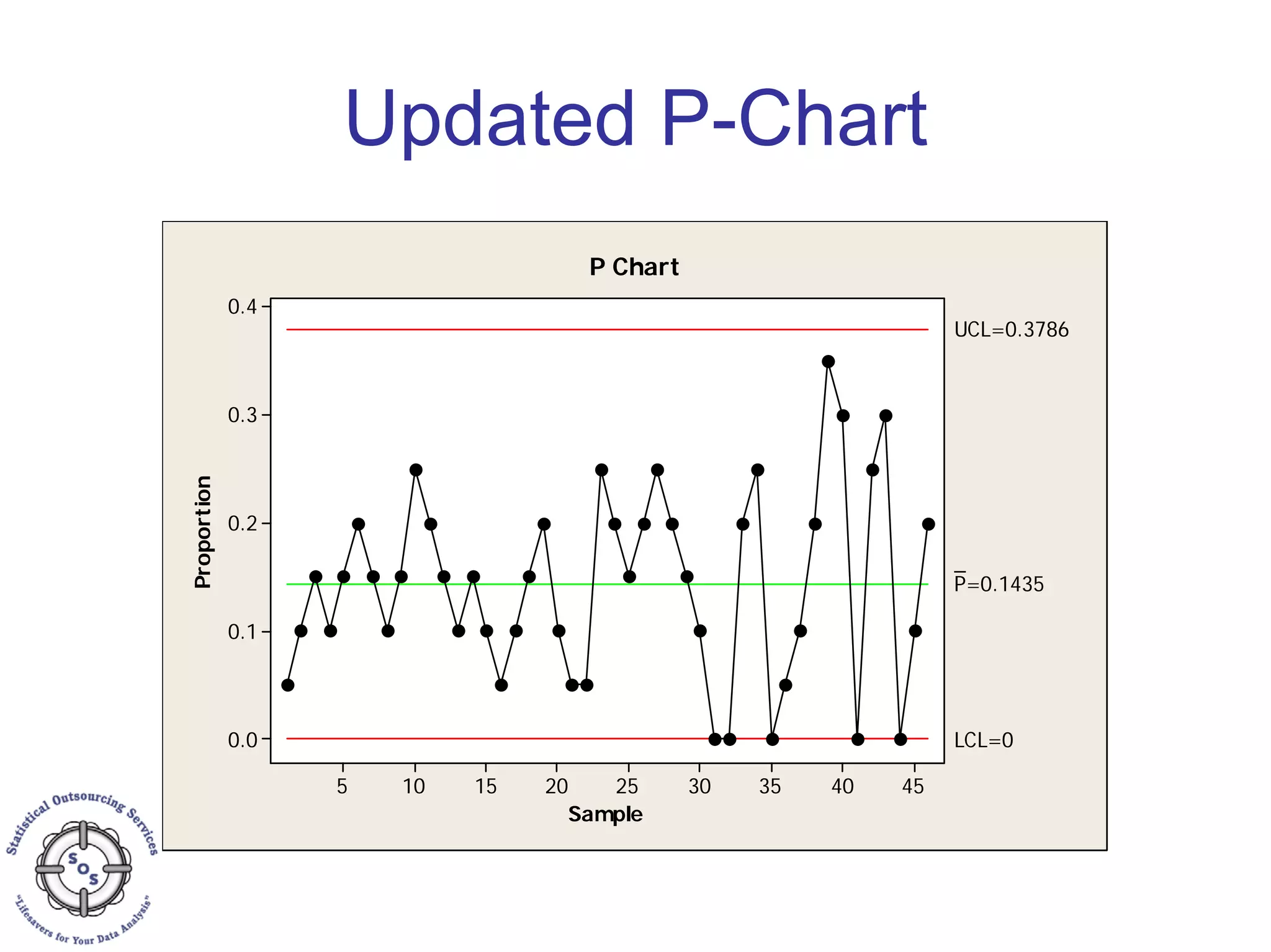

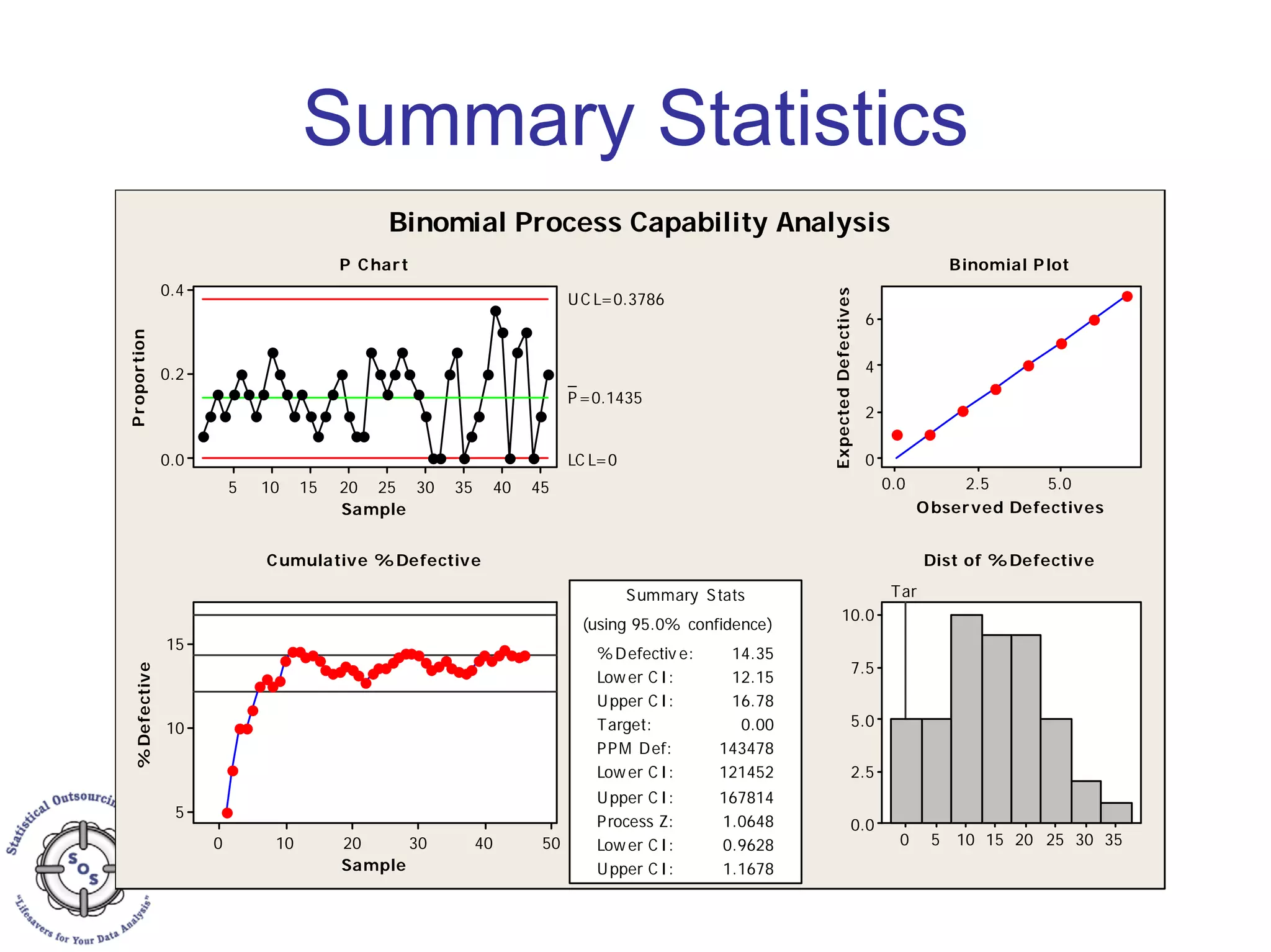

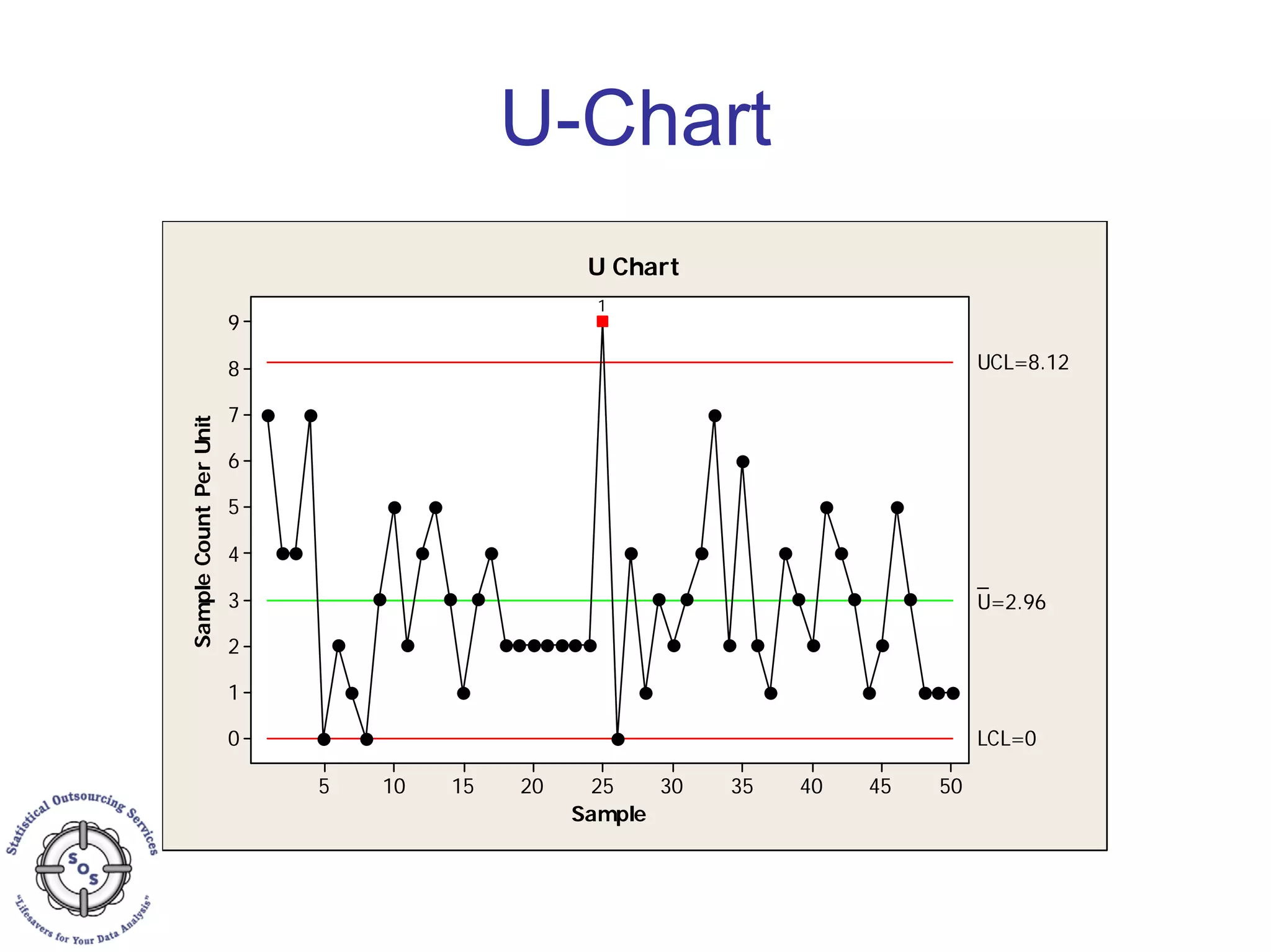

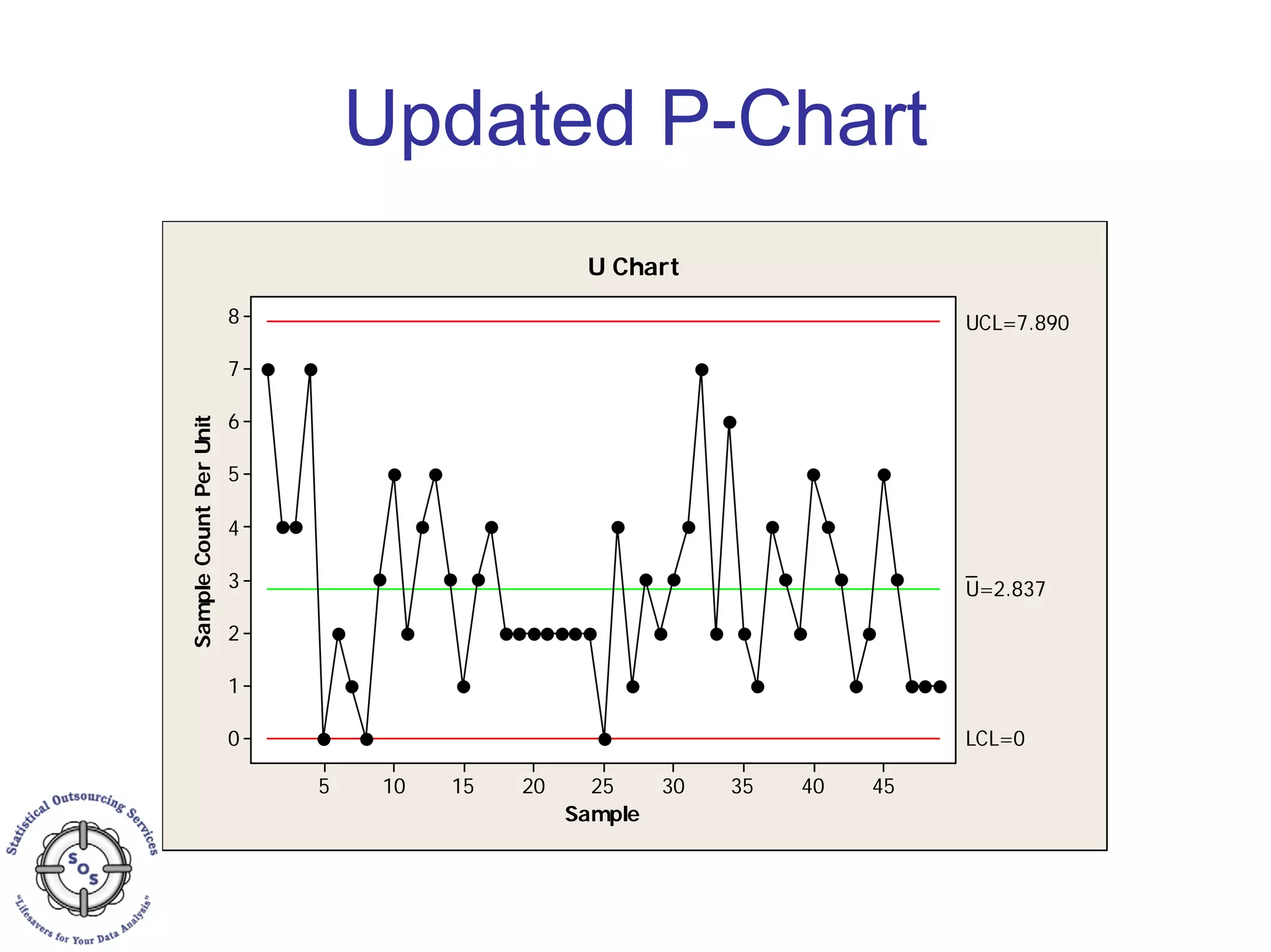

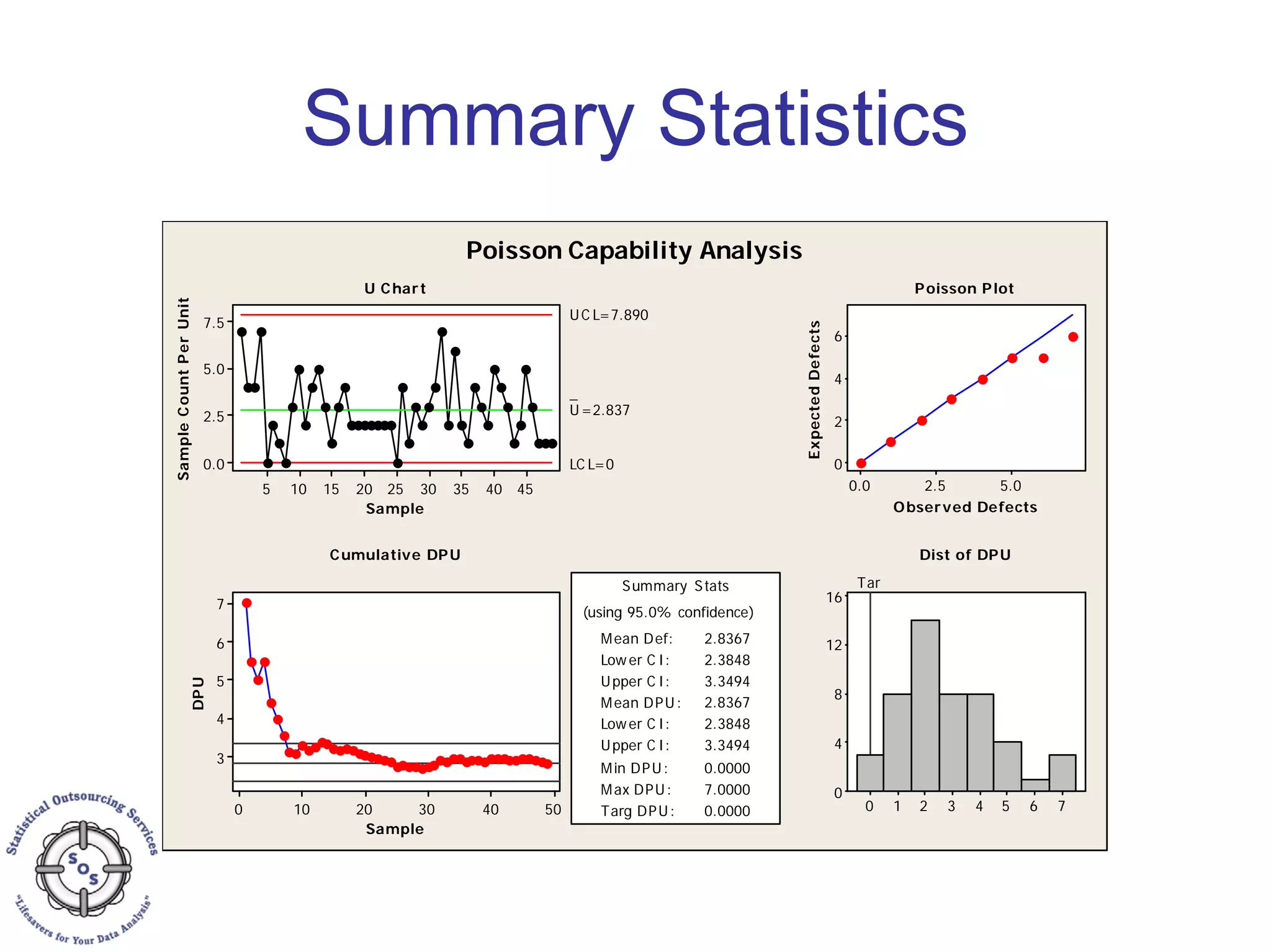

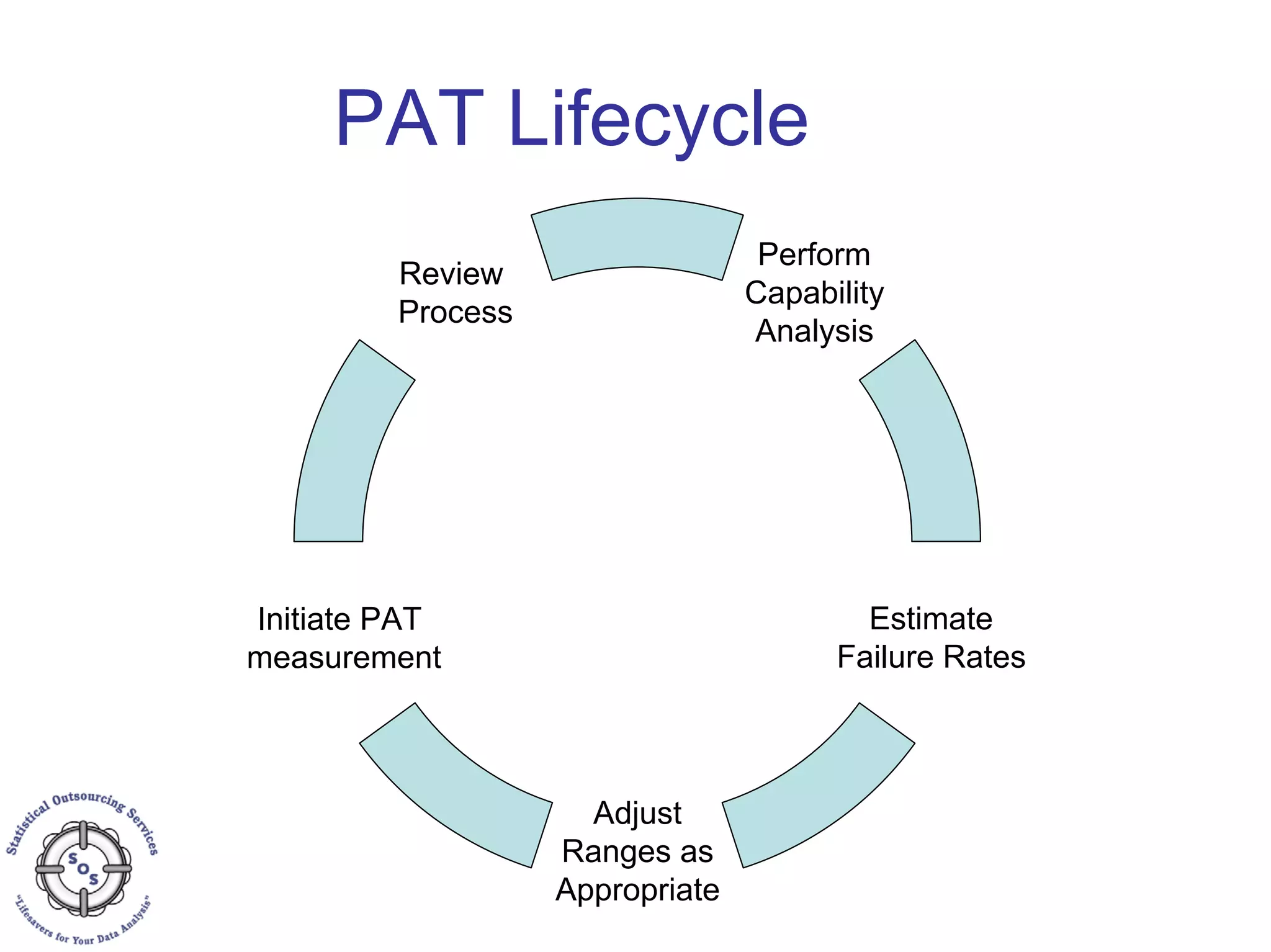

This document discusses process capability analysis and process analytical technology. It begins with an introduction to capability, including histograms and the normal distribution. It then covers capability indices like Cp, Cpk, Pp and Ppk and how to calculate sigma. It discusses using capability analysis with attribute data by calculating defects per million opportunities (DPMO). It concludes with a brief overview of process analytical technology (PAT).