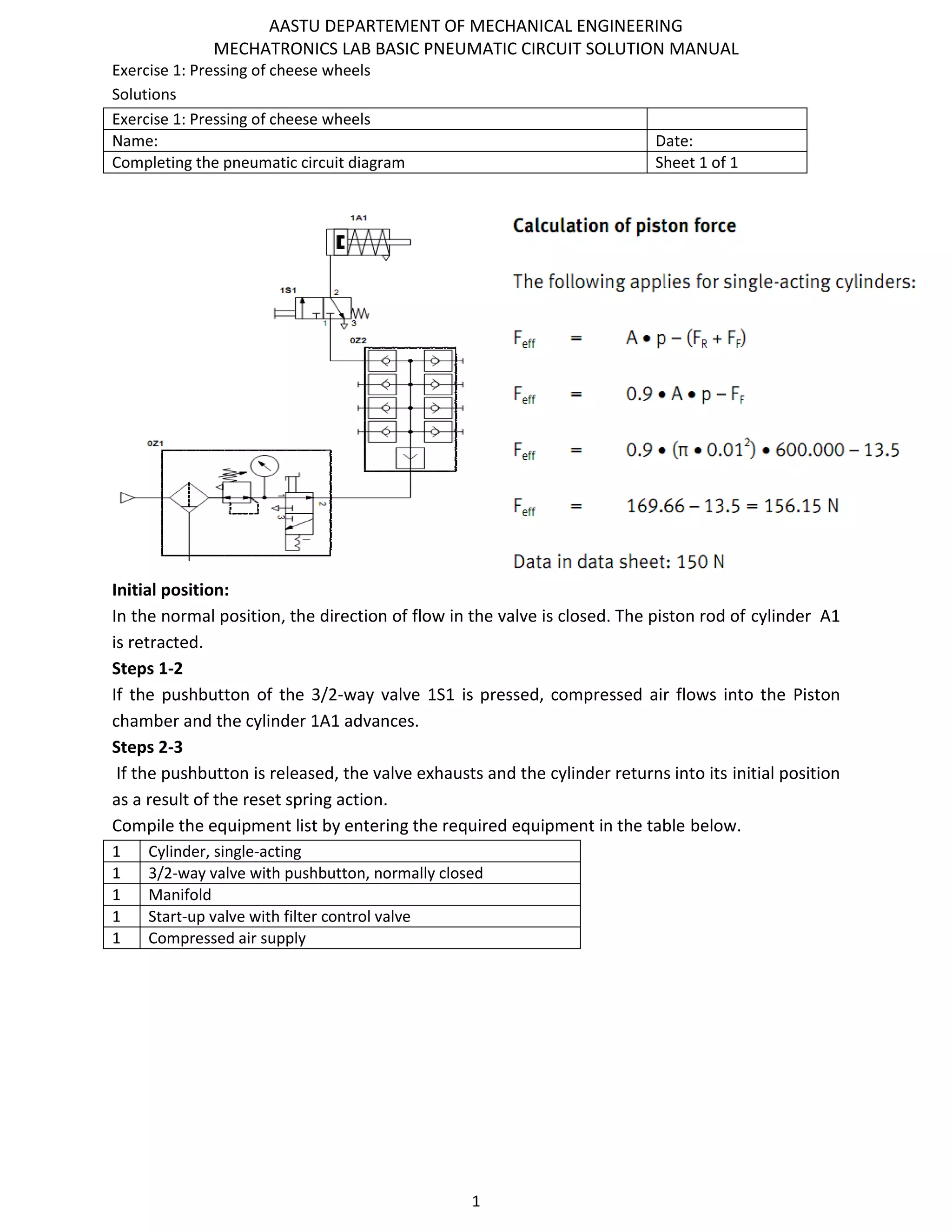

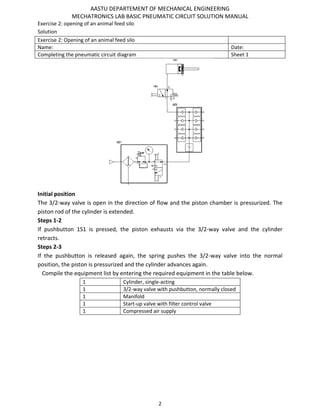

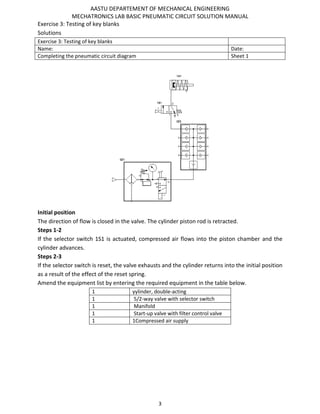

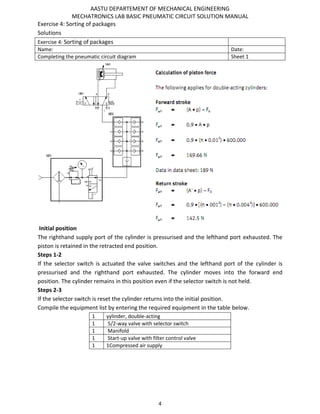

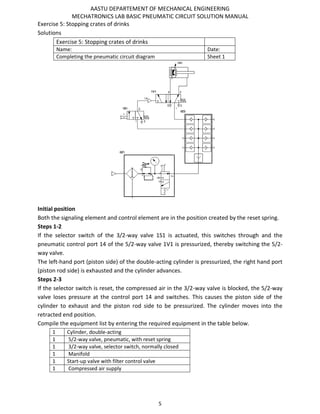

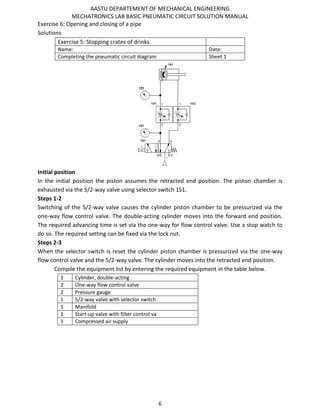

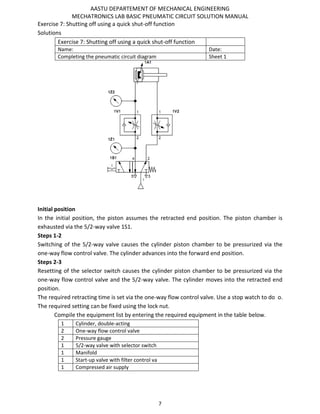

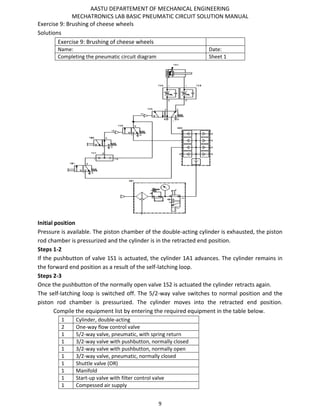

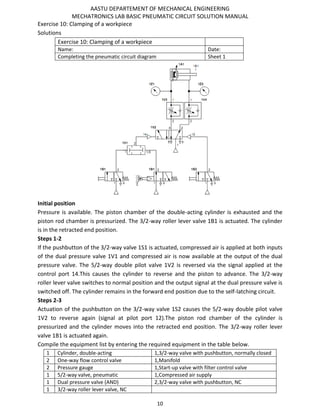

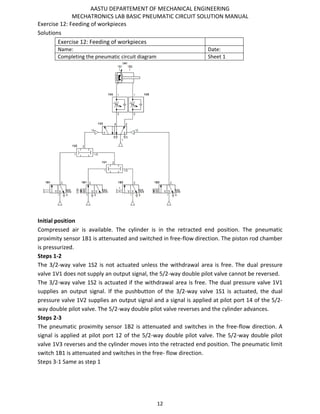

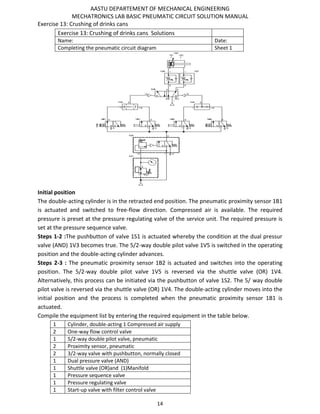

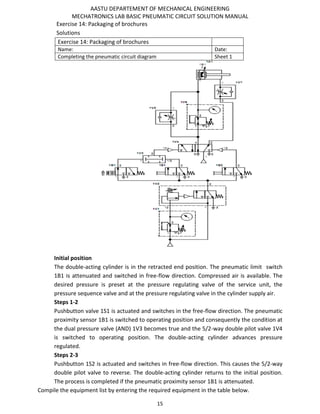

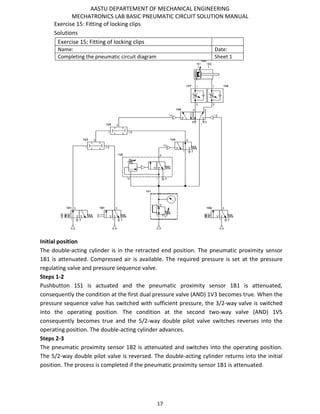

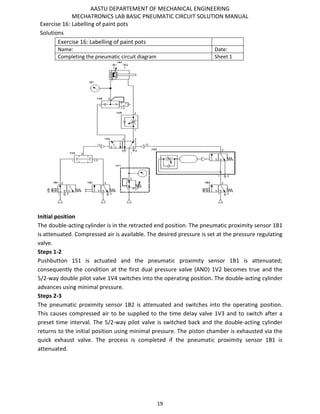

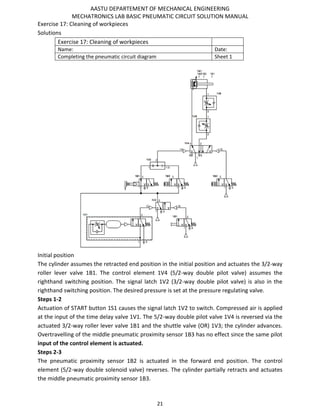

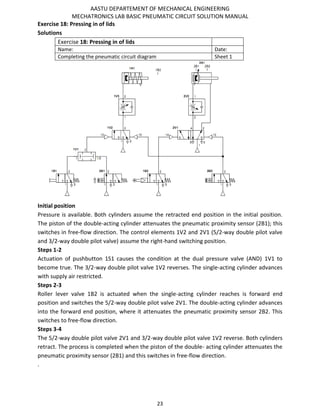

This document contains solutions for 12 exercises involving basic pneumatic circuits. Each exercise provides an initial position description, step-by-step instructions for operating the circuit, and a list of required equipment. The exercises involve circuits for pressing cheese wheels, opening a silo, testing key blanks, sorting packages, stopping crates, opening/closing a pipe, quick shut-off functions, actuating a shut-off device, brushing cheese wheels, clamping a workpiece, operating a sliding door, and feeding workpieces. Detailed diagrams and explanations of valve operations are provided for pneumatically actuating cylinders to perform various mechanical tasks.