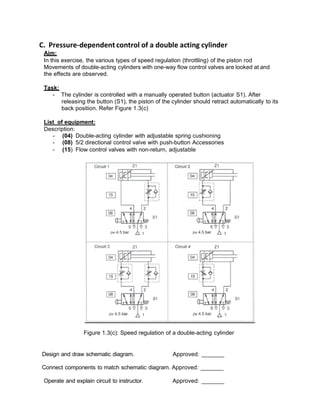

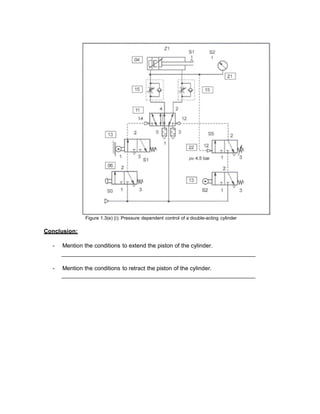

This document provides information and instructions for a practical task involving pneumatic circuits for a Mechanical Engineering diploma program. It includes the objectives, theory, problems, equipment, procedures, and assessment criteria for the task. Specifically, it covers direct and indirect control of pneumatic cylinders using various valves. The task requires students to design and implement pneumatic circuits that directly or indirectly control double-acting cylinders using buttons or pilot-operated valves to meet specified objectives. Circuits are assessed based on setup, task completion, component knowledge, and time management. Safety measures for working with compressed air are also outlined.