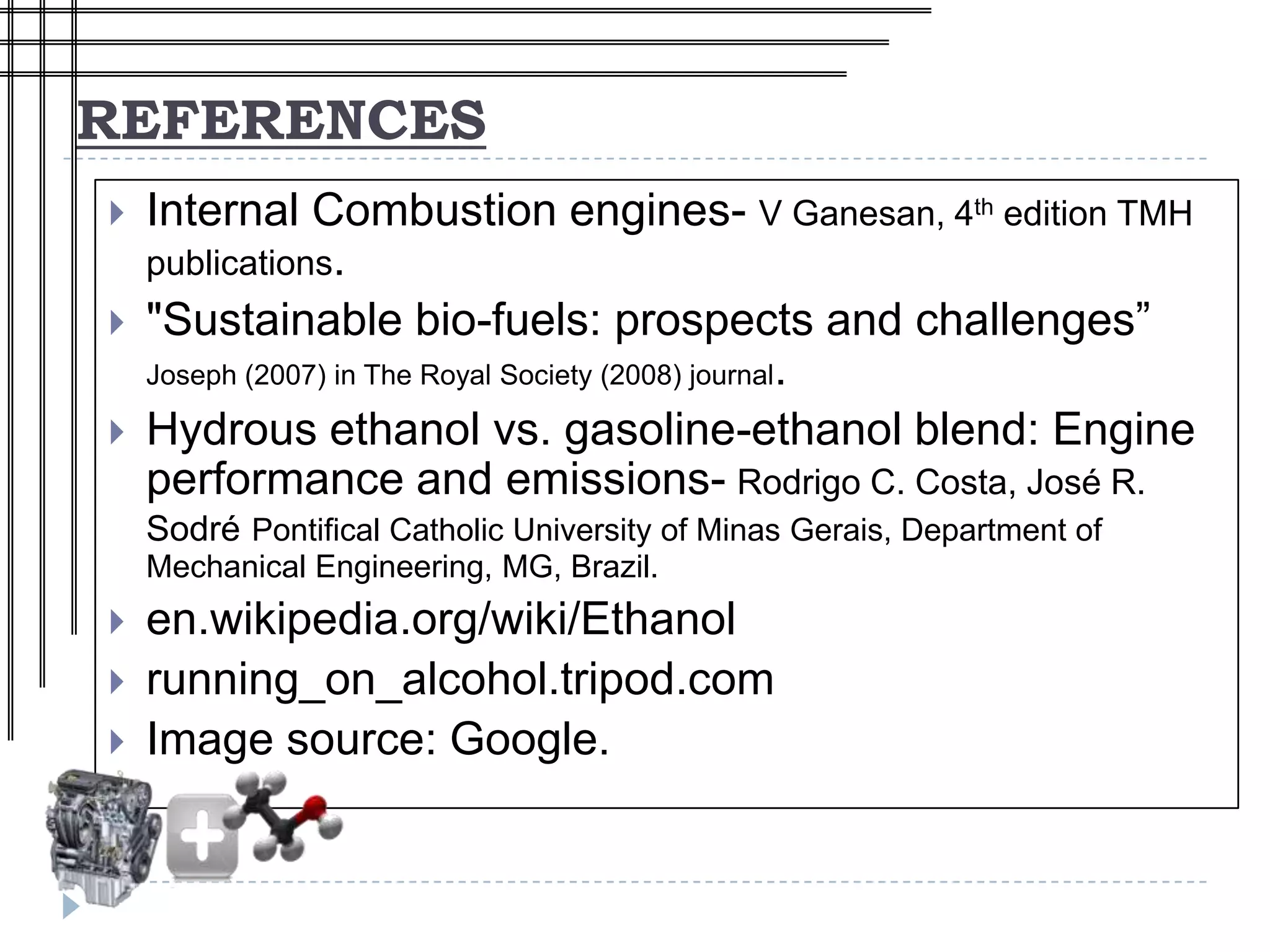

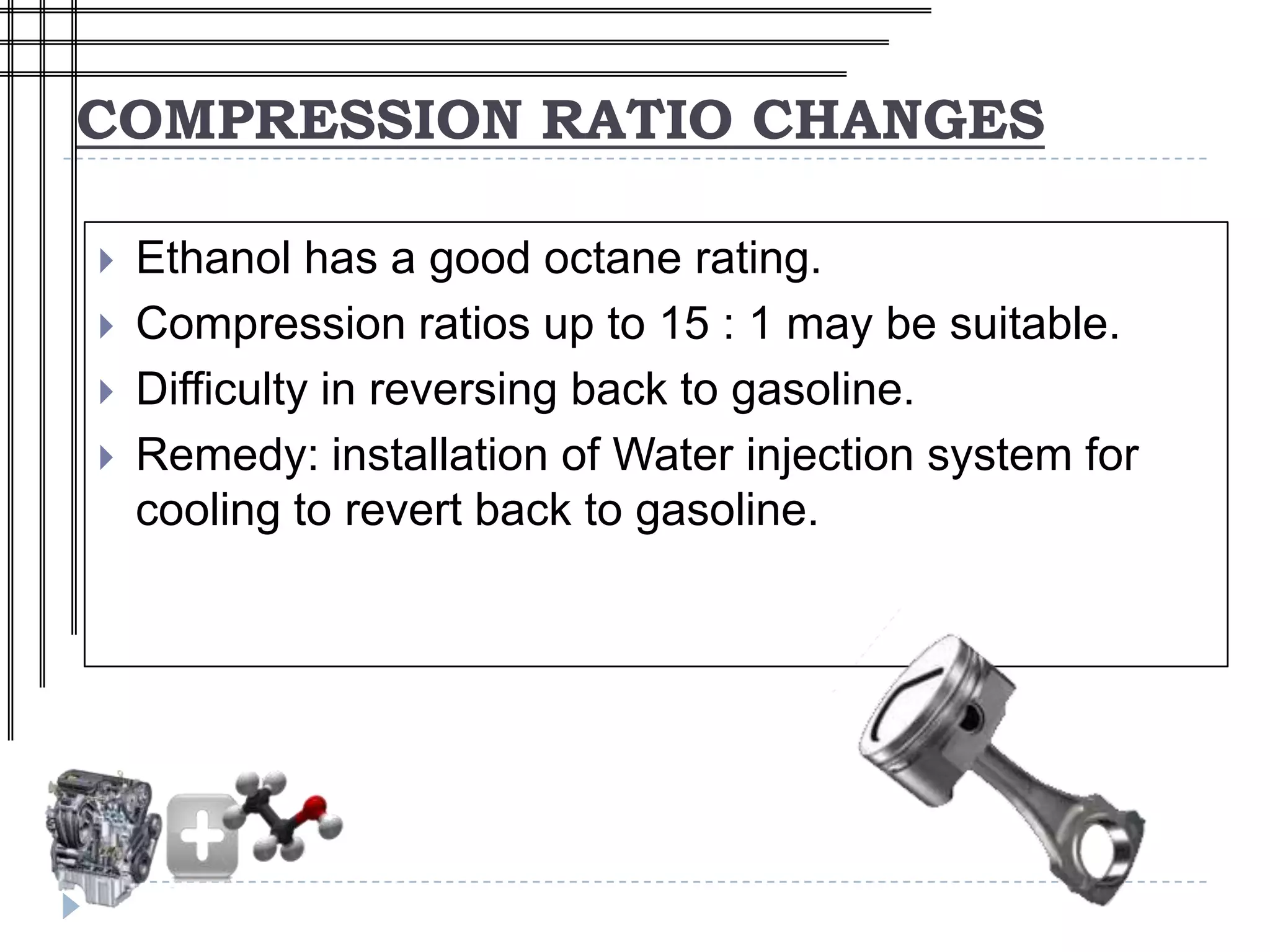

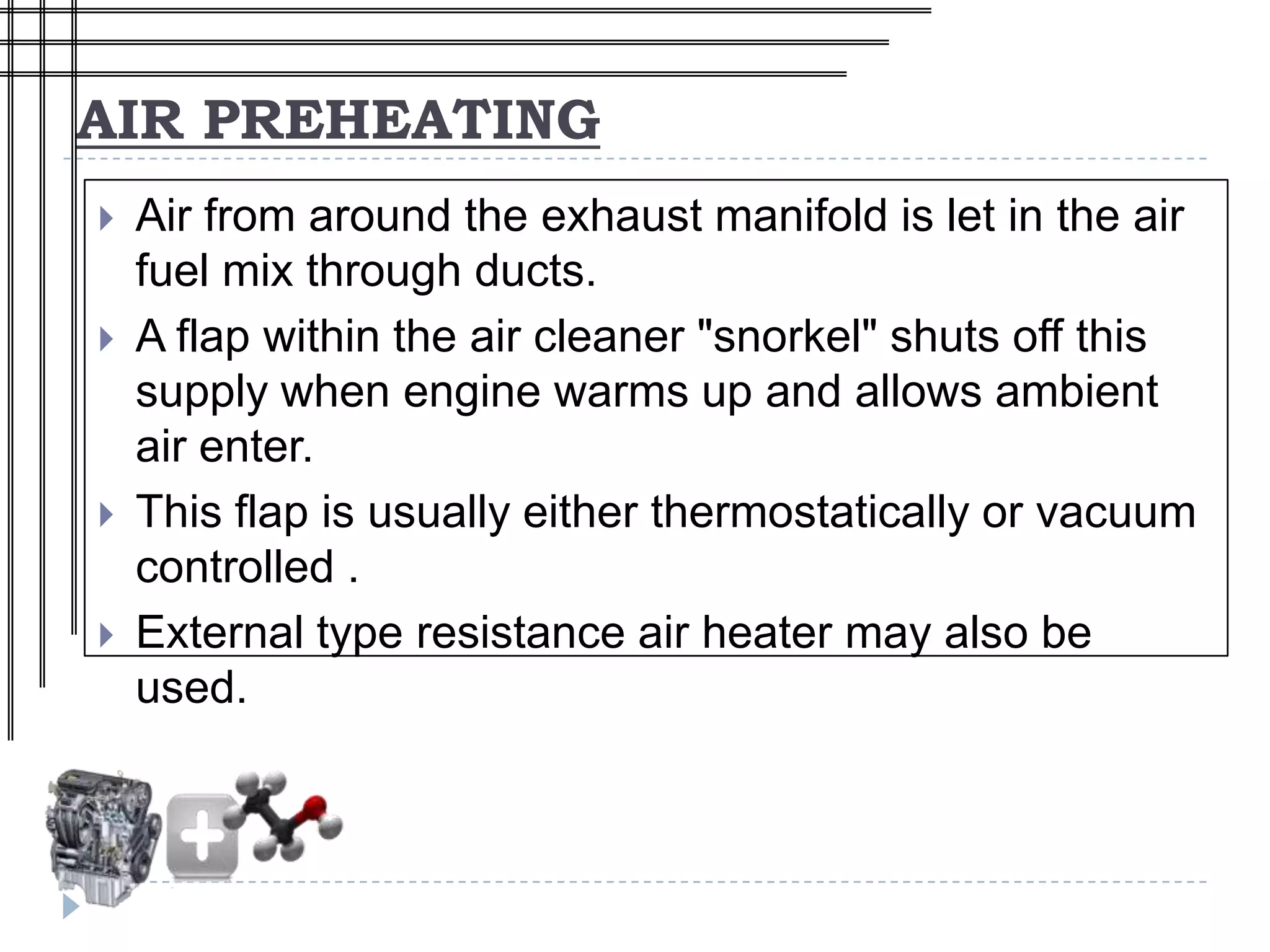

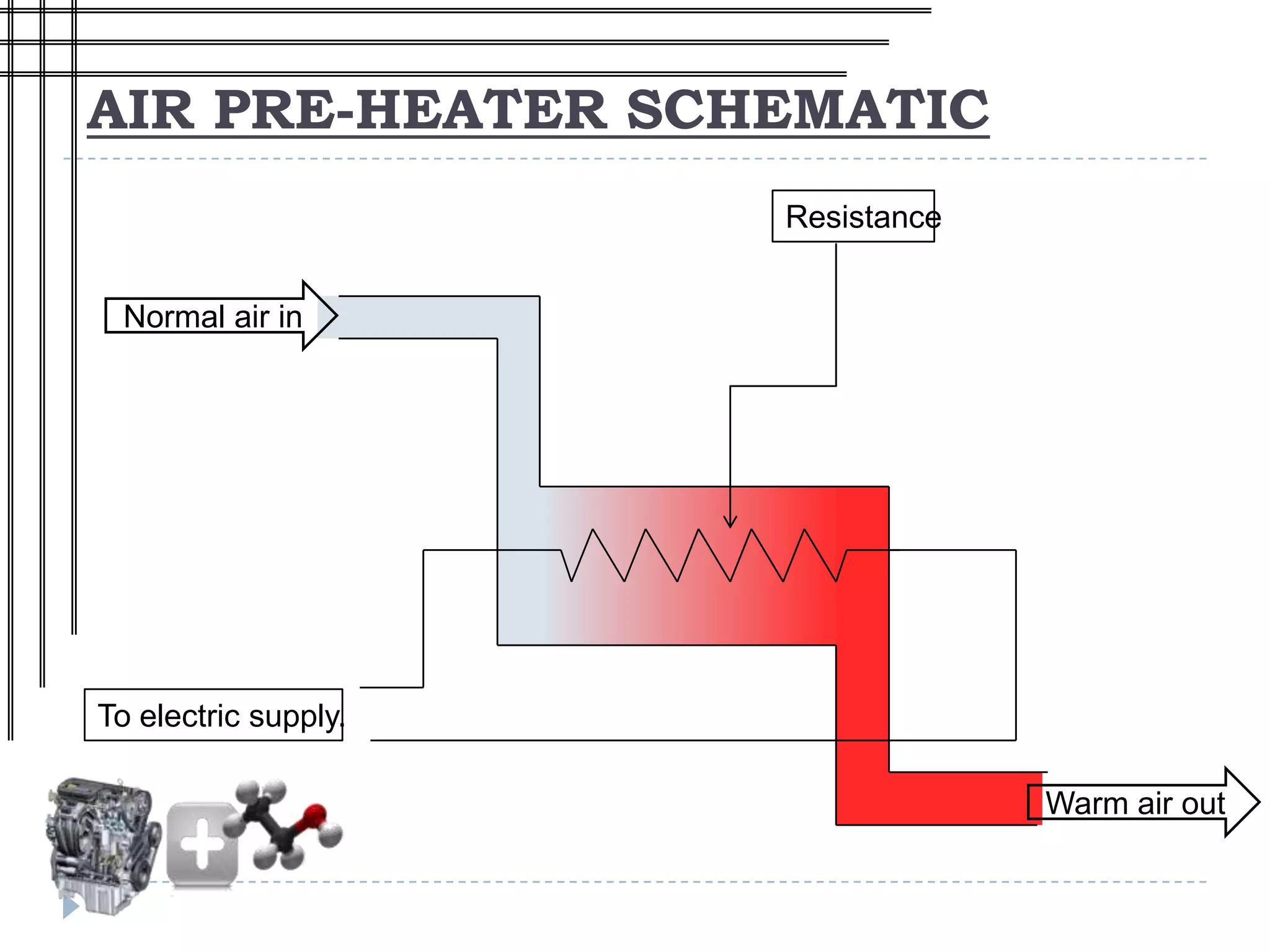

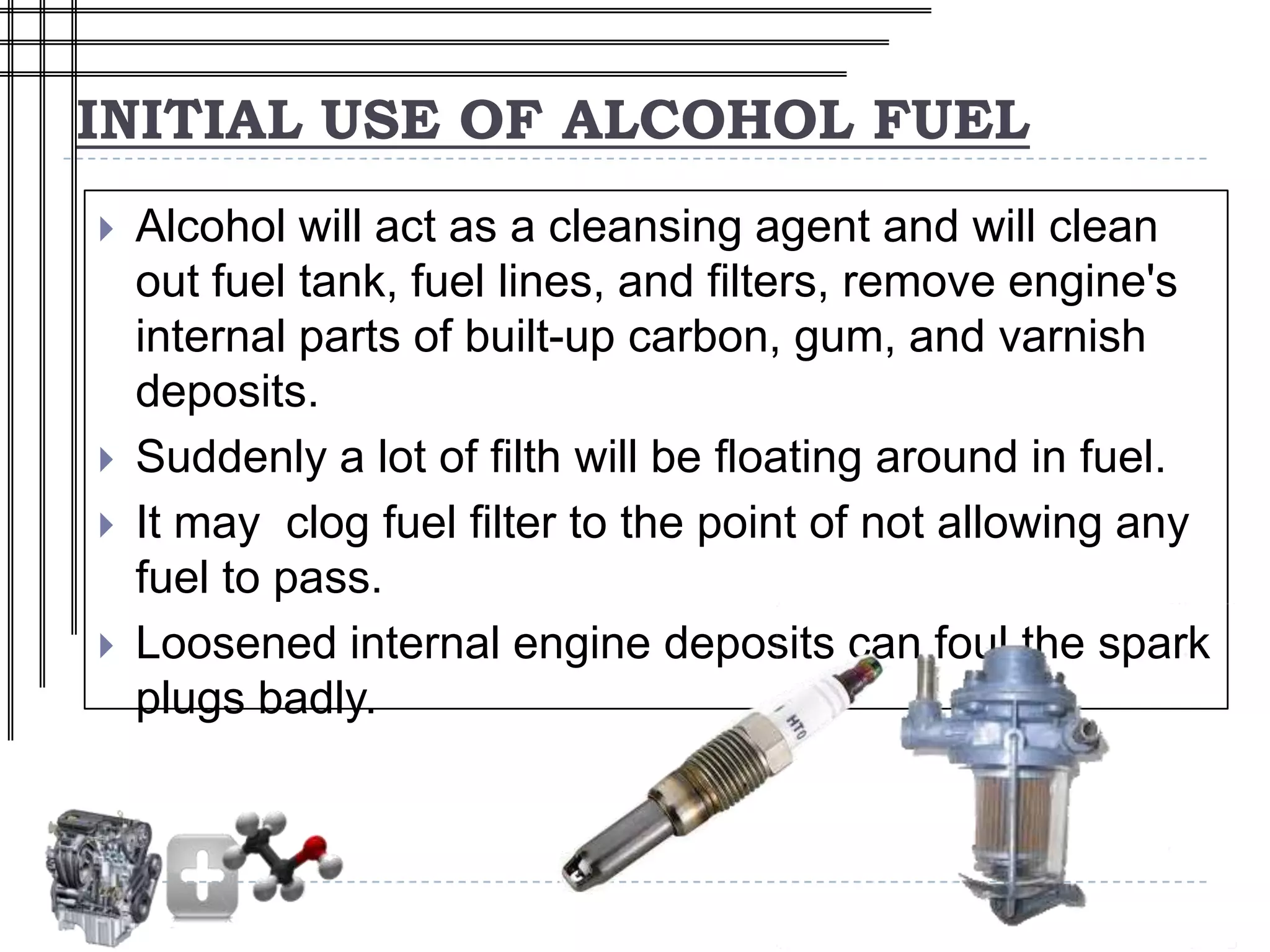

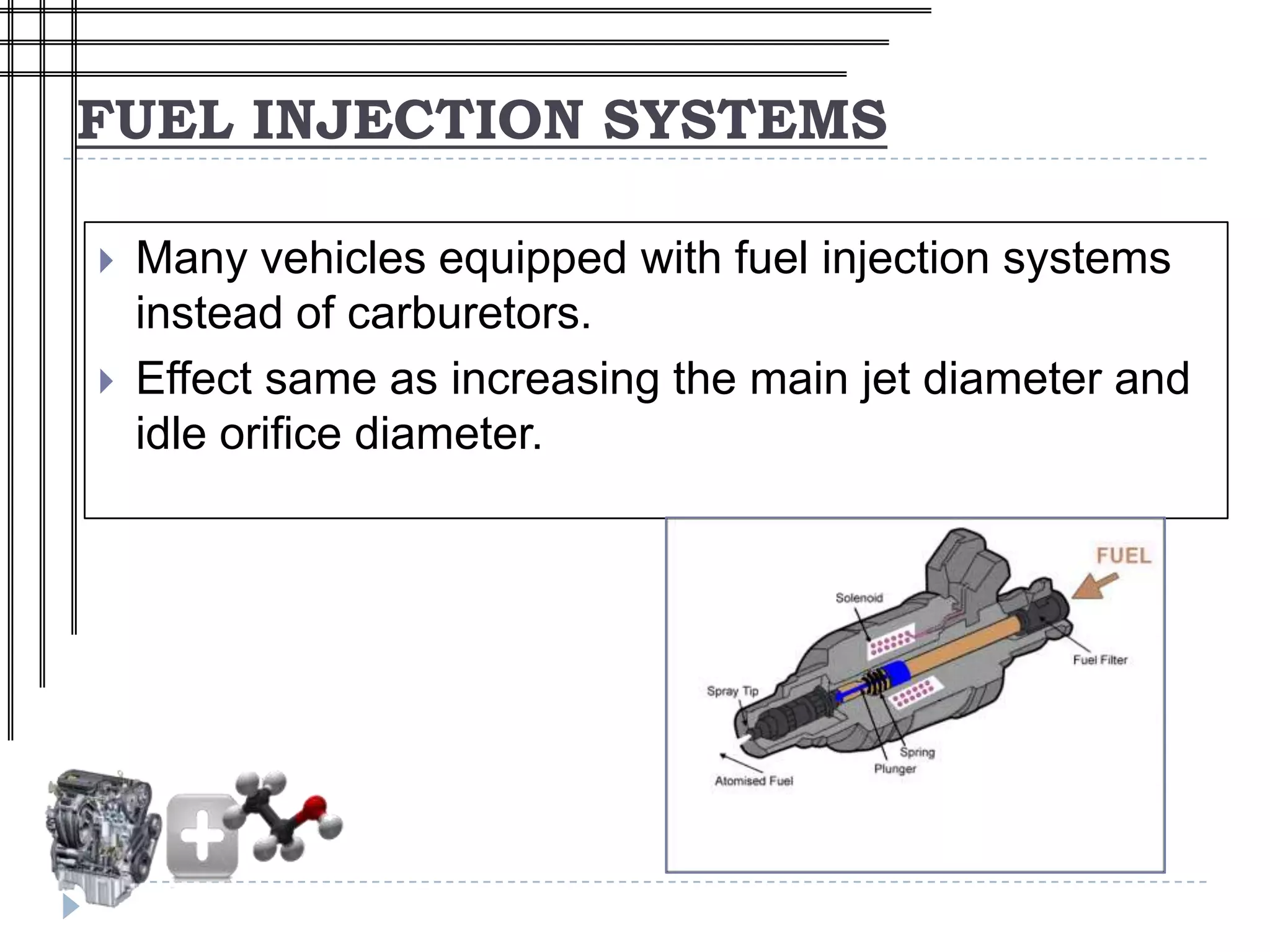

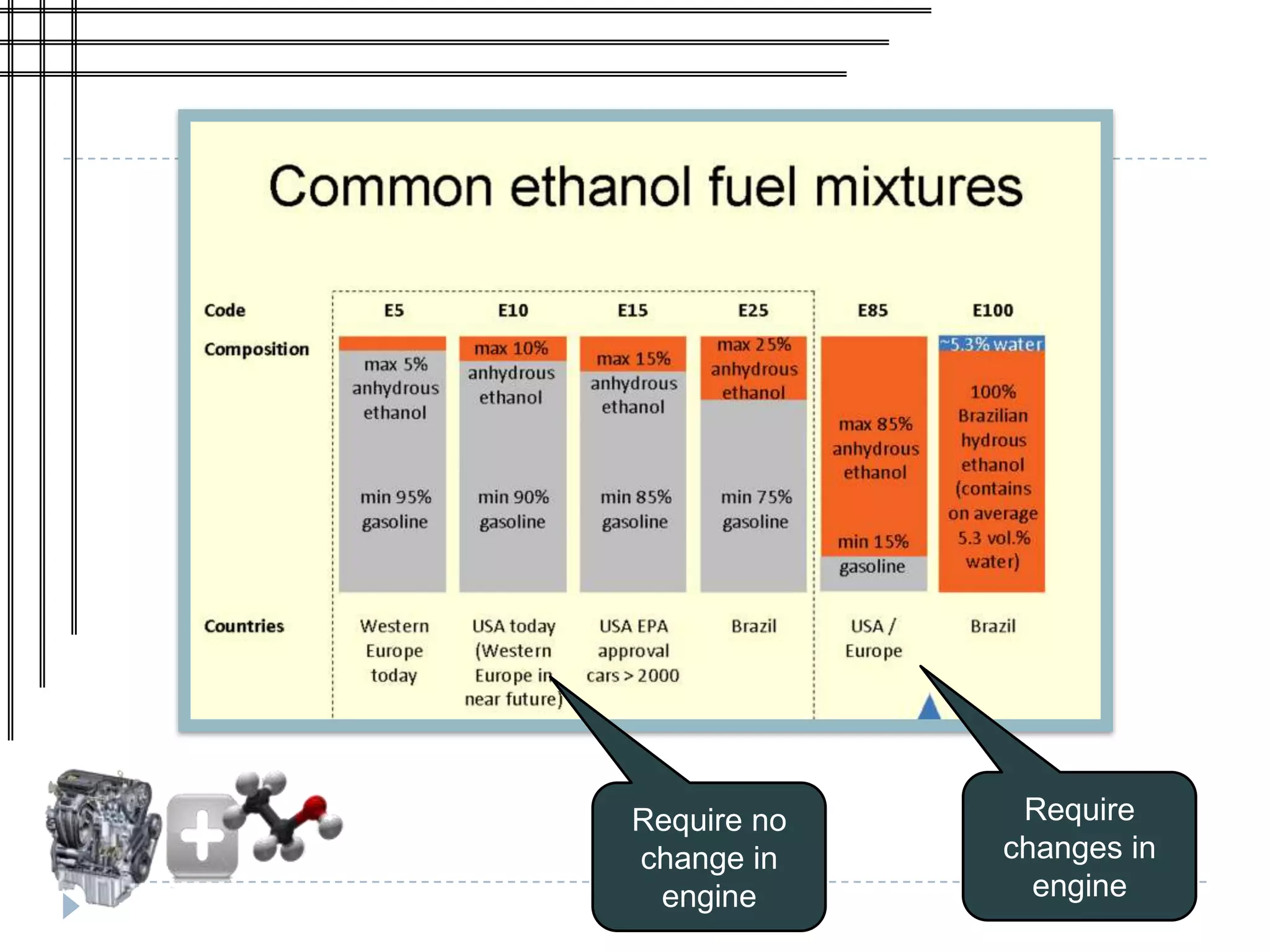

Modifications are needed in gasoline engines to use ethanol fuel blends. For blends up to E10, no changes are typically needed. For higher blends, modifications like increasing the diameter of inlet orifices and the accelerator pump are required to properly adjust the air-fuel ratio. Additional changes like increasing the compression ratio or installing pre-heating systems may be needed for cold starting when using high-ethanol blends. Proper adjustments can help utilize the higher octane and cleaner burning properties of ethanol fuel in engines.

![[edit]

CONCLUSION

Required adjustments in gasoline engines to cope up with different blends of

ethanol fuel

Carburet

syste

Motor oil

manifold

injection

Exhaust

pum

filter

tank

Ethanol

Fuel pr.

Ignition

system

Device

Intake

blend

m

p

Cold

syst.

start

Fuel

Fuel

Fuel

Fuel

or

0

≤5%

E5-

E10

E10-E25

E25-E85

E85-E100

Modifications needed No modifications needed](https://image.slidesharecdn.com/techseminar-121021111912-phpapp01/75/ethanol-engine-modifications-23-2048.jpg)