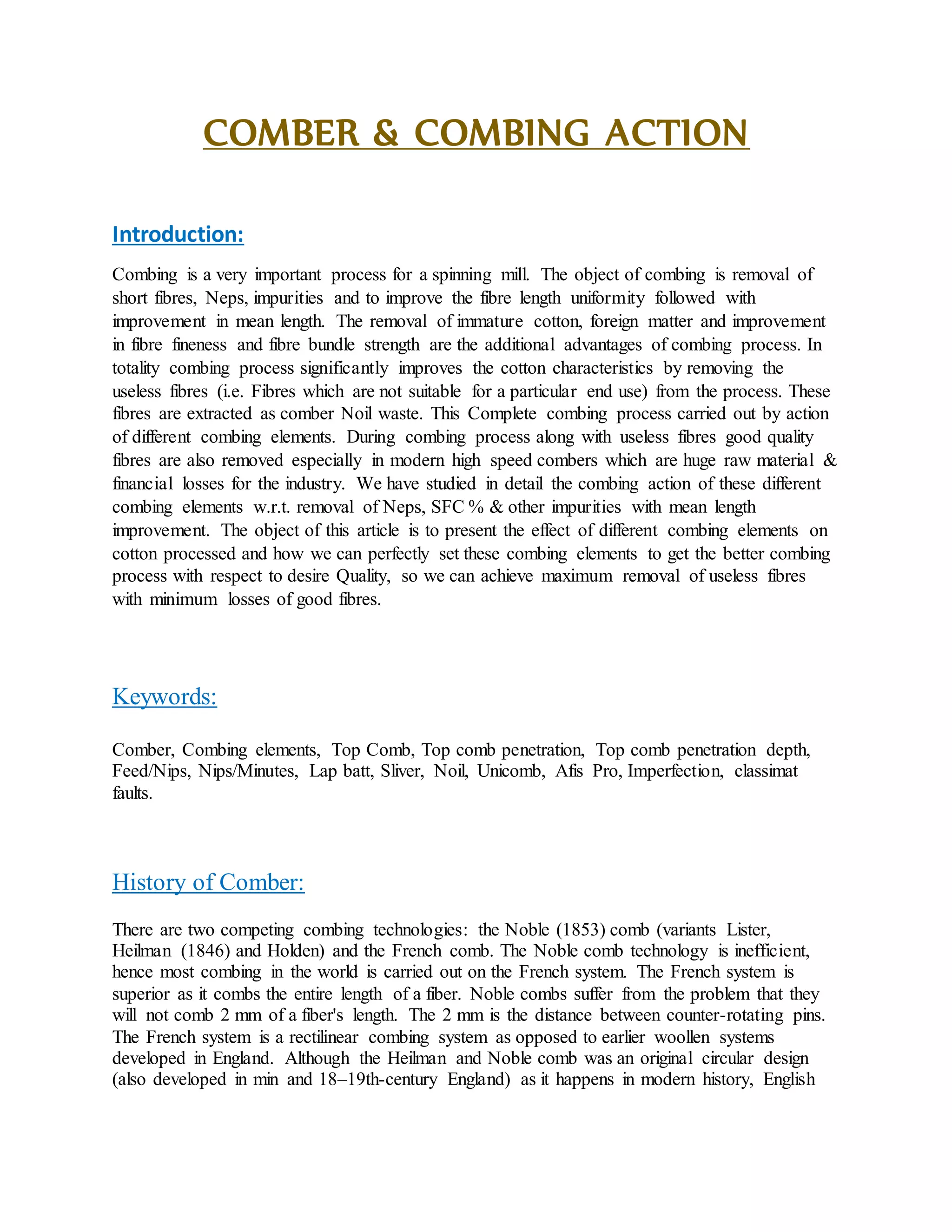

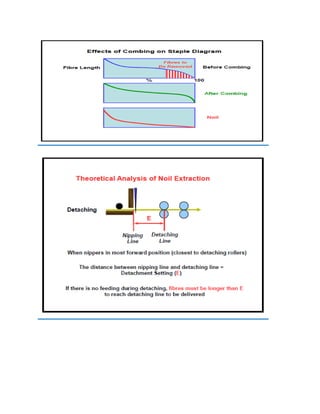

This document discusses the combing process used in spinning mills to improve cotton fiber characteristics. It describes how combing removes short fibers and impurities through the actions of different combing elements like the top comb and nippers. The goal is to extract unusable fibers as noil waste while minimizing good fiber losses. The document provides details on combing machine components, the combing cycle, production calculations, and factors that influence the noil percentage. Overall, it serves to explain how combing upgrades raw cotton material to produce smoother, stronger yarn with fewer imperfections.